Additive for cellulose ester resin, cellulose ester resin composition using same, and optical film

A technology of cellulose ester resin and additives, applied in the directions of diffusing elements, polarizing elements, etc., can solve the problems of insufficient satisfaction and achieve the effect of high Rth value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

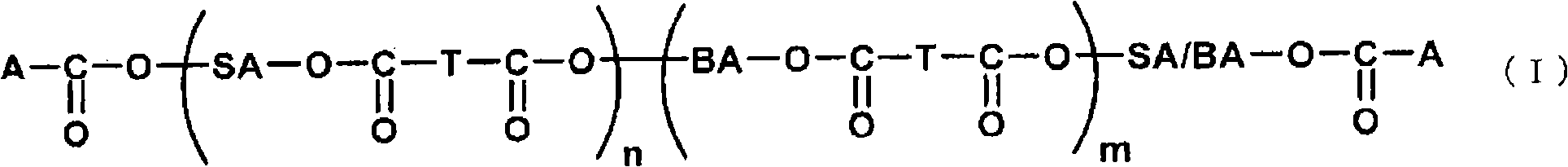

Method used

Image

Examples

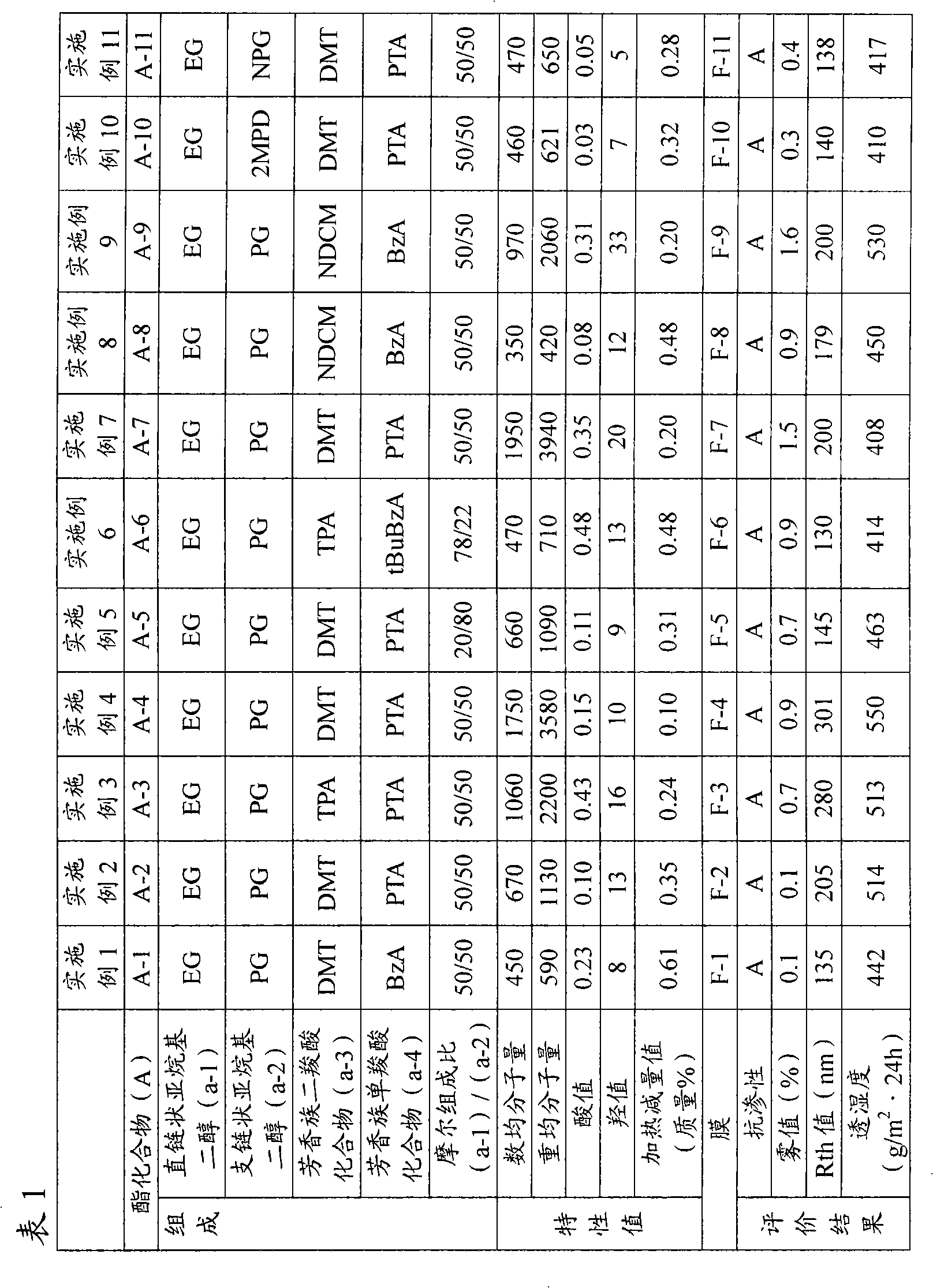

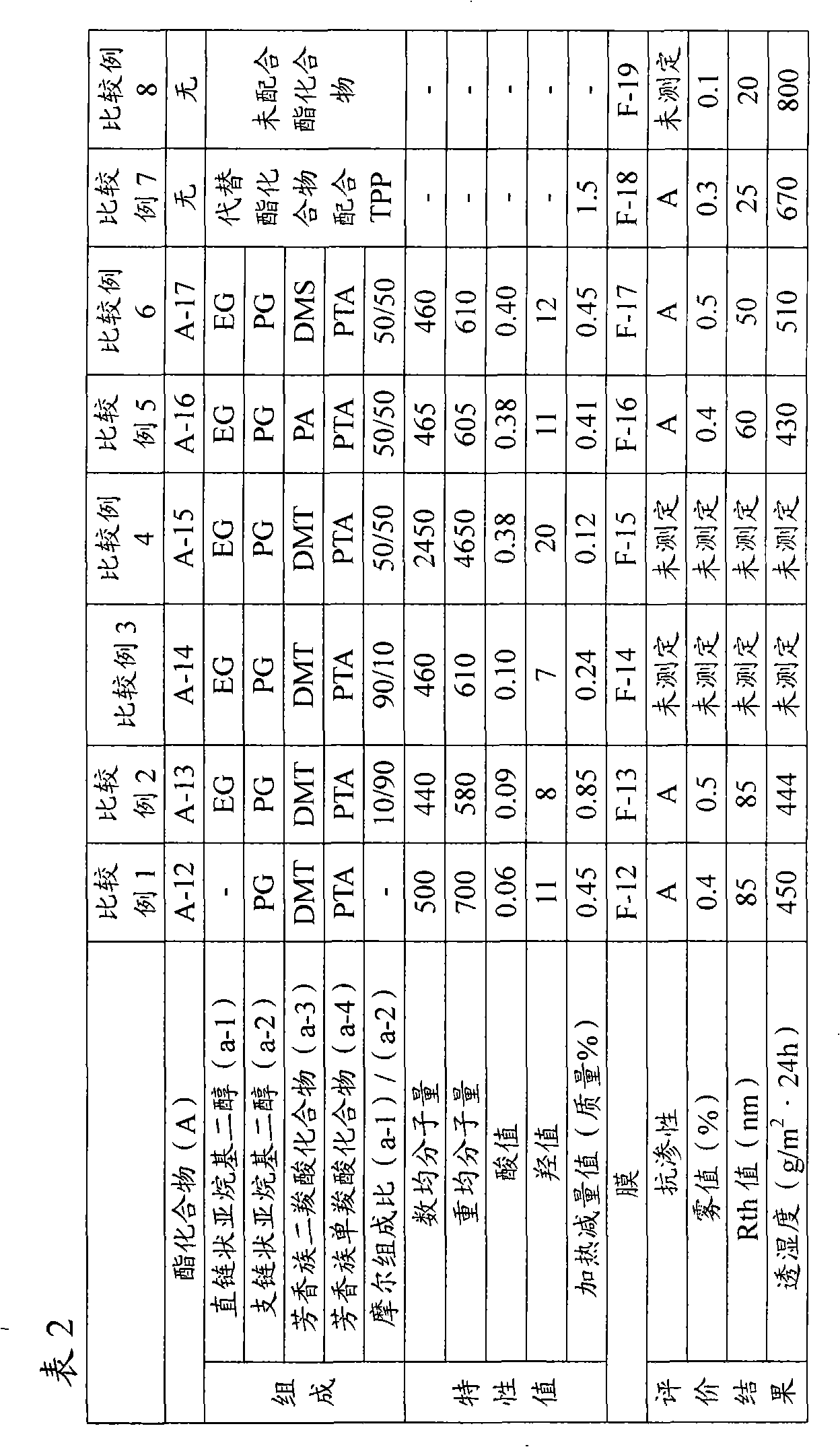

Embodiment 1

[0118] [Example 1] Manufacture of ester compound (A-1)

[0119] 248g of ethylene glycol (hereinafter abbreviated as "EG"), 304g of propylene glycol (hereinafter abbreviated as "PG"), 682g of dimethyl terephthalate (hereinafter abbreviated as "DMT") and 952g of benzoic acid ( Hereinafter abbreviated as "BzA") was charged into a four-neck flask with an inner volume of 3 liters equipped with a thermometer, a stirrer, a reflux condenser, and a nitrogen gas introduction tube, and the temperature was raised. When the temperature in the flask reaches 130°C, add an esterification catalyst