Patents

Literature

45results about How to "Adjustable setting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance powder concrete for 3D (three-dimensional) printing

The invention relates to high-performance powder concrete for 3D (three-dimensional) printing. The concrete is prepared from the following raw materials in parts by weight: 500-900 parts of ordinary Portland cement, 250-350 parts of active mineral admixture, 800-1,300 parts of inert filler, 10-20 parts of composite efficient water reducing agent powder, 2-5 parts of thickener, 4-10 parts of self-curing agent, 2-10 parts of fast setting time regulator, 145-230 parts of water, 3 parts of organic fiber and 40-200 parts of copper plated fiber. The concrete material for 3D printing has the characteristics of ultrahigh strength and toughness, good durability, long full life cycle, high curing rate, good flowing property and easiness in pumping and lifting and is suitable for constructing 3D-printed building structural materials in all kinds of engineering.

Owner:黄贺明

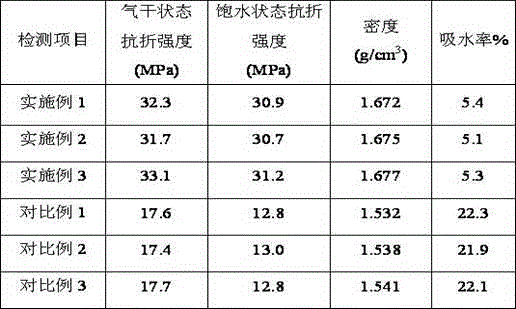

Inorganic composite heat insulation material and preparation method thereof

ActiveCN102093030ADecreased volumetric water absorptionStable physical and chemical propertiesFiberCellulose

The invention relates to an inorganic composite heat insulation material, which is prepared from the following raw materials in part by weight: 100 parts of common silicate cement, 10 to 30 parts of quick hardening sulfate aluminum cement, 10 to 30 parts of gypsum powder, 10 to 40 parts of admixture, 20 to 40 parts of mineral fiber, 150 to 200 parts of vitrified micro bubbles, 4 to 8 parts of re-dispersible latex powder, 2 to 4 parts of cellulose ether, 0.1 to 0.3 part of starch ether, 0.2 to 1.0 part of water reducing agent, 0.2 to 0.6 part of retarder, 1 to 3 parts of early strength agent, 0.5 to 3 parts of water repellent, and 0.02 to 0.06 part of air entraining agent. The raw materials are mixed uniformly to prepare dry powder, and the dry powder and water are mixed in a weight ratio of 1: (0.8-1.2) and stirred to form slurry for use. The inorganic composite heat insulation material has good workability, quick strength development, high construction efficiency, good adhesive property, low drying shrinkage, heat insulation, hydrophobic property, fire resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

