Patents

Literature

31results about How to "Has hydration activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

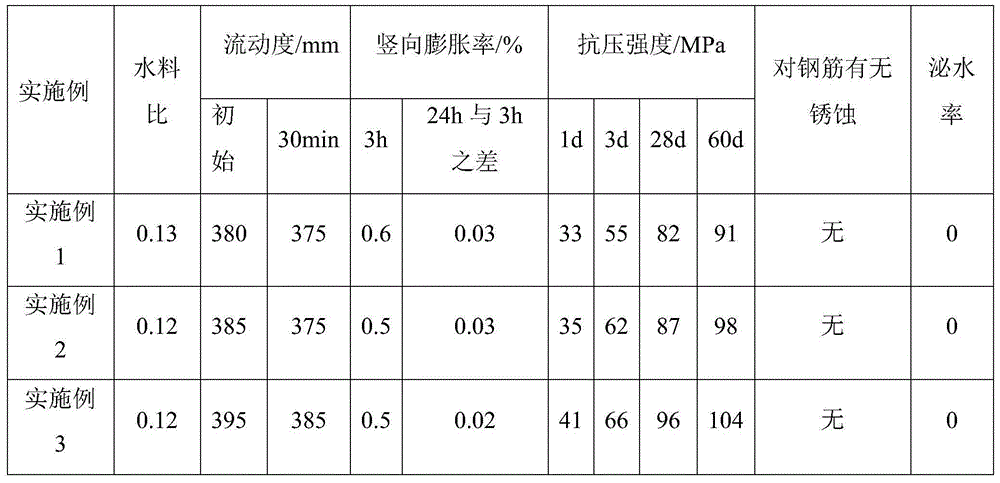

High fluidization micro expansive high-strength grouting material

ActiveCN104402345AReduce physical water consumptionImprove early strengthSolid waste managementChemical admixtureSlag

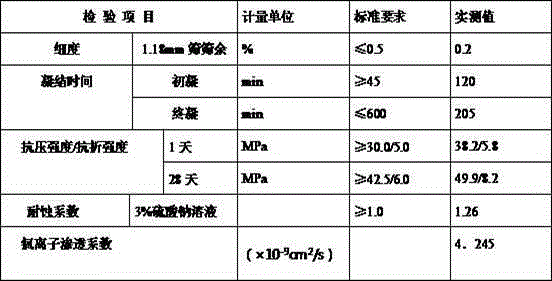

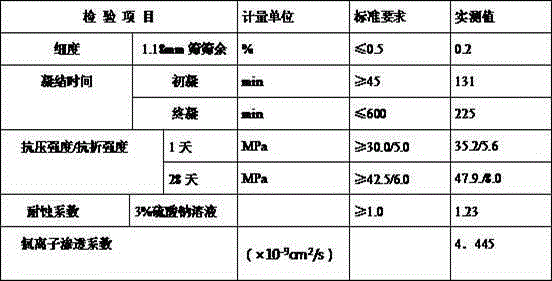

The invention discloses a high fluidization micro expansive high-strength grouting material which comprises the following raw materials by mass percentage: 23-34% of cement, 3-5% of microbead, 5-7.5% of phosphorus slag composite powder, 2.5-3.5% of silica fume, 2.5-3.5% of quartz powder, 46-55% of fine aggregate, 0.7-1% of water reducer, 0.01-0.03% of defoaming agent, 2.5-3.5% of expanding agent and 0.5-1% of early strength agent. The grouting material has the advantages of high strength in the early stage and later stage, good flowing property and adjustable expansiveness by taking the cement as a major binding material and employing the silica fume, the microbead and the phosphorus slag composite powder with different hydration activities together with a chemical additive matched with a binding material system and an aggregate system with reasonable gradation, and is particularly applicable to high precision equipment mounting, secondary grouting of an equipment foundation, bolt anchoring, crack repairing, duct grouting and the like.

Owner:中建西部建设西南有限公司

Curb produced by using waste ceramic slag and waste road concrete and manufacturing method

InactiveCN103058613AImprove performanceEnhance and improve performanceSolid waste managementBrickCalcium formate

The invention relates to a curb produced by using waste ceramic slag and waste road concrete and a manufacturing method. The curb is characterized in that the waste ceramic slag, the waste road concrete, waste incineration residue, waste granite slag, silicate cement, calcium oxide powder, calcium sulfate powder, polycarboxylate efficient water reducing agent, calcium formate, sodium sulfate and water are used as raw materials; and the raw materials are stirred to be moist through a stirrer, extruded by using a hydraulic machine and manufactured into the waste ceramic slag and waste road concrete curb under the pressure of 25 to 30MPa, and the curb is naturally dried and cured for 28 days at normal temperature by using a water spraying method. The raw materials can be manufactured into top wall bricks, plaza bricks and sidewalk bricks with different sizes; and the curb has the advantages of light weight, high strength, pollution prevention, low cost and high benefits. The invention meets the requirements for national energy conservation and emission reduction development and low-carbon economy.

Owner:清远绿由环保科技有限公司 +1

Method for preparing construction waste micro-powder composite admixture

InactiveCN103086619AHas hydration activityPromote participation in hydration reactionsSolid waste managementCement productionAlkalinityPowder mixture

The invention discloses a method for preparing a construction waste micro-powder composite admixture. The method comprises the steps of: evenly mixing construction waste with lime and desulfurized gypsum, and grinding at room temperature to obtain a micro-powder mixture with specific surface area larger than 400m<2> / kg, wherein the mixing weight of the construction waste accounts for 90%-98% total weight of the micro-powder mixture, the mixing weight of the lime accounts for 1%-5% and the mixing weight of the desulfurized gypsum accounts for 1%-5%; mixing the ground micro-powder mixture with an additive of which the weight accounts for 1%-5% total weight of the micro-powder mixture to obtain a mixed material; and mixing the mixed material with slag in a weight ratio of 1:1 and then carrying out ball milling until the specific surface area of the material is larger than 450m<2> / kg, thereby obtaining the construction waste micro-powder composite admixture. The method has the advantages that the alkalinity of concrete can be supplemented, the mixing quantity of a construction waste micro-powder auxiliary gelation material in the concrete is increased and the carbonization resisting capacity of the concrete can be improved.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Collaborative process for carbonizing and hydrating steel slag

The invention belongs to the technical field of building materials, and particularly relates to a collaborative process for carbonizing and hydrating steel slag. The process comprises the following steps: (1) pre-wetting lightweight ceramic sand; (2) uniformly mixing the pre-wetted lightweight ceramic sand, the steel slag and quartz sand in parts by weight: 50 to 70 parts of the steel slags, 18 to30 parts of the quartz sand and 5 to 20 parts of the pre-wetted lightweight ceramic sand; and (3) pressing and forming, namely, immediately placing the mixture into a carbonizing box for carbonizing,and then performing standard curing. According to the collaborative process for carbonizing and hydrating the steel slag, a carbonizing curing and pre-wetted ceramic sand internal curing collaborative mechanism is introduced by utilizing the chemical characteristics of carbonizing activity and hydrating activity of the steel slag; the overall reaction degree of the steel slag is improved; the mechanical properties and the durability of a steel slag product are further improved; the prepared steel slag product has the characteristics that the homogeneousness of a carbonized matrix is high, themechanical properties and the durability are excellent, the cost is low, and the environment friendliness is high.

Owner:WUHAN UNIV OF TECH

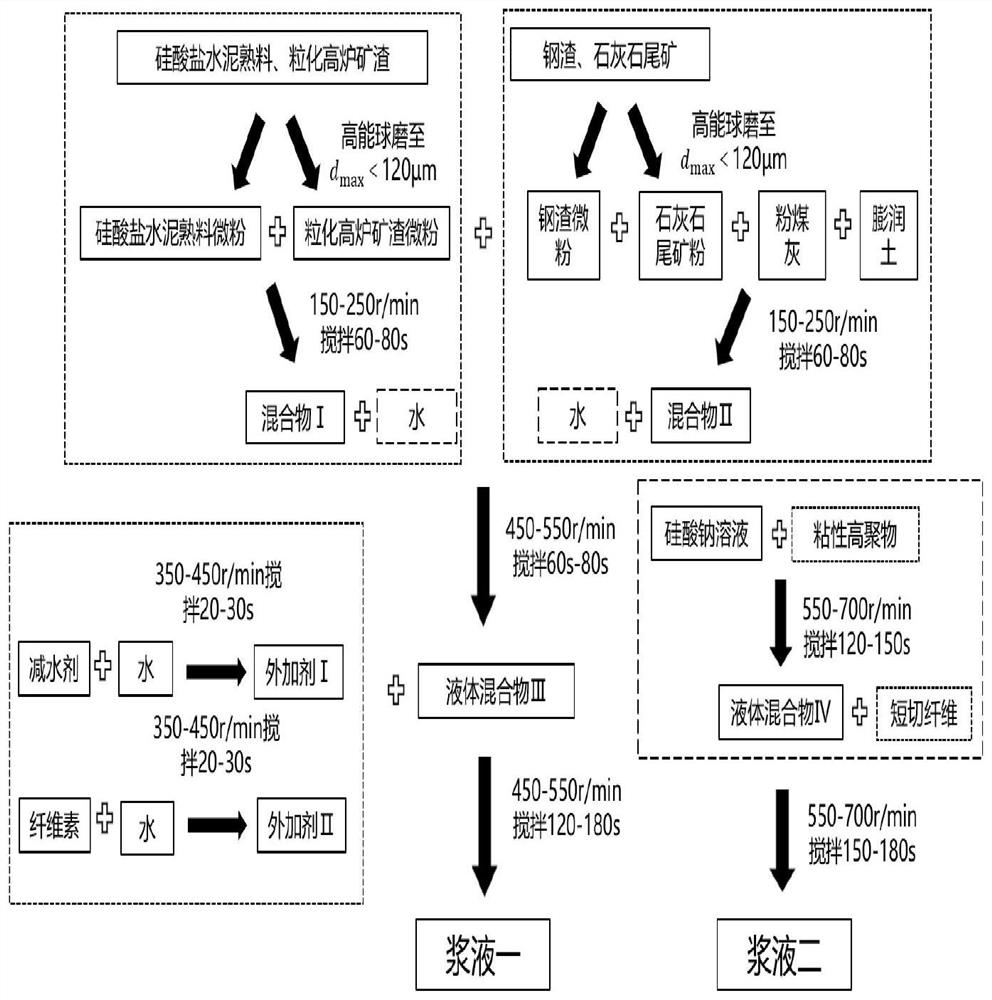

High-water-pressure super-large-diameter underwater shield tunnel double-liquid grouting slurry, process and application

ActiveCN114180930AImprove performanceImprove pore structureSolid waste managementUnderground chambersCelluloseFiber

The invention discloses a high-water-pressure super-large-diameter underwater shield tunnel double-liquid grouting slurry, and a process and application thereof. The slurry I is prepared from the following raw materials: 35-45 parts of cement clinker; 15 to 25 parts of slag; 24 to 35 parts of fly ash; 15-25 parts of steel slag; 5 to 15 parts of bentonite; 4-10 parts of limestone tailings; 0.3-2 parts of a water reducing agent; 0.5 to 2.5 parts of cellulose; the slurry II is prepared from the following raw materials in parts by weight: 0.2-3.8 parts of chopped fibers; 96-99 parts of a sodium silicate solution; and 0.8-4.8 parts of a viscous high polymer. A double-slurry preparation process of crushing, screening, grinding, grouped mixing and grouped stirring at different speeds is formed, the volume ratio of the slurry I to the slurry II is (1: 1)-(10: 1) during grouting, the slurry is injected into a shield gap through the grouting process of shield tail six-point location and segment 3 + 2 + 1 splicing synchronization, and the grouting method can be applied to a high-water-pressure super-large-diameter underwater shield tunnel with the water pressure larger than or equal to 0.5 MPa and the diameter larger than or equal to 14 m.

Owner:OCEAN UNIV OF CHINA

Method for producing high-salinity maritime work cement through mineral waste residue waste materials

The invention discloses a method for producing high-salinity maritime work cement through mineral waste residue waste materials. The high-salinity maritime work cement is prepared from, by weight, 30-40 parts of mineral waste residues, 40-50 parts of sulphate aluminum cement clinker, 0.03-0.05 part of composite activating agents, 2-4 parts of early strength agents, 0.3-0.5 part of water reducing agents, 0.005-0.007 part of air entraining agents and 0.3-0.5 part of retarder. The method for producing the high-salinity maritime work cement comprises the steps that the mineral waste residue waste materials, the sulphate aluminum clinker, the composite activating agents and the early strength agents are smashed, ground into powder and homogenized respectively and then dosed, mixed and homogenized according to proportions, then the water reducing agents, the air entraining agents and the retarder are added, mixed and homogenized, and the product is obtained. The high-salinity maritime work cement has the performance of common cement, further has the excellent characters of early-stage hardness resisting, long-term corrosion resistance, retardation progressive increasing and the like, and is especially suitable for ports, wharfs and other engineering which are corroded by corrosive media.

