Multi-functional acid-resistant concrete gel powder

A technology for concrete and gel powder, applied in the field of building materials, can solve the problems of inability to use, poor impermeability, and high cost, and achieve the effects of increasing retention efficiency, reducing the risk of being corroded, and improving composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

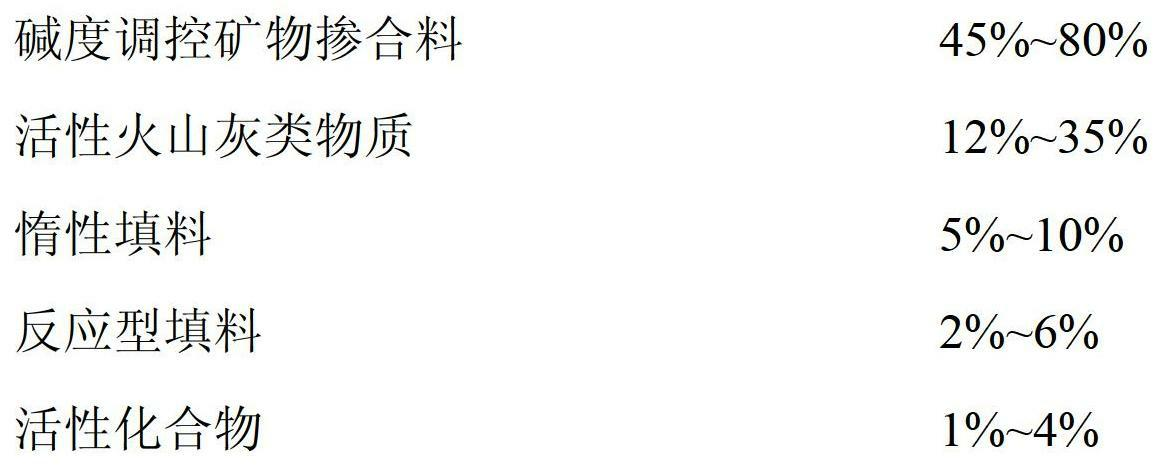

[0032] Mix the following components by weight and stir evenly to obtain the multifunctional concrete acid-resistant gel powder of the present invention:

[0033]

[0034] Among them: the alkalinity control mineral admixture is fly ash; the active pozzolanic substance is amorphous silica powder; the inert filler is diabase powder; the reactive filler is calcium oxide powder; the active compound is β-naphthalenesulfonic acid formaldehyde Condensate.

Embodiment 2

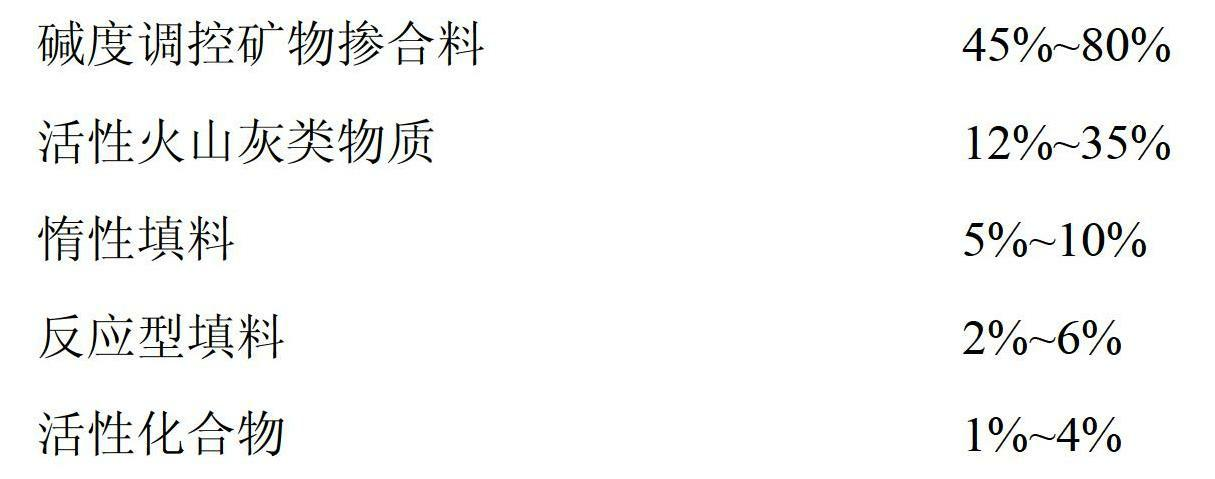

[0036] Mix the following components by weight and stir evenly to obtain the multifunctional concrete acid-resistant gel powder of the present invention:

[0037]

[0038] Among them: the alkalinity control mineral admixture is superfine mineral powder; the active volcanic ash is encrypted silica powder; the inert filler is anhydrous aluminum silicate powder; the reactive filler is superfine calcium carbonate powder; the active compound is allyl alcohol poly Oxyethylene ether.

Embodiment 3

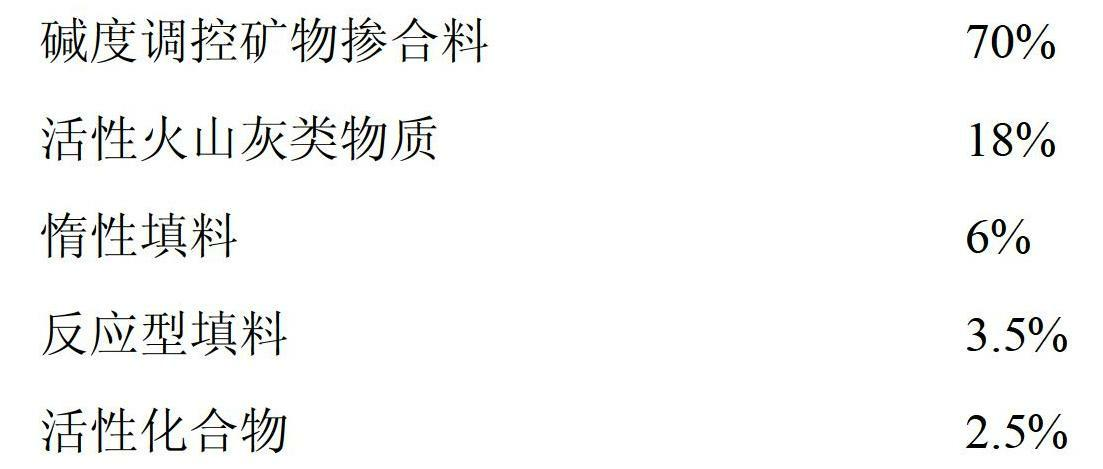

[0040] Mix the following components by weight and stir evenly to obtain the multifunctional concrete acid-resistant gel powder of the present invention:

[0041]

[0042] Among them: the alkalinity control mineral admixture is ultrafine mineral powder; the active pozzolan is amorphous silica powder; the inert filler is anhydrous aluminum silicate powder; the reactive filler is calcium oxide powder; the active compound is allyl alcohol polyoxyethylene ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com