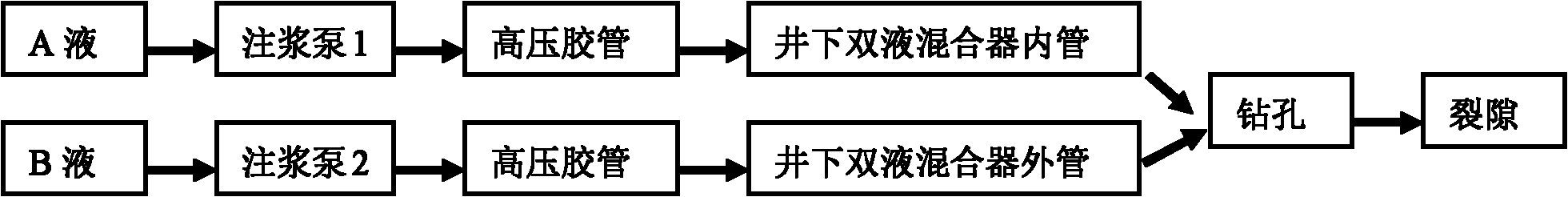

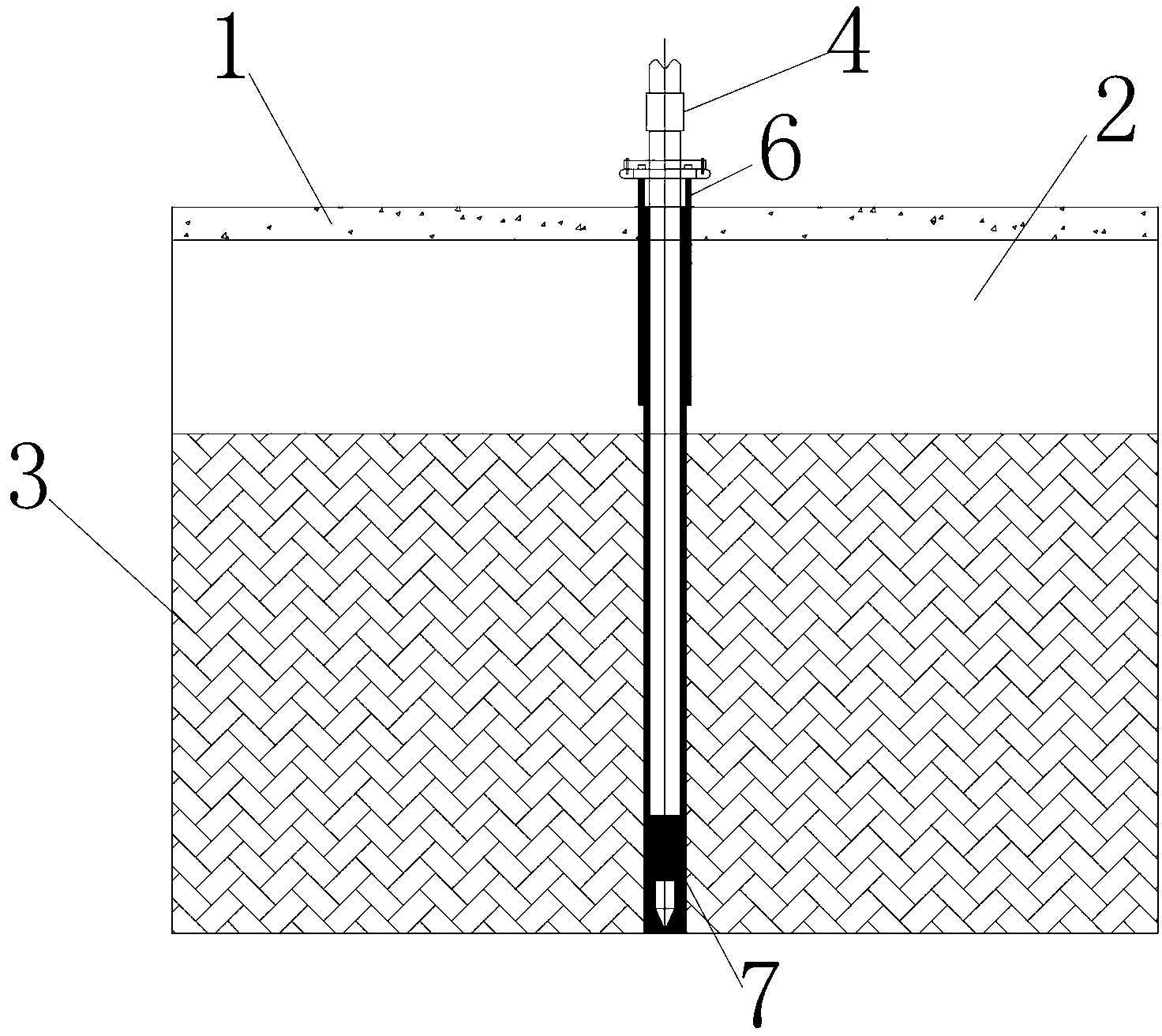

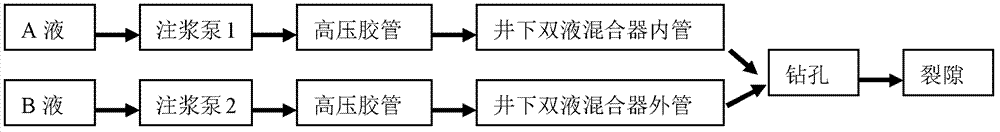

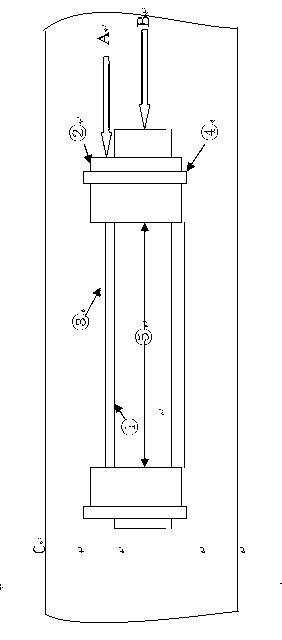

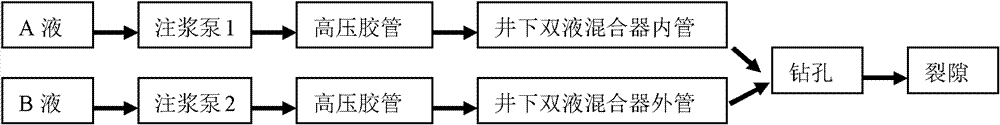

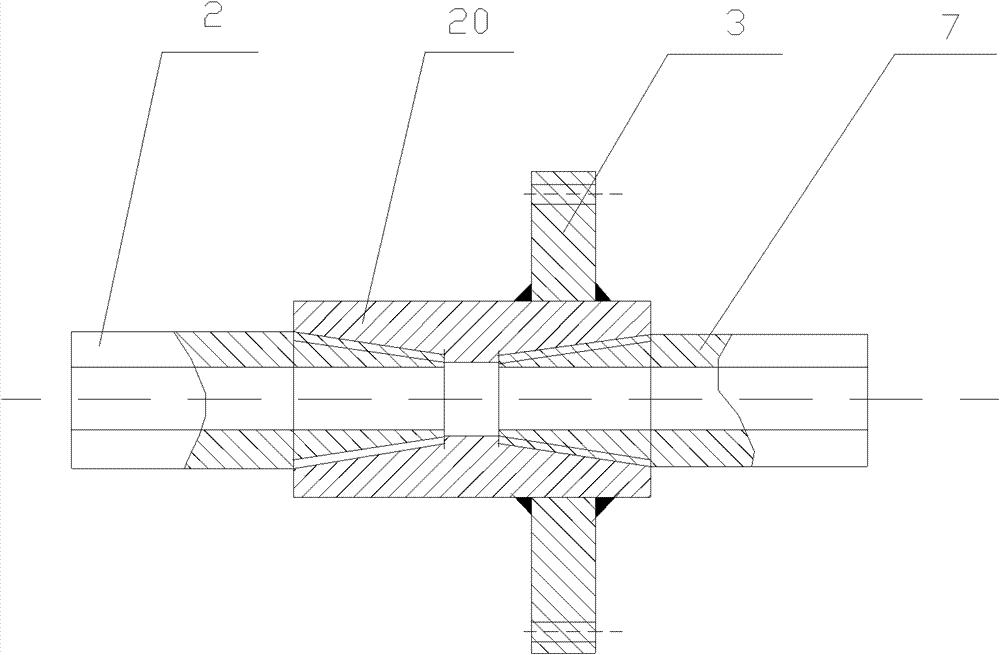

Underground double liquid grouting process and underground double liquid grouting machine thereof

ActiveCN102080552AEliminate the evil effect of cloggingAdjustable setting timeUnderground chambersTunnel liningSlurryPulp and paper industry

The invention relates to an underground double liquid grouting process, which comprises the following steps: (1) making preparations for implementing the double liquid grouting process and judging whether the grouting conditions are met; and (2) implementing the double liquid grouting process. The invention also discloses an underground double liquid grouting machine. An underground double liquidgrouting machine comprises an inner grouting tube and an outer grouting tube which are nested together, wherein the inner and outer grouting tubes are two independent airtight tubes. According to theinvention, a drill rod and a drill hole water-stopping casing pipe are respectively used as a grout conveying pipeline, the double pipeline grouting is realized, and the position for mixing two grouts and the running time of the grouts in the drill hole after the grouts are mixed are both adjusted by changing the depth of the grouting tubes in the drill hole, thus achieving the purpose of adjusting the coagulation time of the double grouts in the deeper drill hole and eliminating the disastrous effect of blocking the drill hole with the grouts, thereby ensuring a better grouting effect.

Owner:SHANDONG UNIV

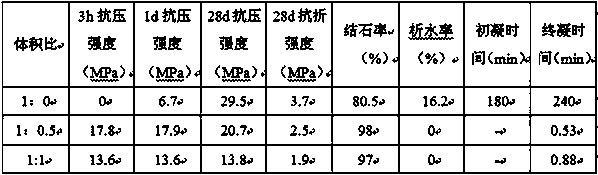

Fly ash solidification foamed material for preventing coal spontaneous combustion and preparation method thereof

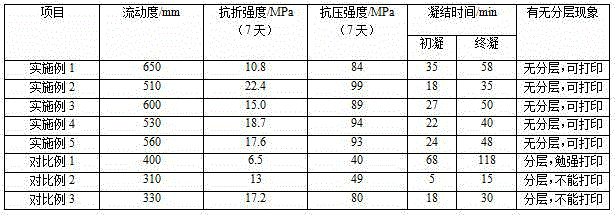

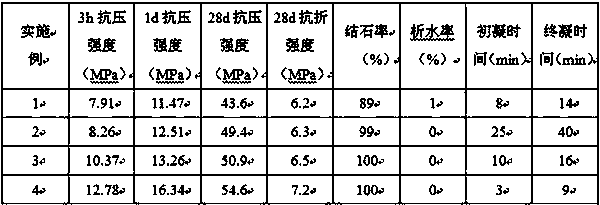

ActiveCN103387410AEvenly dispersedEvenly suspendedSolid waste managementCeramicwareCoal spontaneous combustionCompressive strength

A fly ash solidification foamed material for preventing coal spontaneous combustion and a preparation method thereof. The fly ash solidification foamed material comprises the following ingredients, by weight: 40-60 parts of water, 100 parts of fly ash, 25 parts of complex powder for chemically self-producing gas, 1-5 parts of an accelerator, 1-4 parts of an activator, 0.6-1.5 parts of a water reducer, and 0.5-1 parts of a foam stabilizer. The preparing method comprises: adding the foam stabilizer in water and stirring to form a uniform foam solution; adding the fly ash, the complex powder for chemically self-producing gas, the accelerator, the activator, and the water reducer in a dry-blending mixer to form a blended powder; and finally adding the blended powder into the uniform foam solution to obtain the fly ash solidification foamed material. The material of the invention is light in weight, safe and low in costs, and has strong crack penetration capability, adjustable solidification time, great compressive strength, low heat conductivity coefficient, and a good heat insulation effect; foam fluid can uniformly cover loose coal-rock mass; carbon dioxide is released during a foaming reaction process to well dilute the oxygen concentration in residual coal space; and the operation technique is simple.

Owner:CHINA UNIV OF MINING & TECH

Plastic stabilizer for wet-mixed mortar

InactiveCN104556812AImprove performanceShorten the setting timeWater soluble polysaccharidesProcess engineering

The invention discloses a plastic stabilizer for wet-mixed mortar. The plastic stabilizer comprises the following components in parts by weight: 0.1-5 parts of a water retention agent, 0.1-5 parts of an air entraining agent, 0.1-1 part of a defoaming agent, 0.01-1 part of water soluble polysaccharide, 1-10 parts of a special effect retarder, 1-10 parts of a water reducing agent and 68-98 parts of water. The plastic stabilizer for the wet-mixed mortar, provided by the invention, is liquid, is beneficial for automatic feeding and metering, and overcomes the defects that most mortar additives on the market are solid powder products and cannot realize automatic metering. Meanwhile, the water retention rate of the plastic stabilizer for the wet-mixed mortar, provided by the invention, can reach 98%, so that the setting time of the mortar can be deferred to 10-72 hours.