Owner:广西云燕特种水泥建材有限公司

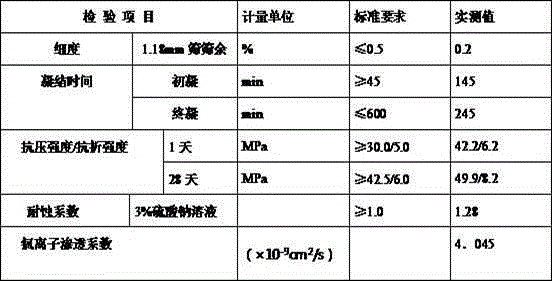

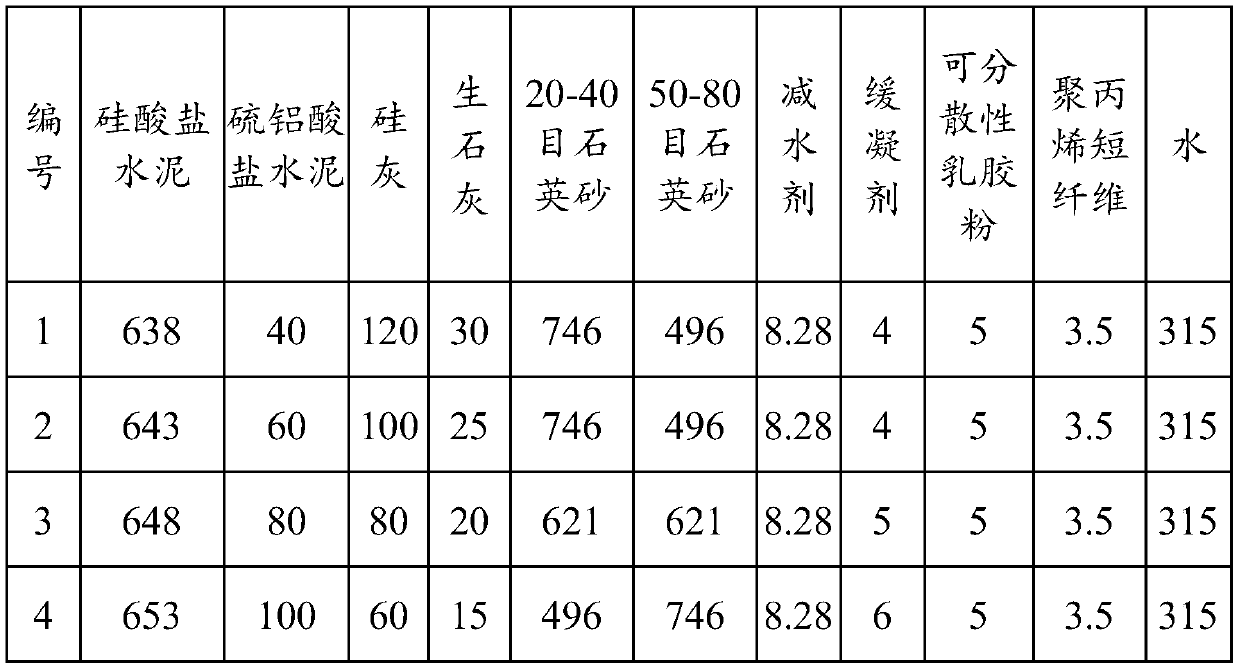

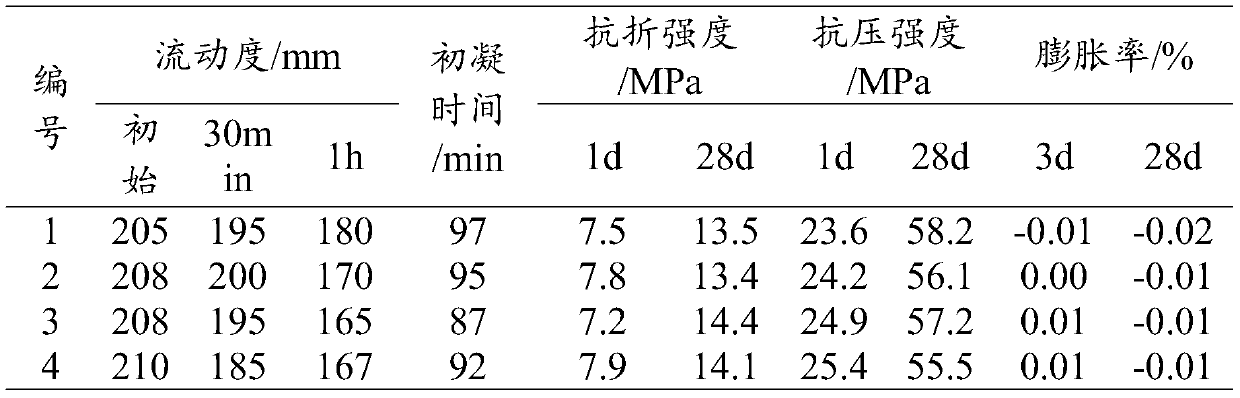

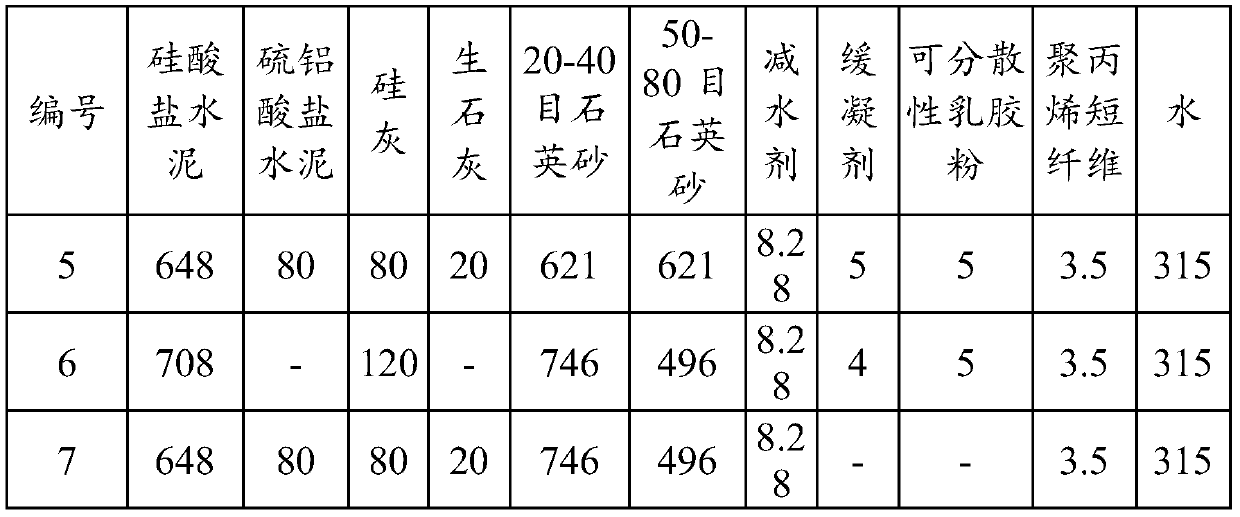

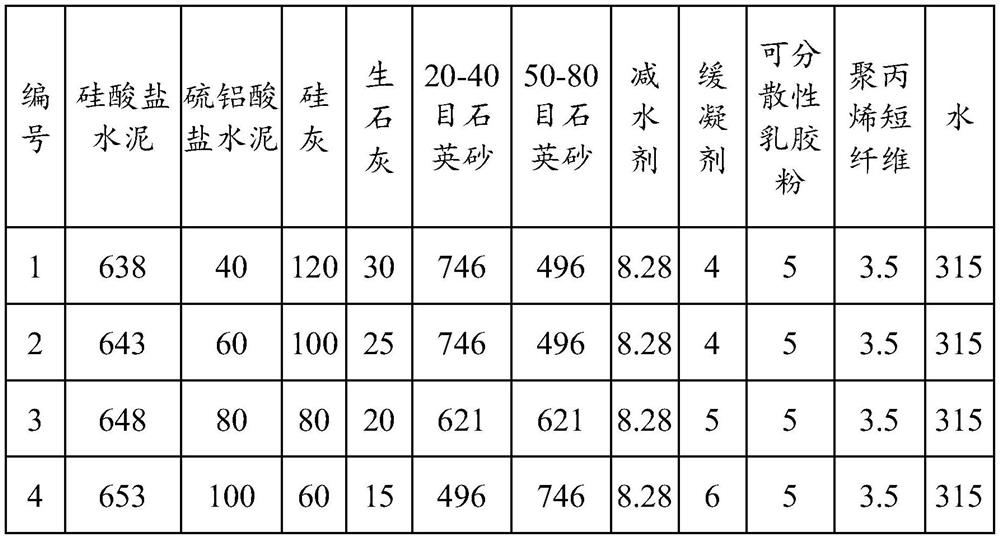

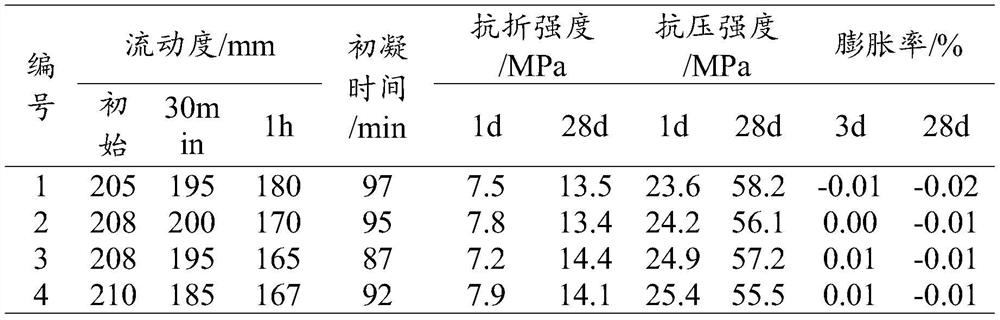

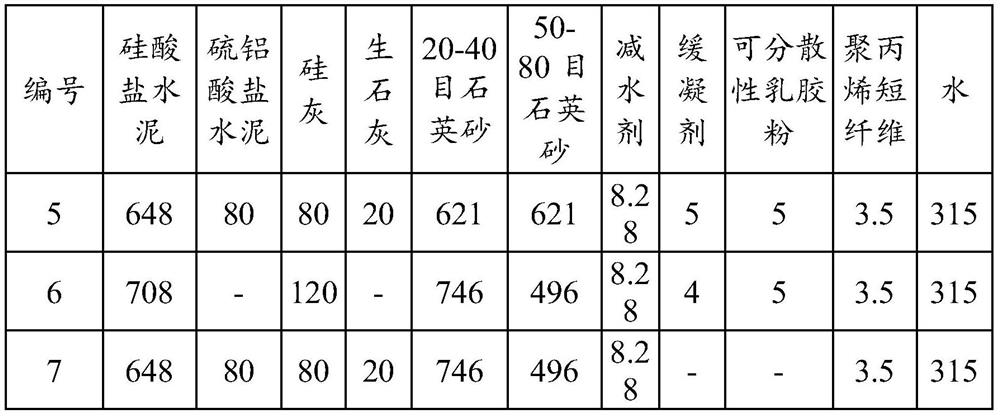

Material suitable for 3D printing concrete shear wall and preparation method of material

ActiveCN110540394AProlong clotting timeImprove early strengthAdditive manufacturing apparatusFiberHigh rise

A preparation method uses Portland cement, sulphoaluminate cement, silica fume, quick lime, 20-40-mesh quartz sand, 50-80-mesh quartz sand, a water reducing agent, a retarder, dispersible latex powder, polypropylene short fibers and water as raw materials, varieties of gelling materials, admixtures, aggregate and additives are adjusted, and therefore the 3D printing concrete material having the advantages of having high mechanical strength, good initial fluidity, convenient printing construction, achieving requirements for strength and durability of concrete of high-rise buildings, ensuring the collapse resistance and aesthetics of printed components, and being suitable for cast-in-situ construction operation is prepared.

Owner:山东中岩建材科技有限公司

Tailing cementing filling material and preparation method thereof

The invention discloses a tailing cementing filling material and a preparation method thereof, wherein the tailing cementing filling material comprises mine acid wastewater neutralizing residue, ball-milled slag, an excitant, tailings and water according to a mass ratio of 45-70:65-95:5-15:830-870:300-400. According to the invention, the method completely utilizes the existing waste residues of mines and smelting plants, and has characteristics of high waste residue utilization rate, excellent mechanical property and good flowability.

Owner:厦门紫金矿冶技术有限公司

High active cement clinker, high active cement and high-early-strength cement composition

ActiveCN102432205AEmission reductionHas hydration activitySolid waste managementPolymer scienceGypsum

The invention provides a high active cement clinker, a high active cement and a high-early-strength cement composition. The High active cement clinker adopted as the solidifying material and the matrix of a high-early-strength cement is characterized by comprising more than 70 % of C3S, less than 5 % of C2S and more than 1 of L.S.D, calculated through Bogue formula. The free lime amount of the cement clinker is 0.5-7.5 % by weight.

