Patents

Literature

262results about How to "Impermeable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulphoaluminate cement base synchronous slip casting material and preparation method

InactiveCN101693615AFulfil requirementsEarly strengthSolid waste managementSodium BentoniteCarboxylic acid

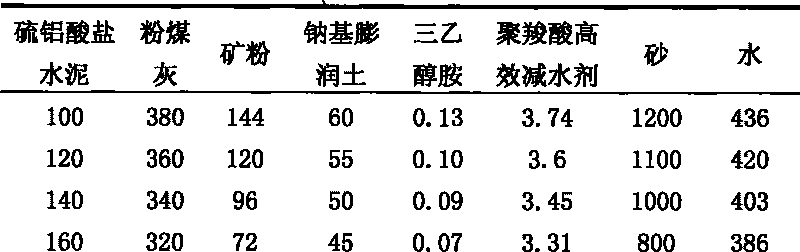

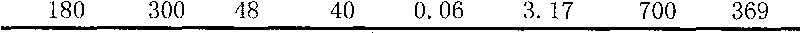

The invention relates to a synchronous slip casting material and a preparation method for tunnels, in particular to a sulphoaluminate cement base synchronous slip casting material, which is characterized in that the sulphoaluminate cement base synchronous slip casting material is prepared by a basal body component and an externally-mixing component, wherein the basal body component comprises sulphoaluminate cement, coal ash, powdered ore, sand and water, the externally-mixing component comprises polycarboxylic acids highly-effective water reducing agent, sodium bentonite and triethanolamine early-strength admixture, the proportioning (kg / m3) of each component is that sulphoaluminate cement: 100-200, coal ash: 300-400, powdered ore: 45-455, sand: 700-1200, water: 350-500, polycarboxylic acids highly-effective water reducing agent: 3.0-4.0, sodium bentonite: 40-60, and triethanolamine early-strength admixture: 0.05-0.2. The synchronous slip casting material prepared by the method has the characteristics of excellent early-stage intensity, underwater non-dispersibility, permeability-resisting and corrosion resistance, and can be used in large-scale river-sea-crossing tunnels or underground engineering.

Owner:武汉市商品混凝土管理站

Cement concrete pavement patching material and preparation method thereof

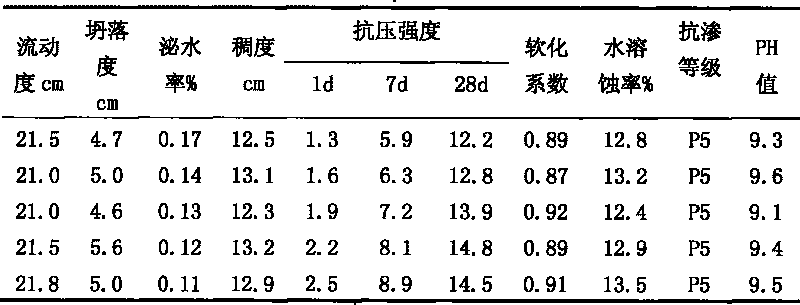

The invention discloses a cement concrete pavement patching material. The cement concrete pavement patching material consists of the following materials in percentage by weight: 15.6%-23.6% of portland cement, 15.6%-23.6% of sulfate aluminum cement, 6%-15% of ground calcium carbonate powder, 2.5%-7% of redispersible latex powder, 0.08%-1.8% of lithium carbonate, 0.7%-1.03% of fiber, 0.1%-0.22% of tartaric acid, 0.02%-0.06% of cellulose ether, 26.56%-59.04% of quartz sand, 0.08%-0.25% of a polycarboxylate water reducer, 0.08%-0.33% of an organic silicon antifoaming agent and 0.2%-0.55% of an organic silicon water repellent. The cement concrete pavement patching material disclosed by the invention is adopted, so that ultra-thin patching, ultra-strong compressive strength bonding strength and ultra-strong durability can be realized, and therefore, the damaged part of the cement pavement can be timely repaired without the need of closing traffic for a long time.

Owner:广州市昌福环保新材料股份有限公司

Lightweight insulating brick and production process thereof

The invention relates to the field of building materials, in particular to a lightweight insulating brick. The lightweight insulating brick is prepared by mixing the following raw materials: 8 to 15 percent of gelled material, 30 to 50 percent of aggregate, 25 to 55 percent of lightweight material, 1 to 2 percent of aids and 3 to 4 percent of waterproof powder. Because lightweight materials of industrial and agricultural wastes are added into the lightweight insulating brick, the lightweight insulating brick changes waste into valuable, protects the environment, is energy-saving, insulates sound and heat, has strong insulating property and is warm in winter and cool in summer; and compared with an air-entrained cement building block, the lightweight insulating brick has the advantages of strong water resistance, water leakage resistance, high strength, strong safety, good compactness, slurry drop resistance, low investment and easy popularization.

Owner:连来才

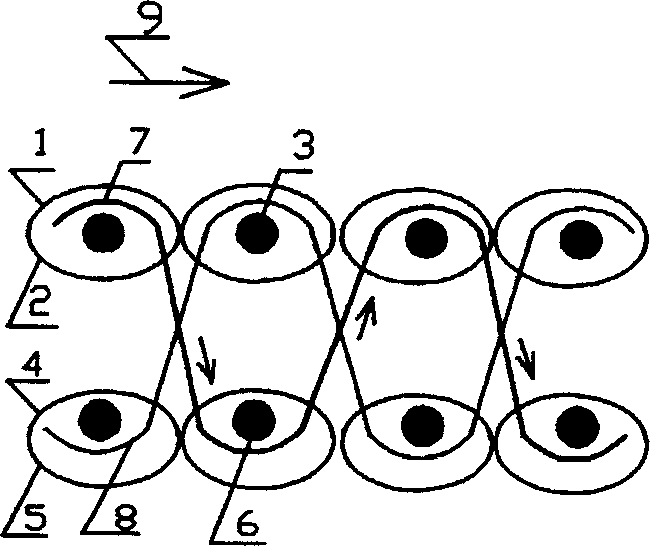

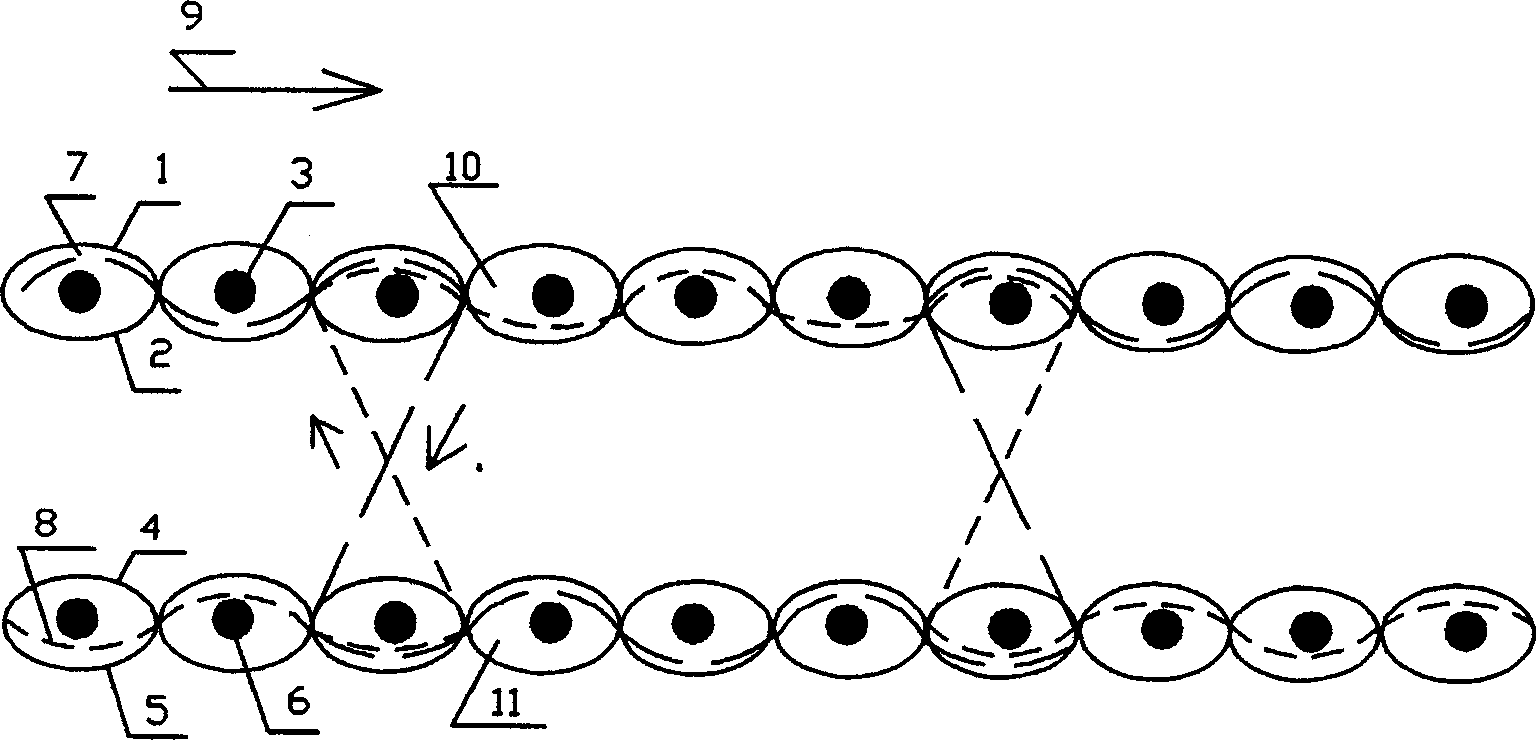

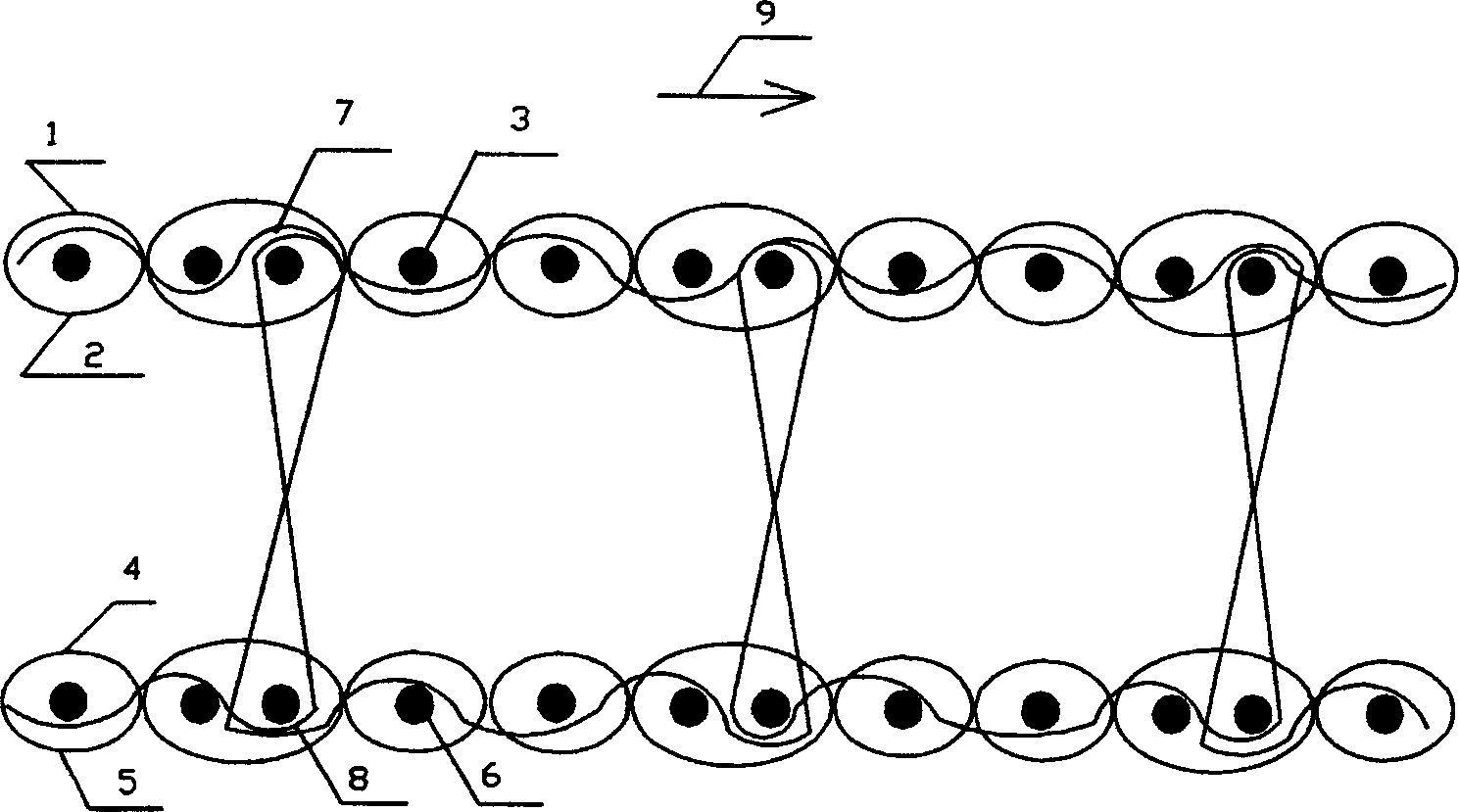

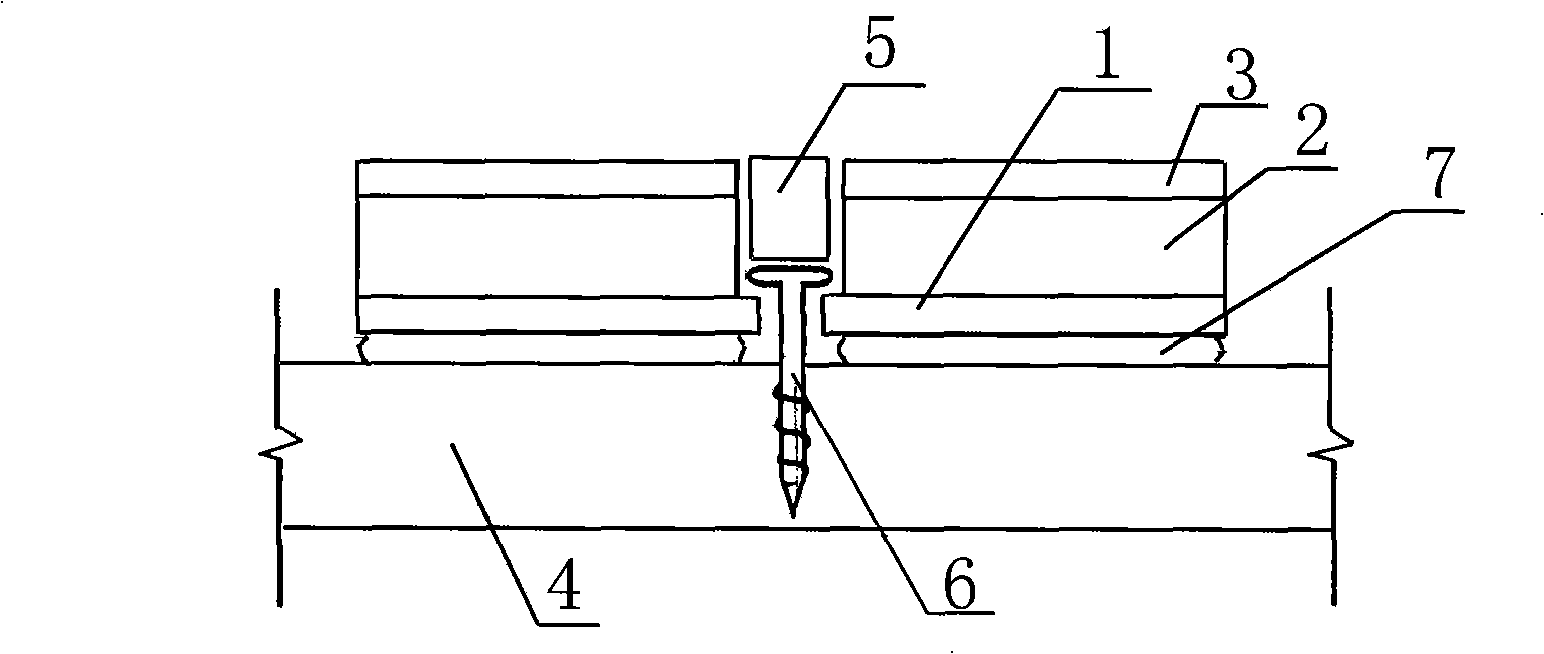

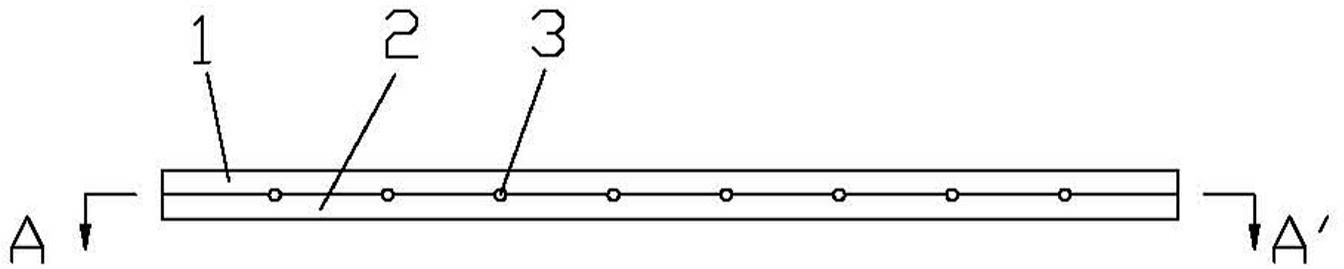

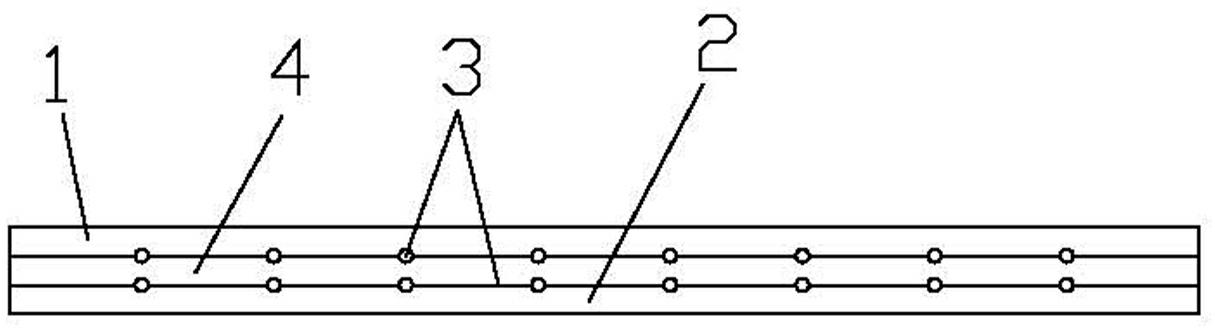

Three-dimensional woven hollow layer-connecting fabric

ActiveCN1807731AGood vertical supportAnti-corrosionOrnamental textile articlesMulti-ply fabricsSpatial structureMechanical engineering

