Method for improving working stability of end mill and high-stability end mill

An end mill, stability technology, applied in the direction of milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problem of unsatisfactory use of end mills, and achieve the effects of improving the processing finish, improving processing quality, and decentralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

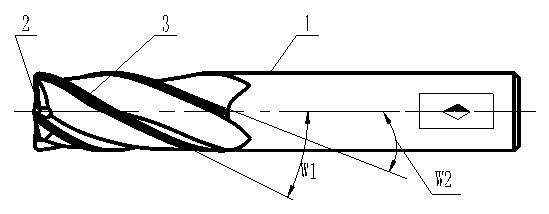

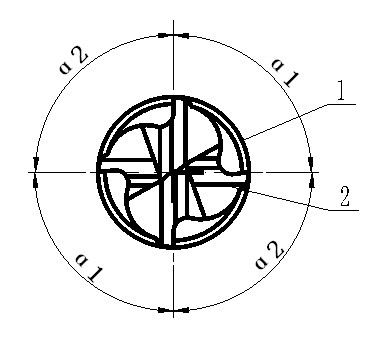

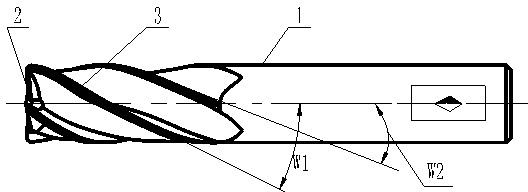

[0012] Embodiments of the present invention: when adopting a method for improving the working stability of the end mill of the present invention to make the end mill, the end mill can be made according to traditional techniques, methods and materials. When making, the cutter of the end mill The number of teeth is made into an even number, and the end edges of the teeth are distributed on the same circle according to unequal divisions. The helix angle of the helical groove of the peripheral edge of each cutter tooth is not equal to the helical angle of the helical grooves of the peripheral edges of the adjacent cutter teeth, which can improve the working stability of the end mill when machining workpieces.

[0013] The structure diagram of a kind of highly stable end mill of the present invention constructed according to the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com