A material suitable for 3D printing concrete shear walls and its preparation method

A 3D printing and concrete technology, applied in the direction of additive processing, etc., can solve the problems of not meeting the performance requirements of rapid setting of materials, failing to meet the vertical accumulation performance of 3D printing, and the high cost of printing materials, so as to improve the setting time and early Strength, meet the requirements of mechanical properties, and good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Portland cement, sulphoaluminate cement, silica fume, quicklime, 20-40 mesh quartz sand, 50-80 mesh quartz sand, water reducer, retarder, dispersible latex powder, polypropylene short fiber and Water is used as the raw material, and the retarder is a mixture of citric acid and boric acid with a mass ratio of 1.2:1. The molar ratio of polycarboxylate superplasticizer raw materials is: methallyl polyoxyethylene ether: acrylic acid: thioglycolic acid: hydrogen peroxide: VC =1:4.2:0.13:0.23:0.03. Use the following steps to prepare a material suitable for 3D printing concrete shear walls:

[0032] 1) take each raw material by mass parts;

[0033] 2) Mix the water reducing agent and the setting retarder evenly and prepare them as admixtures for later use;

[0034] 3) Put sulphoaluminate cement, Portland cement, silica fume, quicklime, 20-40 mesh quartz sand, 50-80 mesh quartz sand into the mixer for mixing, after mixing evenly, add dispersible latex powder and polypropylene ...

Embodiment 2

[0044] The method suitable for 3D printing concrete shear wall materials is to mechanically transport the 3D printing concrete material prepared according to the mix ratio to the printing nozzle of the 3D printer, open the pre-designed model on the 3D printer operating platform, and click Start printing. Among them, the nozzle of the printer is 50mm, the printing height of a single layer is 30mm, the walking speed is 5cm / s, and the printing interval between layers is 60s.

[0045] Through the 3D printing test of the 3D printed concrete shear wall material of the present invention, the observation results: the printing time is controlled within 1 hour, there is no clogging during the printing process, the surface is smoother when extruded, the mechanical strength of the concrete is high, and the concrete shrinks less without cracks. The printing effect is good and the appearance is beautiful.

Embodiment 3

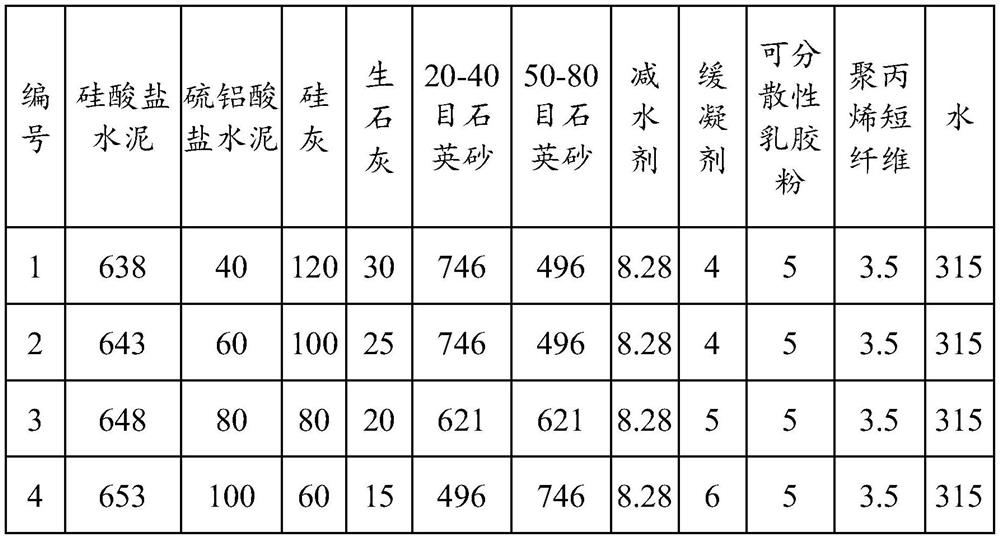

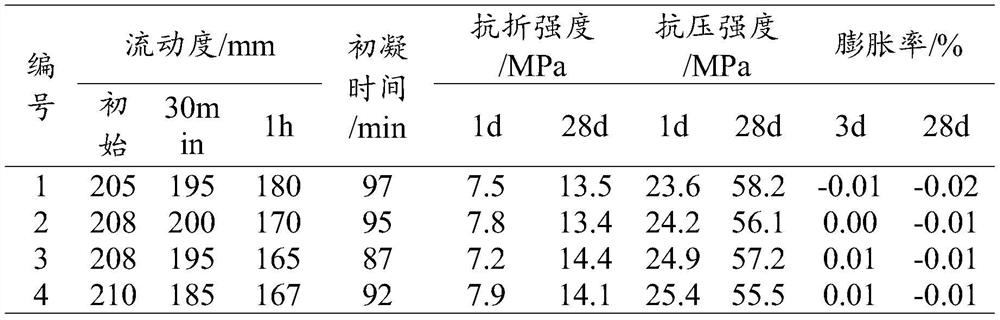

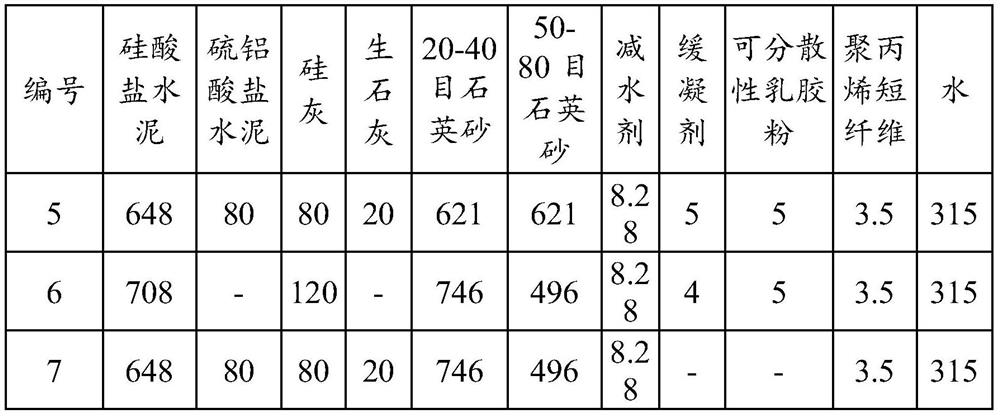

[0047] By adjusting the addition ratio of each raw material, use the jump table fluidity tester to test its fluidity, and use the cement mortar setting time tester to test its setting time. The No. 5 water reducer is a slow-release polycarboxylate water reducer. Test its fluidity with a table fluidity tester, and test its setting time with a cement mortar setting time tester. See Table 3 for the mix ratio and Table 4 for the test results.

[0048] Table 3 3D printing concrete shear wall material ingredient list

[0049]

[0050] Table 4 Test results of 3D printed concrete shear wall materials

[0051]

[0052] The test results of No. 5 and No. 6 show that if the slow-release polycarboxylate superplasticizer is used, or without the addition of sulphoaluminate cement and quicklime, the 3D printed concrete shear wall material presents the main problem of the fluidity of the 3D printed material. If it is too large, the viscosity is low, the early hydration reaction rate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com