This invention relates to a three-dimensional machine-weaving hollow layer contiguous fabric, which includes the superstratum face (10) that is formed from interweaving by the superstratum warp thread (1), (2) and weft thread (3), the substrate face (11) interweaved by the substrate warp thread (4), (5) and weft thread (6), wherein the weft thread (3) and (6) also interweave with the figured texture weave (7), (8) besides interweaving with the warp thread (1), (2) and (4), (5), and when the weft thread is weaving from one layer from another layer of the fabric, its space walking direction is contrary to the inducing thread direction of the fabric. The frame characteristic of the layer contiguous fabric in this invention is obvious; the vertical supporting action of the figured texture weave between the two faceplates is well. The configuration of the space structure is various, and it is fit for sweeping weaving. And the material enhanced by this invention has the character of preventing corrosion, preventing filter, light weight, nice mechanical performance.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

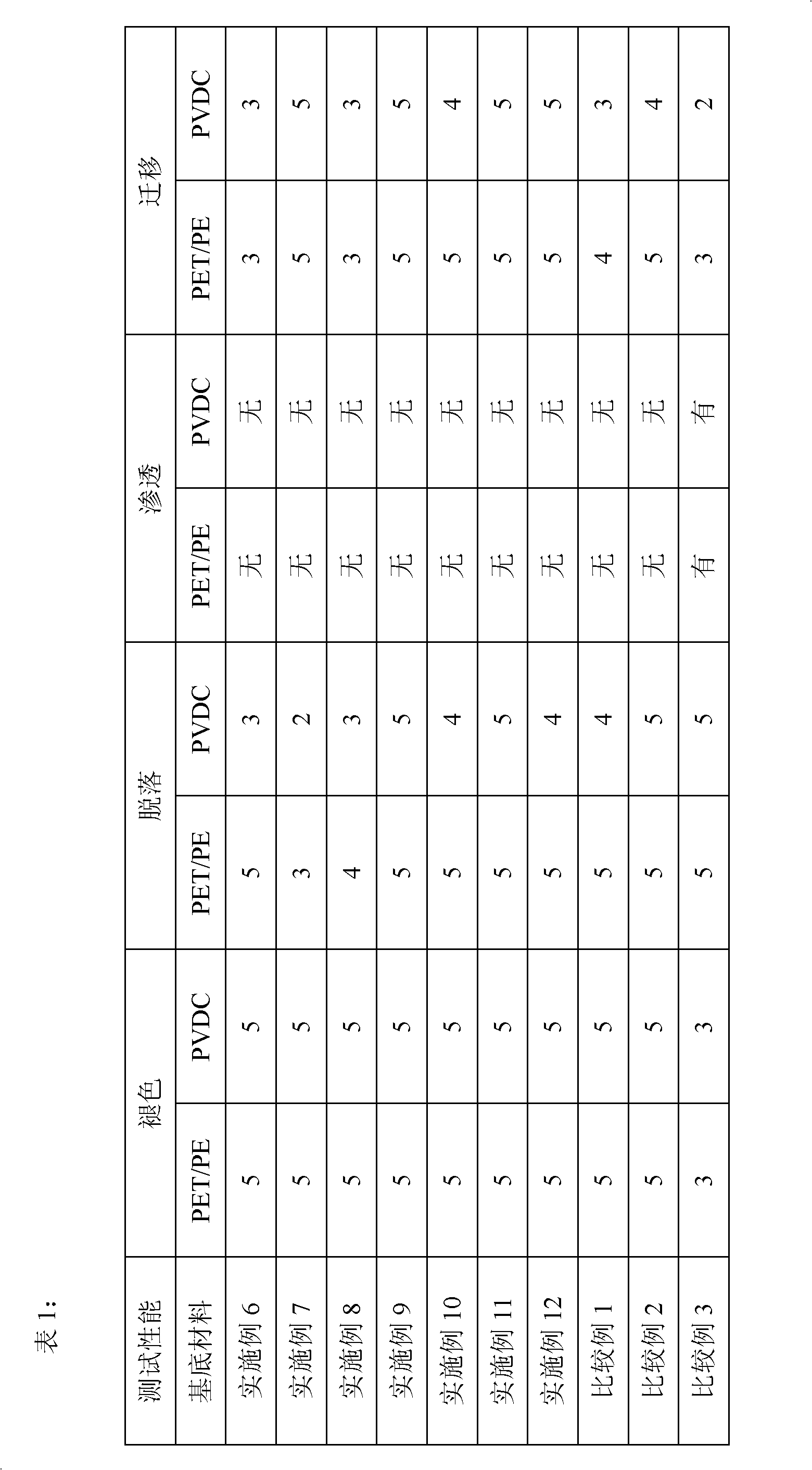

High-temperature steam endurance ink for spraying code and printing

The invention relates to high-temperature steam endurance ink for spraying code and printing, containing one or more organic solvents, resin and coloring agents. In addition, the consistency of the ink is 2.8-6.2CP / 25DEG C, the conductivity is 500-1,500muS and the surface tension is 27-30Dyn / cm. The high-temperature steam endurance ink for spraying code and printing can be applied to the surfaces of various packaged objects required to be treated at high temperature. The mark and the substrate adopting the high-temperature steam endurance ink have strong adhesive force and favorable adhesiveness and cannot fade, fall off, permeate and shift after being subjected to high-temperature digestion. The dried mark can be also scraped by a cleaning agent.

Owner:北京赛腾标识系统股份公司

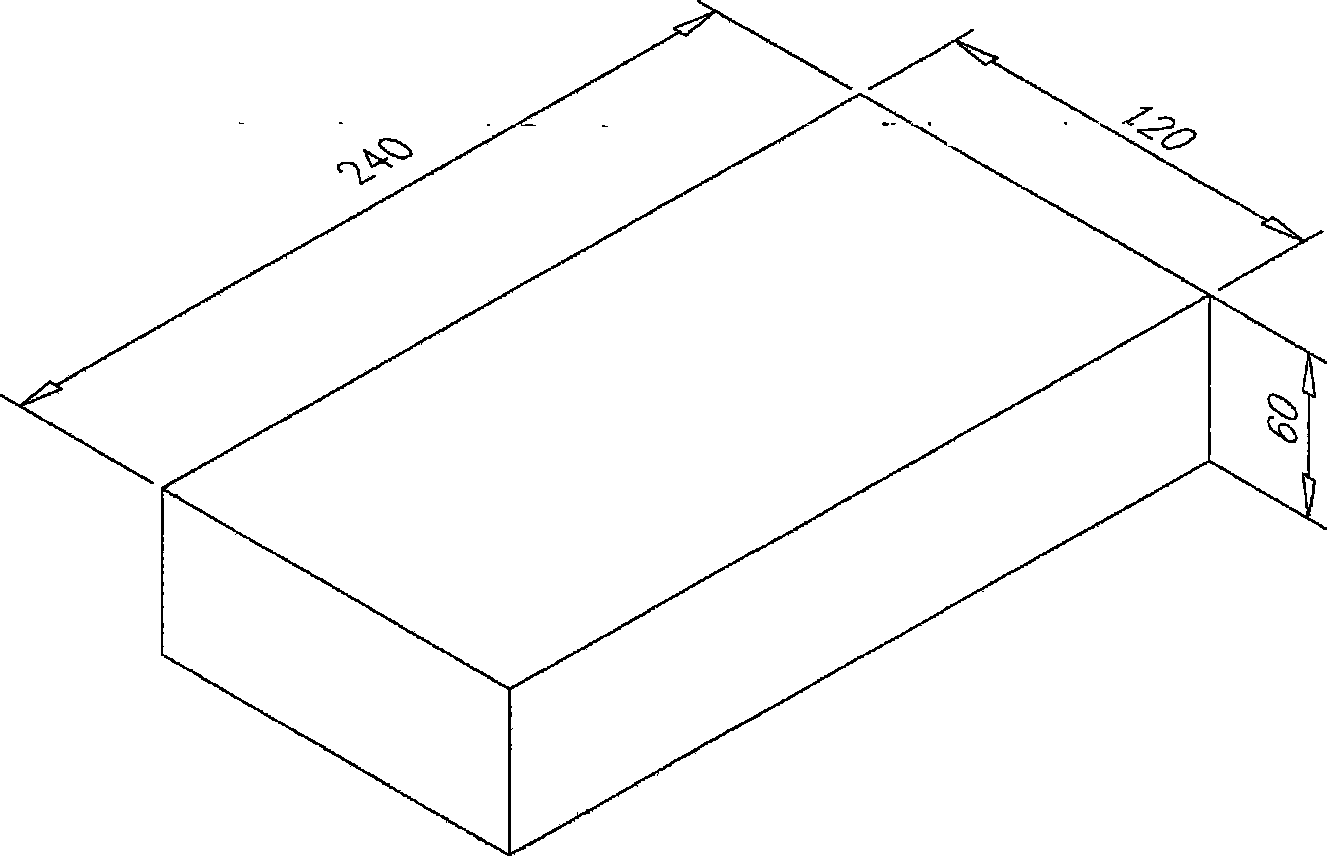

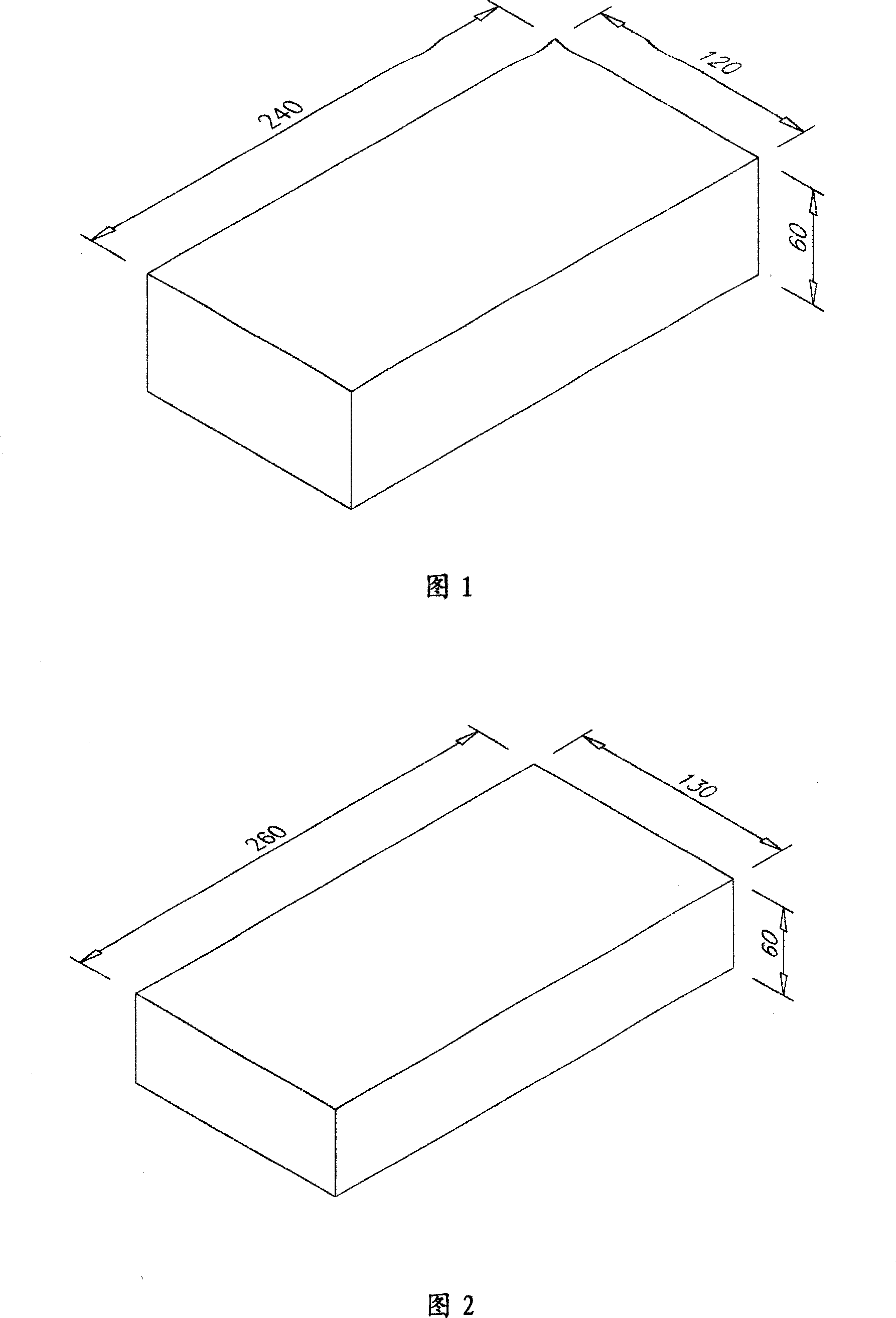

Grey brick mechanically manufactured from lime sludge and construction wastes and method for manufacturing same

The invention discloses a gray brick mechanically manufactured from lime sludge and construction wastes and a method for manufacturing the same. The materials for mechanically manufacturing the gray brick comprise the following raw materials in portion by weight: 1,015 to 1,135 portions of construction waste crushed materials, 240 to 290 portions of cement, 810 to 1,010 portions of lime sludge, 60 to 75 portions of gray lime, and 100 to 125 portions of water, wherein the particle size of the construction waste crushed materials is less than 15 millimeters. If necessary, less than 20 portions of fly ash and proper amount of activating agent can be added to the materials. The method for mechanically manufacturing gray brick comprises the following steps: firstly, crushing the construction wastes; secondly, mixing the construction waste crushed materials with the other materials according to the proportions; and thirdly, pressing the mixture by adopting a mechanical method so as to produce the gray brick of the invention. The gray brick and the method for manufacturing the same recycle the sludge and the construction wastes in a reducing, harmless and resource-utilizing mode, and solve the problem that substituting materials and products are hard to find after clay bricks are forbidden to use and the problem of gray brick sources for civilian constructions.

