Silicon-brass-structure-based micro-texture tool and machining method and application thereof

A technology of organizational structure and processing method, which is applied in the direction of lathe tools, metal processing equipment, workpieces, etc., can solve the problems of slow flow velocity on the cutting surface of chips, unfavorable chip deformation and fracture, etc., and improve chip breaking performance , Improve chip breaking performance or easy cutting performance, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for processing a micro-textured cutter based on a silicon brass structure, comprising the steps of:

[0035] (1) Tool preparation: first select the YG8 cemented carbide tool and determine the cutting edge position to be processed, grind and polish the rake face of the tool with 1500# metallographic sandpaper, clean and dry with alcohol.

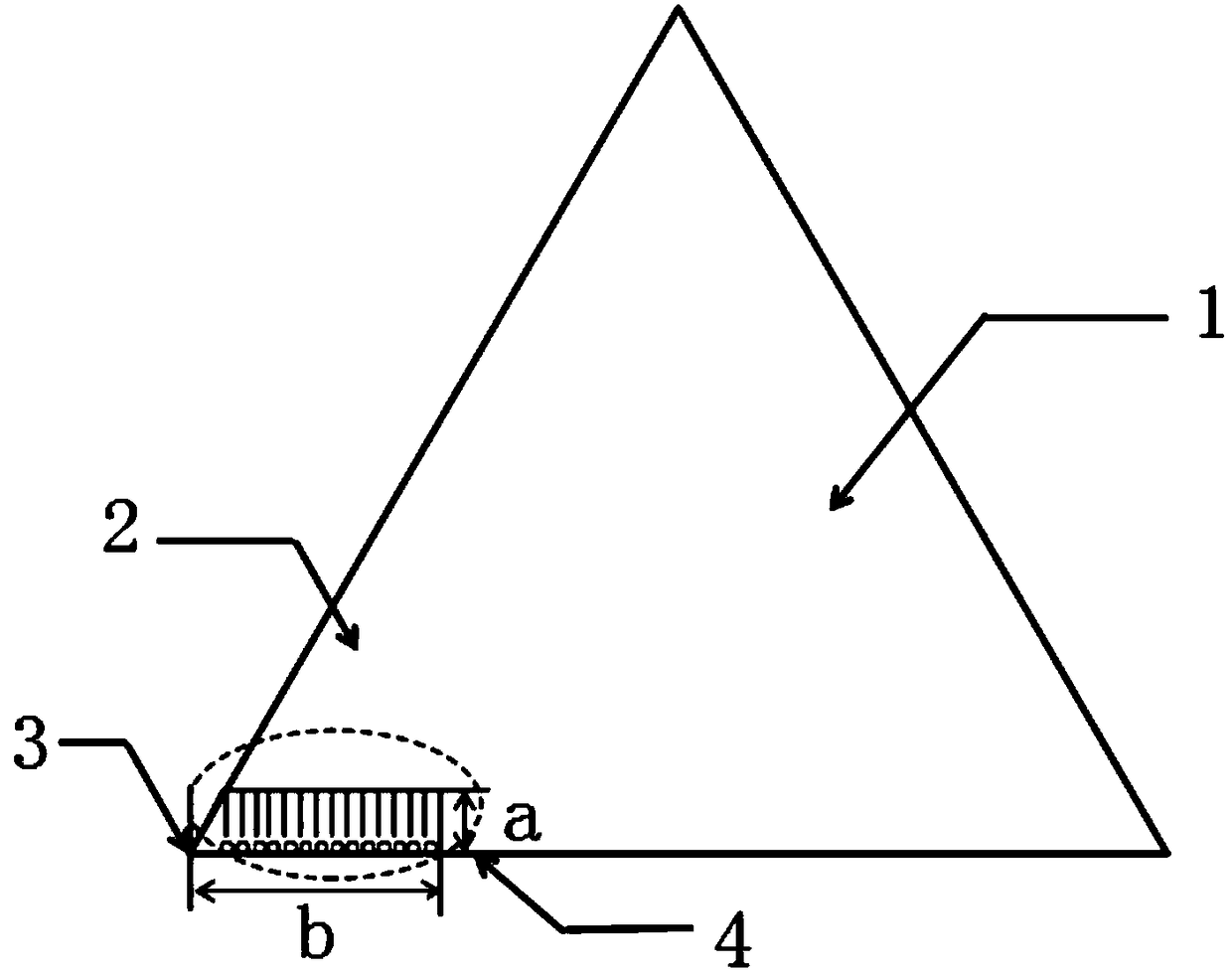

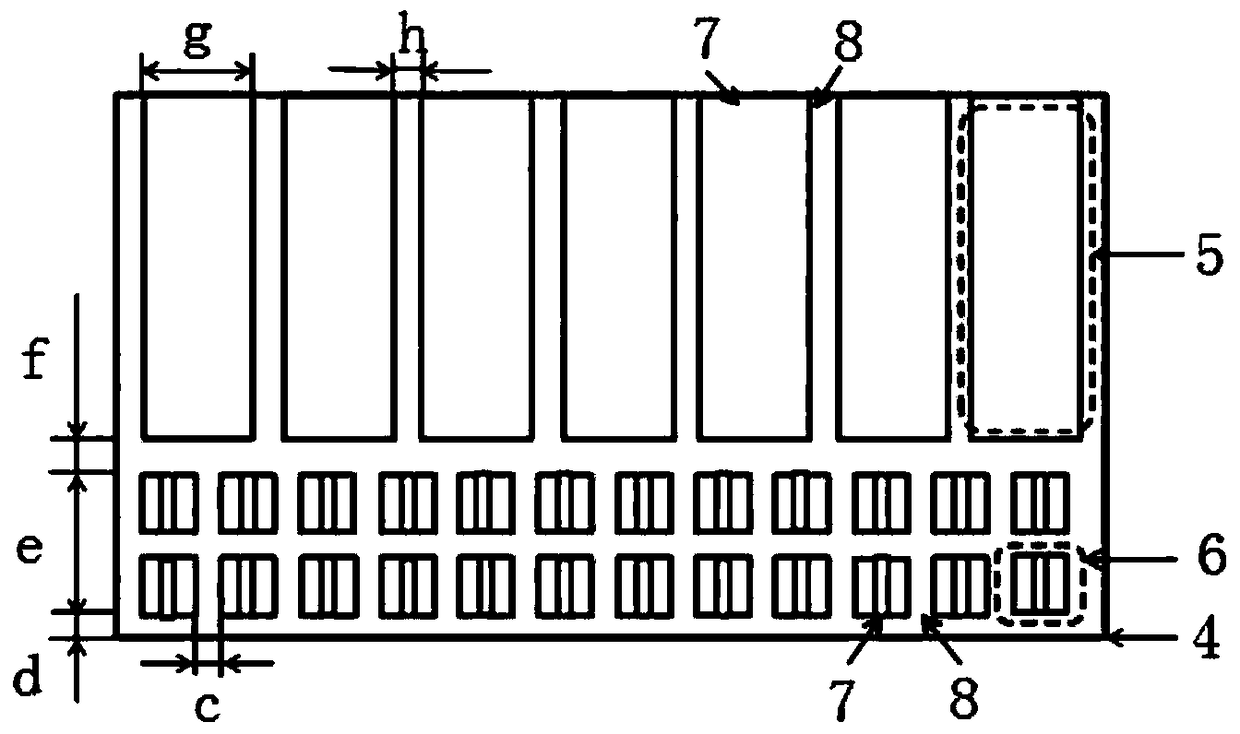

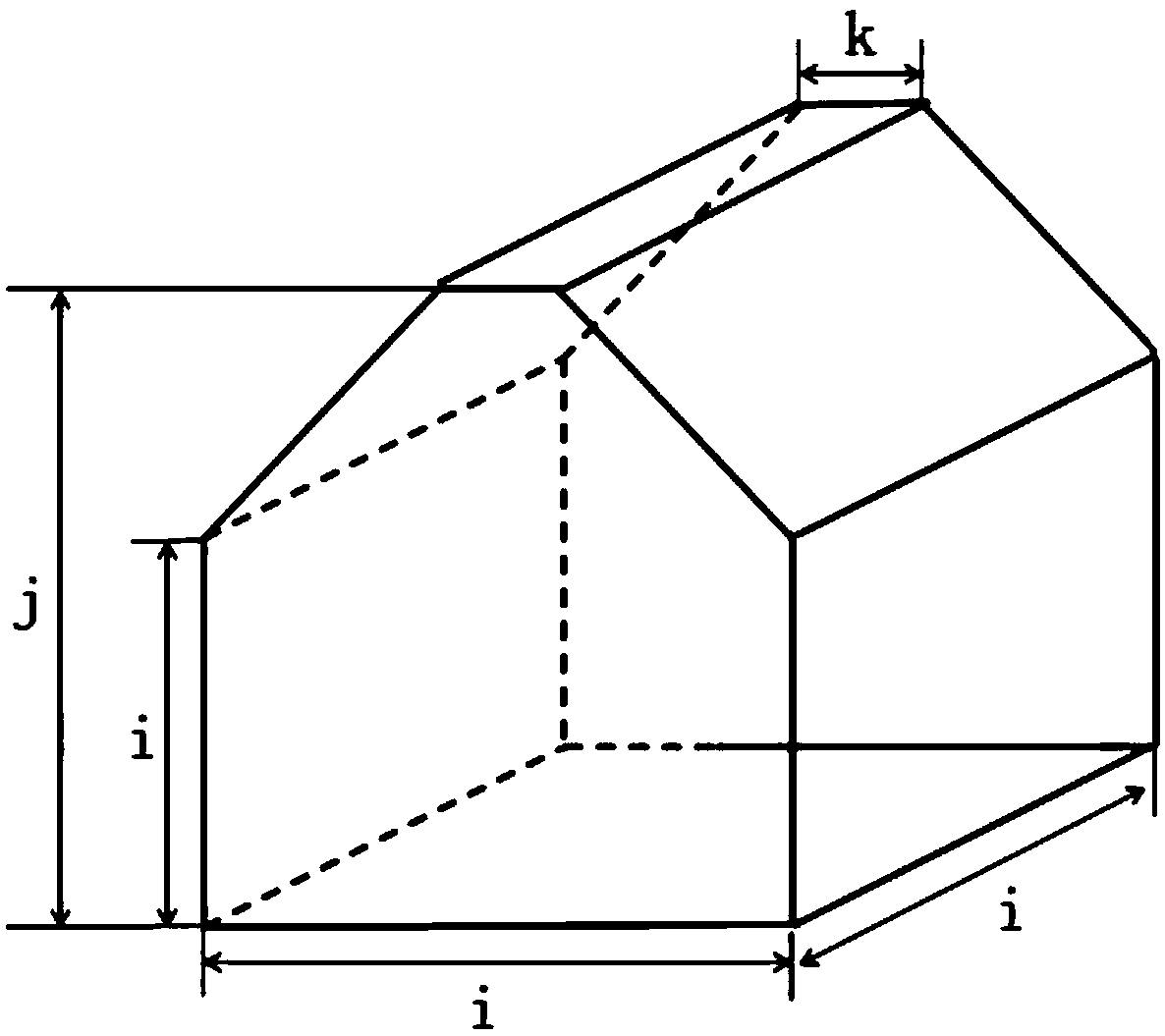

[0036] (2) Composite micro-texture design: place the polished tool on the laser processor, and focus the laser energy on the tool. Then, the composite micro-texture of convex texture and longitudinal texture was designed at 20 μm