Owner:JIANGSU ZHONGKAI NEW MATERIALS

Inorganic cured foam material for surface leaking stoppage of shallow buried coal seam mining area and preparation method of inorganic cured foam material

InactiveCN103396154APromotes hydrationImprove foam production efficiencySolid waste managementCeramicwareFiberCopper oxide

The invention discloses an inorganic cured foam material for surface leaking stoppage of a shallow buried coal seam mining area and a preparation method of the inorganic cured foam material, which belong to the inorganic cured foam material and the preparation method thereof. The leaking-stoppage cured foam comprises water, coal ash, slaked lime, cement, ox horn powder, aluminum powder, copper oxide, polyphosphoric acid, aluminum hydroxide, hydroxypropyl methyl cellulose and steel fiber. The preparation method of the inorganic cured foam material comprises the following steps of: firstly, adding the coal ash, the cement, the hydroxypropyl methyl cellulose, the steel fiber and the slaked lime in water to form a coal ash substrate serous fluid; secondly, adding the ox horn powder into a little water for stirring to form prefabricated mucus, and sufficiently stirring the coal ash substrate serious fluid and the prefabricated mucus to form a mixed solution; thirdly, adding an inorganic adhesive system into the mixed solution and sufficiently stirring to form a mixed adhesive solution; and finally, adding the aluminum powder for sufficiently stirring uniformly, foaming the serious fluid by utilizing an organic self-foaming system, and preparing the inorganic cured foam material for surface leaking stoppage of the shallow buried coal seam mining area. According to the invention, the seam infiltration capacity is strong, the compressive strength is large, the high temperature resistance and the heat insulation performance are good, and the substrate is purely inorganic and pollution-free.