Owner:TOKYO INST OF TECH +1

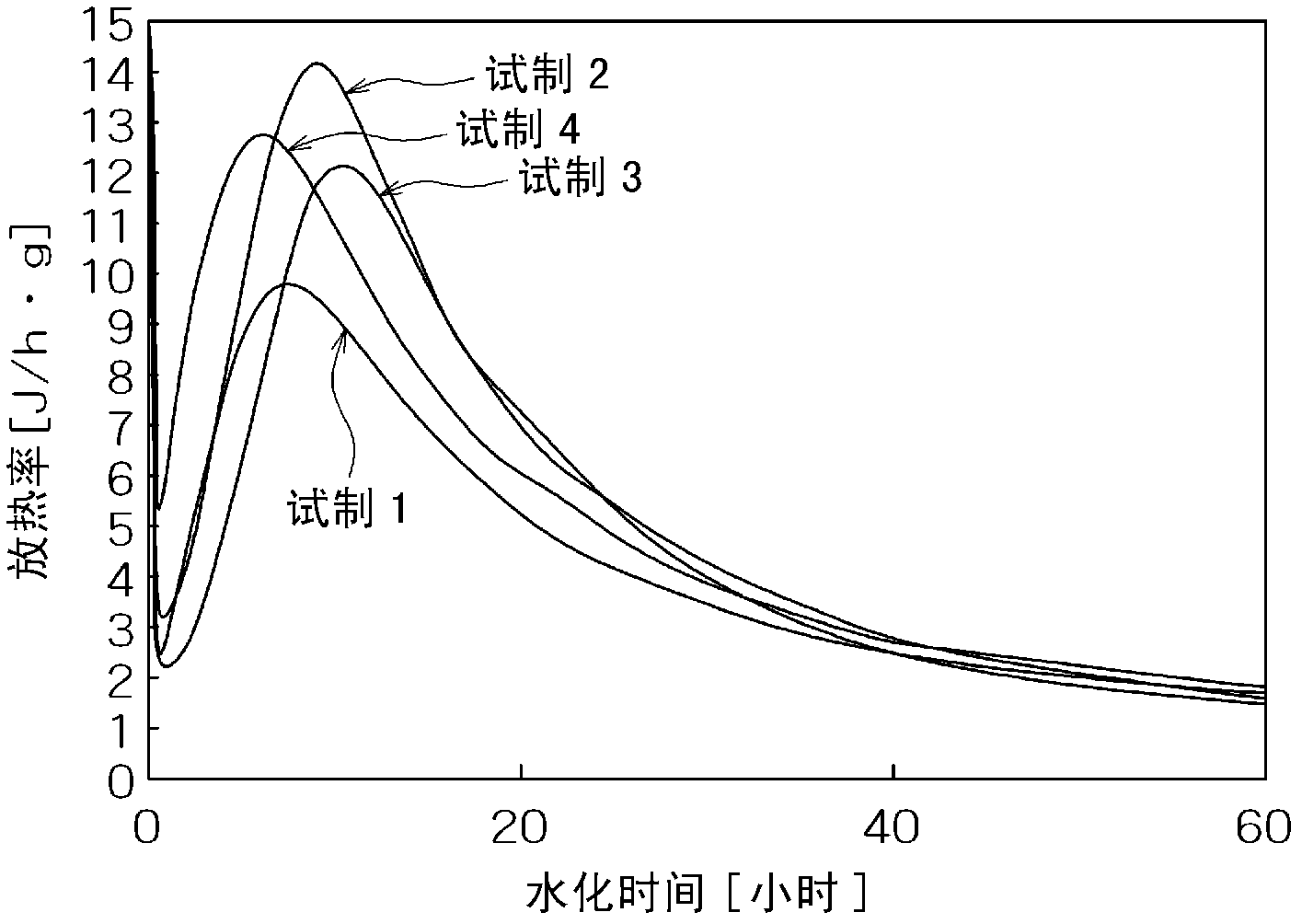

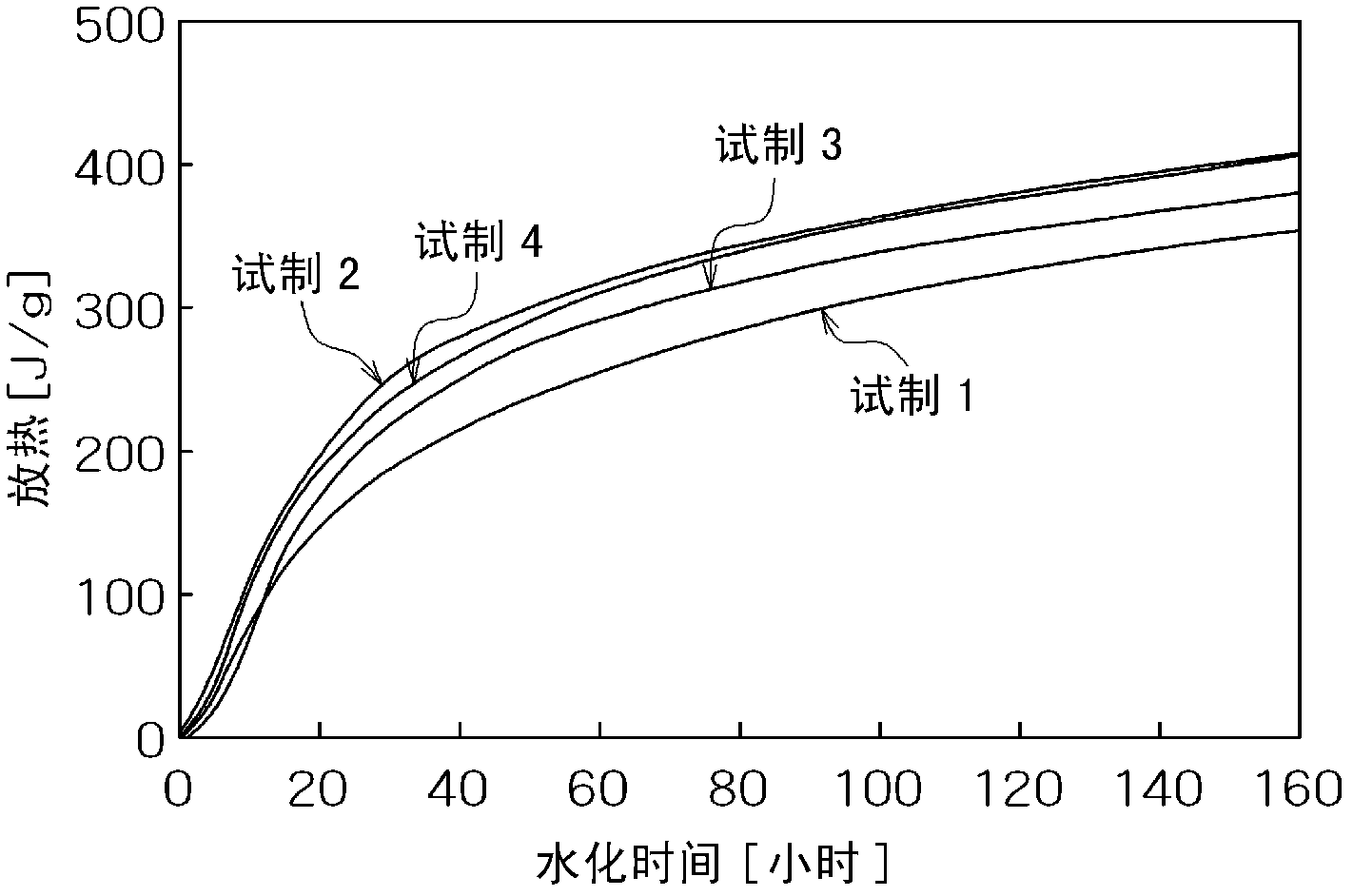

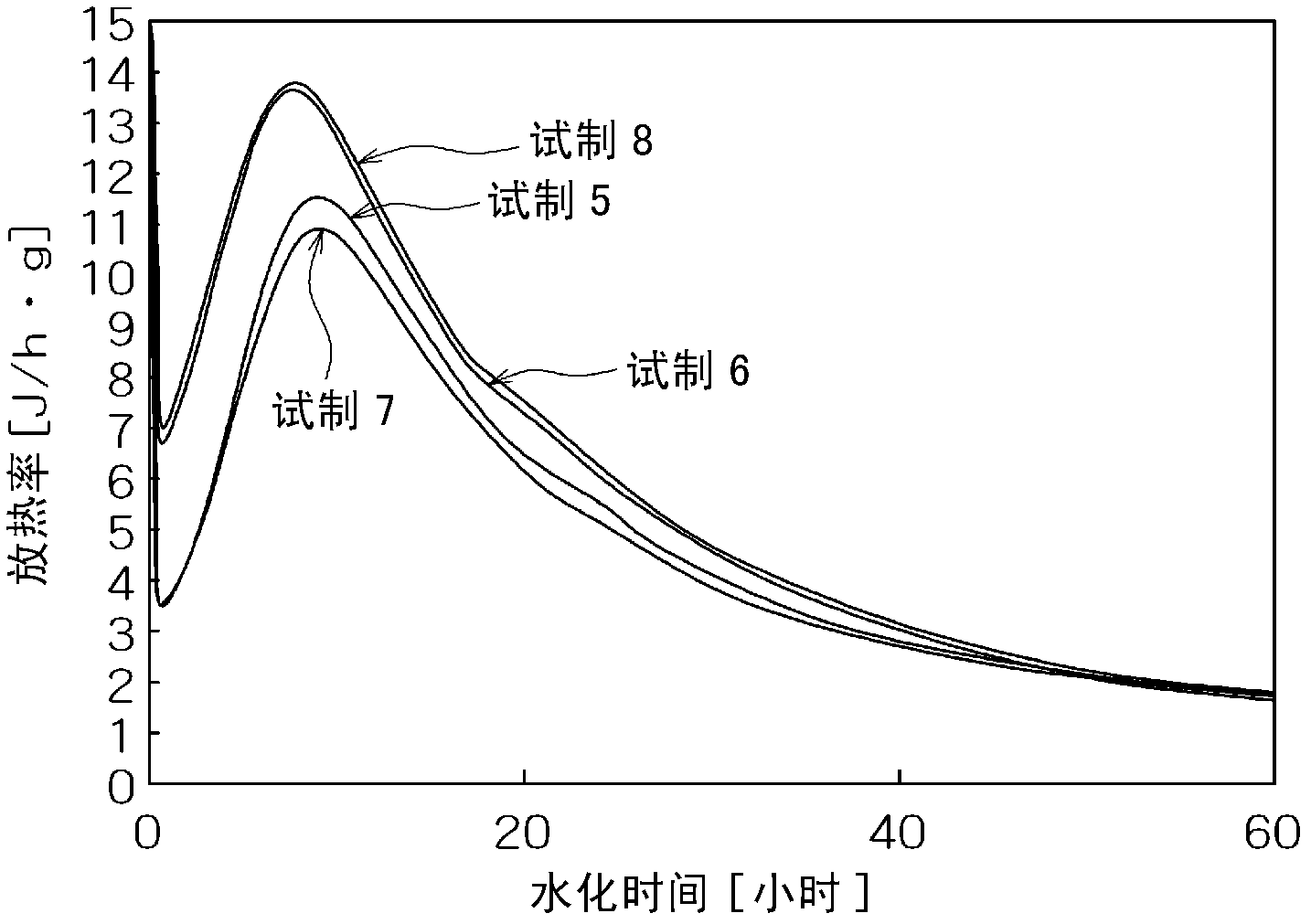

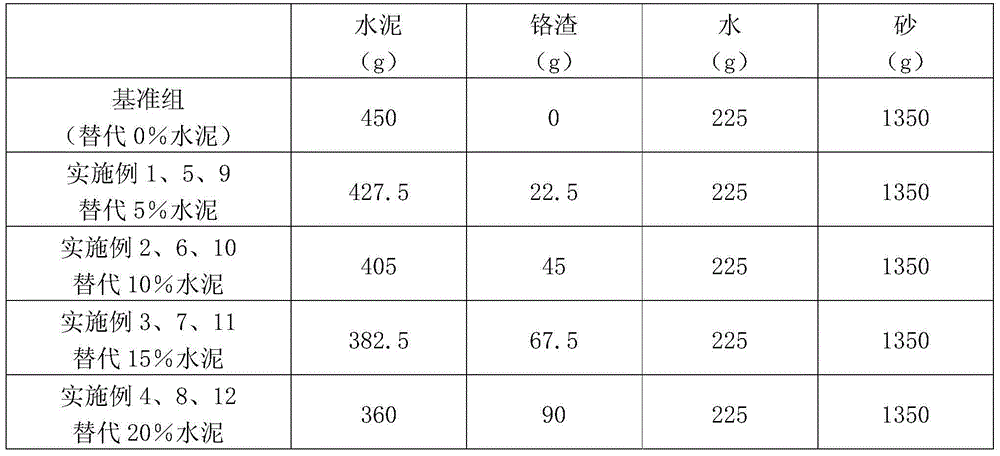

Method for preparing concrete with dry-process detoxified chromium slag as concrete mineral additive

The invention discloses a method for preparing concrete with dry-process detoxified chromium slag as a concrete mineral additive. The method comprises the following steps: grinding the dry-process detoxified chromium slag until the specific surface area of the dry-process detoxified chromium slag is 300 to 600 m2 / kg + / - 20 m2 / kg; and then preparing concrete by using the ground dry-process detoxified chromium slag accounting for no more than 20% (by mass) of the total amount of a cementing material (including cement clinker and a concrete mineral additive containing chromium slag) in the concrete to replace cement clinker or the concrete mineral additive. Detection results show that a concrete material prepared by using the method has mechanical properties and endurance quality identical to or better than a concrete material prepared from a common mineral additive; and with the method, hexavalent chromium in the dry-process detoxified chromium slag can be effectively solidified, pollution of hexavalent chromium to soil, a water body and the like is avoided, so resourceful utilization of the dry-process detoxified chromium slag is realized and the method is of active significance to overcoming of the problem of stockpiling of chromium slag.