tetraisopropyl titanate (hereinafter abbreviated as "TIPT") that is 60 ppm relative to the total amount of EG, PG, DMT and BzA, and stir under nitrogen flow, From 170°C, the temperature was raised to 230°C while distilling off produced water and methanol at a rate of temperature increase of 10°C per hour. Next, by making the temperature in the flask 200° C. and heating for 4 hours under a reduced pr...

Embodiment 2

[0120] [Example 2] Production of ester compound (A-2)

[0121] 235 g of EG, 288 g of PG, 971 g of DMT, and 545 g of PTA were charged into a four-neck flask with an inner volume of 3 liters equipped with a thermometer, a stirrer, a reflux condenser, and a nitrogen introduction tube, and the temperature was raised. When the temperature in the flask reaches 130°C, add the esterification catalyst TIPT which is 60ppm relative to the total amount of EG, PG, DMT and PTA. While stirring under nitrogen flow, start from 170°C at a rate of 10°C per hour. The temperature was raised to 230° C. while distilling off generated water and methanol. Next, by making the temperature in the flask 200° C. and heating for 4 hours under a reduced pressure of about 100 Pa, an ester compound (A-2) (acid value: 0.10, hydroxyl value :13).

Embodiment 3

[0122] [Example 3] Production of ester compound (A-3)

[0123]224 g of EG, 274 g of PG, 871 g of terephthalic acid (hereinafter abbreviated as "TPA"), and 272 g of PTA were charged into a quadruple chamber with an inner volume of 3 liters having a thermometer, a stirrer, a reflux condenser, and a nitrogen gas introduction tube. Start to heat up in the flask. When the temperature in the kettle reaches 130°C, add the esterification catalyst TIPT which is 60ppm relative to the total amount of EG, PG, TPA and PTA, and stir under the nitrogen flow while starting from 170°C at a rate of 10°C per hour. The temperature was raised to 245°C while distilling off generated water and methanol. Next, by making the temperature in the flask 200° C. and heating for 4 hours under a reduced pressure of about 100 Pa, an ester compound (A-3) with a number average molecular weight of 1060 and a weight average molecular weight of 2200 (acid value: 0.43, hydroxyl value :16).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com