Owner:CHINA UNIV OF MINING & TECH +1

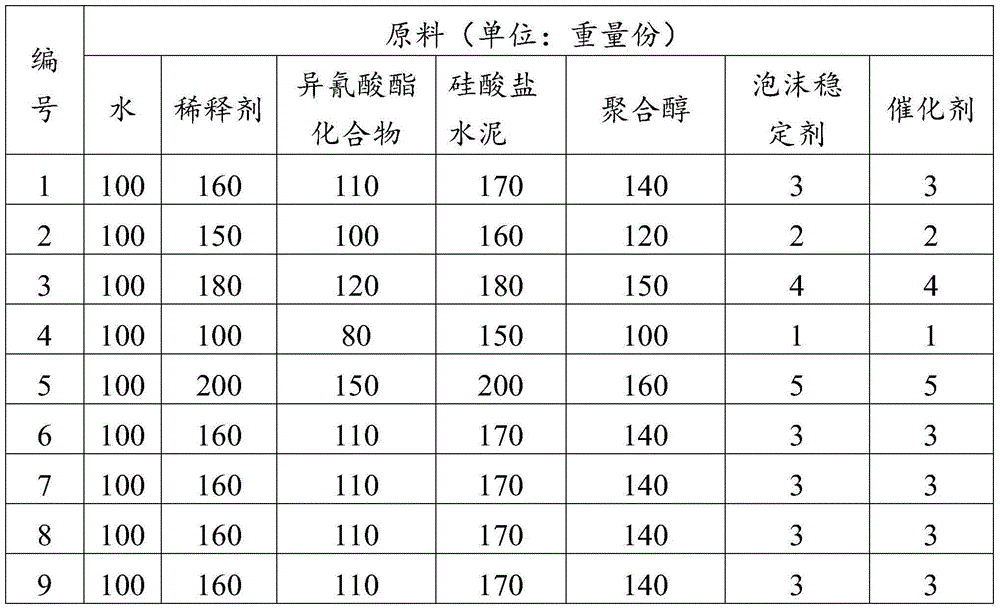

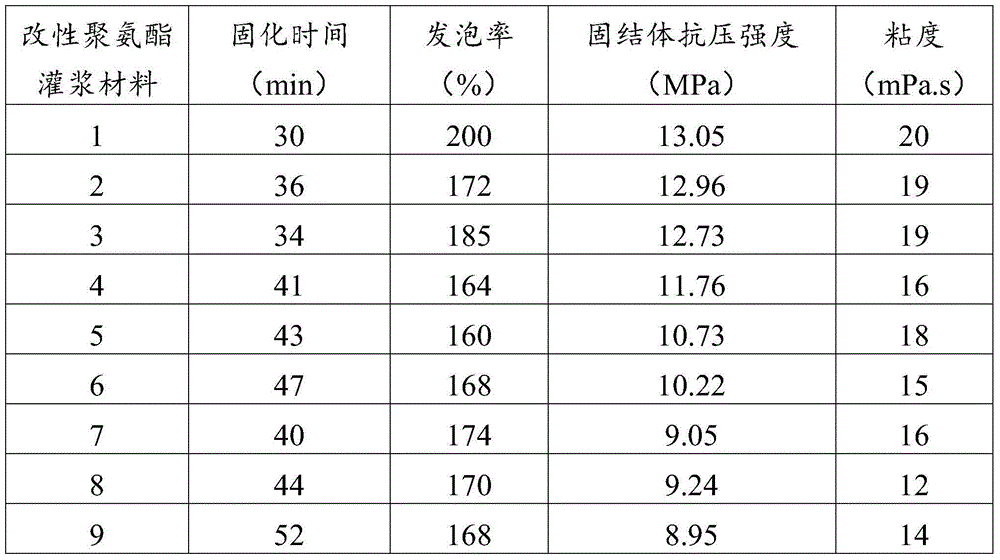

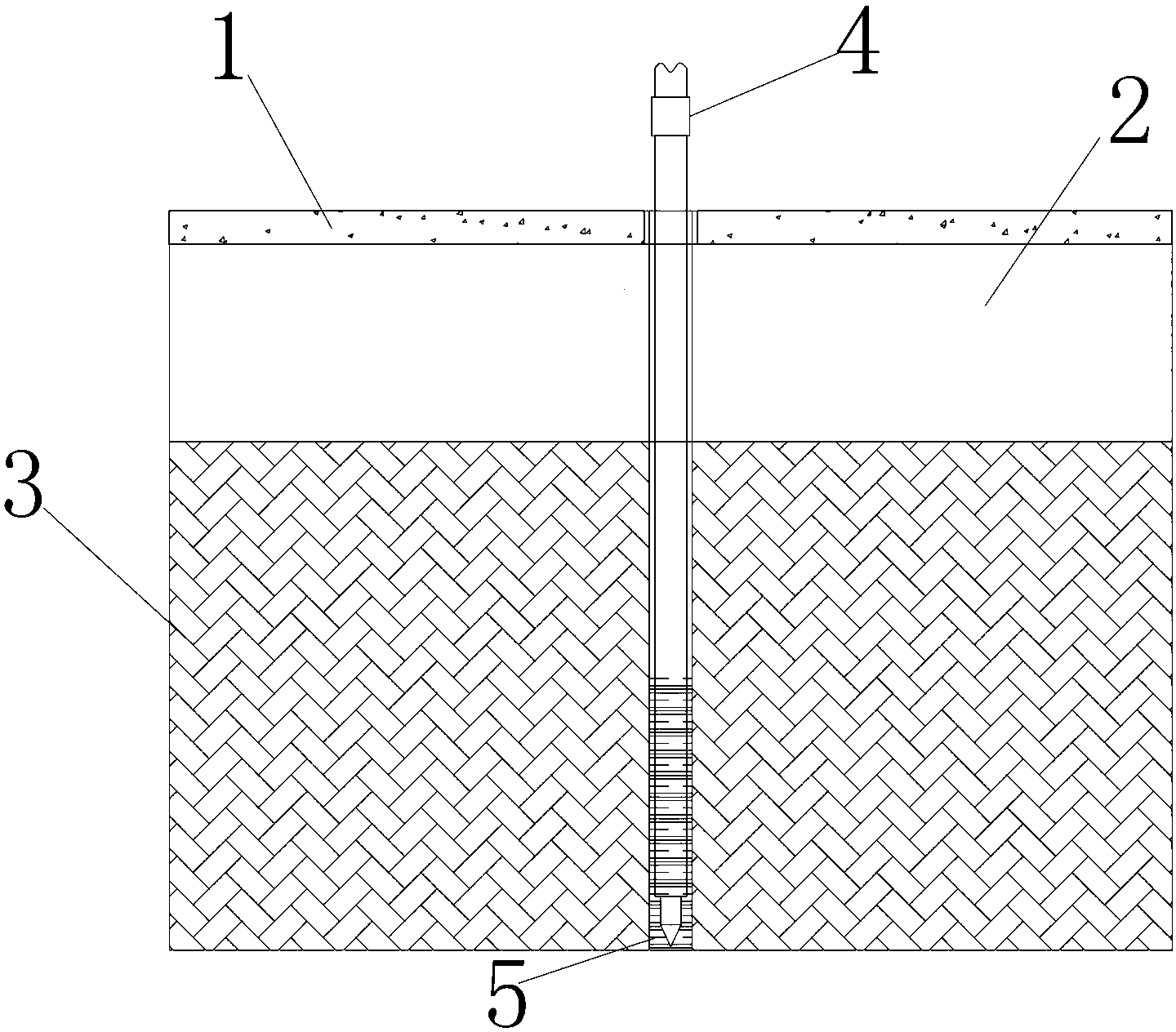

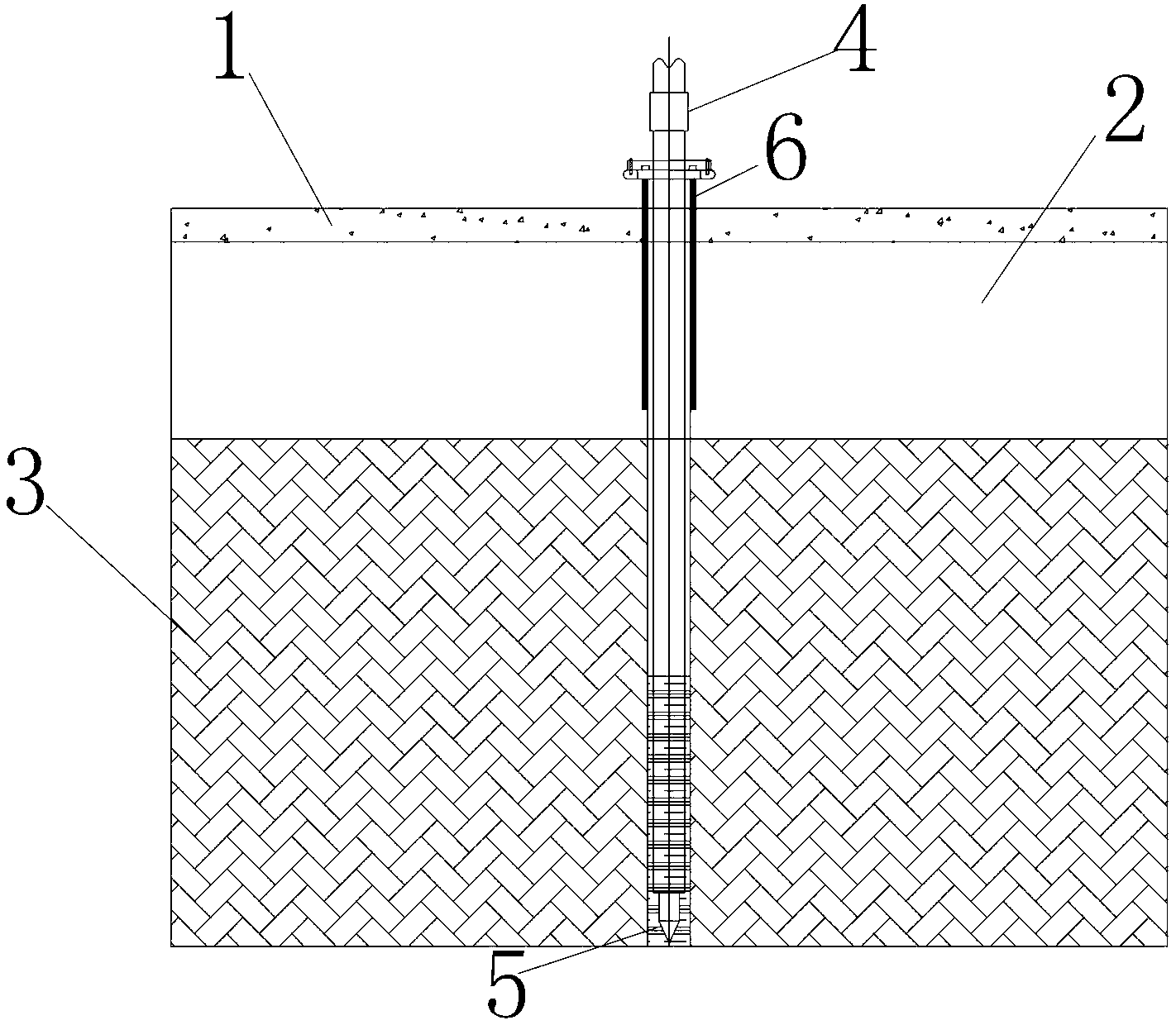

Modified polyurethane grouting material and preparation method and application thereof

ActiveCN104140667ALow costAdjustable setting timeOther chemical processesChemistryEnvironmentally friendly

The invention discloses a preparation method and application of a modified polyurethane grouting material. The preparation method comprises the following steps that firstly, diluents, isocyanate compounds, water and Portland cement make contact and are evenly mixed to obtain a component A, and polymeric alcohol, foam stabilizers and catalysts make contact and are evenly mixed to obtain a component B; secondly, the component A and the component B make contact and are evenly mixed. The preparation method and application of the modified polyurethane grouting material solve the problems of an existing pure polyurethane grouting material that the cost is high, induration strength is low, and an inorganic grouting material is long in setting time and slow in strength development, and the obtained material is low in cost, adjustable in setting time, high in foaming induration strength, good in permeability and environmentally friendly.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Hole sealing grout stop material and grouting hole sealing process

The invention discloses a hole sealing grout stop material, which is a hole sealing grout stop material for guaranteeing grouting pressurization under the condition of loose permeable rock-soil body, high underground level or confined water. The hole sealing grout stop material is mainly prepared from clay primary grout, cement and sodium metaaluminate, wherein every 2 L of clay primary grout is mixed with 700-900 g of cement and 12.5-17.5 g of sodium metaaluminate. A grouting hole sealing process comprises hole sealing operation and grouting operation, wherein the hole sealing operation specifically comprises the following steps of: after forming a hole, dropping a grouting pipe to the bottom of the hole and mounting a orifice closer; opening the orifice closer and injecting the hole sealing grout stop material; closing the orifice closer and flushing the grouting pipe by using stable grout; and opening the orifice closer, performing grouting operation after solidifying the hole sealing grout stop material, and guaranteeing reliable hole sealing grouting through continuous lift grouting. The grouting hole sealing process has the advantages of simple steps, less equipment investment, high applicability, capabilities of guaranteeing the reliability of the hole sealing grout and increasing the grouting efficiency and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