Owner:BEIJING TRIUMPH INT ENG +1

Road curing agent and road curing method

InactiveCN108707463AHigh strengthImprove water absorptionIn situ pavingsBuilding constructionsPolyvinyl acetateCarvacryl acetate

The invention belongs to the technical field of road construction and particularly relates to a road curing agent and a road curing method. The road curing agent contains two parts, namely a water agent and a powder agent, wherein the water agent contains the following components by weight percent: 45%-54% of polyvinyl acetate copolymer, 6%-7% of fatty alcohol-polyoxyethylene ether and 40%-49% ofwater; the powder agent contains the following components by weight percent: 80%-90% of desulfurated ash, 9%-18% of quick lime and 1%-2% of nano-clay. The road curing agent has the advantages of low production cost, high strength after being cured, good water tolerance and slight influence to surrounding environments, can be applied to the curing of sandy soil and macadam and is an environment-friendly road curing material.

Owner:南京友西科技集团股份有限公司

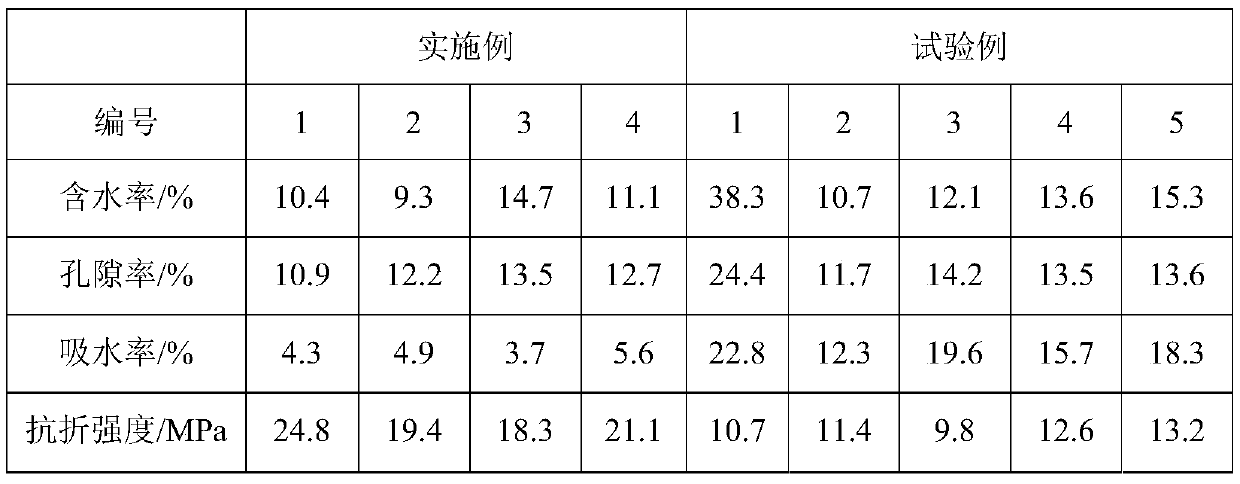

Electromagnetic shielding cement board and semi-dry preparation process thereof

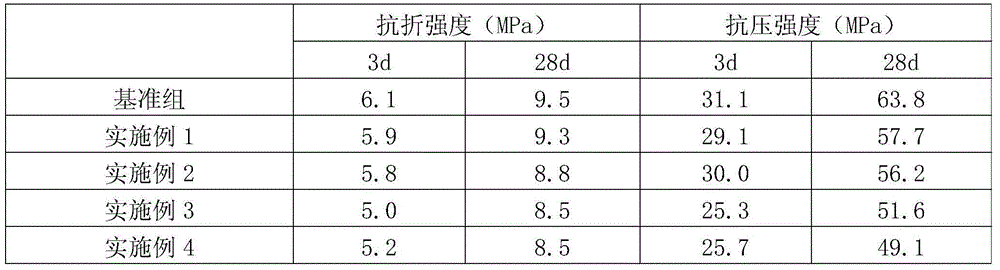

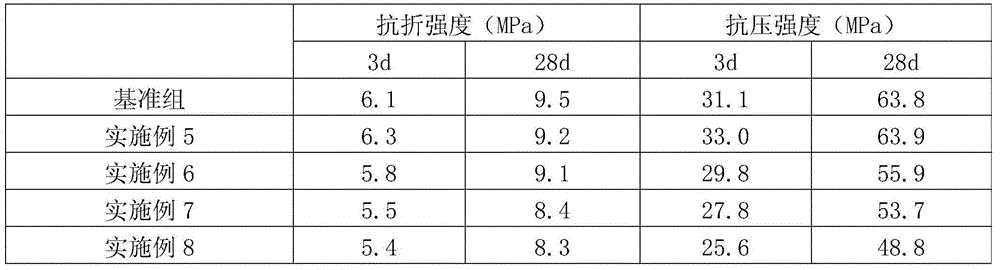

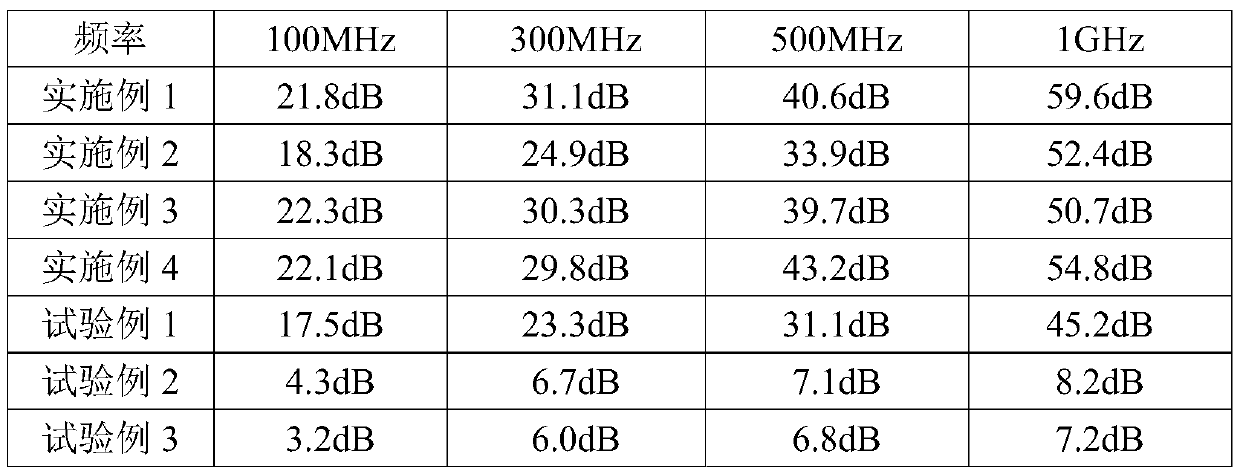

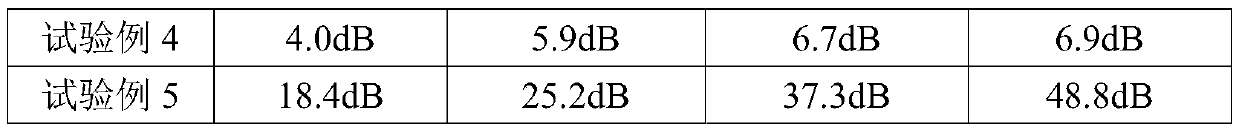

The invention belongs to the technical field of production of a cement board, and particularly relates to a cement board which has an electromagnetic shielding function and is prepared by adopting a semi-dry method. The electromagnetic shielding cement board comprises a material A and a solution B, wherein the material A comprises the following raw materials in parts by weight: 5-70 parts of cement, 5-10 parts of glass fibers, 3-7 parts of silica fume, 5-15 parts of fly ash and 0.3-1.5 parts of polyvinylpyrrolidone. The solution B is prepared from the following raw materials in parts by weight: 90 to 98 parts of water, 1 to 6 parts of silane coupling agent and 0.05 to 0.15 part of Fe3O4-modified graphene oxide. The cement board is low in water content, high in density, low in porosity, lowin water absorption rate, excellent in breaking strength and good in anti-freezing performance, and has good mechanical properties and excellent shielding performance. The product can completely meetthe performance requirements when the cement board is used as a decorative board and an external wall board, and has wide application potential.

