High-strength sulphoaluminate cement and preparation method thereof

A sulfoaluminate cement, high-strength technology, applied in the field of building materials, can solve problems such as the reduction of cement strength, and achieve the effects of improving the strength in the later stage, promoting stable growth, and regulating the setting time of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

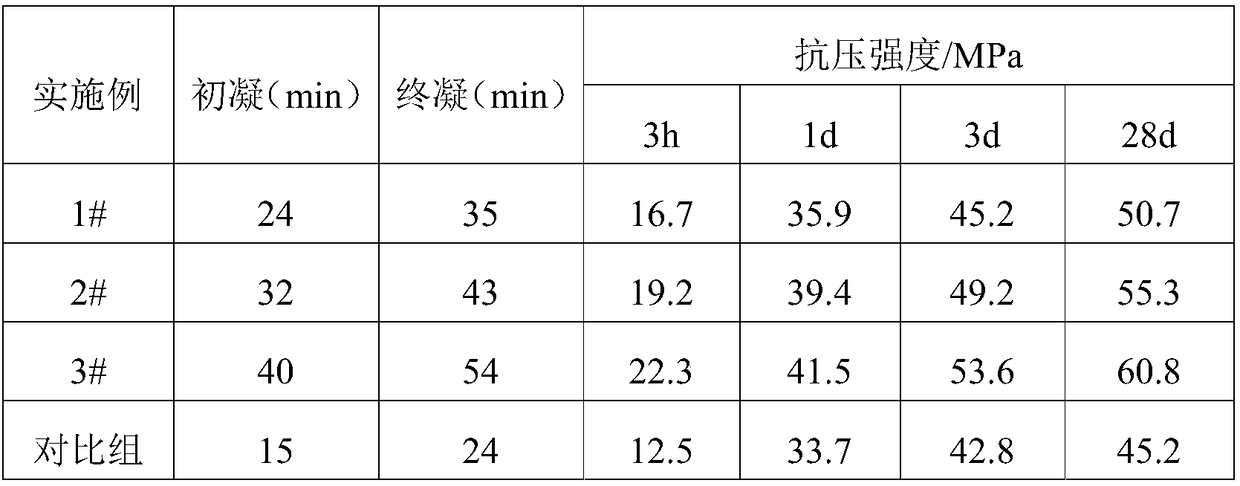

Embodiment 1

[0018] A kind of high-strength sulfoaluminate cement, each component by weight percentage is:

[0019] Sulphoaluminate cement clinker: 76%, silica fume: 9%, dihydrate gypsum: 10%, reinforcing component: 4.5%, retarder: 0.5%; wherein, the reinforcing component is composed of 1% carbonic acid Lithium, 2% calcium hydroxide and 1.5% aluminum sulfate, that is, lithium carbonate, calcium hydroxide, and aluminum sulfate account for 1%, 2%, and 1.5% by weight of high-strength sulfoaluminate cement, respectively. Weigh the raw materials of each component according to the above-mentioned predetermined mass percentage, mix them evenly and grind them together until the fineness is 360m2 2 / kg, made into cement products. According to the national standard GB / T1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, Stability Test Method", GB / T17671-1999 "Cement Strength Test Method" to test the setting time of cement and the strength of mortar specimens, the cement was dete...

Embodiment 2

[0021] A kind of high-strength sulfoaluminate cement, each component by weight percentage is:

[0022] Sulphoaluminate cement clinker: 80%, silica fume: 5%, dihydrate gypsum: 12%, reinforcing component: 2.3%, retarder: 0.7%; wherein, the reinforcing component is composed of 0.5% carbonic acid Lithium, 1% calcium hydroxide and 0.8% aluminum sulfate, that is, lithium carbonate, calcium hydroxide and aluminum sulfate account for 0.5%, 1% and 0.8% by weight of high-strength sulfoaluminate cement respectively. Weigh the raw materials of each component according to the above-mentioned predetermined mass percentage, mix them uniformly and grind them together until the specific surface area is 378m 2 / kg, made into cement products. According to the national standard GB / T1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, Stability Test Method", GB / T17671-1999 "Cement Strength Test Method" to test the setting time of cement and the strength of mortar specimens, the...

Embodiment 3

[0024] A kind of high-strength sulfoaluminate cement, each component by weight percentage is:

[0025] Sulphoaluminate cement clinker: 84%, silica fume: 5%, dihydrate gypsum: 7%, reinforcing component: 3.2%, retarder: 0.8%; wherein, the reinforcing component is composed of 1% carbonic acid Lithium, 2% calcium hydroxide and 1.2% aluminum sulfate, that is, lithium carbonate, calcium hydroxide, and aluminum sulfate account for 1, 2%, and 1.2% by weight of high-strength sulfoaluminate cement, respectively. Weigh the raw materials of each component according to the above-mentioned predetermined mass percentage, mix them uniformly and grind them together until the specific surface area is 385m 2 / kg, made into cement products. According to the national standard GB / T1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, Stability Test Method", GB / T17671-1999 "Cement Strength Test Method" to test the setting time of cement and the strength of mortar specimens, the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com