away from the cutting edge ( figure 1 and figure 2 ). Among them, within 140 μm from the cutting edge, there is a raised texture array, including the bottom of the cube with a side length of 50 μm and the trapezoidal platform at the top, and a single raised texture ( image 3 ) is rectangular, the length is consistent with the side length of the cube, and the width is 10 μm; the longitudinal textu...

Embodiment 2

[0041] A method for processing a micro-textured cutter based on a silicon brass structure, comprising the steps of:

[0042] (1) Tool preparation: first select the YG8 cemented carbide tool and determine the cutting edge position to be processed, grind and polish the rake face of the tool with 1500# metallographic sandpaper, clean and dry with alcohol.

[0043] (2) Composite micro-texture design: place the polished tool on the laser processor, and focus the laser energy on the tool. Then, the composite micro-texture of convex texture and longitudinal texture was designed at 10 μm away from the cutting edge ( figure 1 and figure 2 ). Among them, within 110 μm from the cutting edge, there is a raised texture array, including the bottom of the cube with a side length of 40 μm and the trapezoidal platform at the top, and a single raised texture ( image 3 ) is rectangular, the length is the same as the side length of the cube, and the width is 15 μm; the longitudinal texture p...

Embodiment 3

[0048] A method for processing a micro-textured cutter based on a silicon brass structure, comprising the steps of:

[0049] (1) Tool preparation: first select the YG8 cemented carbide tool and determine the cutting edge position to be processed, grind and polish the rake face of the tool with 1500# metallographic sandpaper, clean and dry with alcohol.

[0050] (2) Composite micro-texture design: place the polished tool on the laser processor, and focus the laser energy on the tool. Then, a composite micro-texture of convex texture and longitudinal texture was designed at a distance of 30 μm from the cutting edge ( figure 1 and figure 2 ). Among them, within 150 μm from the cutting edge, there is a raised texture array, including the bottom of the cube with a side length of 45 μm and the trapezoidal platform at the top, and a single raised texture ( image 3 ) is rectangular, the length is the same as the side length of the cube, and the width is 20 μm; the longitudinal te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com