Owner:UNIV OF JINAN

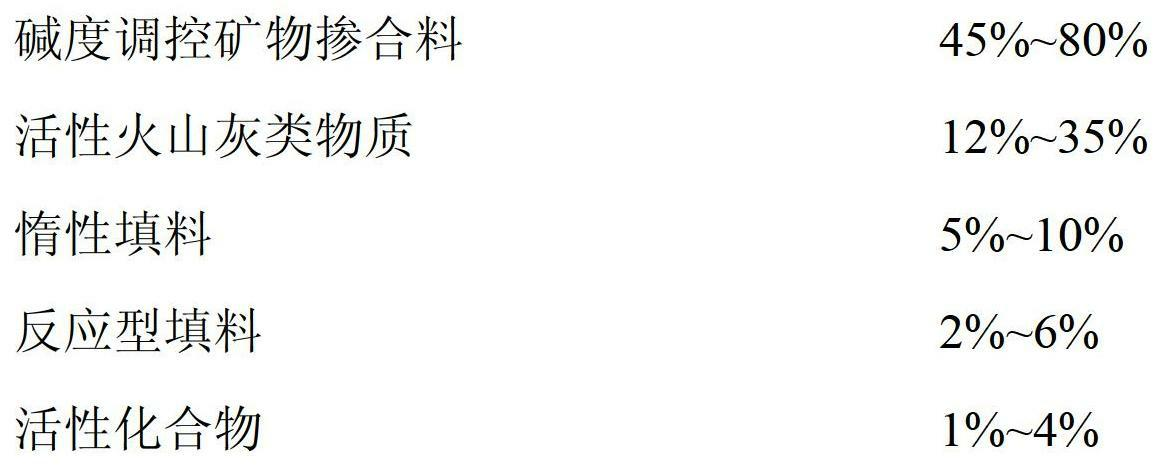

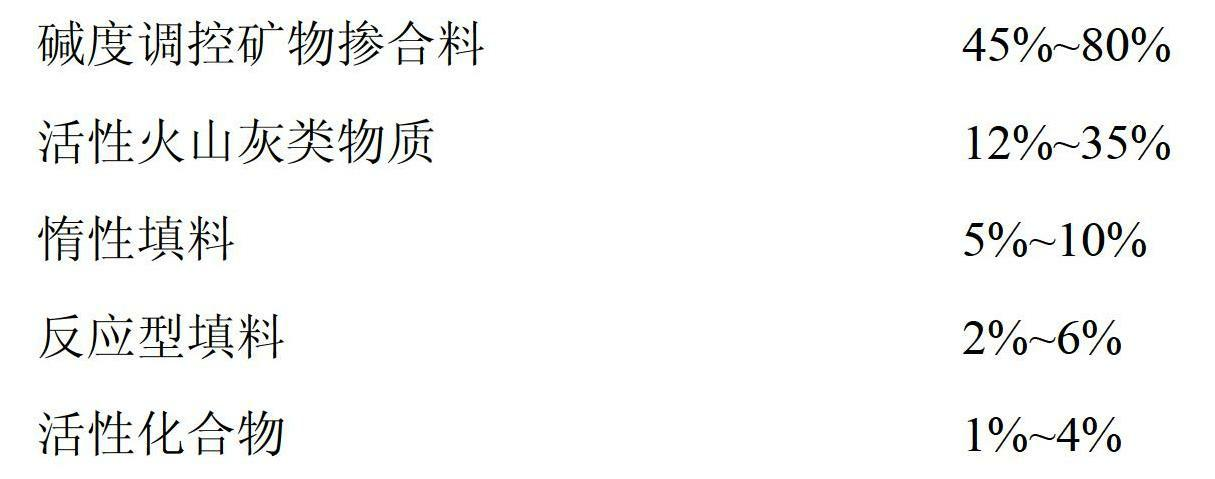

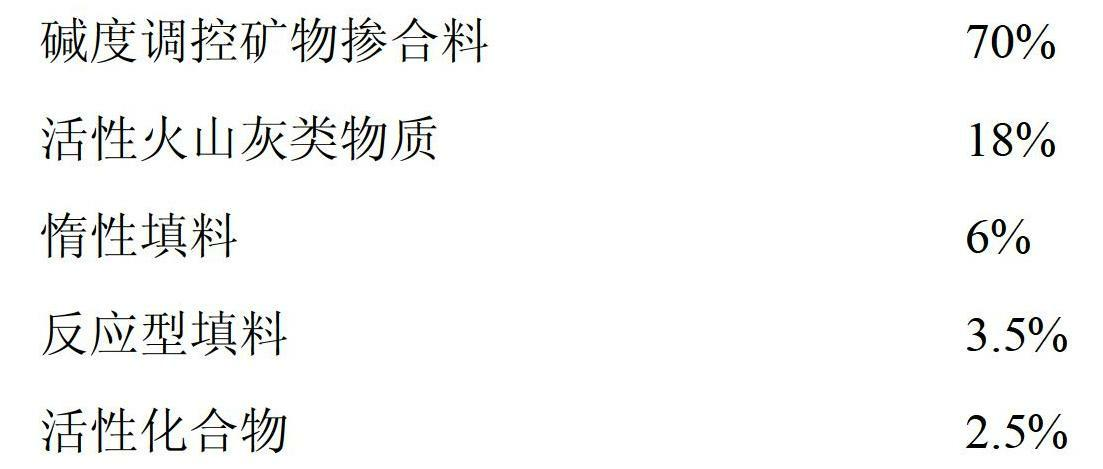

Multi-functional acid-resistant concrete gel powder

InactiveCN102674744AImprove volume stabilityGood acid corrosion resistanceEconomic benefitsAcid corrosion

The invention relates to multi-functional acid-resistant concrete gel powder. The multi-functional acid-resistant concrete gel powder comprises the following components in percentage by weight: 45 to 80 percent of mineral admixture for basicity regulation and control, 12 to 35 percent of active volcanic ash substances, 5 to 10 percent of inert filler, 2 to 6 percent of reactive filler and 1 to 4 percent of active compound. The multi-functional acid-resistant concrete gel powder can remarkably improve the acid corrosion resistance of cement concrete, reduce the risks of surface burst, peeling and strength reduction of concrete under acid environment erosion conditions, and remarkably improve the permeability resistance and volume stability of concrete matrixes, is convenient to construct, and has a remarkable economic benefit. The multi-functional acid-resistant concrete gel powder can be widely applied to concrete works such as ports, wharves, plants, sewage treatment plants, tunnels, roads, bridges and civil buildings which serve in acid environments.

Owner:JIANGSU SOBUTE NEW MATERIALS

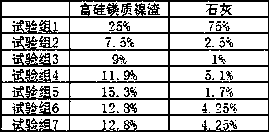

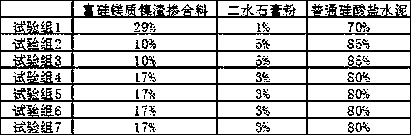

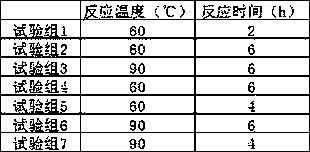

Silicon-rich magnesium nickel-slag anti-freezing cement and preparation method thereof

ActiveCN107804983AHas hydration activityReduce the number of harmful holesCement productionAnti freezingSlag

The invention discloses silicon-rich magnesium nickel-slag anti-freezing cement. The cement comprises the following components: ordinary Portland cement, a silicon-rich magnesium nickel slag containedadmixture and dihydrate gypsum powder. The mass percent of the ordinary Portland cement is 70-90%, the mass percent of the silicon-rich magnesium nickel slag contained admixture is 10-30%, and the mass percent of the dihydrate gypsum powder is 1-5%. According to the invention, with the utilization of the excitation effect of lime, silicon-rich magnesium nickel slag has certain hydration activity,and the hydration activity of the activated silicon-rich magnesium nickel slag contained admixture is still lower than the hydration activity of the Portland cement, so that the Portland cement has adifference with the silicon-rich magnesium nickel slag contained admixture in hydration rate; and the volume is increased in the process that Mg(OH)2 is generated by magnesium components in the silicon-rich magnesium nickel slag, so that the number of harmful holes of the concrete is remarkably reduced, and thus the freezing resistance of the concrete is improved.

Owner:YANCHENG GUOTAI CONCRETE

Fine-grained concrete taking dredged sand as main raw material and preparation method thereof

The invention discloses fine-grained concrete taking dredged sand as a main raw material. The fine-grained concrete is prepared from cement, dredged sand, limestone powder, regenerated glass powder, ahigh-efficiency water reducing agent and water. The invention further discloses a preparation method of the fine-grained concrete with the dredged sand as the main raw material. The preparation method comprises the following steps: S01, weighing the dredged sand, the cement, the limestone powder and the recycled glass powder according to the raw material proportion, adding into a stirring machineand carrying out dry mixing for 1-2 min till even mixing is achieved, S02, adding a polycarboxylate superplasticizer and water by a later mixing method, and performing wet mixing until the mixture isuniformly mixed, S03, adding the uniformly mixed materials into a test mold layer by layer and step by step, firstly adding 1 / 2 of the materials into the test mold, vibrating on a vibrating table for30 seconds, and then vibrating while adding the materials, and S04, covering the surface of the test mold with a thin film after molding, demolding after 12-24 hours, and curing the test piece to a specified age under standard conditions after demolding to obtain the dredged sand fine-grained concrete. The invention provides fine-grained concrete taking dredged sand as a main raw material and thepreparation method of the fine-grained concrete. The dredged sand can be reasonably utilized to be processed into a building material.

Owner:HOHAI UNIV

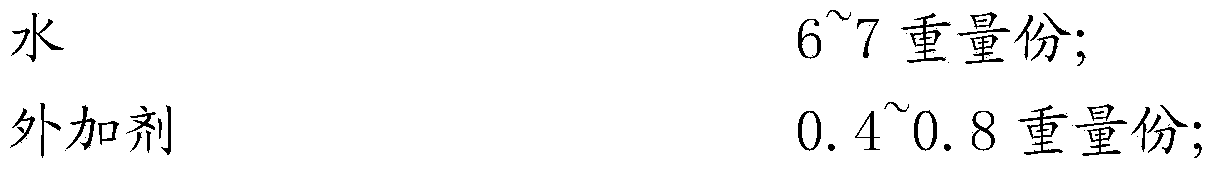

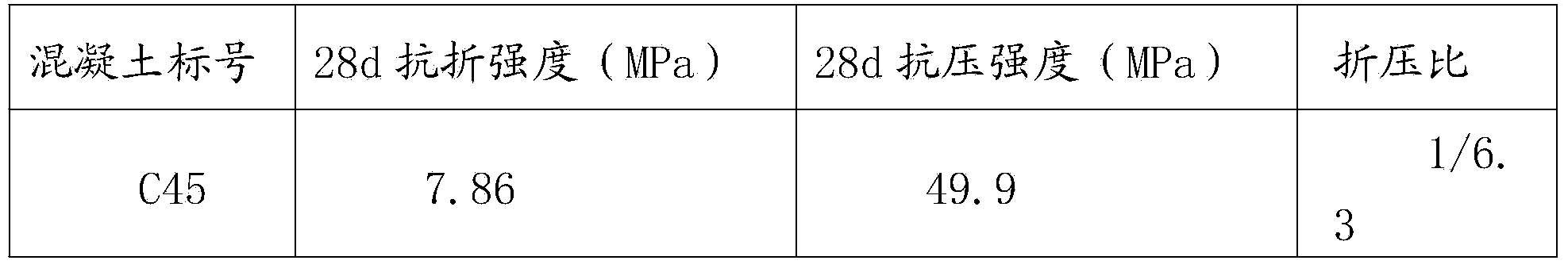

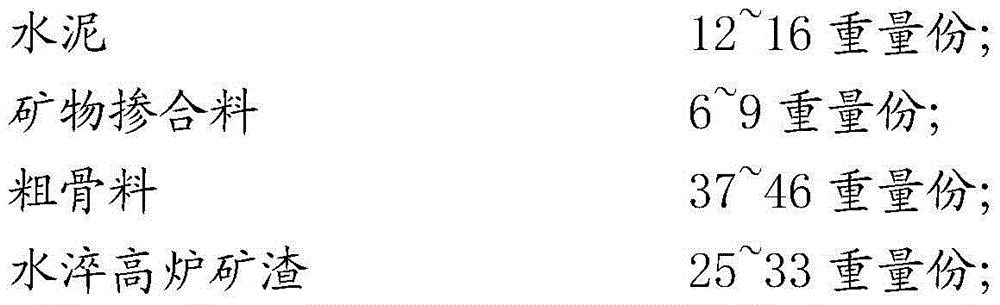

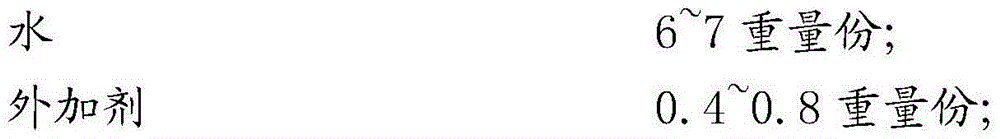

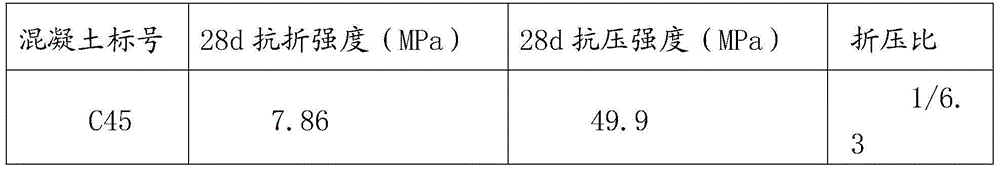

High compressive strength ratio concrete and preparation method thereof

InactiveCN103508707AReduce the water-binder ratioImprove compactness and strengthSolid waste managementSlagQuenching

The invention discloses high compressive strength ratio concrete and a preparation method thereof. The concrete comprises the following constituents: cement, mineral admixtures, coarse aggregate, fine aggregate, water and an additive with the weight ratio of (12-16):(6-9):(37-46):(25-33):(6-7):(0.4-0.8). By replacing frequently used coarse and fine aggregate through porous basalt and water-quenching blast furnace slags and improving the preparation method, the high compressive strength ratio concrete with high bending strength, good durability and low cost is prepared, the bending strength of the concrete can reach more than 7.5 MPa, the compressive strength ratio can reach 1 / 5 to 1 / 7, the problem that the existing high compressive strength ratio concrete has low bending strength, high cost and poor durability is solved, and the concrete can be widely applied to projects, such as large-span bridges, roads, overload pavements and the like, which have higher requirements on bending strength.

Owner:JIANGSU MINGHE GRP

A large fluid micro-expansion high-strength grouting material

ActiveCN104402345BReduce physical water consumptionImprove early strengthSolid waste managementChemical admixtureSlag

The invention discloses a high fluidization micro expansive high-strength grouting material which comprises the following raw materials by mass percentage: 23-34% of cement, 3-5% of microbead, 5-7.5% of phosphorus slag composite powder, 2.5-3.5% of silica fume, 2.5-3.5% of quartz powder, 46-55% of fine aggregate, 0.7-1% of water reducer, 0.01-0.03% of defoaming agent, 2.5-3.5% of expanding agent and 0.5-1% of early strength agent. The grouting material has the advantages of high strength in the early stage and later stage, good flowing property and adjustable expansiveness by taking the cement as a major binding material and employing the silica fume, the microbead and the phosphorus slag composite powder with different hydration activities together with a chemical additive matched with a binding material system and an aggregate system with reasonable gradation, and is particularly applicable to high precision equipment mounting, secondary grouting of an equipment foundation, bolt anchoring, crack repairing, duct grouting and the like.