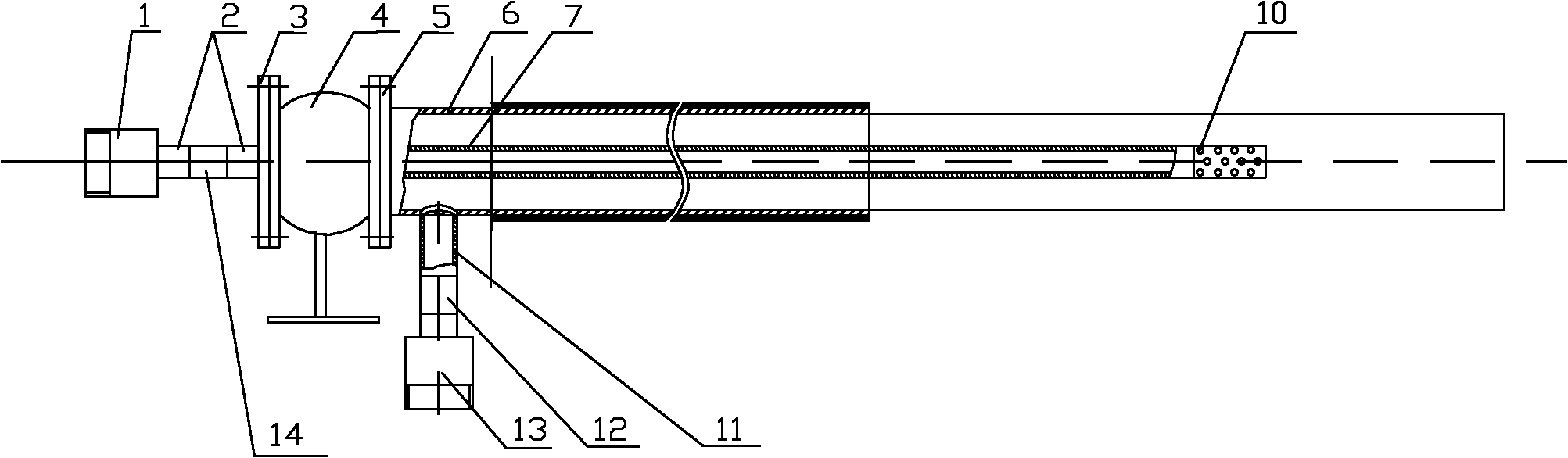

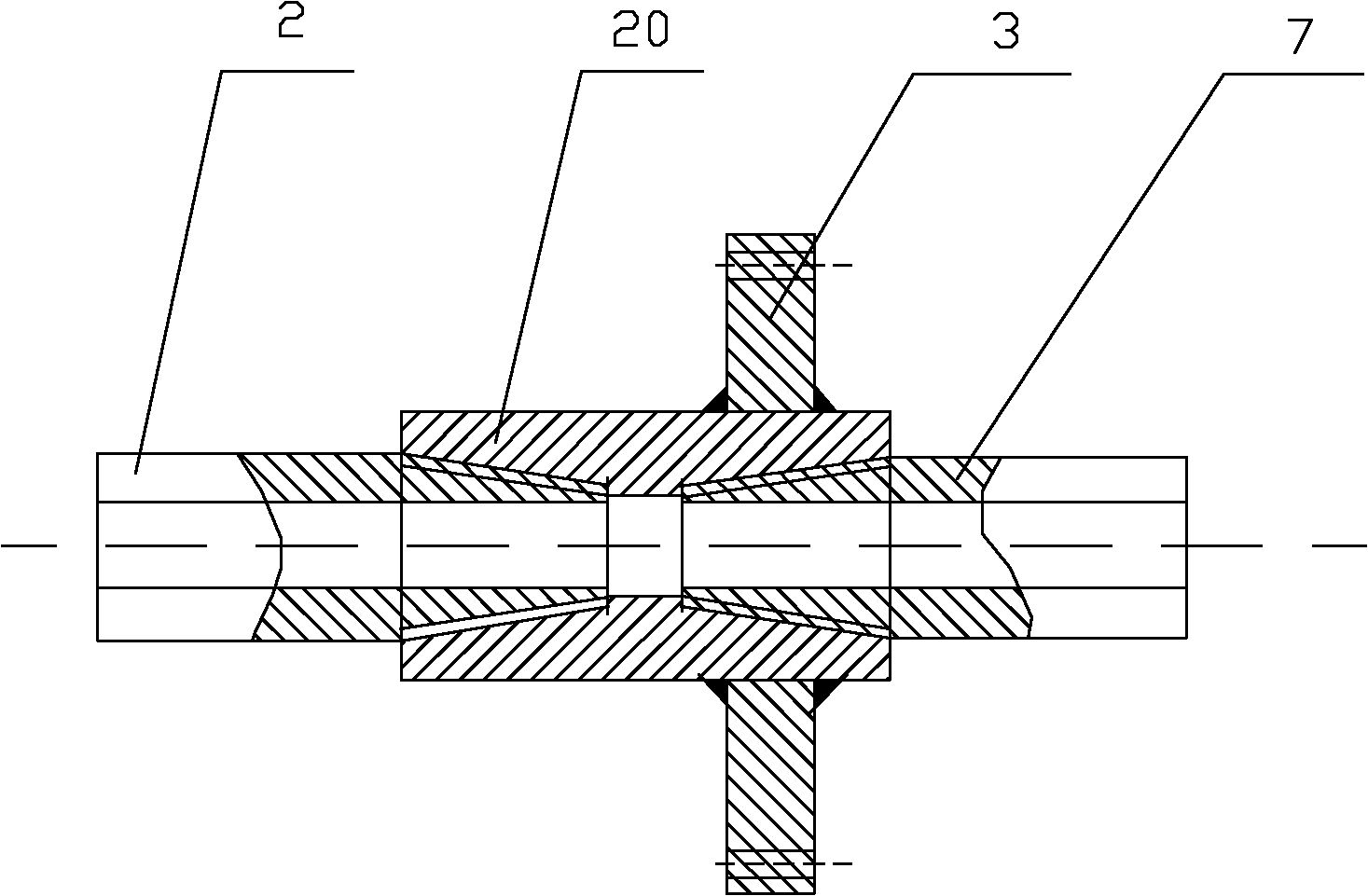

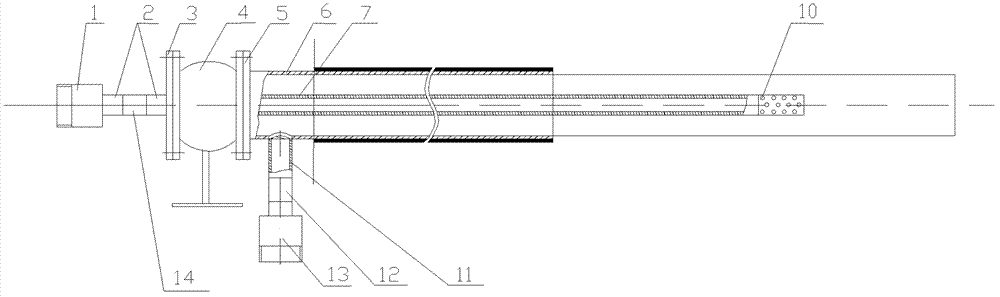

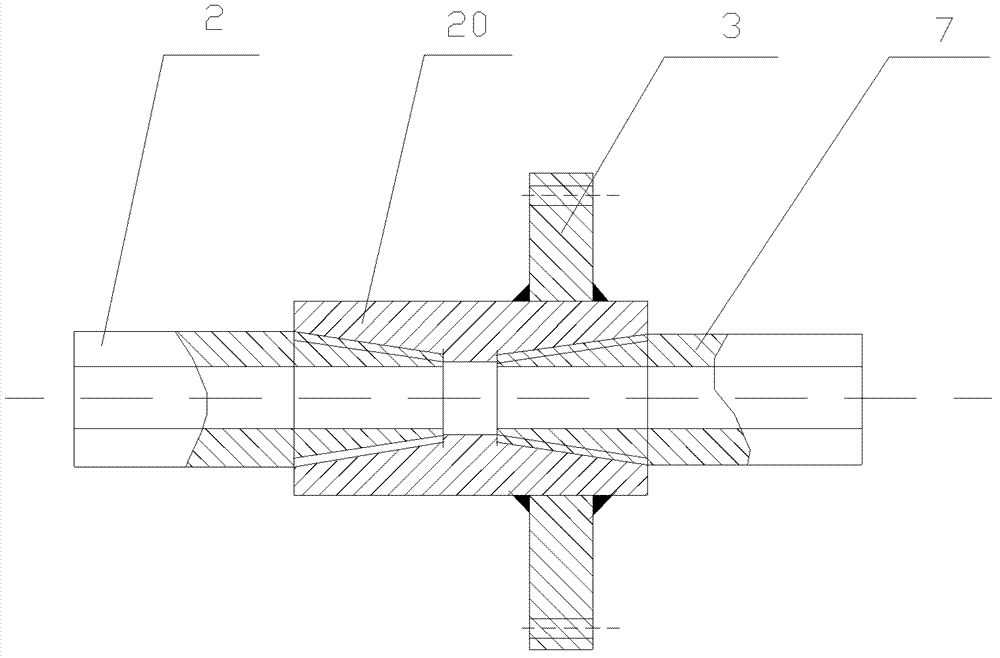

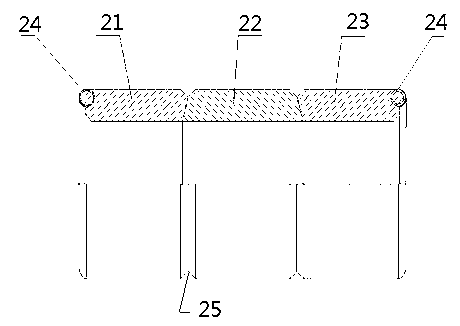

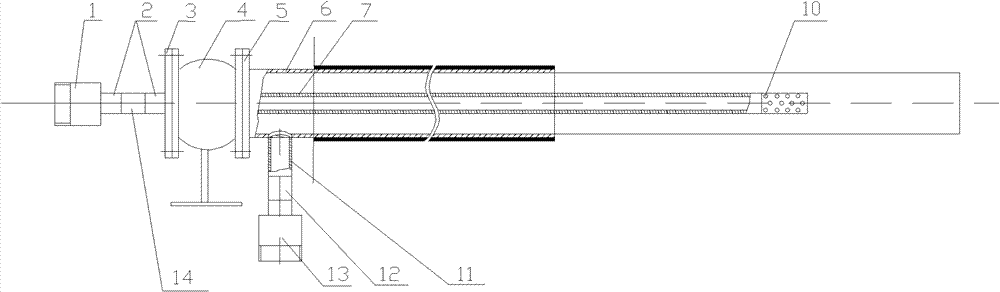

Underground two-fluid grouting device

ActiveCN102852535AEliminate the evil effect of cloggingAdjustable setting timeUnderground chambersTunnel liningDouble tubeEngineering

The invention relates to an underground two-fluid grouting device comprising a grouting inner tube and a grouting outer tube which are nested together, wherein the grouting inner tube and the grouting outer tube are two independent closed pipelines. The grouting inner tube comprises a high-pressure rubber hose joint I, a short tube I, a seal joint, a drill rod and an injector which are sequentially connected, wherein the components are connected to form a closed grouting pipeline, and the short tube I is provided with a check valve I. According to the invention, the drill rod and a drill hole water stopping sleeve are used for being respectively taken as a fluid conveying pipeline, double-tube grouting is realized, depth of a grouting tube in a drill hole is changed for adjusting a position at which two fluids are mixed and the operation time of the mixed fluid in the drill hole, and the aims of adjusting two-fluid solidification time in a deeper drill hole and eliminating a bad result that the drill hole is blocked by the fluid are achieved, so that a better grouting effect is guaranteed.

Owner:SHANDONG UNIV

Binder for installation of thermal insulation decorative plate

The invention provides a binder for installation of a thermal insulation decorative plate. The binder comprises, by weight, 25 to 40% of cement, 25 to 45% of silica sand of 20 to 40 meshes, 8 to 15% of silica sand of 40 to 70 meshes, 3 to 8% of silica sand of 70 to 140 meshes, 0 to 5% of talcum powder, 0 to 5% of ground calcium carbonate powder, 2 to 8% of dispersible latex powder, 0 to 1% of cellulose ether, 0 to 0.6% of plant fibers and 0 to 0.5% of a thixotropic agent. The binder for installation of the thermal insulation decorative plate has the characteristics of high adhesion, strong anti-sliding capability, strong initial adhesion, long construction operation time and difficult skinning, effectively solves the problems produced in thermal insulation decorative plate pasting installation, guarantees enough adhesion between a thermal insulation decorative plate and a wall surface, and improves safety of the thermal insulation decorative plate in engineering application.

