Lathe for fast cutting outer diameters of smooth rolls

A rapid cutting and smooth roll technology, applied in the field of turning processing, can solve the problems of low speed, low processing efficiency, and low tool life, and achieve the effects of reducing cutting volume, improving production efficiency, and increasing cutting depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

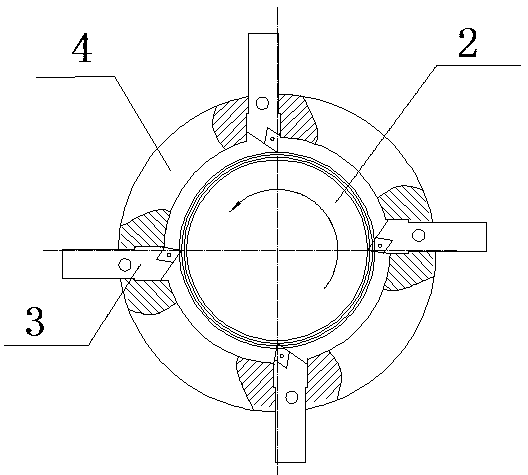

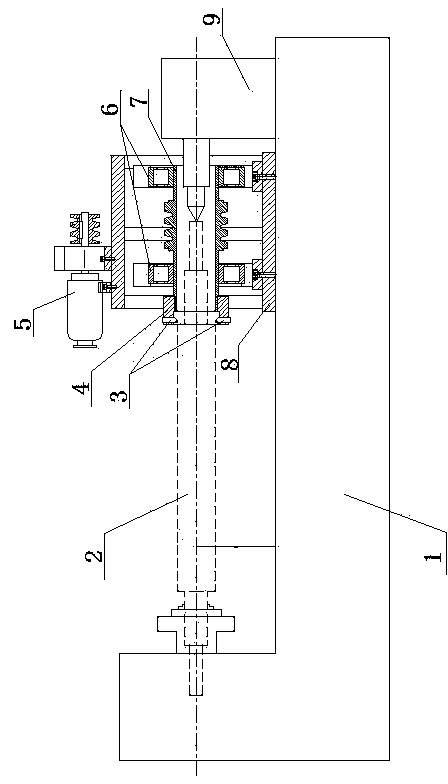

[0011] Refer to attached figure 1 with figure 2 , a lathe for rapidly cutting the outer diameter of smooth rollers, comprising a bed 1, a workpiece clamping device is provided at the front of the bed 1, and a rear top 9 cooperating with the workpiece clamping device is provided at the tail of the bed 1. The bed 1 is provided with a middle supporting plate, and a tool box 8 is installed on the middle supporting plate. In the tool box 8, a hollow shaft 7 coaxially arranged with the rotation axis of the workpiece 2 is installed through a bearing 6, and the hollow shaft 7 is along the direction of the shaft body. There is an inner cavity for the workpiece to pass through, so that the rear top 9 can pass through the inner cavity a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com