Owner:中建西部建设西南有限公司

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components bythe weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

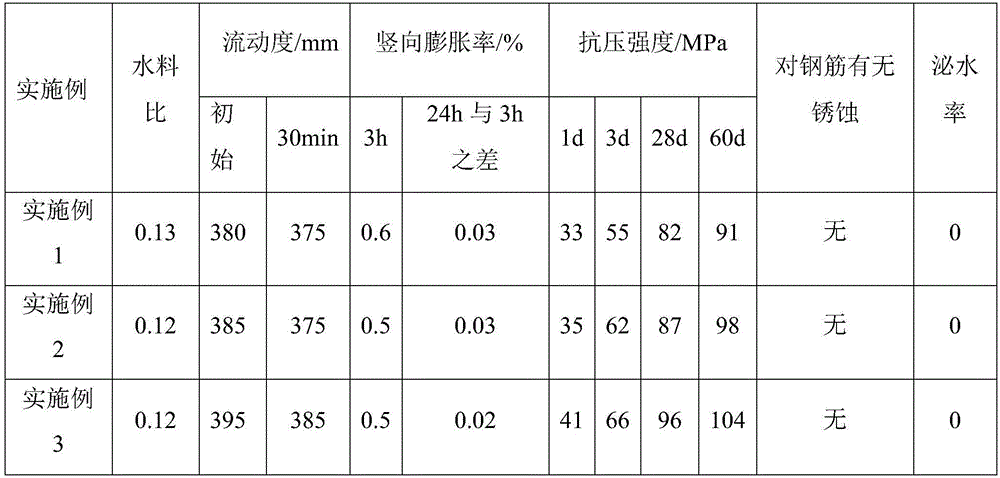

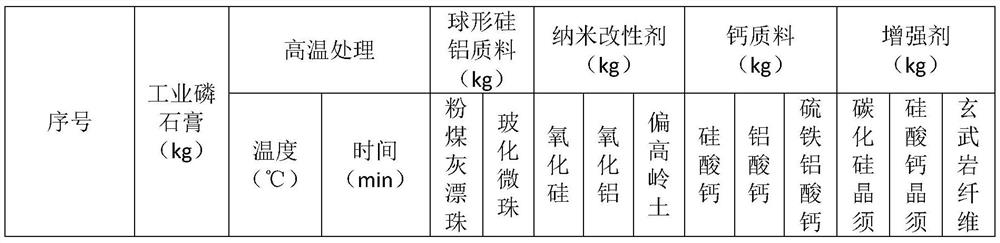

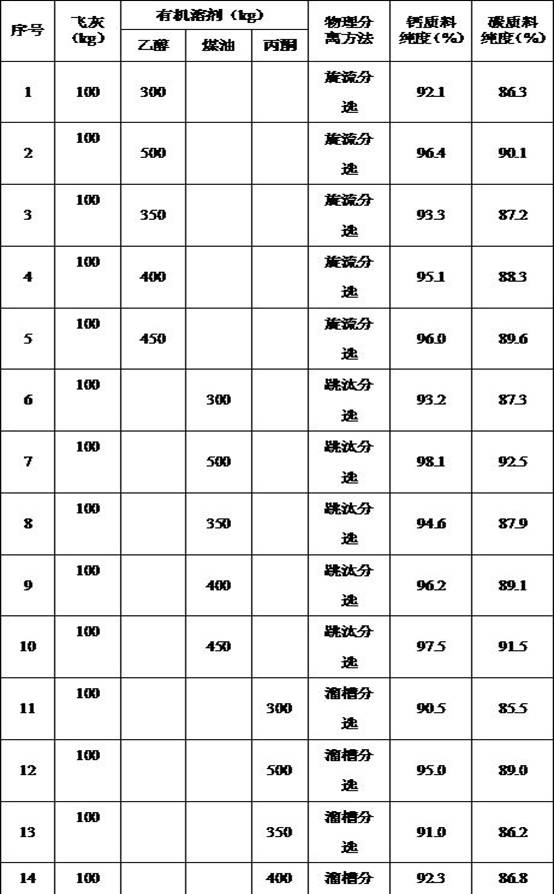

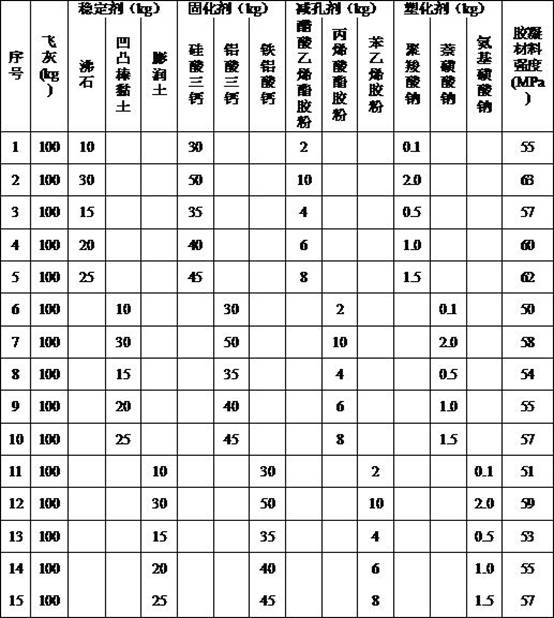

Preparation method of phosphogypsum-based high-fluidity water-resistant mortar

PendingCN112645674AImprove mortar strengthImproves strength and water resistanceComposite materialAluminium salts

The invention relates to the field of mortar, and particularly discloses a preparation method of phosphogypsum-based high-fluidity water-resistant mortar. The method comprises the following steps: step 1, chemical shaping of industrial phosphogypsum: adding the industrial phosphogypsum into an electrolyte solution containing organic acid and metal cations, wherein the metal cations are one of iron ions and aluminum ions provided by ferric sulfate and aluminum sulfate, and performing crystallizing for 30-120 minutes at the temperature of 60-140 DEG C to prepare the phosphogypsum with equiaxed crystal grains; step 2, high-temperature treatment: treating the phosphogypsum at the temperature of 400-1000 DEG C for 1-30 minutes to obtain inert phosphogypsum; and 3, adding the spherical silicon-aluminum material, the nano-powder material, the calcium material, the reinforcing agent, the flow increasing agent, the water-resistant agent and the stabilizer into the inert phosphogypsum, uniformly mixing, adding water, and uniformly stirring to obtain the high-fluidity water-resistant mortar. The mortar prepared by the method disclosed by the invention is high in strength, good in water resistance and high in flowability, and cyclic utilization of resources is realized.