Owner:ASIA CUANON TECH SHANGHAI

Polymer cement mortar for quick repair of concrete and preparation method thereof

The invention discloses a polymer cement mortar for quick repair of concrete and a preparation method thereof, and the polymer cement mortar comprises the following components: 15-25% of cement; 40-60% of quartz sand; 5-10% of limestone powder; 6-12% of polymer emulsion; 0.03-0.06% of a defoaming agent; 0.5-1% of a powder water reducing agent; 0.6-0.9% of iron powder; 0.03-0.12% of a coagulation accelerator; 0.05-0.15% of polypropylene fiber; and balance of water. The method can significantly improve the hydration rate of the polymer cement mortar for quick repair of concrete, reduces the shrinkage rate of the polymer cement mortar for quick repair of concrete, also can improve the bonding strength of the polymer cement mortar for quick repair of concrete with old concrete, the mechanical and construction performance and durability in cold environment of the polymer cement mortar for quick repair of concrete can be improved, and the polymer cement mortar for quick repair of concrete is particularly suitable for quick repair of high speed railway reinforced concrete structures.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

Refractory magnesia cement

Disclosed is a hydraulically and chemically bonding refractory cement, which includes a caustic magnesia component having a BET specific surface area of at least 0.5 m2 / g, and a carboxylic acid component, wherein the carboxylic acid component consists of at least one carboxylic acid that is only slightly water soluble and / or has a low dissolution rate in aqueous solutions, and which carboxylic acid component is capable of generating at least one soluble magnesium salt upon contact of the cement with water. Also disclosed is a corresponding refractory material containing the magnesia cement and to uses thereof for the manufacture of products useful in various industries.