Owner:梁林华 +1

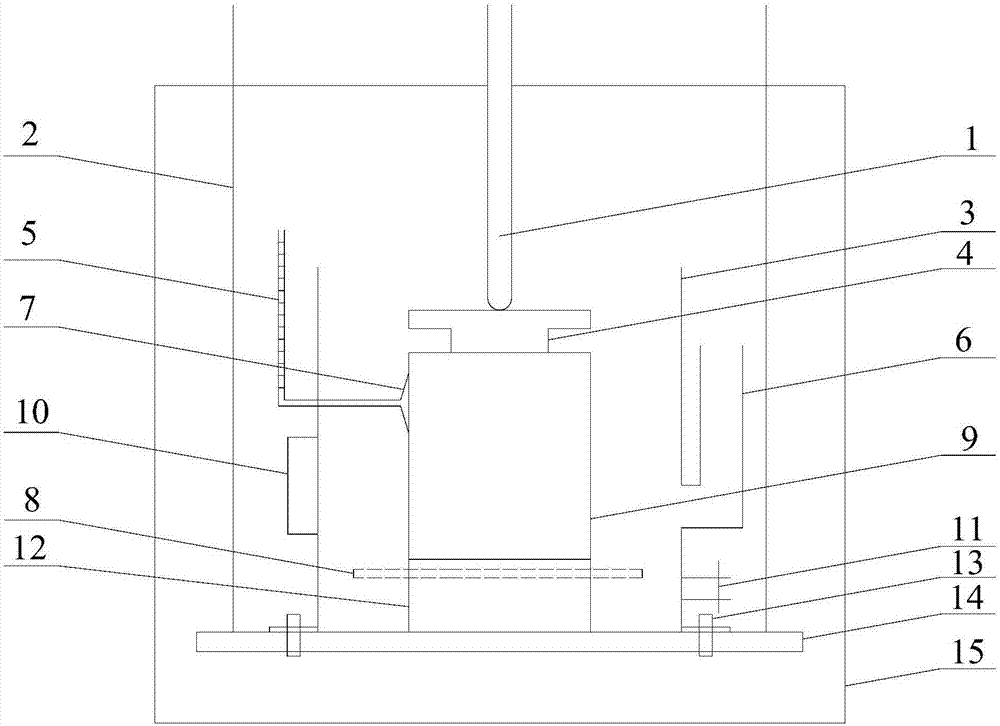

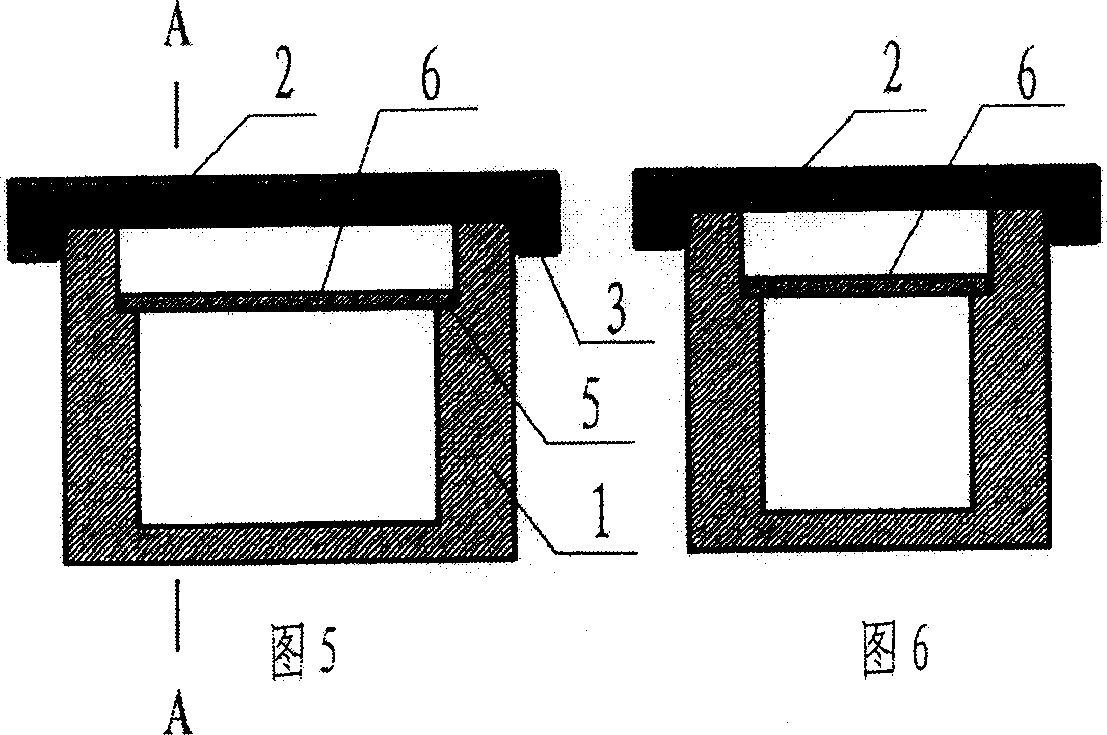

Experimental apparatus and test method for evaluating high temperature performance of drainage asphalt pavement under multi-field coupling effect

ActiveCN107063884AReal evaluation of high temperature performanceRealize synchronous dynamic multi-field couplingMaterial strength using tensile/compressive forcesMulti fieldEngineering

The invention discloses an experimental apparatus and a test method for evaluating the high temperature performance of a drainage asphalt pavement under a multi-field coupling effect. The experimental apparatus comprises a dynamic loading device, a working box, a pressure measurement device, a water pressure dissipation device, a temperature control device, a water outlet and a fixation device. With the experimental apparatus of the present invention, the high temperature performance of the drainage asphalt pavement under the common dynamic change of the dynamic stress field, the temperature field and the hydraulic field can be evaluated, the dynamic water pressure of the drainage asphalt pavement under the dynamic load effect can be measured, and the difference of the high temperature performance of the drainage asphalt pavement during the rainfall process can be simulated; and the experimental apparatus and the test method can be used for the research of the damage on the drainage asphalt pavement in the actual use environment, and have good simulation effects.