Owner:成都建工赛利混凝土有限公司 +1

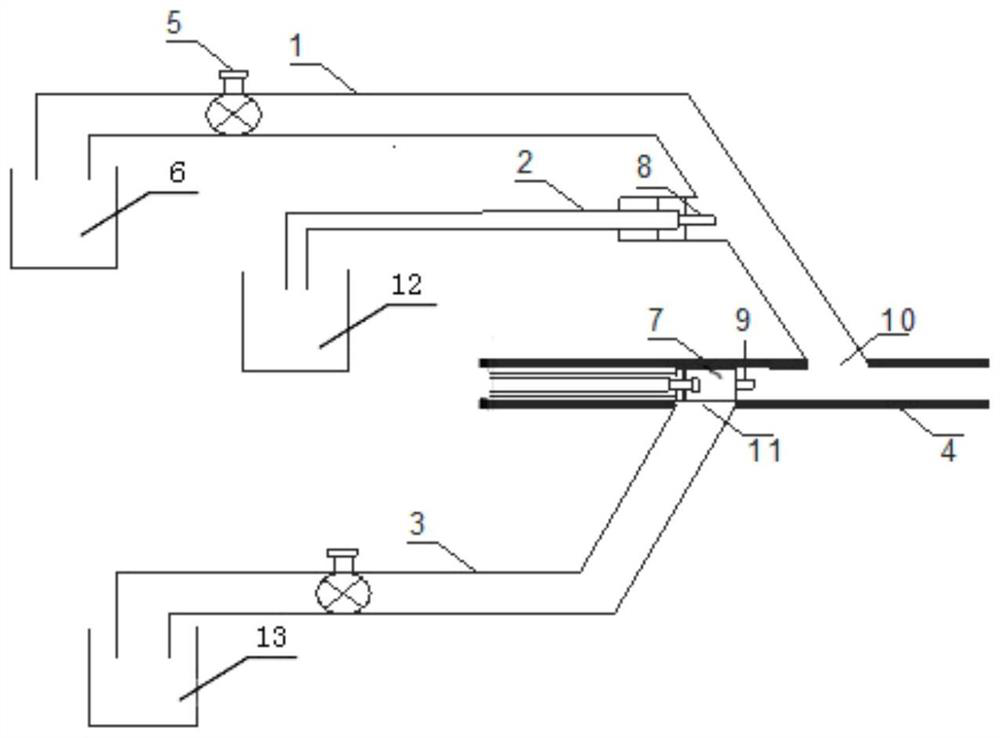

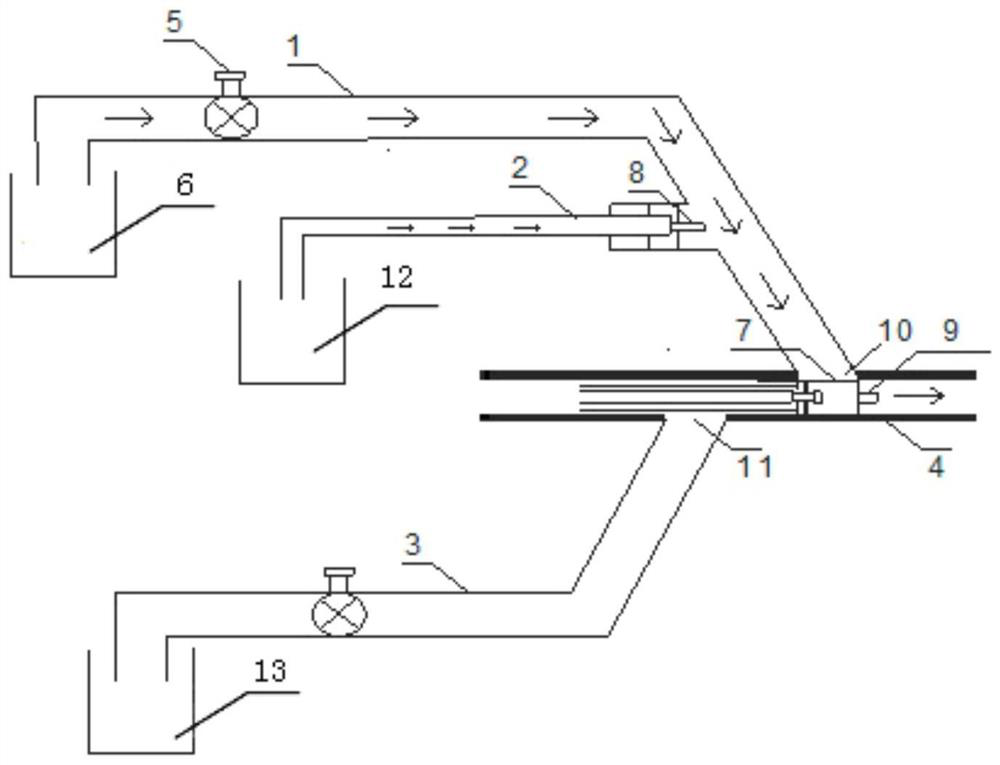

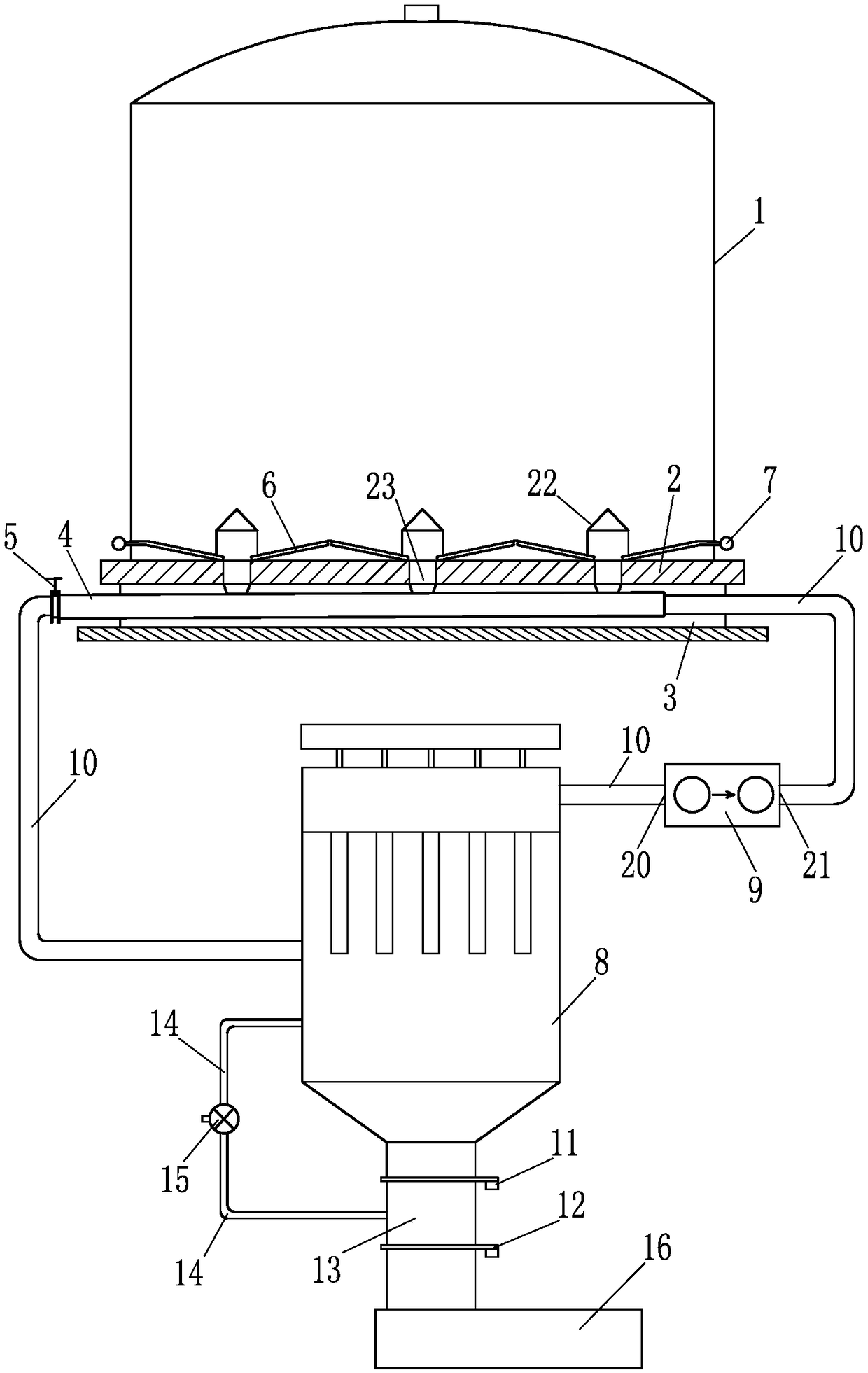

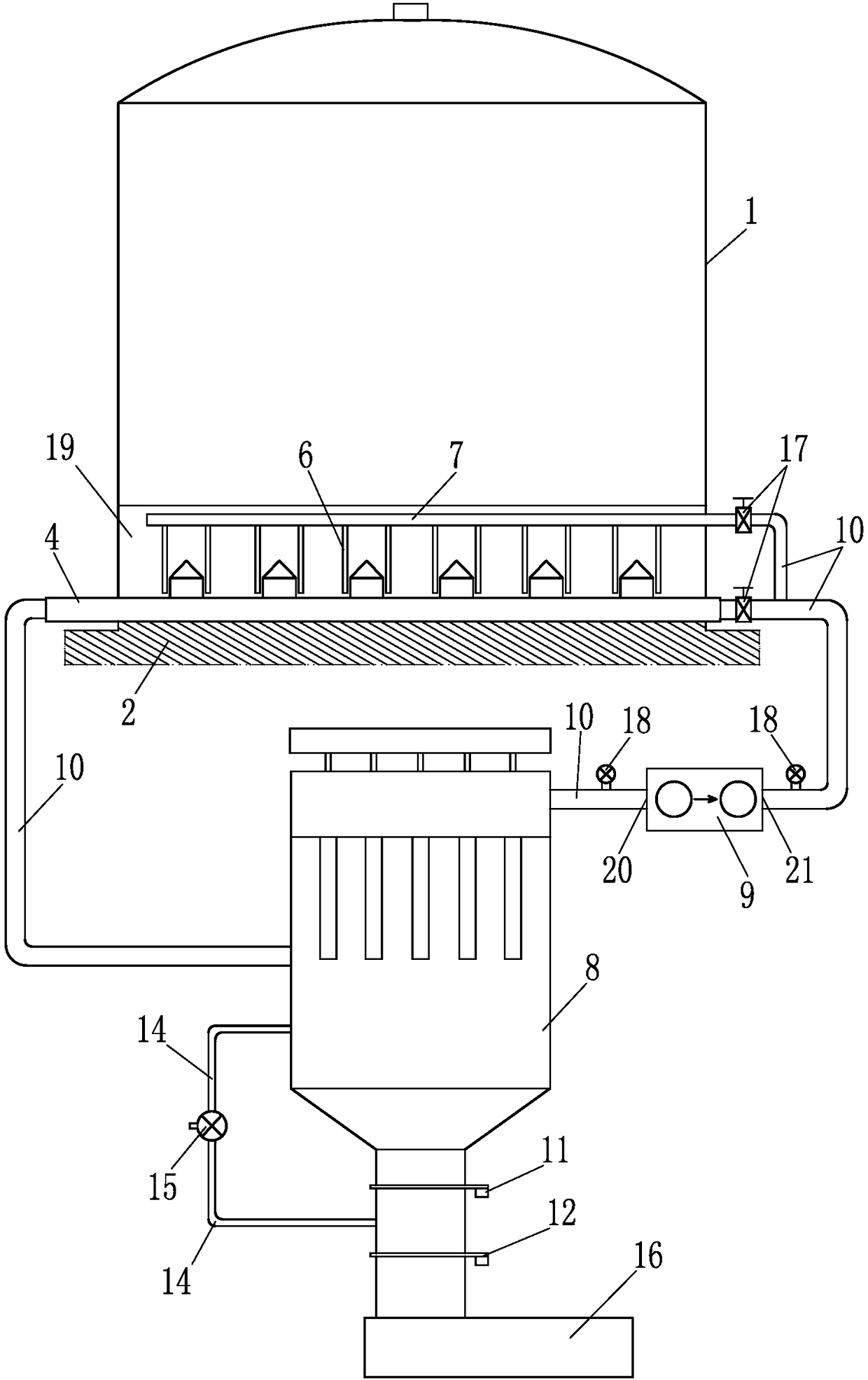

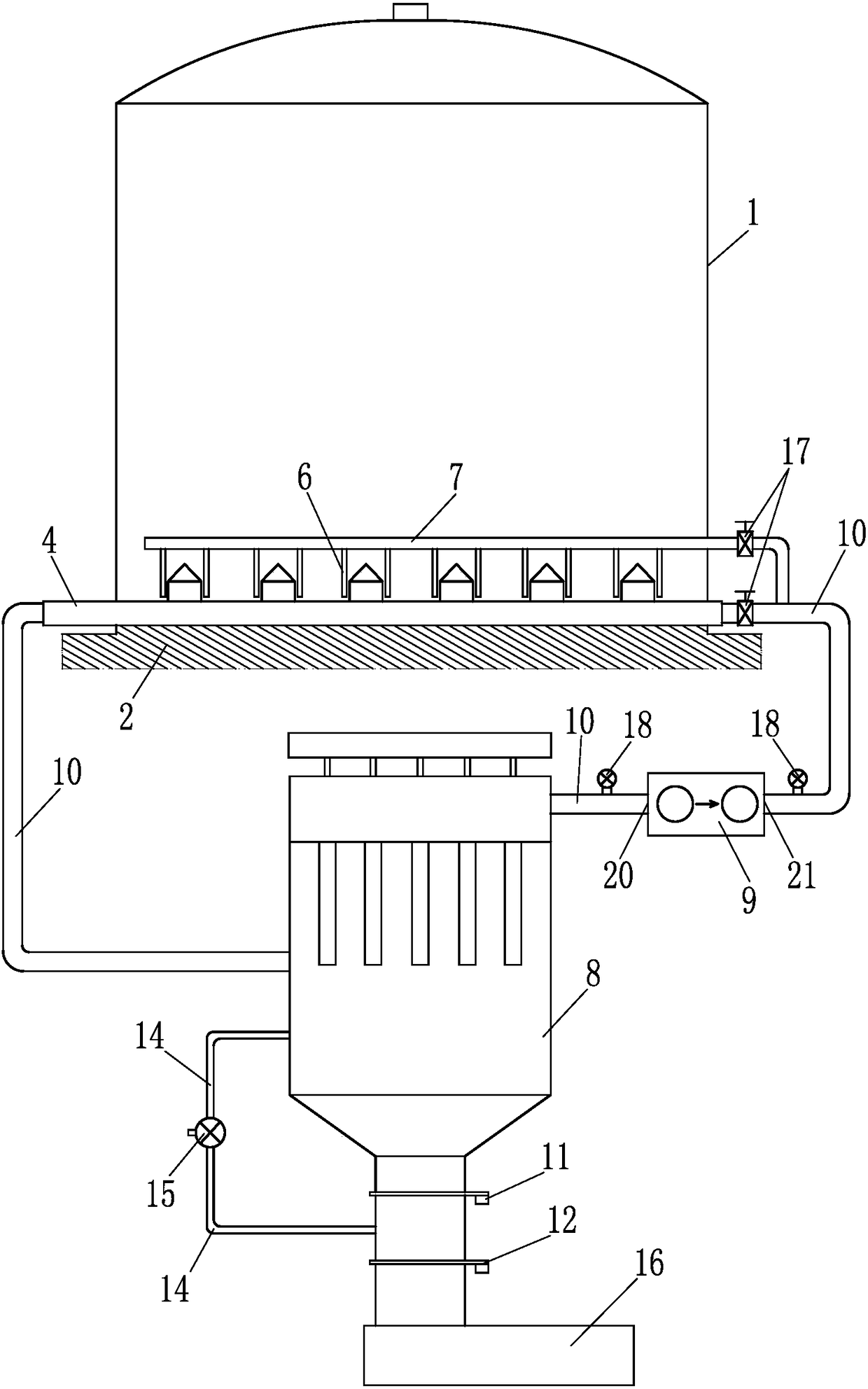

Powder storage warehouse provided with auxiliary discharging device

InactiveCN108128633AImprove discharge efficiencyGuaranteed liquidityBulk conveyorsLoading/unloadingDischarge efficiencyPositive pressure

The invention provides a powder storage warehouse provided with an auxiliary discharging device. The powder storage warehouse comprises a warehouse body, a warehouse bottom and the auxiliary discharging device, wherein a fluidization rod is arranged on the upper surface of the warehouse bottom, a fetching device is arranged on the upper surface of the warehouse bottom or in a gallery of the warehouse bottom and comprises a material conveying pipe, and the material conveying pipe extends outside the warehouse; and the auxiliary discharging device comprises a dust collector and a positive-negative pressure integrated fan, the dust collector is connected with a discharging end of the material conveying pipe and a negative pressure end of the positive-negative pressure integrated fan, respectively through a connecting pipeline, and a positive pressure end of the positive-negative pressure integrated fan is connected with an air supply end of the material conveying pipe through a connectingpipeline. The powder storage warehouse provided with the auxiliary discharging device has the beneficial effects that the structure is simple, the applicability is relatively good, and the discharging efficiency is well guaranteed.

Owner:赵世青

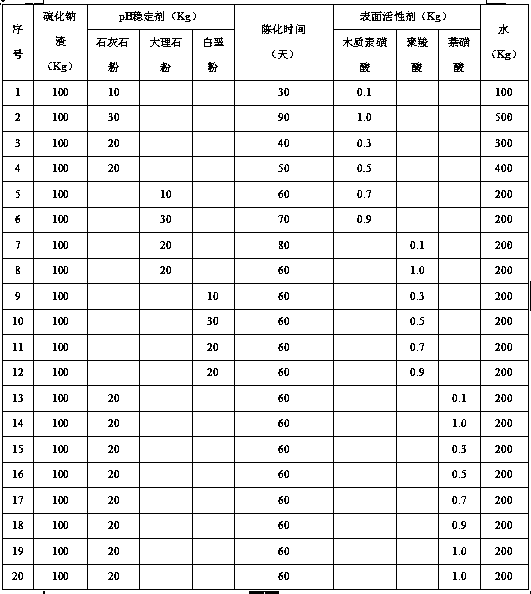

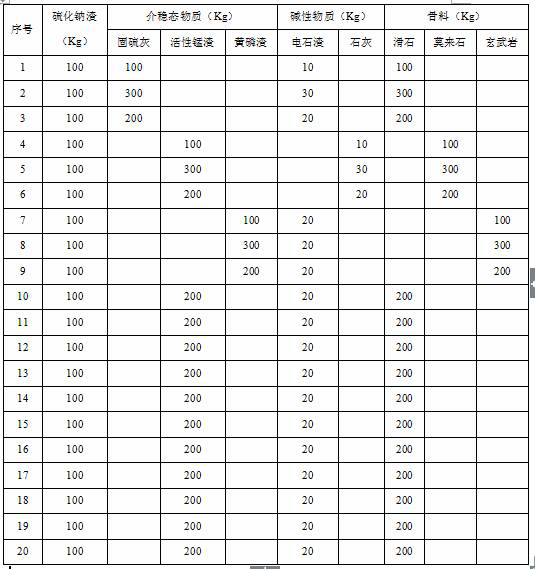

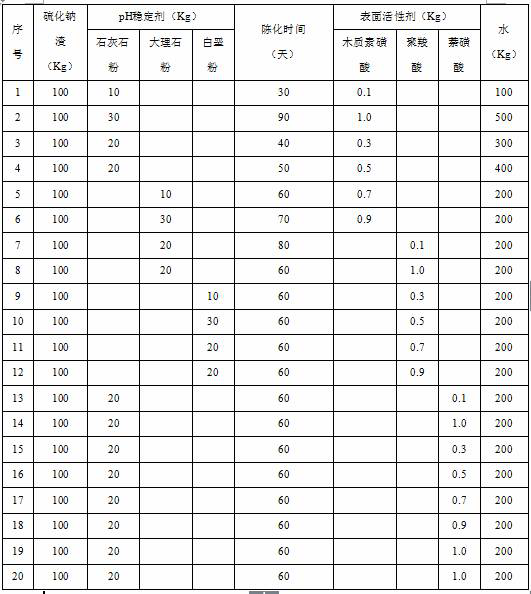

Method for preparing high-strength artificial stone from sodium sulfide slag

The invention discloses a method for preparing artificial stone from sodium sulfide slag, and the method comprises the following steps: adding a pH stabilizer and microorganisms into the sodium sulfide slag, uniformly mixing, performing ageing, adding a surfactant and water, uniformly mixing, and filtering to obtain pretreated sodium sulfide slag; and adding a metastable substance, an alkaline substance and an aggregate into the pretreated sodium sulfide slag, uniformly mixing, pouring the mixture into a grinding tool for compression molding, and performing curing in water to obtain the high-strength artificial stone. Compared with the prior art, the method has the characteristics of low production cost, comprehensive utilization of resources and high added value of the product.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of construction waste micropowder composite admixture