Owner:KERNEOS

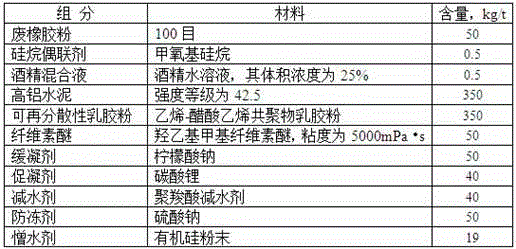

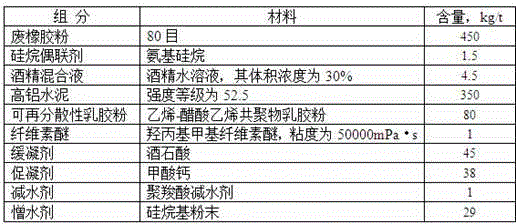

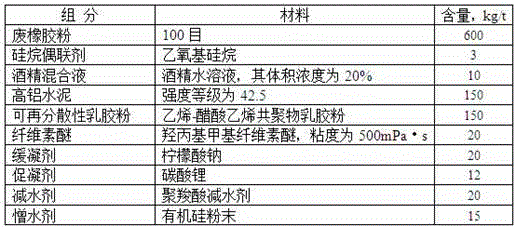

Multifunctional concentrated material used for preparing kitchen and bath cement-based waterproof material

The invention relates to a multifunctional concentrated material used for preparing a kitchen and bath cement-based waterproof material. The multifunctional concentrated material is composed of waste rubber powder, a silane coupling agent, alcohol blend, high-alumina cement, redispersible latex powder, cellulose ether, a delayed coagulant, a coagulation accelerator, a water reducer, an anti-freezing agent (added in winter), and a water repellent, and is a one-component material. The cement-based waterproof material is prepared by mixing the multifunctional concentrated material with cement and quartz powder; is used for kitchen and bath waterproof construction; possesses both excellent characteristics of waterproofing coatings and waterproof mortars, and excellent waterproof performance, so that waterproof effect can be achieved just by a thin coating layer in construction; and also possesses excellent rigidity which is convenient for paving of tiling in following procedures, and is suitable for waterproofing of waterward sides and water lee sides. Addition of waste rubber powder is capable of reducing density of the polymer cement waterproof material, increasing spreading rate of waterproof coatings, changing waste into valuables, and realizing recycling of resources.

Owner:西卡德高(上海)建材有限公司

High-strength consolidation lost circulation additive

The invention discloses a high-strength consolidation lost circulation additive, which consists of the following components in parts by weight: 20-40 parts of calcium carbonate, 5-10 parts of silicon dioxide, 1-4 parts of calcium chloride, 0.1-0.4 part of polyanionic cellulose, 0.1-0.2 part of an XC biopolymer, 5-10 parts of aluminum oxide, 3-8 parts of magnesium oxide and 10-16 parts of oil well cement. The lost circulation additive is prepared by carrying out the following steps: adding the components into a kneading machine based on the parts by weight at normal temperature and under normal pressure according to the conventional preparation method; mixing and stirring uniformly; drying; smashing into a powdery product being 0.01-0.2 millimeter in particle size. The high-strength consolidation lost circulation additive has the characteristics of wide raw material source, high strength, strong suspending power, high mobility, high pumpability, condensing and plugging capabilities, high minimum inflation performance, high solubility, high leakage plugging success rate, simple process and safety in construction, is widely applied to petroleum and geological drilling processes, and is particularly to be applied to fractured hard formations and karst cave formations.

Owner:DONGYING TAIER GASOLINE TECH

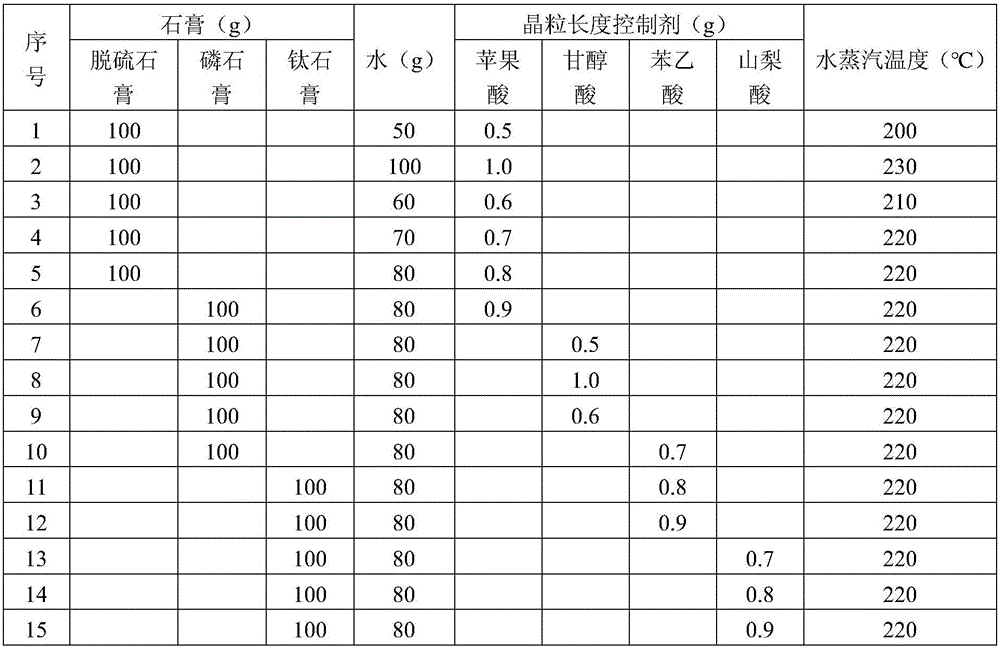

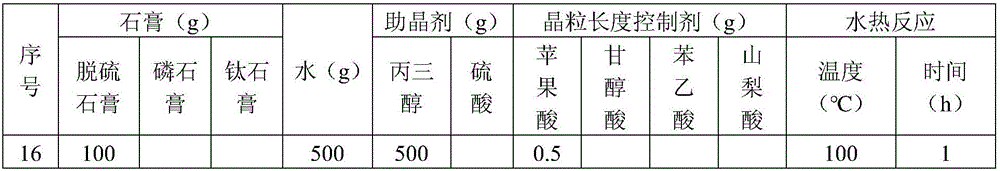

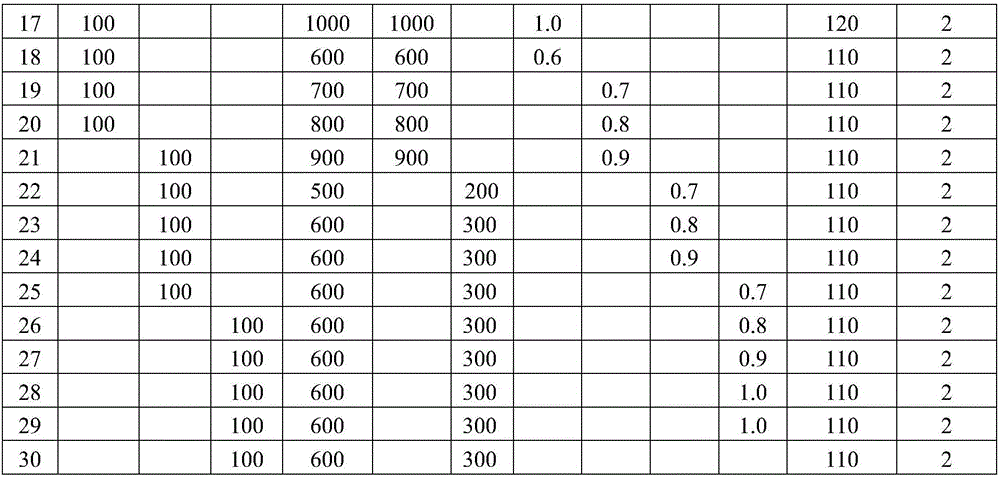

Method for preparing nano high-strength gypsum 3D printing material

ActiveCN106242465AHigh strengthAdjustable setting timeAdditive manufacturing apparatusSolventSetting time

The invention discloses a method for preparing a nano high-strength gypsum 3D printing material; the method comprises the steps: adding water and a crystal grain length controlling agent into gypsum, mixing by a ball mill, and sending the mixture into a water steam phase change ultrafine mill, to obtain nano gypsum; or adding gypsum, water, a nucleation agent and a crystal grain length controlling agent into a reaction kettle, carrying out a hydrothermal reaction, carrying out liquid-solid separation to obtain hemihydrate gypsum, and crushing and drying the hemihydrate gypsum to obtain nano gypsum; or adding gypsum into an autoclave, adding water and a crystal grain length controlling agent, carrying out a hydrothermal reaction to obtain hemihydrate gypsum, and crushing and drying the hemihydrate gypsum to obtain nano gypsum; and adding a setting time controlling agent, a surface modifier, a mortar additive and an enhancer into the obtained nano gypsum, and mixing evenly, to obtain gypsum ink. When the gypsum ink is used, a solvent is added to the gypsum ink and mixed evenly. The product is low in cost and good in performance.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Toughened anti-cracking heat-insulating cement mortar and preparation method thereof

