A Turning Insert with Multiple Feed Directions

A technology of cutting direction and cutting blade, which is applied in the direction of turning equipment, tool holder accessories, manufacturing tools, etc., can solve the problems of cutting depth and cutting feed limitation, unsatisfactory processing surface roughness, and low strength of cutting unit, etc., to achieve The effect of increasing the cutting depth, widening the application range of feed, and increasing the cutting feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

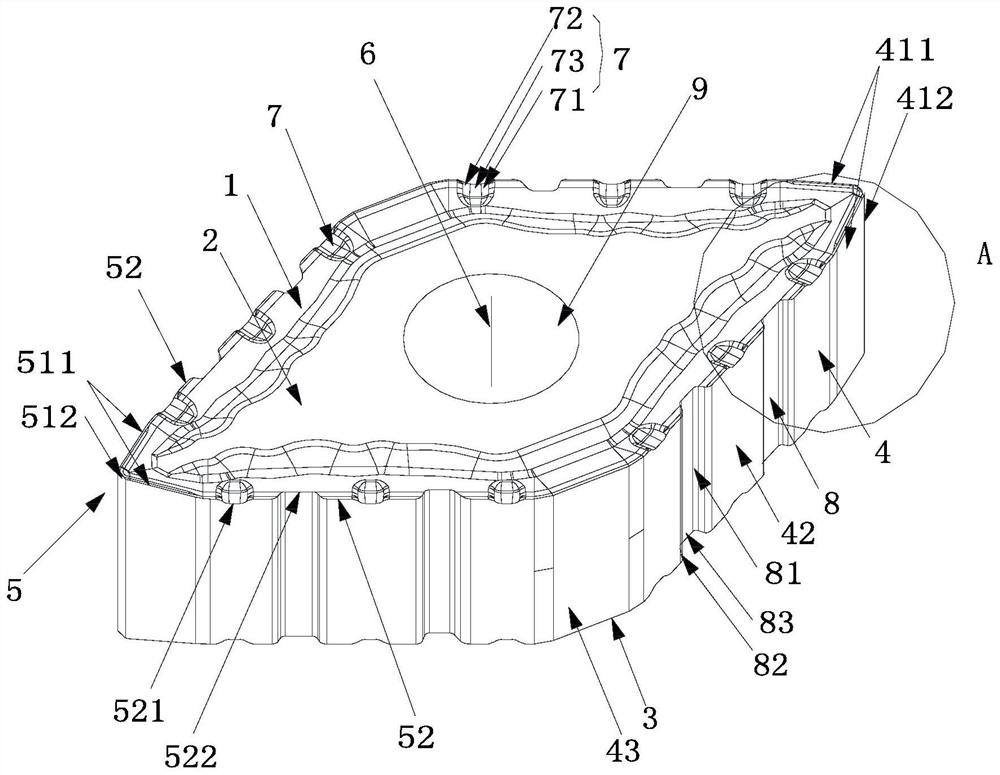

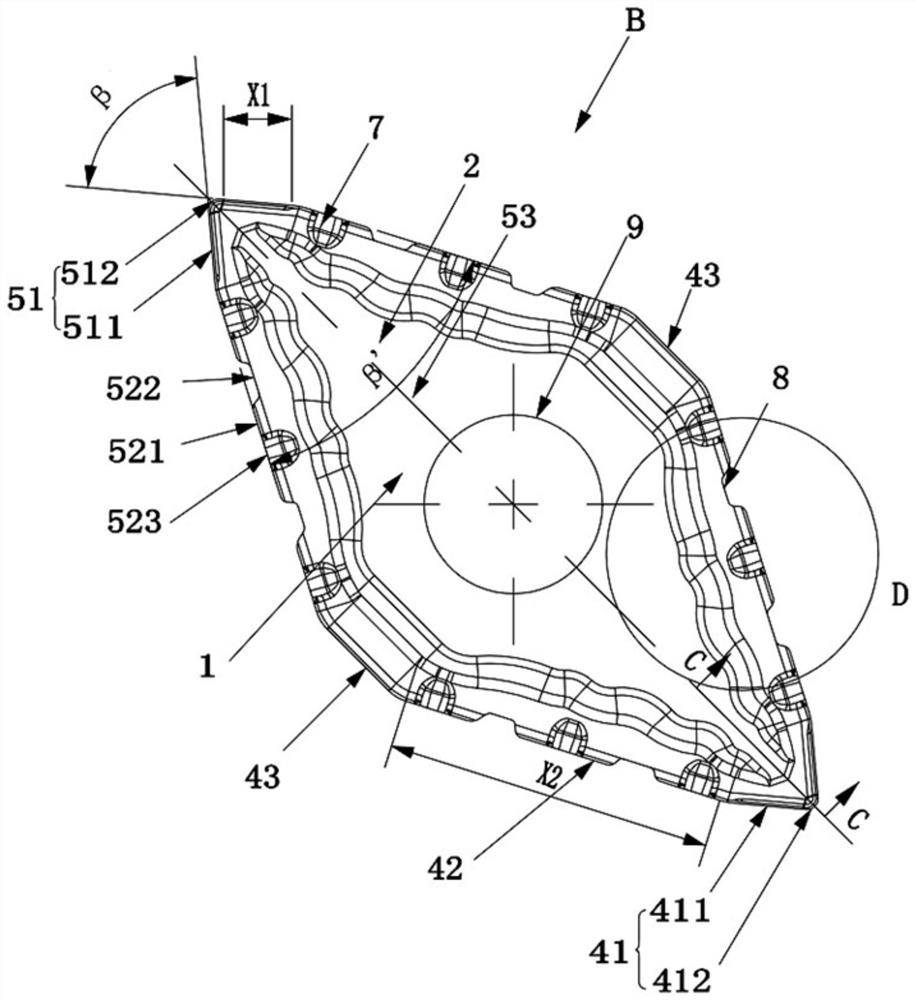

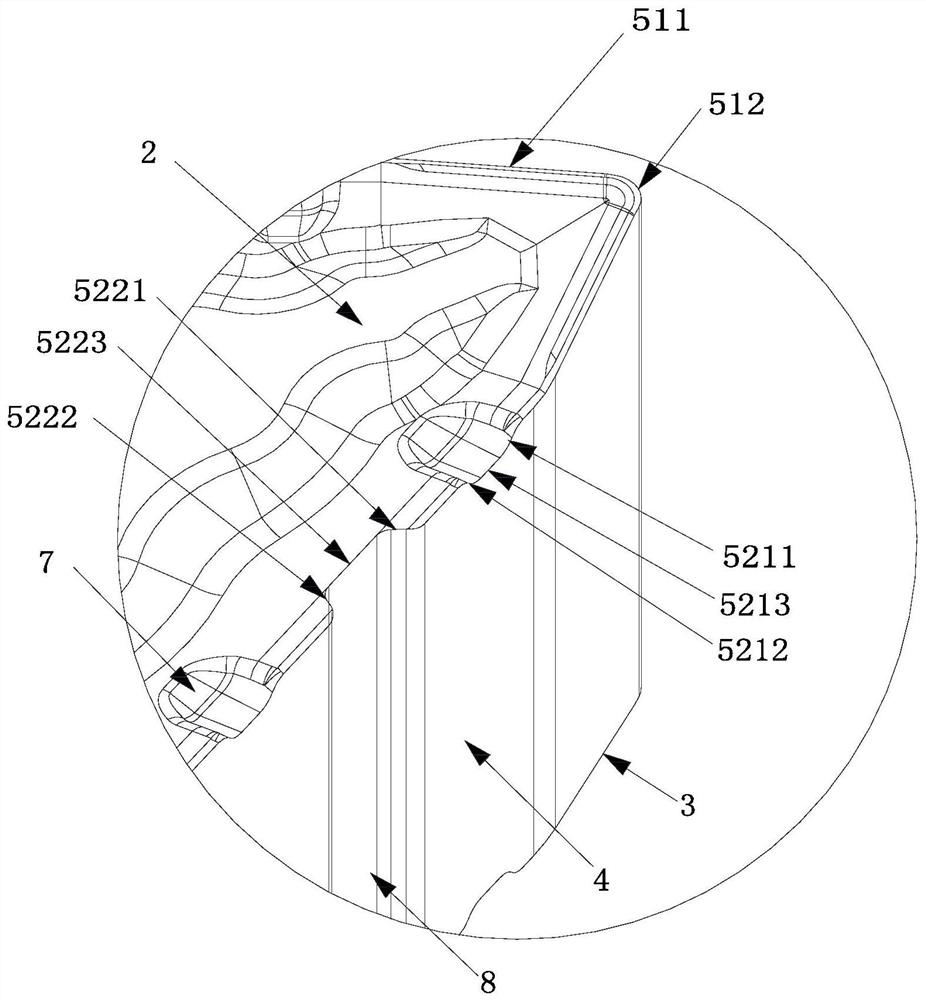

[0034] Figure 1 to Figure 7 Shown is the first embodiment of the turning insert with multiple feed directions of the present invention, the turning insert with multiple feed directions includes a parallelogram plate-shaped insert body 1, the insert body 1 is symmetrical about the central axis 9, and the insert The body 1 is surrounded by an upper surface 2, a lower surface 3, and a side 4 connecting the upper surface 2 and the lower surface 3. A set of acute-angled diagonal positions of the blade body 1 form an acute-angle cutting unit 5, and the acute-angle cutting unit 5 includes Angle cutting edge group 51 and two core cutting edges 52, during turning processing, angle cutting edge group 51, core cutting edge 52 are away from workpiece successively, and angle cutting edge group 51 comprises two angle cutting edges 511 and is posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com