Chip breaking drill bit with S-shaped cutting edge based on Logistic curve

A cutting edge and chip breaking technology, which is applied to twist drills, cutting blades, manufacturing tools, etc., can solve the problems of easy entanglement and difficult chip breaking, and achieve the effects of preventing chip entanglement, ensuring processing quality, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

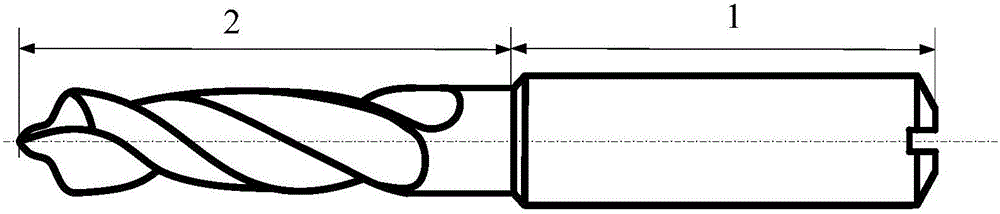

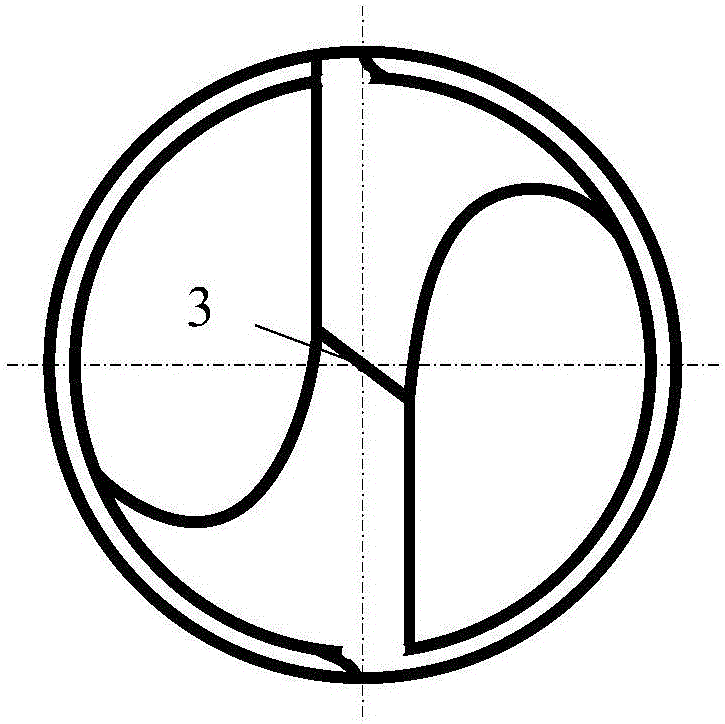

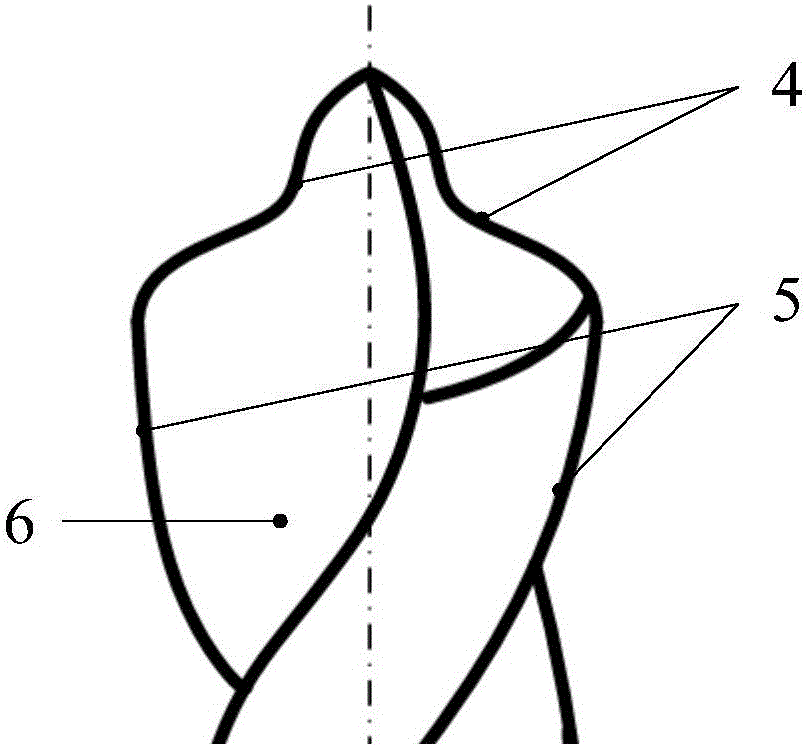

[0015] Based on the Logistic curve of the present invention, there is a chip-breaking drill with an S-shaped cutting edge, the material is cemented carbide, and its structure is as follows: figure 1 figure 2 and image 3 Shown, including shank 1 and cutting part 2. The cutting part mainly includes a main cutting edge 4, a chisel edge 3, a minor cutting edge 5 and a chip flute 6.

[0016] The main cutting edge 4 is mainly composed of a rake face and a flank face, and each point on the main cutting edge satisfies the Logistic curve equation y=1 / (1+2e x ), taking the line connecting the outer edges of the two main cutting edges as the x-axis, the central axis as the y-axis, and the intersection of the x-axis and the y-axis as the origin. The edge shape is S-shaped, which can promote chip deformation, reduce the contact area between chips and the machined surface, improve the chip breaking ability of the tool, and ensure the processing quality.

[0017] The main cutting edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com