Owner:SOUTHEAST UNIV

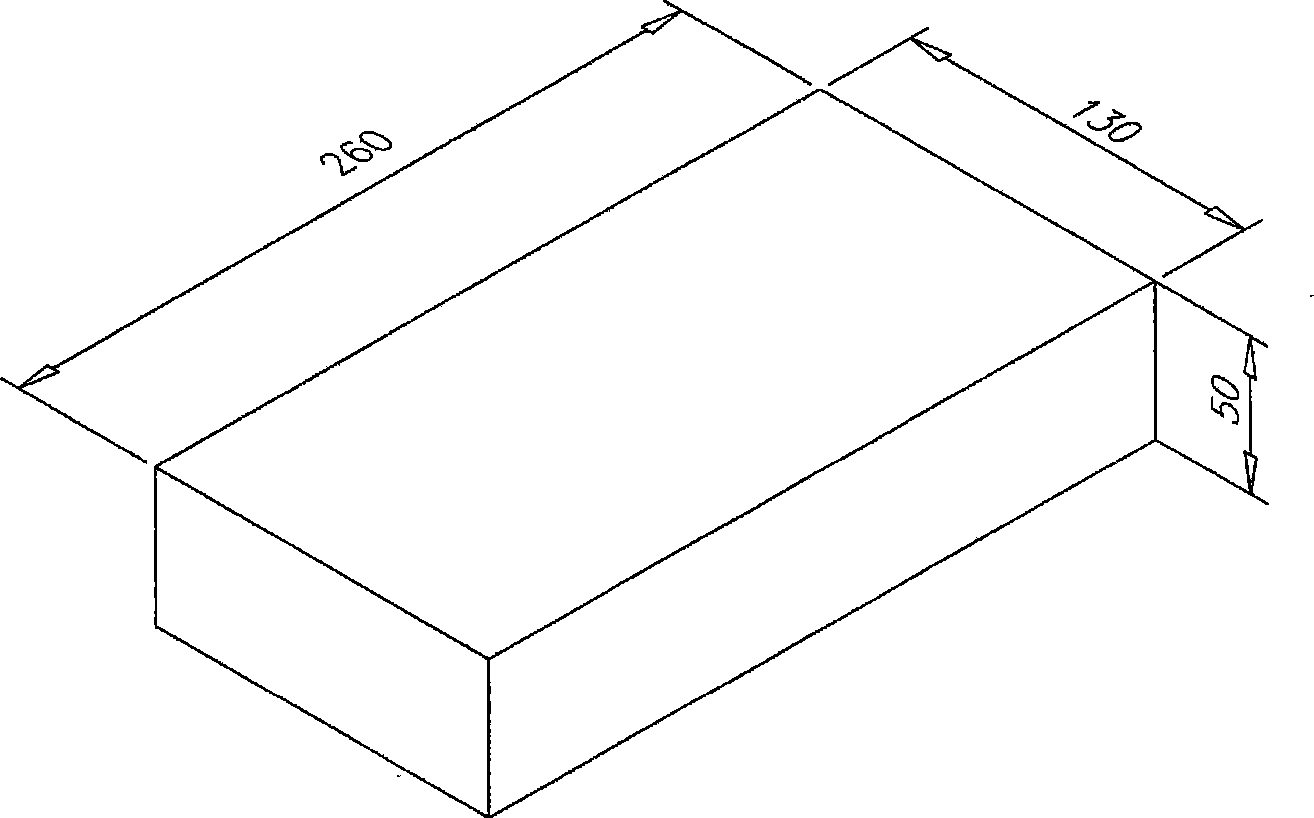

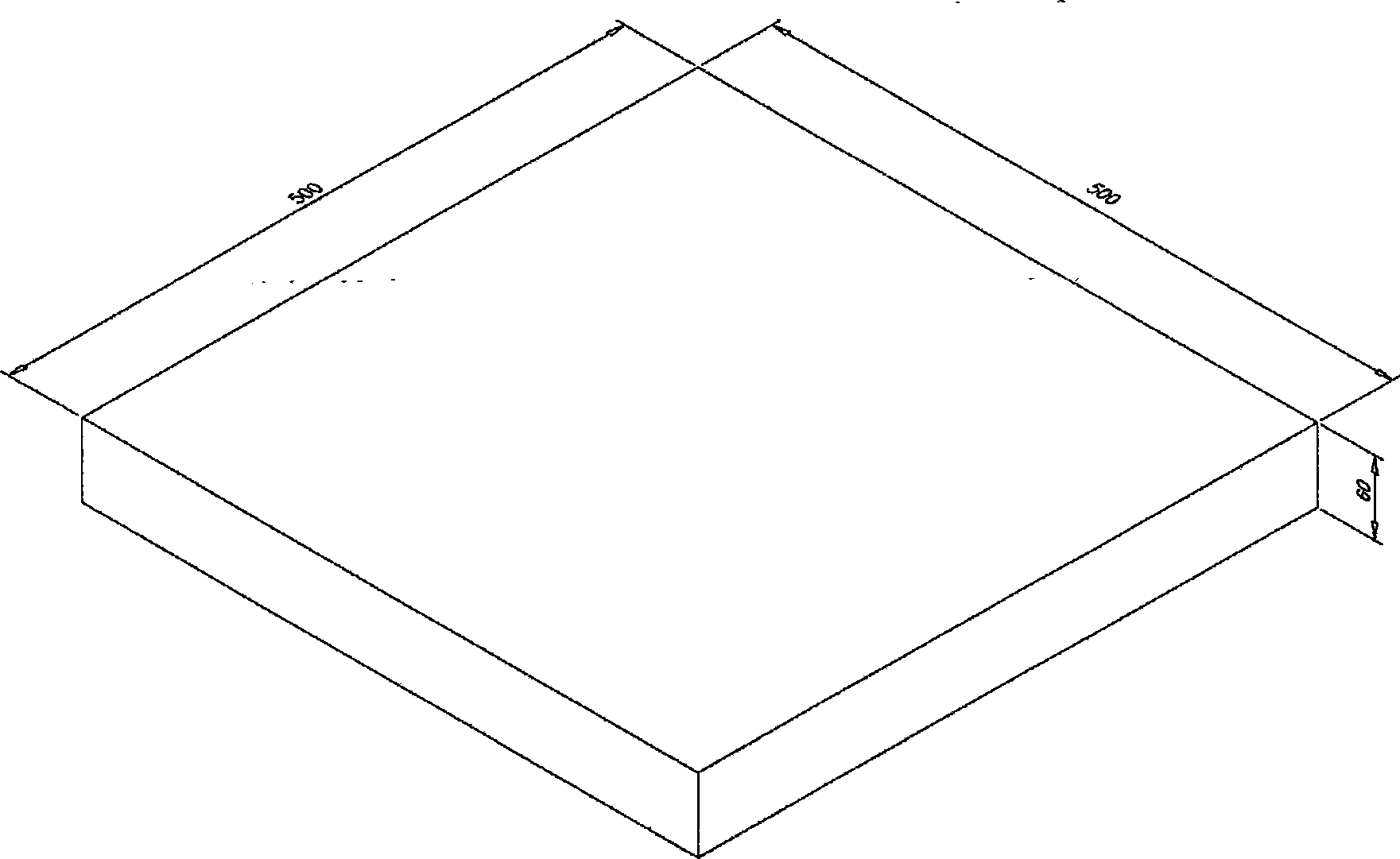

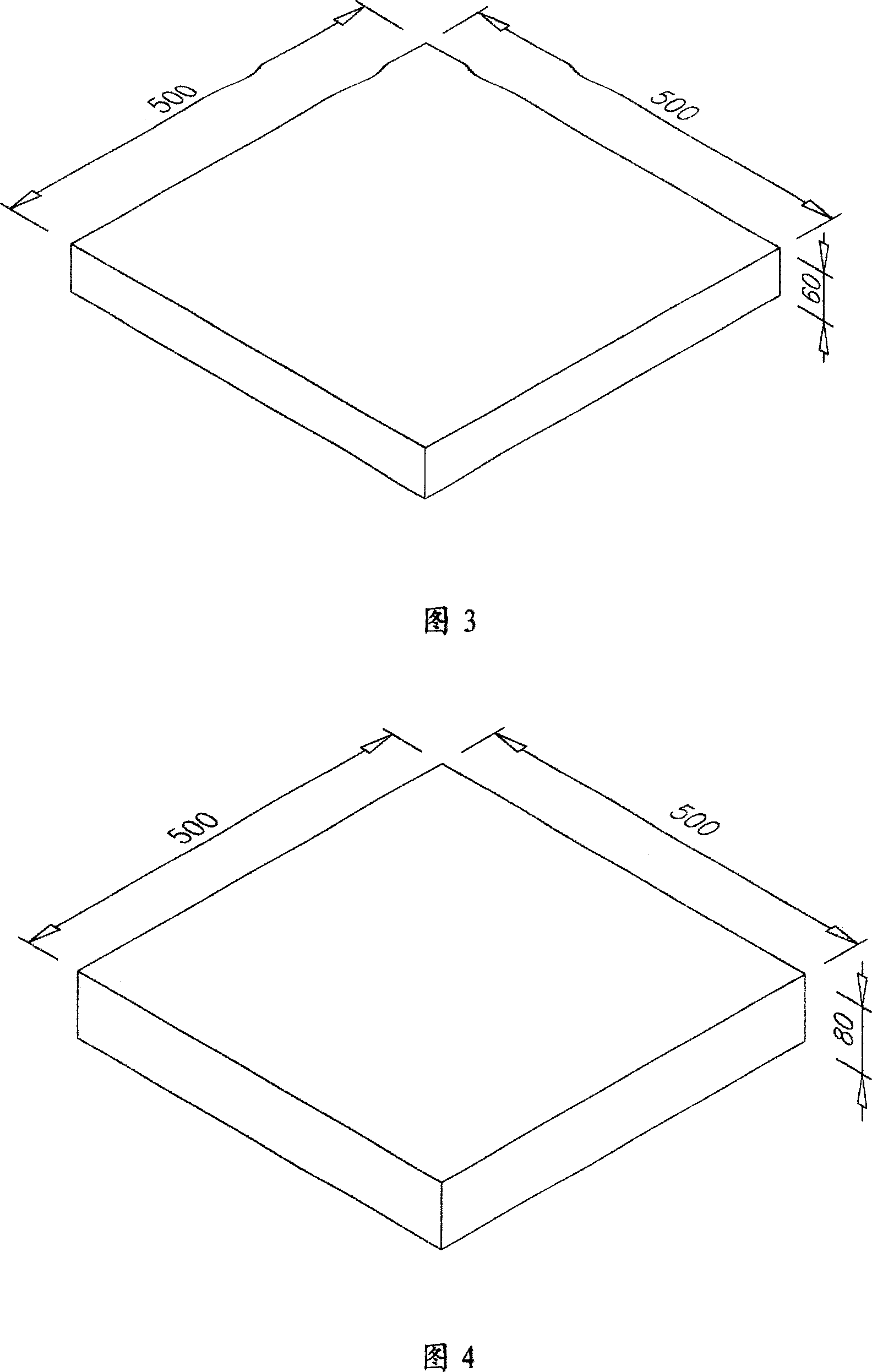

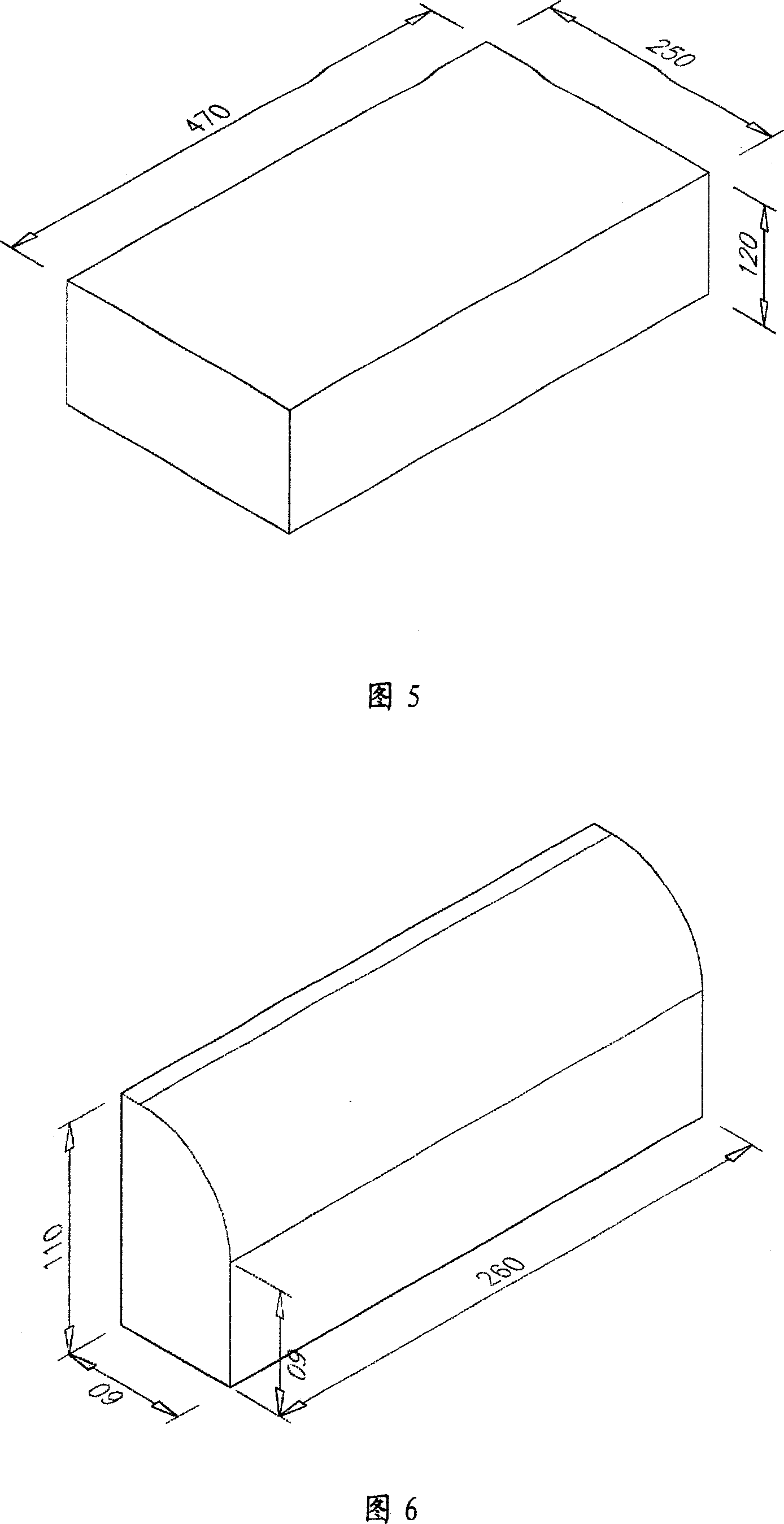

Machine-made archaized blue bricks

InactiveCN101003154ASolve processing problemsAvoid pollutionMixing operation control apparatusCeramic shaping apparatusBrickLitter

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

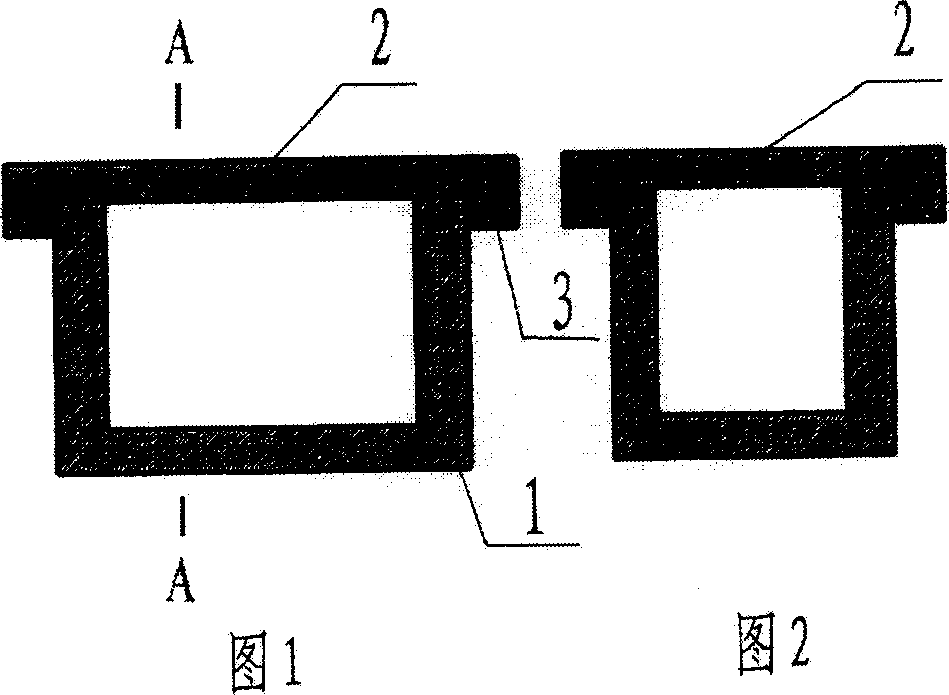

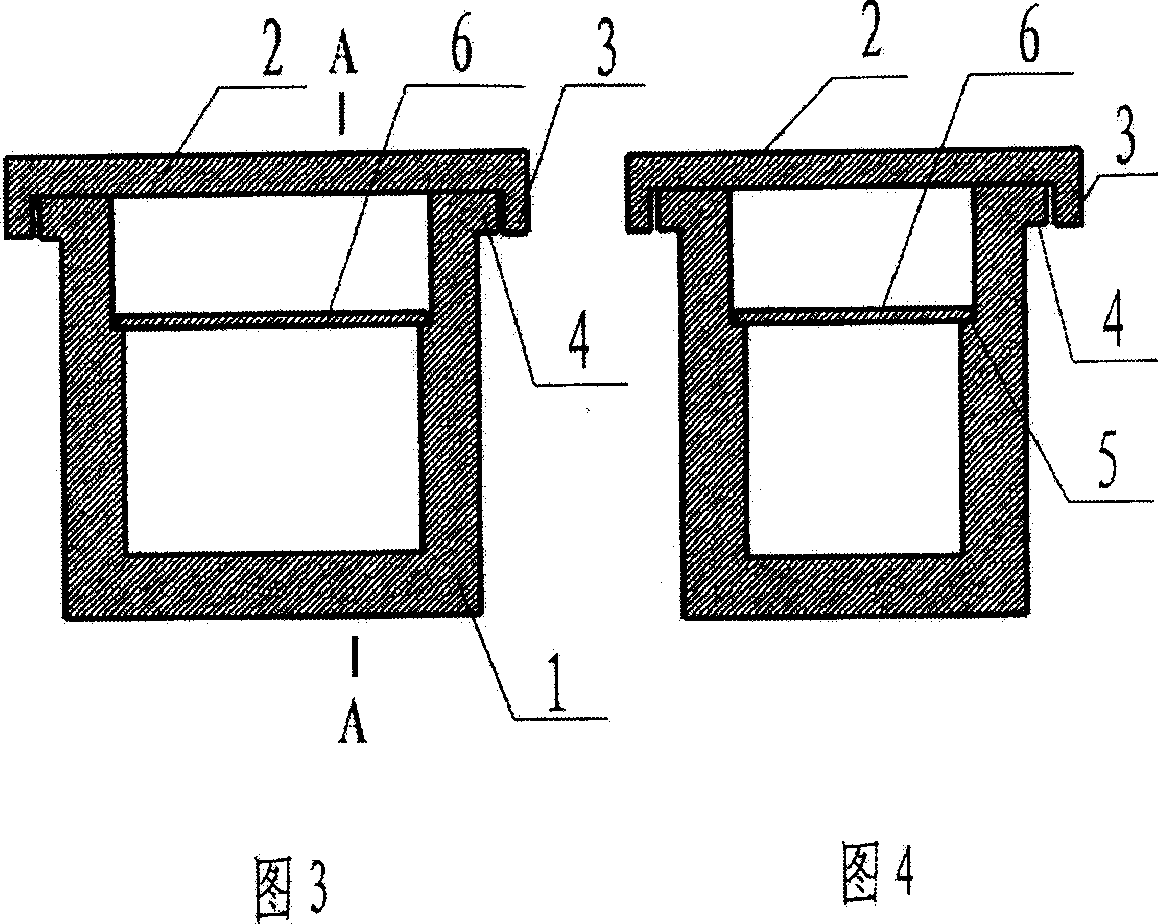

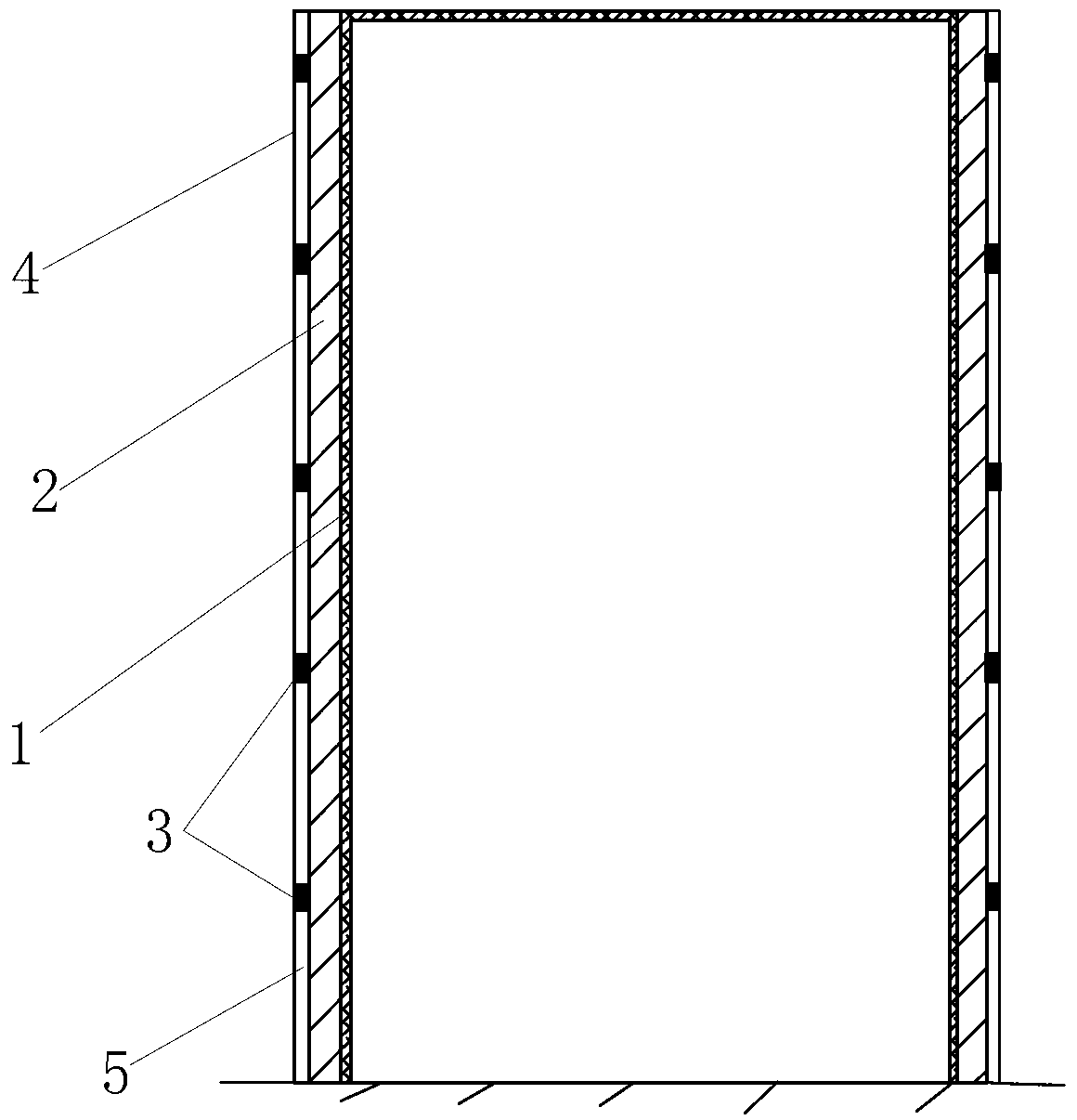

Exterior wall heat preservation decorative lamination integration system and its production and mounting method

InactiveCN101319522AEasy to installImprove ergonomicsCovering/liningsClimate change adaptationSurface layerArchitectural engineering

The invention relates to an external heat insulation board structure for a polyurethane external wall, which is mainly used for the modern building external wall external heat insulation technical field. The structure mainly comprises an inorganic fireproofing bottom layer, a flame-retardant hard polyurethane foam material, a decorative surface layer and so on. The structure has convenient and simple installation: firstly, the surface of a base course wall body is treated to remove floating ash on the surface of the base course wall body, then bonding mortar is used to level the surface of the base course wall body and then is used to directly and dryly paste one surface of the inorganic fireproofing bottom layer of a polyurethane heat insulation board on the surface of the external wall (whether an expanding screw is used to fix is determined according to the concrete requirement); a heat insulation wall body of the external wall can directly use materials such as marbles and so on as a finish layer, so only the waterproofing treatment at the seams needs to be well done, and the work for producing the finish layer on the surface of the wall body is saved. The quick and convenient installation mode improves the work efficiency of the construction and shortens construction period. At the same time, the energy-saving wall body also has the advantages of good heat insulation effect, excellent water resistance, long service life and so on.

