Composite sulphoaluminate cement-based self-leveling material and preparation method thereof

A composite sulphoaluminate and cement-based technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high cost, cost bottleneck impact, high energy consumption, etc., and achieve low production cost , Improve compactness, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

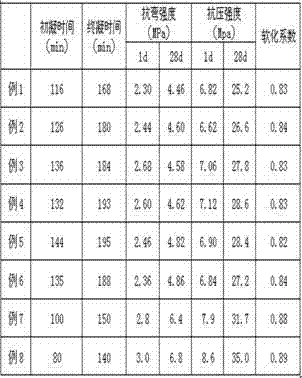

Examples

Embodiment 1

[0021] The weight ratio of each component of the present embodiment:

[0022] Desulfurized gypsum 35%

[0023] Ultrafine Mineral Powder 21%

[0024] Sulphoaluminate cement 32%

[0025] Portland cement 10%

[0026] Polycarboxylate superplasticizer 0.75%

[0027] Coagulant Na 2 SO 4 1.0%

[0028] Water retaining agent MC 0.05%

[0029] Preparation: Weigh the raw materials of each component according to the above-mentioned predetermined mass percentage, and mix them uniformly to obtain the composite sulfoaluminate self-leveling material of the present invention. According to the water-cement ratio of 0.41 ingredients, after testing, the fluidity is 220mm, and the fluidity loss is 3mm after 30 minutes.

Embodiment 2

[0031] The weight ratio of each component of the present embodiment:

[0032] Desulfurized gypsum 38%

[0033] Ultrafine Mineral Powder 17%

[0034] Sulphoaluminate cement 35%

[0035] Portland cement 8%

[0036] Naphthalene superplasticizer 0.5%

[0037] Coagulant K 2 SO 4 1.2%

[0038] Water retaining agent MC 0.07%

[0039] Silicone defoamer XPJ820 0.03%

[0040] Preparation: Weigh the raw materials of each component according to the above-mentioned predetermined mass percentage, and mix them uniformly to obtain the composite sulphoaluminate self-leveling material of the present invention. According to the water-cement ratio of 0.42 ingredients, after testing, the fluidity is 225mm, and the fluidity loses 2mm after 30 minutes.

Embodiment 3

[0042] The weight ratio of each component of the present embodiment:

[0043] Phosphogypsum 50%

[0044] Ultrafine Mineral Powder 14%

[0045] Sulphoaluminate cement 29%

[0046] Portland cement 5.3%

[0047] Polycarboxylate superplasticizer 0.8%

[0048] Coagulant Al 2 (SO 4 ) 3 0.8%

[0049] Water retaining agent HPMC 0.05%

[0050] Silicone defoamer XPJ820 0.05%

[0051] Preparation: Weigh the raw materials of each component according to the above-mentioned predetermined mass percentage, and mix them uniformly to obtain the composite sulphoaluminate self-leveling material of the present invention. According to the water-cement ratio of 0.42 ingredients, after testing, the fluidity is 230mm, and the fluidity will lose 1mm after 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com