Gear pump

a gear pump and gear technology, applied in the direction of machines/engines, rotary/oscillating piston pump components, liquid fuel engines, etc., can solve the problems of fluid leakage from the gear pump, gap formation insufficient prevention of the positional deviation between the body and the housing, so as to prevent the fluid pressure in the gear pump and maintain the pump efficiency of the gear pump. , the effect of increasing the frictional for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

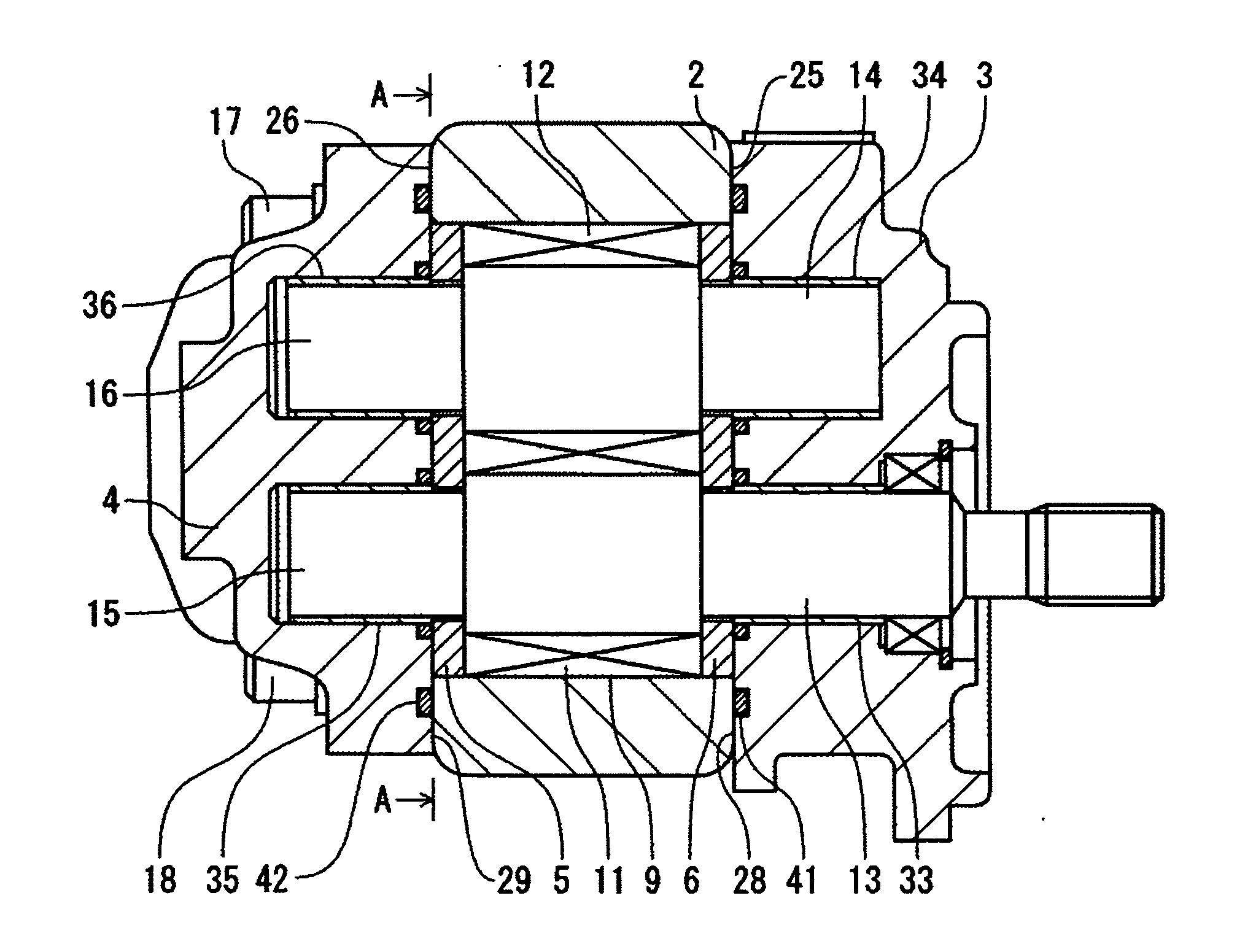

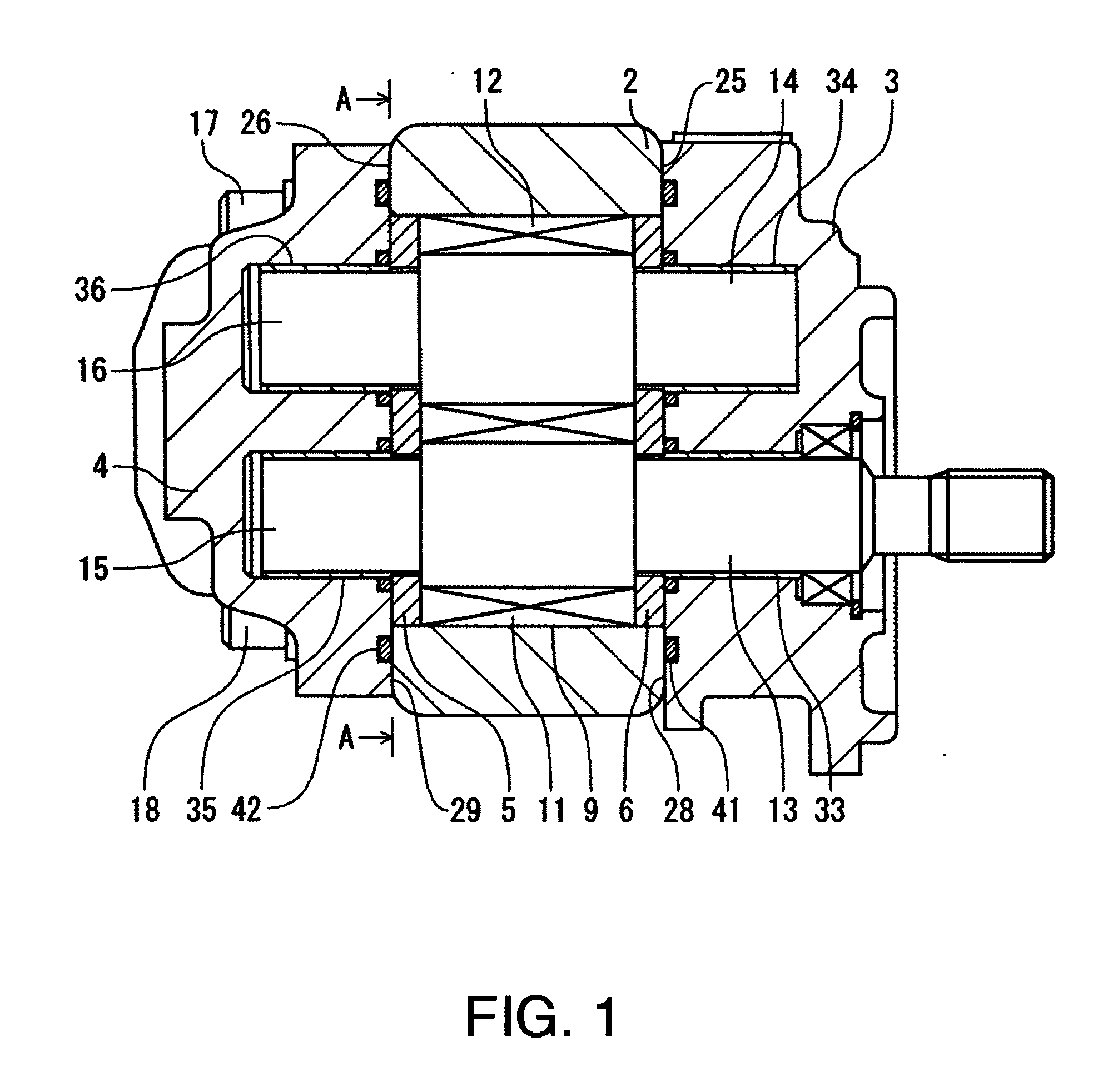

[0012]An embodiment of this invention will be described below with reference to the figures.