Owner:董海光

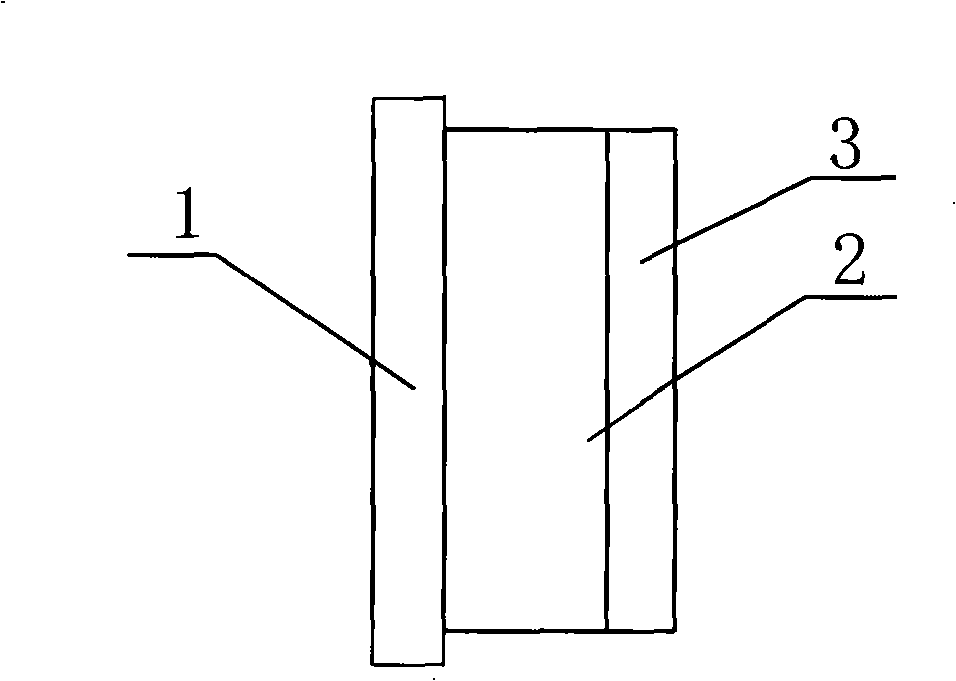

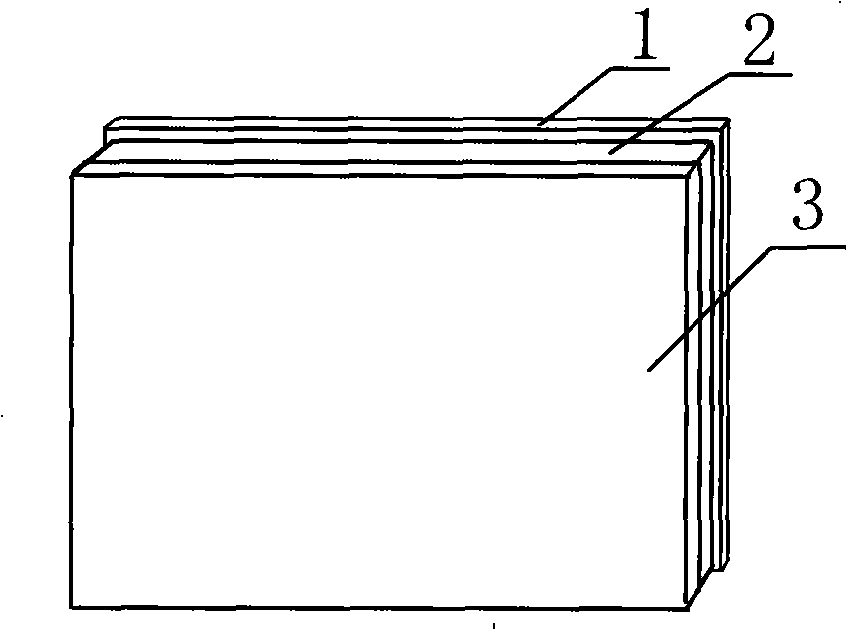

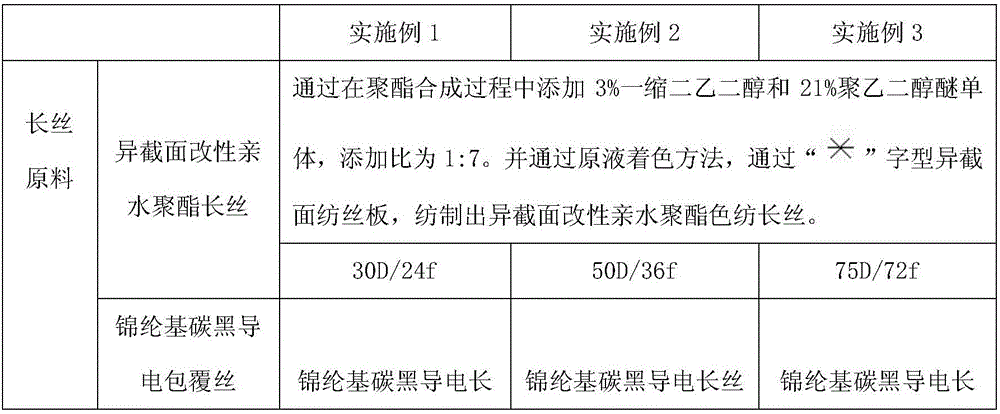

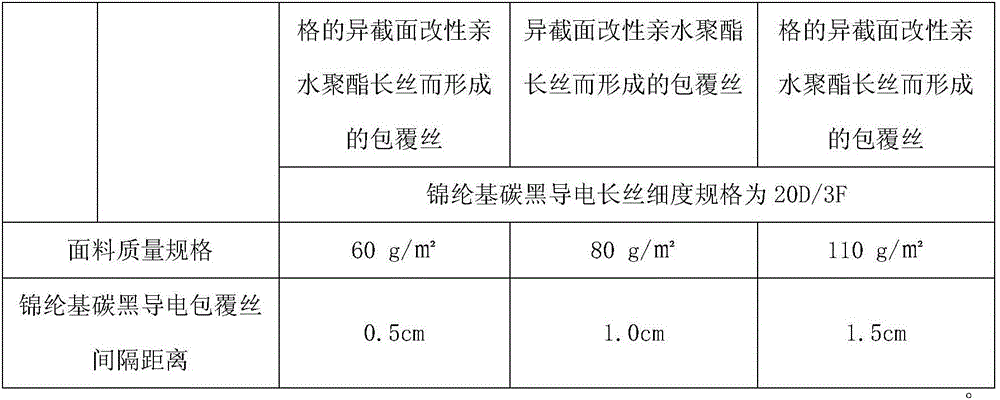

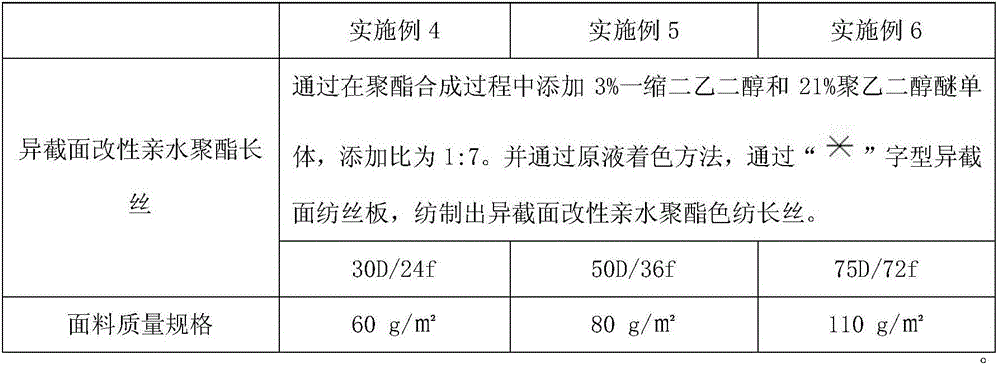

Surgical gown fabric and production technology thereof

ActiveCN106541680AGood resistance to high temperature chlorine bleachingEasy to prepareProtective equipmentSynthetic resin layered productsPolyesterYarn

The invention discloses a surgical gown fabric and a production technology thereof, and particularly provides the surgical gown fabric with reusable, antibacterial, anti-spatter and anti-static properties and other properties and the production technology thereof. The surgical gown fabric is characterized in that the fabric comprises a surface layer fabric, a middle layer bacterium-proof film and an inner layer fabric; the surface layer, the middle layer and the inner layer is bonded through a bonding technology to form a composite fabric; the surface fabric is a material woven from special-shaped cross-section modified hydrophilic polyester filaments and chilon based carbon black conductive covered yarn; the middle layer bacterium-proof film is a PTFE microporous film; the inner layer fabric is a material woven from special-shaped cross-section modified hydrophilic polyester filaments. The provided medical surgical gown fabric is simple in preparing method, the product has reusable, antibacterial, anti-spatter and anti-static properties and other properties, and the surgical gown fabric has good wearing comfort of being hygroscopic, fast to dry and the like.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

Reactive type modified bituminous waterproof sheet material with gold foil surface

ActiveCN102975419AGood weather resistanceAdvantages of weather resistanceWater-setting substance layered productReaction layerBituminous waterproofing

The invention relates to a reactive type modified bituminous waterproof sheet material with a gold foil surface. The reactive type modified bituminous waterproof sheet material with the gold foil surface is characterized by comprising a gold foil sheet layer, a modified bituminous binding layer, and an isolating membrane protection layer, wherein the modified bituminous binding layer is arranged in the middle, the gold foil sheet layer is arranged at the upper layer and the isolating membrane protection layer is arranged at the lower layer; and the three layers of waterproof sheet materials are bound together by hot melting in the production process. The waterproof sheet material is a high-grade sheet material used for exposed walls or interior walls needing water resistance, the reactive type modified bituminous layer can creep and permeate into cement gel and concrete pores in the solidification process of cement and concrete, the chemical cross-linking reaction can be produced at a contact interface so as to form a basal plane reaction layer with high binding force, inreversible binding, both severe and soft binding and relatively durable binding, a close, firm and inreversible binding effect can be achieved, and the reactive type modified bituminous waterproof sheet material can be applied to columns, inner walls, outer walls and basements of important places needing the water resistance.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

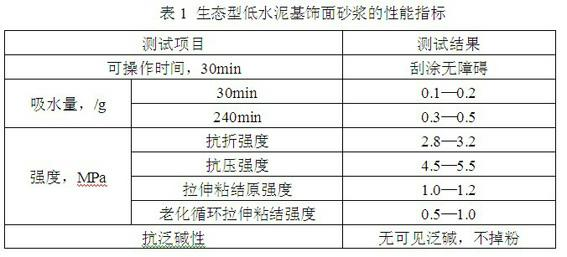

Ecological low cement-based finishing mortar

The invention relates to an ecological low cement-based finishing mortar. The ecological low cement-based finishing mortar consists of the following components in percentage by weight: 12.5 percent of white cement, 50 percent of high-whiteness quartz sand, 30 percent of ground limestone, 0.15 to 0.2 percent of cellulose ether, 0.3 to 0.4 percent of lignocellulose, 0.2 to 0.4 percent of water repellent, 0.2 percent of efflorescence inhibitor, 6 percent of redispersible latex powder and 0.4 to 0.5 percent of starch ether. The materials are uniformly mixed and then added with water which is 18 percent of the total weight of the materials, and after uniform mixing, the ecological low cement-based finishing mortar is produced. The white cement, the quartz sand and the ground limestone are elaborately proportioned and then added with the other auxiliary materials, consequently, the product cost is low, and the ecological low cement-based finishing mortar has the characteristics of good weather fastness, seepage resistance, water-proofness, mould-proofness, energy saving, environment-friendliness, easiness in dry powder storage, long guarantee period, and the like, convenience in transportation, and is suitable for the construction of inner and outer walls of buildings under various environmental weather conditions.

Owner:河南省德嘉丽科技集团有限公司

Environment-friendly shield construction single-liquid synchronous grouting slurry

ActiveCN101935198AHigh energy consumptionSolve the problem of occupying a lot of landSolid waste managementHigh energySlurry

The invention relates to materials applicable to underground engineering construction, in particular to environment-friendly shield construction single-liquid synchronous grouting slurry. The slurry comprises the following materials in percentage by weight: 55 to 70 percent of sand, 10 to 20 percent of desulphurization gypsum, 10 to 20 percent of fly ash and the balance of additive and water, wherein the additive is a water-soluble high-molecular polymer thickening agent and / or a high-performance polycarboxylic water reducing agent; the water-soluble high-molecular polymer thickening agent is 0.5 to 1.0 percent of the total weight of the desulphurization gypsum and the fly ash; and the high-performance polycarboxylic water reducing agent is 0.75 to 1.25 percent of the total weight of the desulphurization gypsum and the fly ash. Compared with the conventional single-liquid synchronous grouting, the grouting slurry has the advantages of substituting the lime powder with high energy consumption and high pollution for waste desulphurization gypsum, along with the same performance. The grouting slurry solves the problems of a large amount of land occupied by the desulphurization gypsum and serious environmental pollution, also avoids the use of the lime powder with high energy consumption and high pollution and fulfills the aims of energy conservation and environmental protection. Meanwhile, a new way is found for the application of the desulphurization gypsum.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

Artificial stone plate graphic pattern preparation method

InactiveCN101190546AImpermeableAging resistantCeramic shaping plantsSurface layering apparatusEngineeringArtificial stone

A preparing method used for a pattern tracery on an artificial slate includes procedures of prefabricating a spare artificial slate (1), taking pictures and scanning of a real object (2), printing and plate making (3), printing (4), transfer printing (5), film pressing (6) and cutting and forming (7). A specific technique flow is as follows: in the first procedure, the artificial slate is prepared and reserved after the surface treatment by a sanding machine; the second procedure is that the pattern tracery is scanned and the real object is taken photos ; the third procedure is that the scanned pattern tracery or photos is utilized to carry out platemaking before printing; the fourth procedure is the platemaking is printed on a transfer film; the fifth procedure is the pattern tracery on the transfer film is transferred on the spare artificial slate surface; the sixth procedure is a film pressing is carried out to the artificial slate, wherein the transfer of the pattern tracery is finished; the seventh procedure is a finished artificial slate product provided with pattern traceries is cut and formed. The method has the advantages that various pattern traceries such as natural landscape, characters, animals and plants, flowers-bird, fish and worms, pavilions, or letterform can be formed according to different needs; the method is scientific and reasonable; the equipment investment is low.

Owner:天津市河东区盛隆化工厂

Breathable rubber and use thereof

The invention relates to a rubber material and a rubber material product. The invention aims to provide the rubber with permeability, so as to promote updating and upgrading of products in various industries. The invention adopts the technical proposal that the permeable rubber has the compositions of general rubber. The invention is characterized in that the compositions in weight portion of the permeable rubber are 40 to 65 portions of natural rubber, 0.5 to 60 portions of polyethylene oxide, 6 to 9 portions of butadiene-styrene rubber, 1 to 3 portions of sulfur, 1 to 1.5 portions of accelerant, 2 to 4 portions of zinc carbonate, 0.2 to 0.4 portion of stearic acid, 8 to 12 portions of white carbonic acid, 1.2 to 1.4 portions of antiaging agent and 1.3 to 1.7 portions of homogenizing agent. The permeable rubber can be used for manufacturing footwear materials and mackintoshes.

Owner:吴鹏

High strength crack resistant concrete and preparation method, composition and application thereof

The invention discloses high strength crack resistant concrete and a preparation method, a composition and application thereof, the composition includes a component A, a component B, a component C and a component D, the component A is isocyanate, the component B includes polyester polyol, polyether polyol, polyvinyl alcohol, a lauric acid type organic tin catalyst and a cyclopentane foaming agent; the component C includes cement, fly ash and mineral powder, and the component D includes quartz sand and gravel. The invention also provides a method for preparing the high strength crack resistant concrete from the composition used for the high strength crack resistant concrete. The invention further provides the application of the high strength crack resistant concrete, including application in the engineering construction and maintenance and reinforcement. The high strength crack resistant concrete has the characteristics of high strength, strong steel bridge surface adhesion steel bridge, rich toughness, corrosion resistance, water resistance, permeability resistance, frost resistance, impact resistance, aging resistance, simple construction, short construction period and suitable construction costs.

Owner:BEIJING ZHONGKE JIAGU BUILDING MATERIAL SCI &TECH CO LTD

Fiber reinforced artificial stone tomb box and its manufacturing method

InactiveCN1776163AWide variety of sourcesImpact resistantUrnsCeramic shaping apparatusSuperplasticizerSlurry

This invention relates to a fiber reinforced artificial stone tomb box and making method, which contains fiber reinforced artificial stone made box unit with cavity and box cover with lower convex edge engaged with upper edge of box unit. The method contains mixing and agitating raw material into slurry, laying fiber net fabric in mold, putting slurry in mold, by molding, maintenance, stripping, repairing, finishing, spraying surface treating liquid to get products, raw material ratio is 30-60 part of cement, 40-65 part of fine aggregate, 1-4 part fiber filament, 1-8 part of anti-cracking permeability-reducing admixture, 0.2-1 part of superplasticizer, 1-5 part of silicate intensifier, 0-4 part of surface treating liquid, 0-0.5 part antifoaming agent and 0-0.5 part of paint. Said invention has advantages of fine anti-impact ability and impermeability, high strength, fine outline and low cost.