InactiveCN103086619BHas hydration activityPromote participation in hydration reactionsSolid waste managementCement productionComposite constructionAlkalinity

The invention discloses a method for preparing a construction waste micro-powder composite admixture. The method comprises the steps of: evenly mixing construction waste with lime and desulfurized gypsum, and grinding at room temperature to obtain a micro-powder mixture with specific surface area larger than 400m<2> / kg, wherein the mixing weight of the construction waste accounts for 90%-98% total weight of the micro-powder mixture, the mixing weight of the lime accounts for 1%-5% and the mixing weight of the desulfurized gypsum accounts for 1%-5%; mixing the ground micro-powder mixture with an additive of which the weight accounts for 1%-5% total weight of the micro-powder mixture to obtain a mixed material; and mixing the mixed material with slag in a weight ratio of 1:1 and then carrying out ball milling until the specific surface area of the material is larger than 450m<2> / kg, thereby obtaining the construction waste micro-powder composite admixture. The method has the advantages that the alkalinity of concrete can be supplemented, the mixing quantity of a construction waste micro-powder auxiliary gelation material in the concrete is increased and the carbonization resisting capacity of the concrete can be improved.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

A material suitable for 3D printing concrete shear walls and its preparation method

ActiveCN110540394BProlong clotting timeImprove early strengthAdditive manufacturing apparatus3d printAluminate

The present invention uses Portland cement, sulphoaluminate cement, silica fume, quicklime, 20-40 mesh quartz sand, 50-80 mesh quartz sand, water reducer, retarder, dispersible latex powder, polypropylene short Fiber and water are used as raw materials, and by adjusting the types of cementitious materials, admixtures, aggregates and admixtures, the preparation has high mechanical strength, good initial fluidity, convenient printing and construction, and achieves the strength and durability of concrete for high-rise buildings. Performance requirements, while ensuring the collapse resistance and aesthetics of the printed components, suitable for 3D printed concrete materials in cast-in-place construction operations.

Owner:山东中岩建材科技有限公司

A kind of high folding ratio concrete and preparation method thereof

Owner:JIANGSU MINGHE GRP

A synergistic process of carbonization and hydration of steel slag

Owner:WUHAN UNIV OF TECH

A kind of method for preparing high-strength artificial stone from sodium sulfide slag

This patent discloses a method for preparing artificial stone from sodium sulfide slag. After adding a pH stabilizer and microorganisms to the sodium sulfide slag and mixing them uniformly for aging, adding a surfactant and water, stirring evenly, and filtering to obtain pretreated sodium sulfide slag. Add metastable substances, alkaline substances, and aggregates to the pretreated sodium sulfide slag, mix them evenly, pour them into abrasive tools, press them into shapes, and cure them in water to obtain high-strength artificial stones. Compared with the existing technical solutions, the method has the characteristics of low production cost, comprehensive utilization of resources and high added value of products.

Owner:SOUTHWEAT UNIV OF SCI & TECH

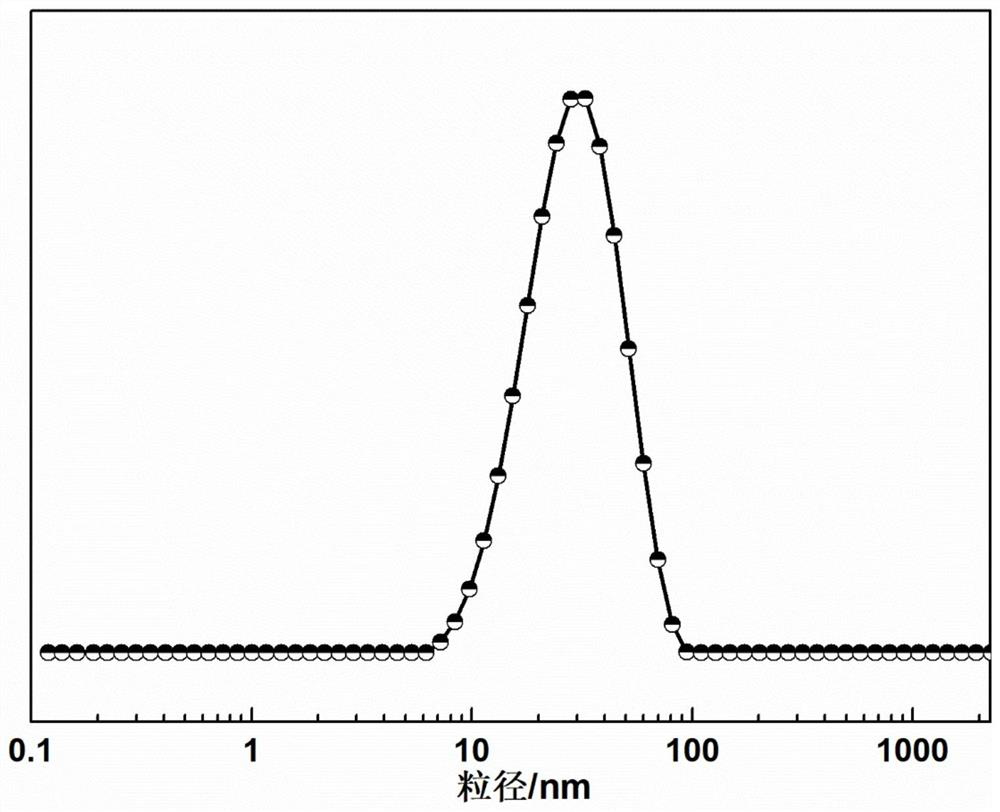

Concrete waste slurry slag grinding aid and preparation method thereof

ActiveCN113698130AImprove grinding efficiency and effectReduce particle agglomerationSolid waste managementCement productionPhosphateEsterification reaction

The invention discloses a concrete waste slurry slag grinding aid and a preparation method thereof, and belongs to the technical field of concrete waste slurry disposal. The concrete waste slurry slag grinding aid comprises the following raw materials by mass: 5-12% of silicate ester, 20-40% of polyol, 30-50% of alcohol amine, 3-6% of water, 5-15% of a phosphorylation reagent and 0.1-0.5% of a catalyst. Silicate ester, polyol, alcohol amine, water and a phosphorylation reagent are used as main raw materials, and under the action of a catalyst, the concrete waste slurry slag grinding aid is prepared through a hydrolysis reaction of the silicate ester, modification of hydroxyl and alcohol amine and an esterification reaction of a phosphate group. The grinding efficiency and effect of the concrete waste slurry residues in the grinding process can be effectively improved, so that the particle agglomeration is reduced, the material fluidity is improved, the activity and filling effect of the concrete waste slurry residues are improved, and the porosity of the concrete waste slurry residues is reduced.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD

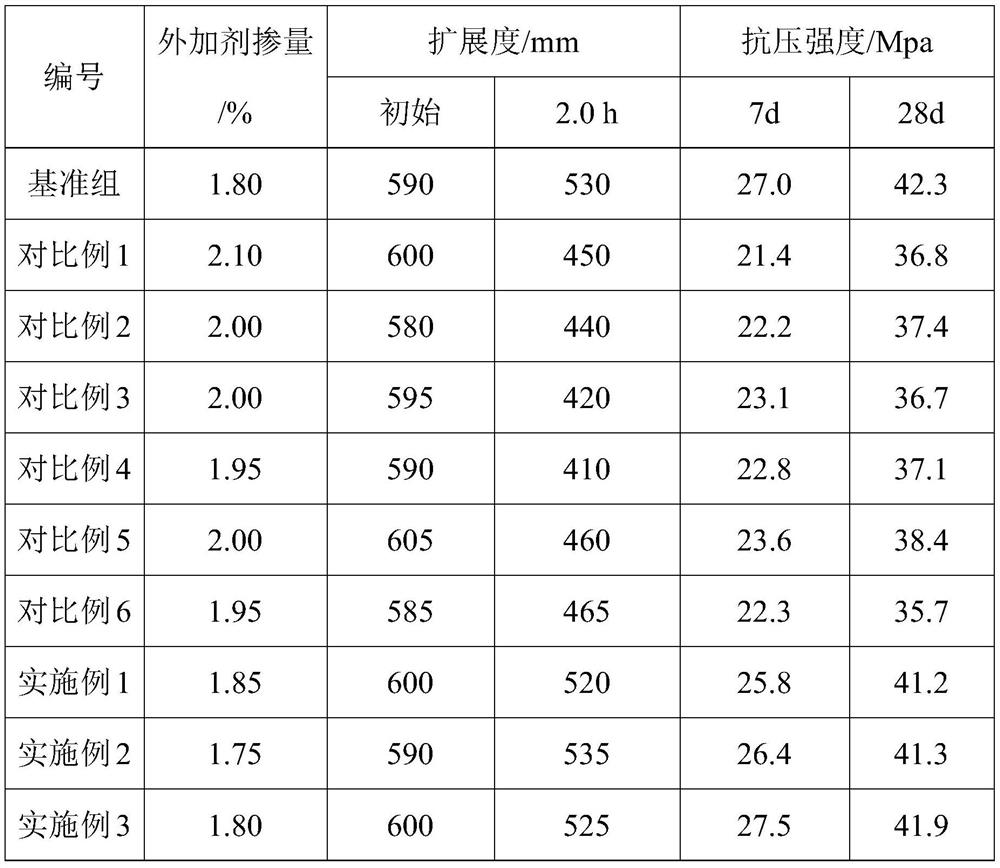

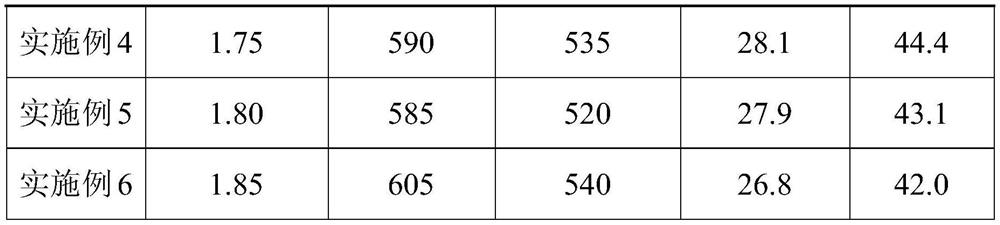

Method for physical and chemical separation of waste incineration fly ash and preparation of cementing material

ActiveCN113683322AIncrease power generationNot corrosiveSolid waste managementCement productionOrganic solventSlag

The invention discloses a method for physical and chemical separation of waste incineration fly ash and preparation of a cementing material. The invention discloses the method for physical and chemical separation of the waste incineration fly ash and preparation of the cementing material, wherein the method is characterized by comprising the following steps: dispersing fly ash in an organic solvent, and carrying out physical separation and filtration to obtain a calcium material, a chlorine material and a carbon material; adding a stabilizer, a curing agent, a pore reducing agent and a plasticizer into the calcium material, and uniformly mixing to obtain the cementing material; adding water and a trapping agent into the chlorine material, and filtering to obtain metal slag and a chlorine salt solution; and feeding the carbon material into a garbage incinerator for combustion. The method has the characteristics of low production cost and high efficiency.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for producing concrete blending material by using igneous rock

The invention discloses a method preparing admixture of concrete by use of igneous rock. The specific procedures are that (1) the igneous rock, fly ash and slag are mixed by quality percent ratio of 50 to 100 percent, 0 to 50 percent and 0 to 50 percent; (2) active activator accounting for 0 to 15 percent (by mass percentage) of the sum of the igneous rock, fly ash and slag is added and uniformlymixed; the mixture is placed into a ball mill for milling; the active activator is one in calcium oxide, calcined gypsum, mirabilite and alum; the mixture is milled until reaching a specific surface area of 400 to 600m<2> / kg, thus obtaining the admixture of igneous rock for concrete. The invention is simple in production, wide in material source, low in cost, little in electricity consumption during milling, and applicable to industry, civil construction as well as underground and harbor projects.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com