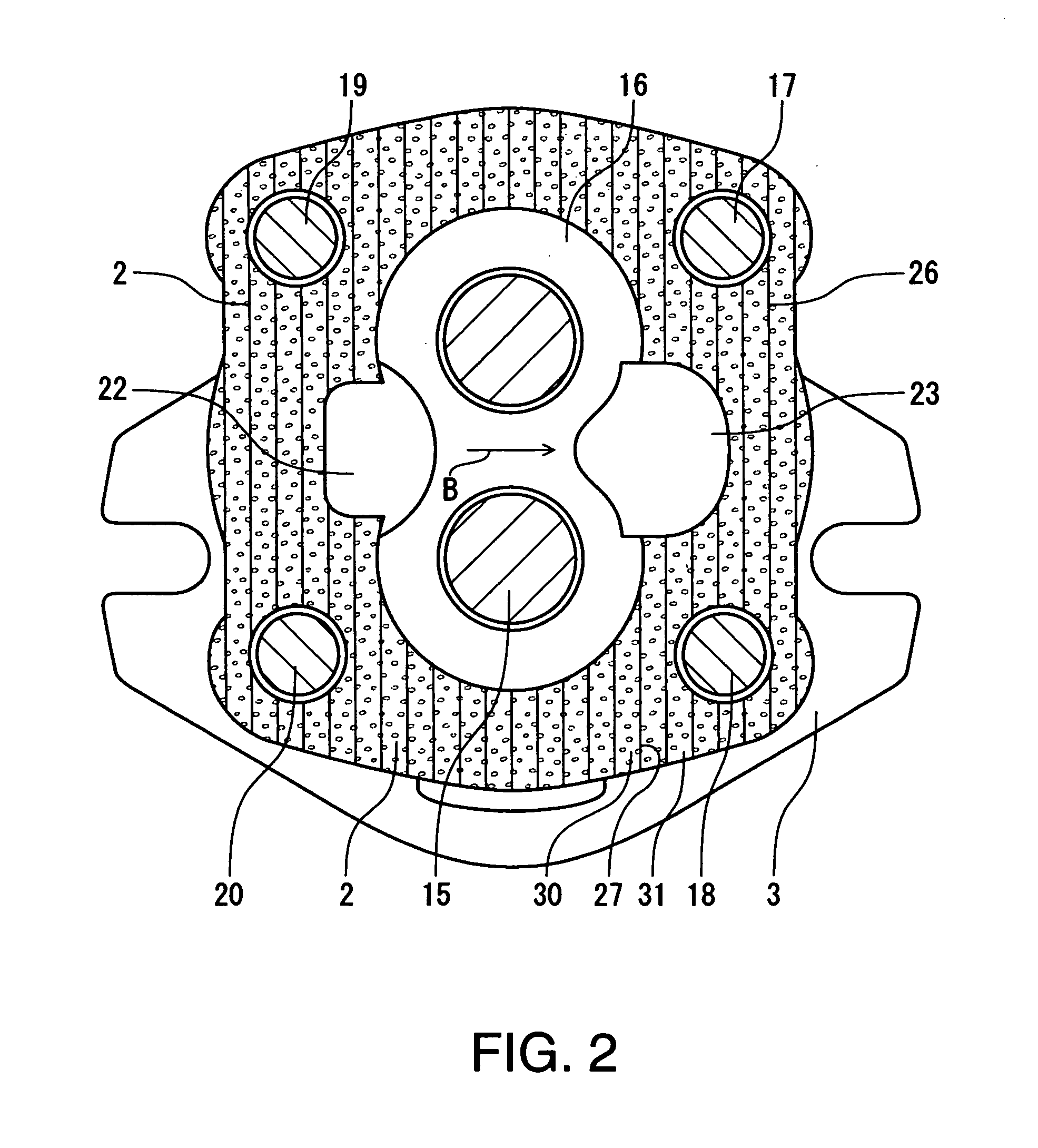

[0013]As shown in FIG. 1, a gear pump 1 comprises a body 2 into which a drive gear 11 and a driven gear 12 are incorporated as a pair of gears, and housings 3, 4 that contact the body 2 from either side. Side plates 5, 6 are interposed between respective end faces of the drive gear 11 and driven gear 12 and the housings 3, 4.

[0014]A gear chamber 9 that houses the drive gear 11 and driven gear 12 is provided on an inner side of the body 2, and the housings 3, 4 contact respective end surfaces 25, 26 of the body 2.

[0015]The housing 3 includes an end surface 28 that contacts the end surface 25 of the body 2 so as to close one end of the body 2 and function as a mounting flange attached to a support member, not shown in the figure.

[0016]A seal ring 41 is interposed between the end surface 25 of the body 2 and the housing 3, and the gear chamber 9 is sealed by the seal ring 41.

[0017]It should be n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com