Owner:张正锋

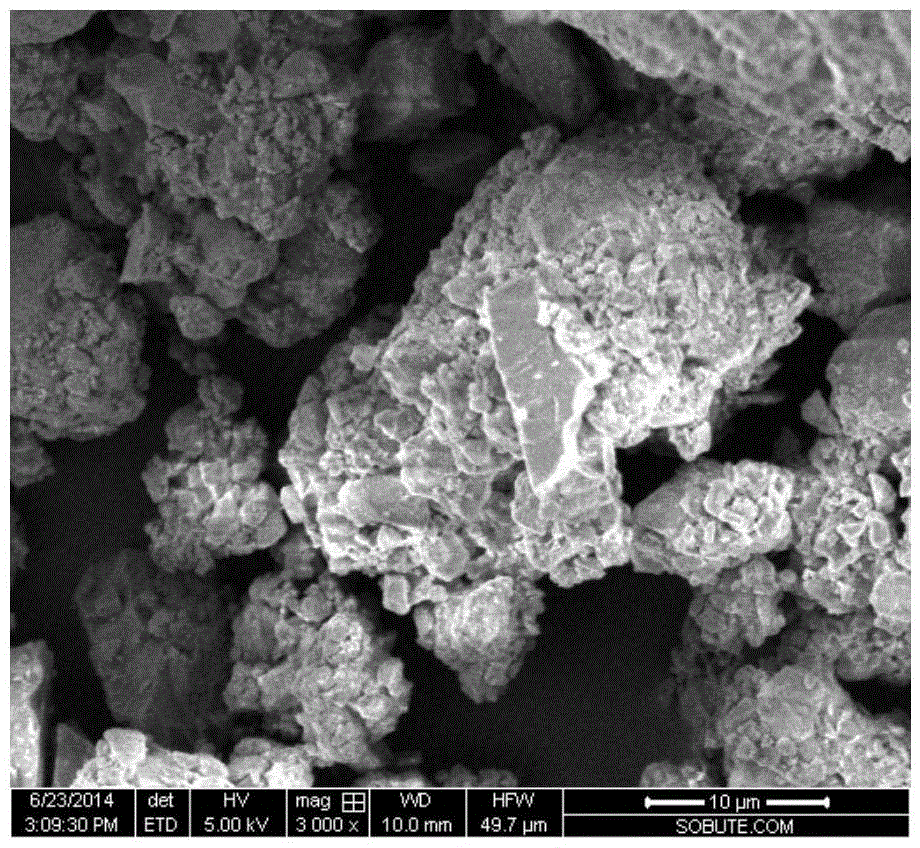

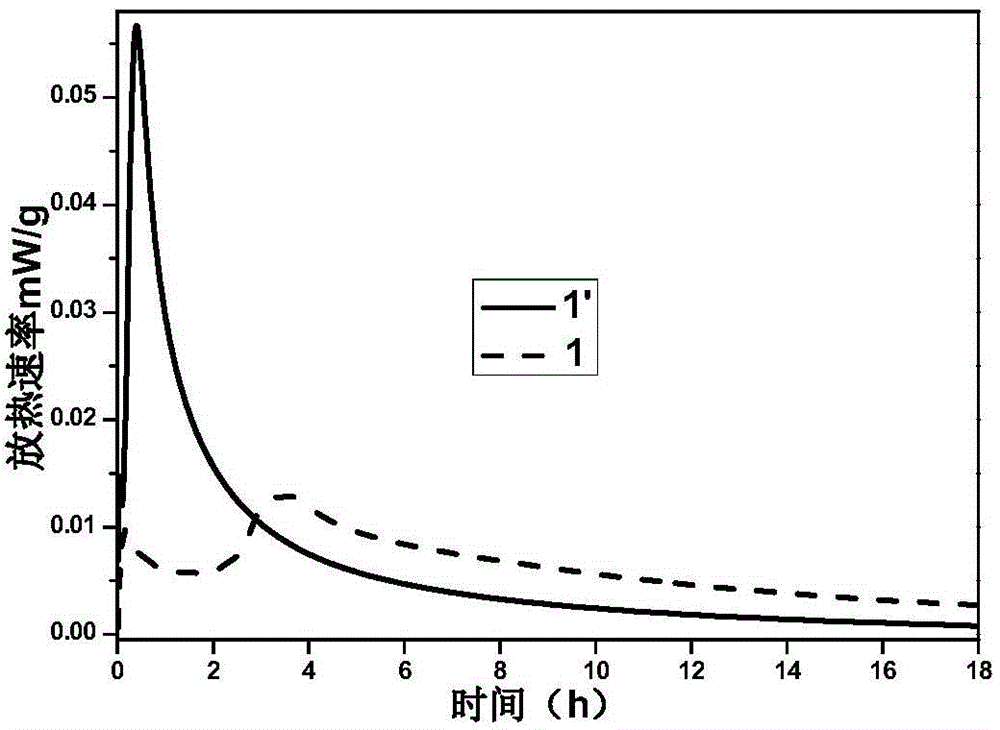

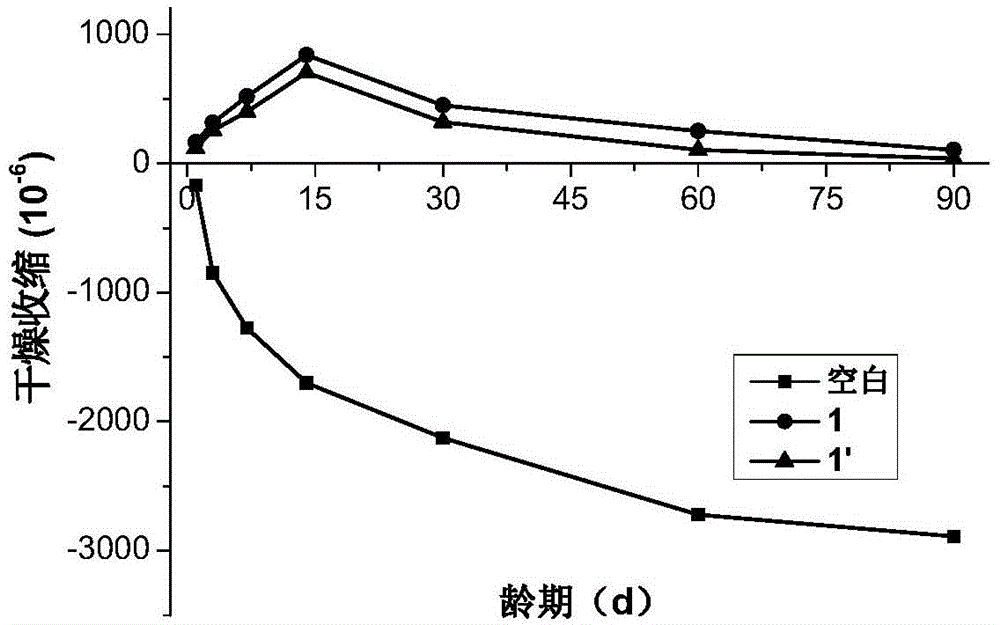

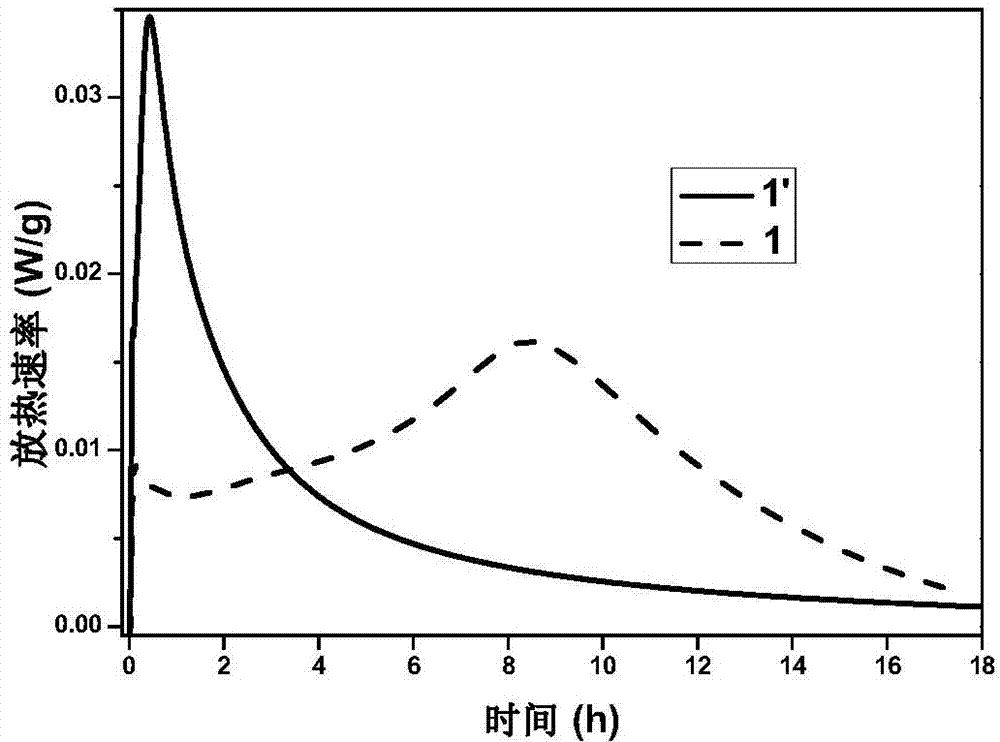

Modified calcium oxide expansion agent for cement concrete and preparation method of modified calcium oxide expansion agent

The invention provides a modified calcium oxide expansion agent for cement concrete. The modified calcium oxide expansion agent for the cement concrete has the specific surface area of 100-600m<2> / kg and is prepared from a degradable high polymer and calcium oxide expansion clinker. According to the modified calcium oxide expansion agent for the cement concrete, provided by the invention, the invalid hydration of calcium oxide at a plastic stage of concrete is reduced, the hardened expansion quantity is increased, and the shelf life of the product can be further prolonged; the expansion agent can be applied to the crack resisting and seepage prevention of a concrete structure and can be used for greatly improving the durability of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

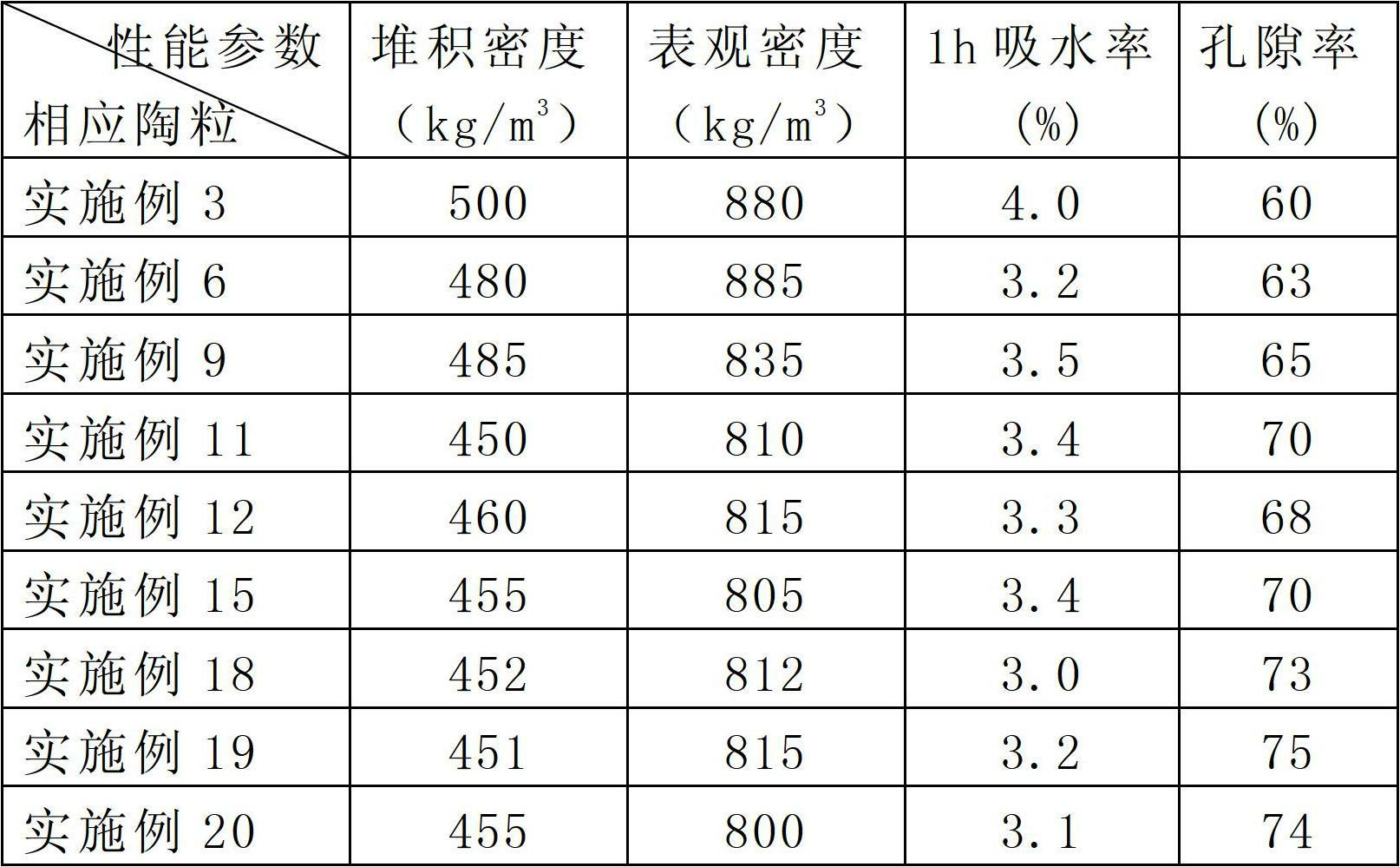

Efficient sound-absorbing ceramsite

InactiveCN102633491AImprove the sound absorption coefficientLightweight and high strengthCeramic materials productionCeramicwarePorositySludge

The invention relates to an efficient sound-absorbing ceramsite, belonging to the technical field of a building material. Aiming to solve the problems that city pollution can not be well solved, product properties are poor, the poor sound-absorbing effects are poor and the production cost is high in the prior art by mainly using the shale as ceramsite, can be solved, The invention provides the efficient sound-absorbing ceramsite, which is prepared from raw materials mainly consisting of raw materials of 60-80% of sludge, 5-20% of the shale, 5-20% of coal ash and 1.0-10% of additive. The efficient sound-absorbing ceramsite provided by the invention has the properties of wide sound-absorbing frequency band, fire resistance, good durability, freezing resistance, seismic resistance, high sound-absorbing coefficient, high porosity, light weight, high strength, heat resistance, anti-permeability and the like. The efficient sound-absorbing ceramsite further can be used for preparing a road barrier and a metro sound-absorbing material and has wide application prospect. Furthermore, the efficient sound-absorbing ceramsite provided by the invention mainly uses city sludge, so that not only can the problem of the city sludge be solved well, but also the overuse of a natural resource of the shale is reduced.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

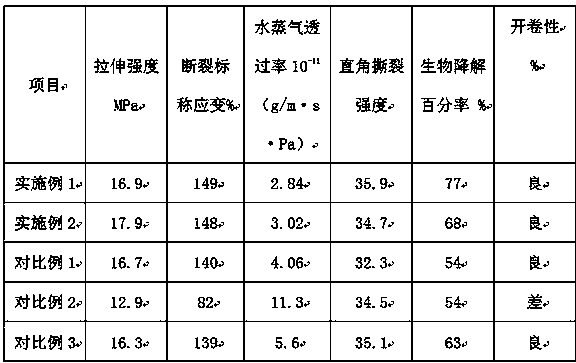

Environment-friendly degradable edible film packaging material

InactiveCN109054105AHigh strengthAct as a crosslinking agentFlexible coversWrappersNon toxicityPermeation

The invention discloses an environment-friendly degradable edible film packaging material. The environment-friendly degradable edible film packaging material is prepared from the following raw materials in parts by weight: 43-77 parts of modified starch, 22-61 parts of dandelion extract, 13-17 parts of konjac gelatin powder, 32-57 parts of edible gelatin, 21-37 parts of modified casein, 10-15 parts of carboxymethyl cellulose, 3-9 parts of chitosan, 2-7 parts of plasticizers, 7-13 parts of agar, 1-3 parts of citric acid, 2-4 parts of antibacterial liquid, 0.5-1.5 parts of plant extract, 2-4 parts of cactus juice, 2-6 parts of glutinous rice juice and 2-7 parts of carrot powder. The environment-friendly degradable edible film packaging material has the advantages of edibility, capability ofpackaging food, preventing oxygen permeation and protecting the original taste of fatty food, high nutritional value after eating, capability of meeting environmental safety requirements, non-toxicity, safety, high oxygen permeation resistance, water and oil resistance, high temperature resistance, easiness in degradation, high strength, good comprehensive performance and high cost performance.

