Electrolytic machining method of difficult-to-cut material, fine-module internal gear and device

A processing method and internal gear technology, applied in the direction of electric processing equipment, electrochemical processing equipment, processing electrodes, etc., can solve the problems of complex electric field variation, complex stable flow field design, and difficult cathode design, etc., to achieve electrolytic processing flow field Stabilization, improvement of processing efficiency and forming accuracy, and stable processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

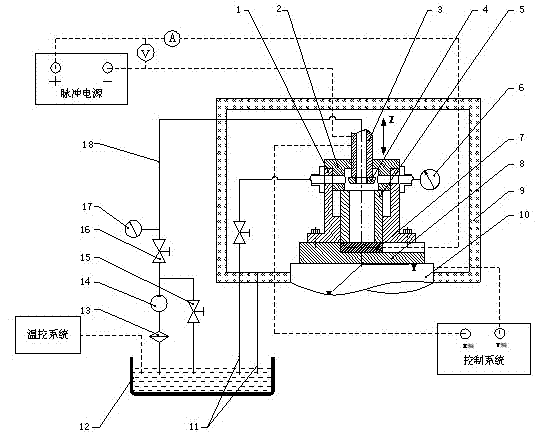

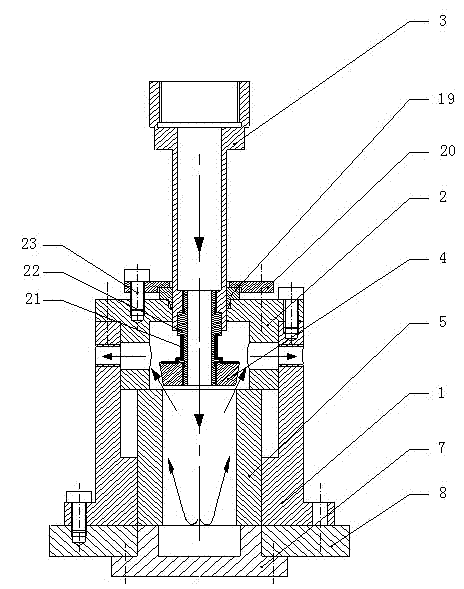

[0043] The device for implementing this electrolytic machining process is as figure 1 As shown, it includes a pulse power supply, an electrolyte circulating filter system, a processing machine tool control system, a cathode system, a workpiece 5, a workpiece fixture, a sealing part, a work box 9, and a workbench 10. Wherein the cathode system includes a tool cathode 4, a cathode connecting rod 3, and a cathode connector 22. The tool cathode 4 is installed at one end of the cathode connector 22, and the other end of the cathode connector 22 is threadedly connected with the cathode connecting rod, and the three have connected electrolyte aisle. The liquid inlet pipe 18 of the electrolyte circulating filter system is connected with the cathode connecting rod 3 . The workpiece fixture includes an end cover 2 , a plexiglass cavity 1 , and a conductive voltage block 7 . Wherein, the workpiece 5 is placed in the plexiglass cavity 1, and the workpiece is radially positioned by its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com