Owner:合肥旭亚新材料科技有限公司

Thermal light and thin fabric

InactiveCN103668662AStrong hygroscopicityGood warmth retentionWoven fabricsYarnEnvironmentally friendlyYarn

The invention discloses thermal light and thin fabric which is formed by interweaving of A yarn and B yarn, wherein the A yarn comprises, by mass, 60%-75% of wool fibers and 25%-40% of bamboo-carbon fibers, the B yarn comprises, by mass, 50%-60% of kapok fibers, 20%-30% of mulberry silk fibers and 10%-20% of modal fibers, and both the A yarn and the B yarn are formed through twisting by means of the siro spinning technology. In this way, the fabric is light and thin, breathable, good in thermal performance, capable of inhibiting and resisting bacteria, non-toxic, harmless, environmentally friendly, and safe.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

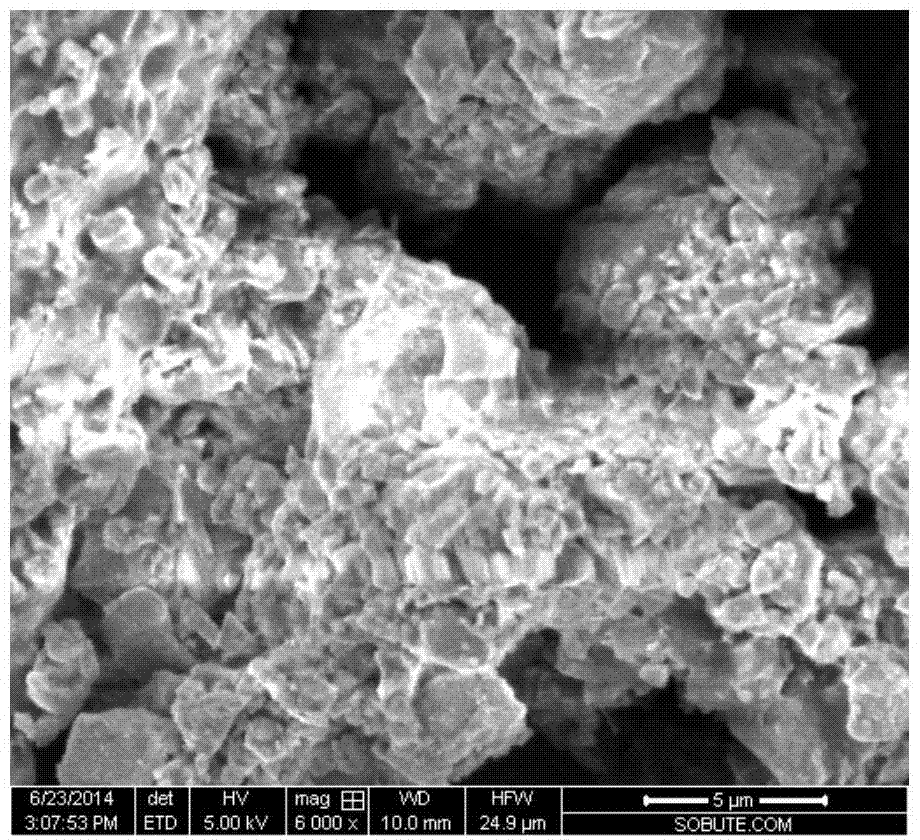

Modified calcium oxide cement concrete expansion agent and preparation method thereof

ActiveCN104710121ASmall water absorptionStrong resistance to moisture absorptionCrack resistanceAcrylic resin

The invention provides a modified calcium oxide cement concrete expansion agent and a preparation method thereof. The modified calcium oxide cement concrete expansion agent consists of acrylic resin and a calcium oxide expansion clinker, wherein the surface of the calcium oxide expansion clinker is wrapped with the acrylic resin; the mass of the acrylic resin accounts for 0.01 to 10 percent of the total mass of the modified calcium oxide cement concrete expansion agent; the specific surface area of the modified calcium oxide cement concrete expansion agent is 100 to 600m<2> / kg. According to the modified calcium oxide cement concrete expansion agent, a hydration process of the calcium oxide expansion clinker can be regulated, ineffective hydration in the plastic stage of concrete can be reduced, expansion after hardening can be increased, and the shelf life of the expansion agent product can be prolonged; the modified calcium oxide cement concrete expansion agent can be used for the crack resistance and seepage resistance of a concrete structure, and the durability of the concrete can be greatly improved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

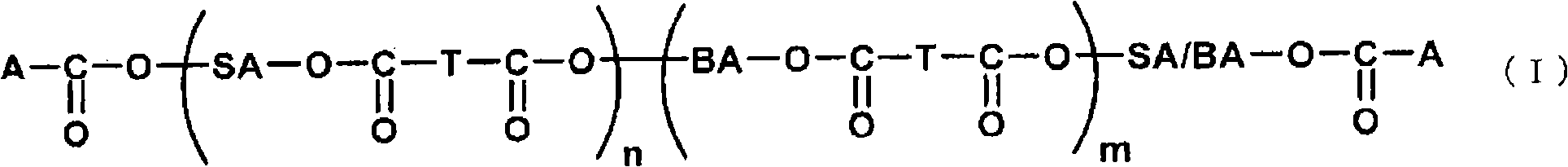

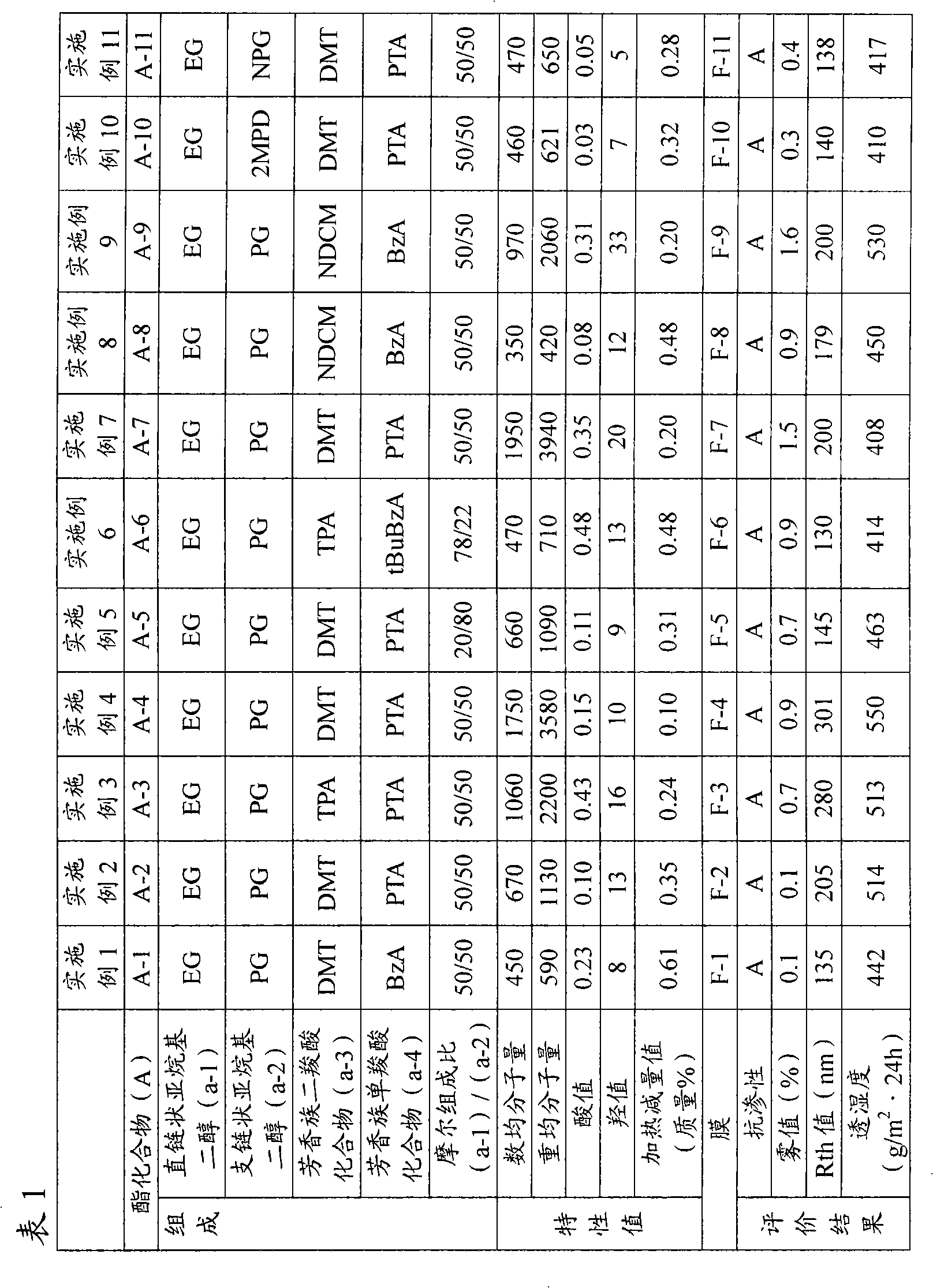

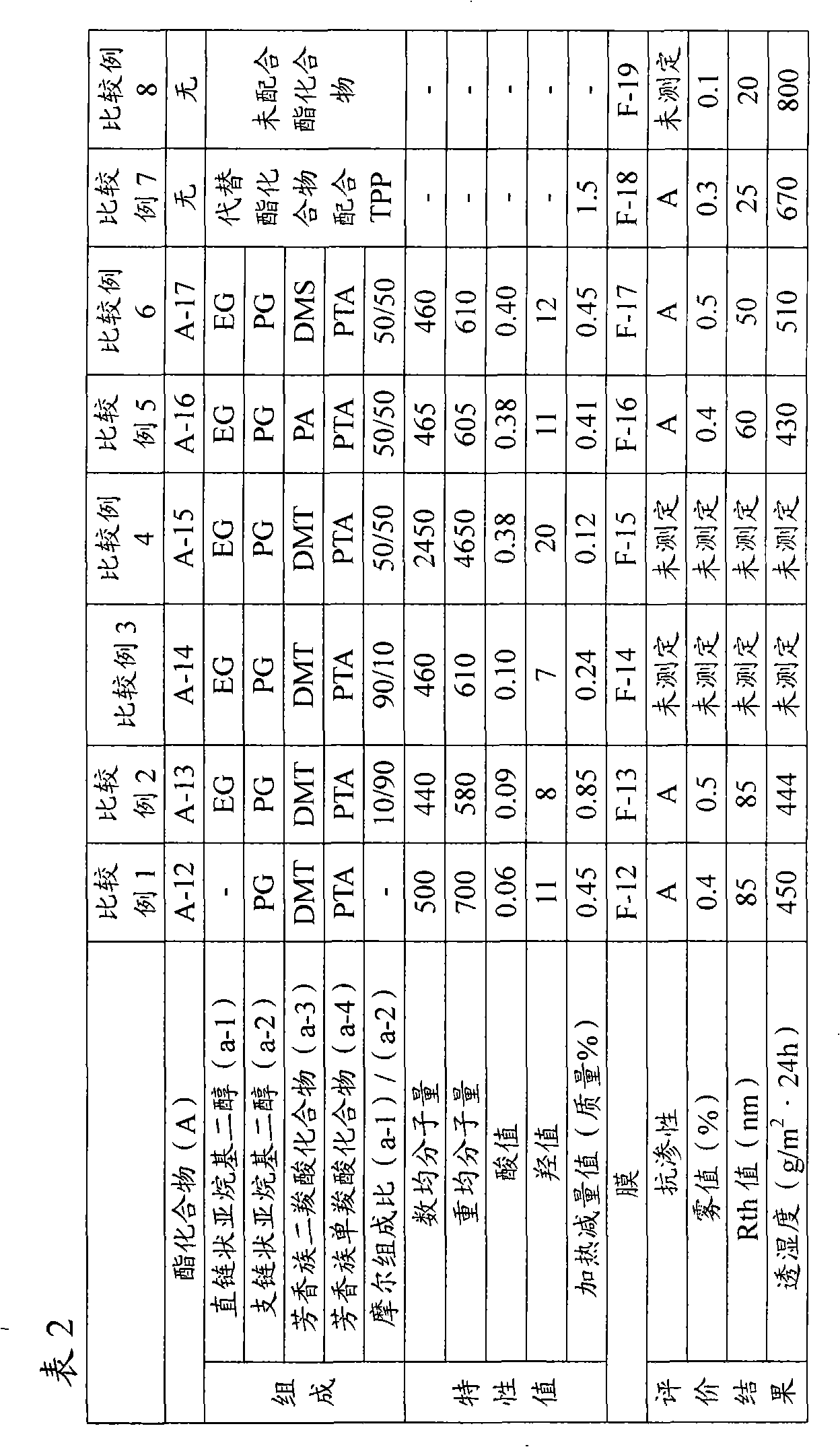

Additive for cellulose ester resin, cellulose ester resin composition using same, and optical film

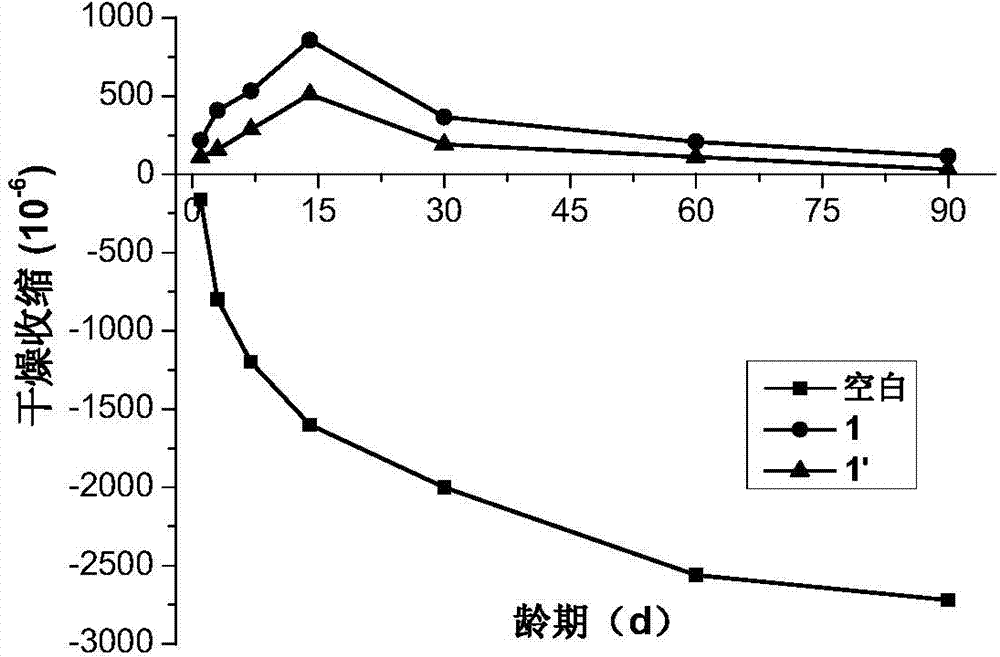

ActiveCN101845154AImpermeableHigh Rth valueDiffusing elementsPolarising elementsCelluloseMoisture permeability

The invention provides an additive for a cellulose ester resin, a cellulose ester resin composition using same, and an optical film formed of the resin composition. The additive for the cellulose ester resin contains an ester compound (A) which is an ester compound produced through an esterification reaction by a straight chain alkylene glycol (a-1), a branch chain alkylene glycol (a-2), a dicarboxylic acid such as terephthalic acid or an aromatic dicarboxylic acid compound (a-3) such as an alkyl ester of the terephthalic acid, and the aromatic monocarboxylic acid compound (a-4), wherein the molar ratio (a-1) / (a-2) of the straight chain alkylene glycol (a-1) to the branch chain alkylene glycol (a-2) is arranged between 85 / 15 and 15 / 85; and the number average molecular weight of the ester compound is arranged between 300 and 2000. The optical film has a high retardation value, the transparency and the moisture permeability resistance.

Owner:DIC CORP

Adhesive mortar for ceramic tile

The invention relates to a mortar and provides an adhesive mortar for a ceramic tile. The adhesive mortar for the ceramic tile contains tailings, is high in tensile adhesive strength and low in cost, does not pollute the environment, and has a heat preservation effect. The adhesive mortar for the ceramic tile comprises the following materials in parts by weight: 30-35 parts of ecological cement, 0.5-0.6 part of polyving akohol, 30-50 parts of tailings, 5-10 parts of polypropylene monofilament, 1.3-2.8 parts of a defoamer, 12-17 parts of a water reducer, 17-19 parts of coal ash, 7-9 parts of glass bead, 21-32 parts of ceramic sand, 1.5-2.5 parts of cellulose ether, 4-8 parts of redispersible powder and 70-90 parts of water, wherein the ceramic sand comprises sand grains with the grain diameters of 0.10-2.0 mm and with a plurality of pores not communicated in the surfaces.

Owner:荣达新型建材(福建)集团有限公司

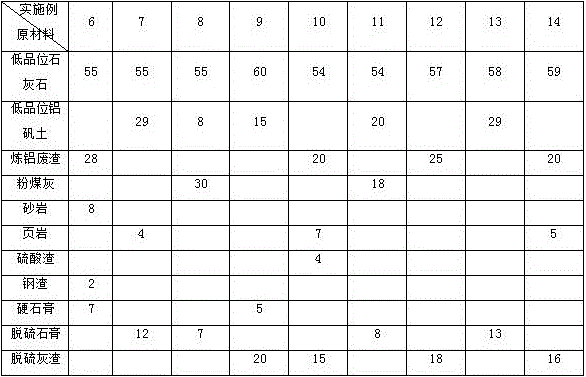

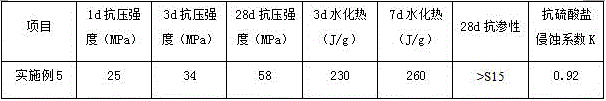

Cement clinker and preparation method thereof

The invention discloses a cement clinker and belongs to the technical field of cement clinker production. The clinker is prepared from the following raw materials in percentage by mass: 30 to 60 percent of calcareous materials, 0 to 25 percent of siliceous materials, 10 to 40 percent of aluminum materials, 0 to 10 percent of ferrous materials and 5 to 20 percent of gypsum materials; a mineral composition of the clinker is prepared from 10 to 40 percent of C4AS, 25 to 40 percent of C2S and 10 to 30 percent of C4AF. According to the clinker disclosed by the invention, the iron content of the cement clinker is low, and the seawater erosion resisting ability of the clinker is improved; the cement clinker is especially suitable for marine engineering.

Owner:JIAHUA SPECIAL CEMENT

Shock-resistance light-weight fireproof plate

The invention discloses a light-weight fireproof plate, which is simple in structure, convenient to manufacture and high in shock resistance. One or more layers of flexible net layers are arranged between an upper base material and a lower base material which are made of fireproof materials; and the upper base material, the lower base material and the flexible net layers are integrated together. The light-weight fireproof plate is fireproof, dampproof, soundproof, waterproof and deformation-proof, has light weight, high shock resistance, and can be widely applied in building fields, such as partition walls, floors, floor splints and the like.

Owner:佛山市欧朗板业有限公司

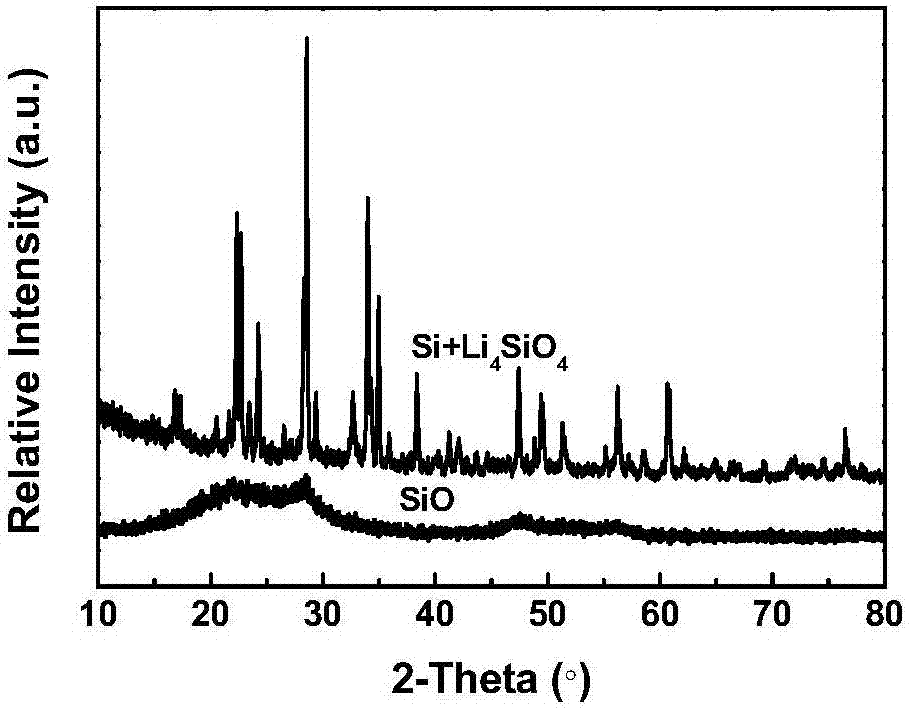

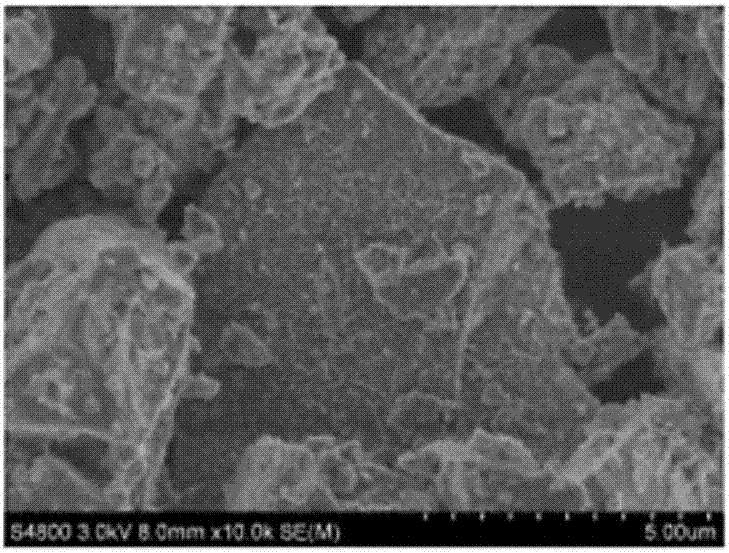

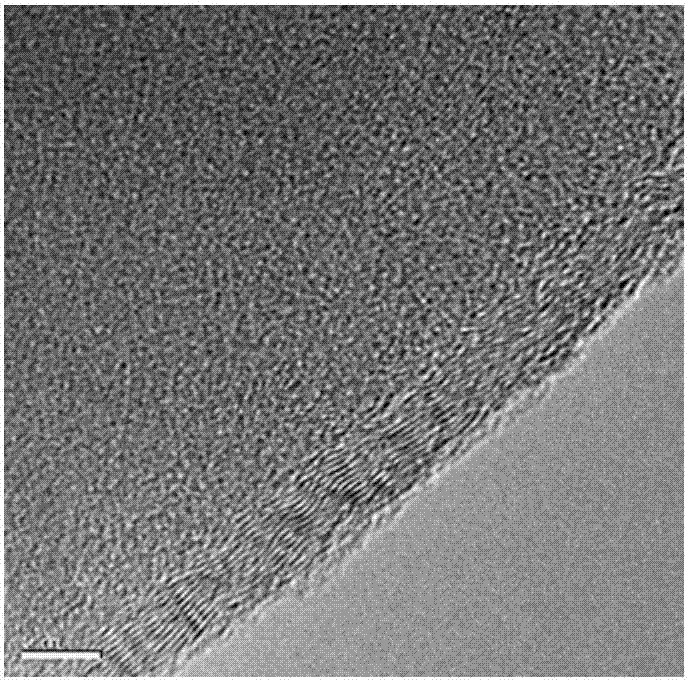

Composite silicon based electrode material, preparation method and application thereof

InactiveCN107394161AImprove stabilitySmall volume change rateCell electrodesSecondary cellsWater basedSolvent

Relating to the field of electrode materials, the invention in particular provides a composite silicon based electrode material, a preparation method and application thereof. The composite silicon based electrode material is mainly composed of a pre-lithiated silicon based core and a graphene layer coating the pre-lithiated silicon based core. The composite silicon based electrode material has the advantages of high environmental stability, good inertness to solvent, high initial coulomb efficiency and good cyclic stability, has no change after storage in the air for 24h or more, has initial coulomb efficiency up to 90% or more, shows good inertness to water based solvents and oil based solvents, and has a capacity retention ratio up to92% or more after 20 cycles.

Owner:PEKING UNIV

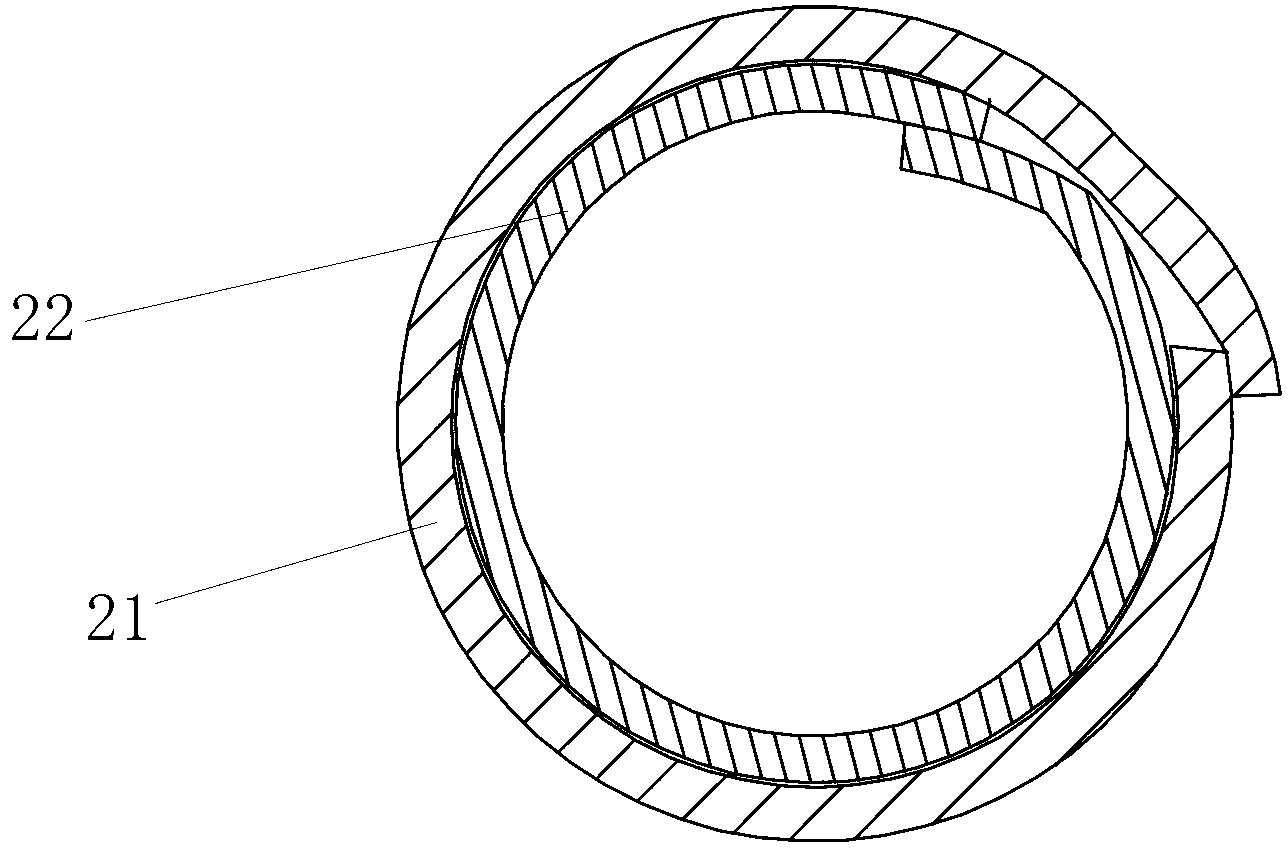

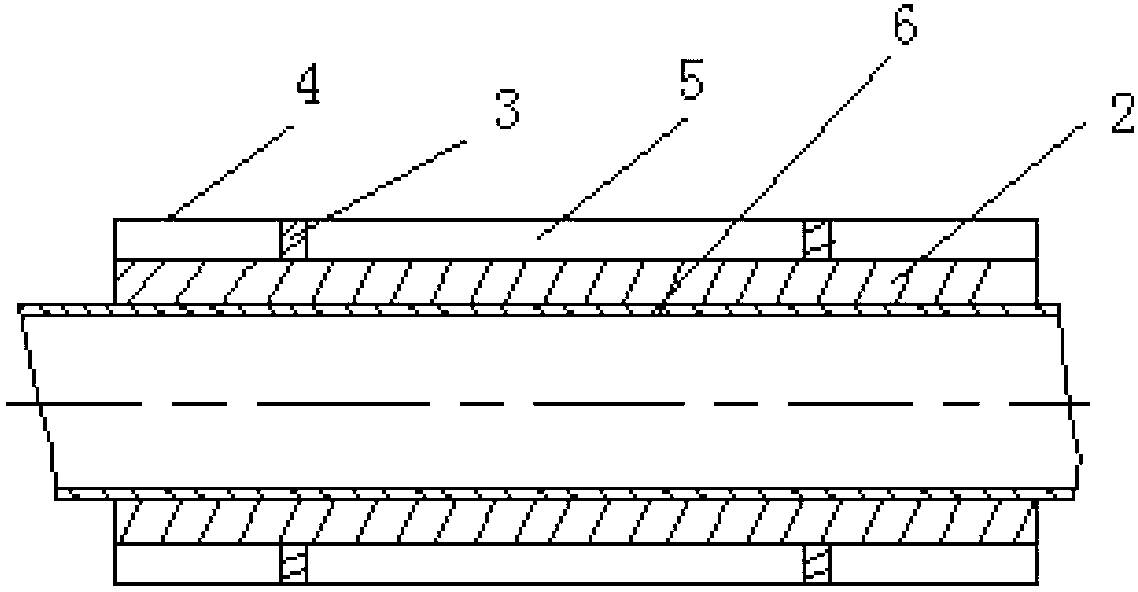

Thermal insulation structure of thermal medium storage tank and thermal medium pipe of solar photo-thermal power generation system

ActiveCN103231869APlay a protective effectImpermeableThermal insulationDomestic cooling apparatusThermal insulationEngineering

The invention discloses a thermal insulation structure of a thermal medium storage tank and a thermal medium pipe of a solar photo-thermal power generation system. The thermal insulation structure comprises thermal insulation composite layers, fixed parts, support strips and an outer protecting layer. All groups of thermal insulation composite layers are sequentially wrapped on a tank body of the thermal medium storage tank or the peripheral surface of the thermal medium pipe group by group according to a sequence from inside to outside. The support strips are fixed outside the thermal insulation composite layer of the outermost side in a surrounded mode along the circumference and are one layer or two layers of stacked aerogel strips of 1-3cm in thickness; and the support strips are parallelly arranged on the thermal insulation composite layer of the outermost side at intervals of 0.5-1.0 meter. The outer protecting layer is wrapped on the outer side of the support strips, and an annular cavity is formed between the outer protecting layer and the thermal insulation composite layer of the outermost side and is an air thermal insulation layer. According to the thermal insulation structure, a mode of jointly utilizing the thermal insulation composite layers and the air thermal insulation layer on the outer surface of the tank body or the pipe is adopted, thermal insulation effect is remarkable, and cost of the air thermal insulation layer is extremely low.

Owner:常州循天节能科技有限公司

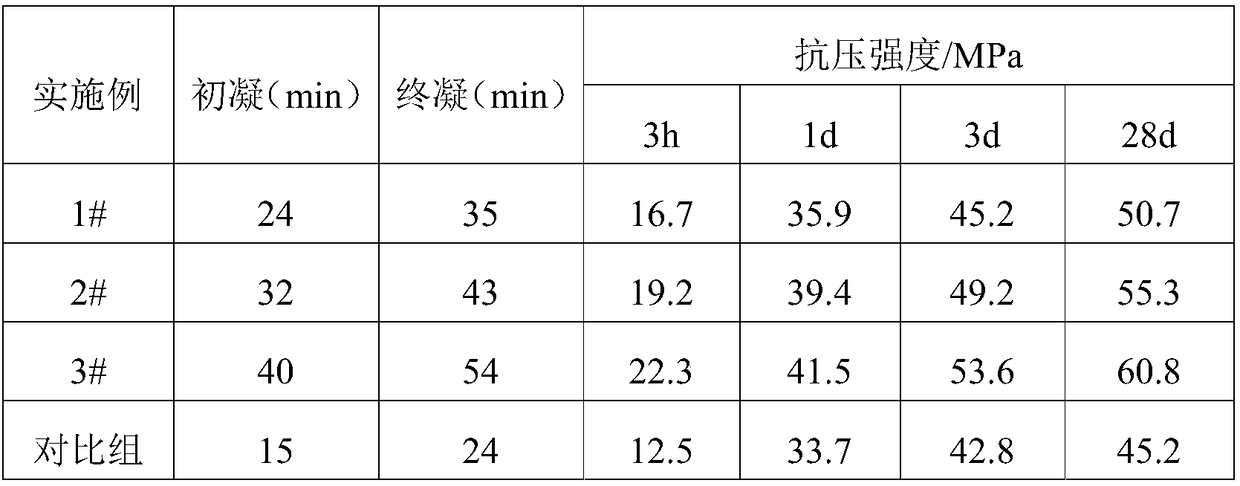

High-strength sulphoaluminate cement and preparation method thereof

The invention relates to high-strength sulphoaluminate cement and a preparation method thereof. The high-strength sulphoaluminate cement contains the following components by weight percent: 75-85% ofsulphoaluminate cement clinker, 5-10% of silica fume, 5-15% of gypsum, 0.5-5% of reinforcing components, and 0-1% of a retarder. In the mineral composition of the sulphoaluminate cement clinker, the content of calcium sulphoaluminate is greater than 60%. In the silica fume, the content of SiO2 is greater than 85%. Dihydrate gypsum or natural anhydrite is adopted as the gypsum. The reinforcing component is prepared from lithium carbonate, calcium hydroxide and aluminum sulfate, wherein the weight percentages of lithium carbonate, calcium hydroxide and aluminum sulfate in the high-strength sulphoaluminate cement are respectively 0.2-1%, 0.3-2% and 0-2%. The retarder is industrial borax or boric acid. According to the invention, the setting time of the sulphoaluminate cement can be effectively adjusted, so as to meet the construction requirement of actual engineering; the sulphoaluminate cement is remarkably improved in both early-stage and long-term strength, and has the advantages of freezing resistance, and impermeability and erosion resistance, and the application scope of the sulphoaluminate cement is expanded.

Owner:YANGZHOU UNIV

Tissue culture method for chrysanthemum under LED condition

InactiveCN101015277AImprove utilization efficiencyImprove growth qualityGreenhouse cultivationHorticulture methodsLong root lengthFiber

The invention provides a new method for tissue culturing chrysanthemum. It employs cold light source (light-emitting diode) as light source, and determines the optimum ratio of red light to blue light and the best light emitting strength. It takes poromeric fluoroethylene resin film as culturing container for tissue culture sprout; and employs rock fiber block as culture medium. The growing speed for tissue culture sprout is one time faster than that with normal culture method. The tissue culture sprout and replanting sprout are characterized by largest plant height, largest leaf number, root number, longest root length and largest dry net weight of haulm and root, high rate of emergence and little pollution rate.

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com