The invention discloses toughened anti-cracking heat-insulating cement mortar and a preparation method thereof, and relates to the technical field of cement mortar. The toughened anti-cracking heat-insulating cement mortar comprises, by parts, 85-105 parts of Portland cement, 25-30 parts of modified zeolite, 25-30 parts of quartz sand, 25-30 parts of butyl acrylate, 10-20 parts of molding agent, 5-10 parts of tributyl phosphate, 5-10 parts of modified coconut fiber, 5-10 parts of carbon fiber and graphene reinforcing agent, 2-6 parts of hydroxypropylmethylcellulose, 2-6 parts of sodium carbonate, 2-6 parts of binder, 1-4 parts of calcium chloride, 1-4 parts of hydroxypropylmethylcellulose ether, 1-4 parts of sodium dodecylbenzene sulfonate and 55-65 parts of water. The anti-cracking performance and the heat insulation of the cement mortar are improved.

Owner:合肥易美特建材有限公司

Composite resin water blocking material and preparation method thereof

InactiveCN109777384AImprove liquidityEasy to achieve long radius pluggingDrilling compositionCross-linkSalicylic acid

The invention discloses a composite resin water blocking material and a preparation method thereof. The composite resin water blocking material comprises the following raw materials in percentage by mass: 3-9% of a formaldehyde solution, 1-4% of phenol, 1-5% of salicylic acid, 0.05-0.3% of sodium hydroxide, 0.5-3% of hydrolyzed polyacrylamide, 0.1-0.5% of a phenolic aldehyde cross-linking agent, 0.2-0.4% of a stabilizer and the balance of water. The preparation method comprises the following steps: putting water and phenol into equipment, heating to 60 DEG C, after the phenol is sufficiently molten, adding sodium hydroxide, and stirring for 30 minutes; adding the formaldehyde solution, heating to 80 DEG C, and continuously stirring for one hour; adding the salicylic acid, and stirring for30 minutes at a constant temperature; adding the hydrolyzed polyacrylamide, and stirring for 2 hours; adding the phenolic aldehyde cross-linking agent, uniformly stirring, and keeping a constant temperature of 90 DEG C, thereby obtaining the composite resin water blocking material 12 hours later. The composite resin water blocking material is applicable to oil-water well water blocking of a low permeability reservoir at a mineralization degree (200,000 mg / L or less) at a temperature (25-120 DEG C), the producible oil index can be increased by 50% or greater, the oil-water well water blocking cost can be lowered, and the economic benefits of oilfield development can be increased.

Owner:SHAANXI CHANGXING PETROLEUM TECH CO LTD

High-strength consolidation plugging agent

ActiveCN103773340BHas the property of consolidatingHigh strengthDrilling compositionSolubilityCellulose

The invention discloses a high-strength consolidation lost circulation additive, which consists of the following components in parts by weight: 20-40 parts of calcium carbonate, 5-10 parts of silicon dioxide, 1-4 parts of calcium chloride, 0.1-0.4 part of polyanionic cellulose, 0.1-0.2 part of an XC biopolymer, 5-10 parts of aluminum oxide, 3-8 parts of magnesium oxide and 10-16 parts of oil well cement. The lost circulation additive is prepared by carrying out the following steps: adding the components into a kneading machine based on the parts by weight at normal temperature and under normal pressure according to the conventional preparation method; mixing and stirring uniformly; drying; smashing into a powdery product being 0.01-0.2 millimeter in particle size. The high-strength consolidation lost circulation additive has the characteristics of wide raw material source, high strength, strong suspending power, high mobility, high pumpability, condensing and plugging capabilities, high minimum inflation performance, high solubility, high leakage plugging success rate, simple process and safety in construction, is widely applied to petroleum and geological drilling processes, and is particularly to be applied to fractured hard formations and karst cave formations.

Owner:DONGYING TAIER GASOLINE TECH

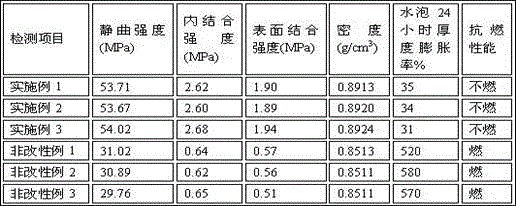

Preparation method and application of water glass modified fiber

InactiveCN106192511AHigh strengthHigh densitySolid waste managementWood working apparatusFiberHigh density

The invention relates to a chemical field, and relates to a preparation method and application of a water glass modified fiber. The preparation method comprises the following steps: grinding dry plant straw or wood slices with barks, spraying a coupling agent into a coarse blend fiber under a vacuum stirring condition, continuously stirring, pressurizing and stirring; then decompressing and vacuumizing, spraying a mixture after water glass is mixed with a water glass coagulating agent, and maintaining vacuum stirring; then pressurizing and stirring; slowly decompressing, then putting in a fluidized bed for drying, obtaining a primary modified fiber after drying, spraying the coupling agent into the primary modified fiber, and uniformly mixing to obtain a secondary modified fiber. A high density board produced by using the modified fiber has the advantages of high density, high strength, small using amount of adhesive and fiber saving, a great number of plant straw smashed fibers can be used, the production cost is greatly reduced, meanwhile the board quality is improved, no waste water or waste residue is discharged in the production process, and the environment is protected; therefore, the water glass modified fiber has great popularization values.

Owner:SHANDONG YUANGEN CHEM TECH RES & DEV CO LTD

Inorganic binding material for assembled prefabricated parts, and preparation method and application thereof

ActiveCN109896830ALow acquisition energy consumption costEmission reductionBridge structural detailsBuilding constructionsFiberWeather resistance

The invention provides an inorganic binding material for assembled prefabricated parts, and a preparation method and an application thereof. The inorganic binding material is prepared from a componentA and a component B, wherein the component A comprises, by weight, 50-100 parts of a magnesium compound, 15-35 parts of fly ash, 0.5-1.5 parts of a superplasticizer and 6-12 parts of a composite retarder; and the component B comprises, by weight, 15-30 parts of phosphate, 50-120 parts of quartz sands, 0.5-5 parts of fibers, 1-3 parts of a waterproofing agent and 3-6 parts of a pH stabilizer. Theinorganic binding material for assembled prefabricated parts has the advantages of adjustable solidification time, high bonding strength, high tensile strength, good bonding durability, low shrinkage,good weather resistance, good high temperature resistance, low cost and environmental friendliness.

Owner:山东塔罗斯智能装备有限公司

Thermal insulation material and method for making the same

ActiveUS10160691B2Easy to adjustFast mechanical performance acquisition kineticsSolid waste managementHeat proofingThermal insulationAmorphous phase

A cellular structure thermal insulation material includes by weight as compared to the material total weight:from 4 to 96% of a hydraulic binder, which prior to being contacted with water, includes at least one phase selected from C3A, CA, C12A7, C11A7CaF2, C4A3$ (Yee lemite), C2A(1-x)Fx (where x belongs to [0, 1]), hydraulic amorphous phases having a C / A molar ratio ranging from 0.3 to 15 and such that cumulated amounts of Al2O3 of these phases be ranging from 3 to 70% by weight of the hydraulic binder total weight,from 4 to 96% of at least one filler,the material having a pore volume ranging from 70% to 95%. The use of a mineral foam for making thermal insulation material as well as methods for making the mineral foam are also described.

Owner:KERNEOS

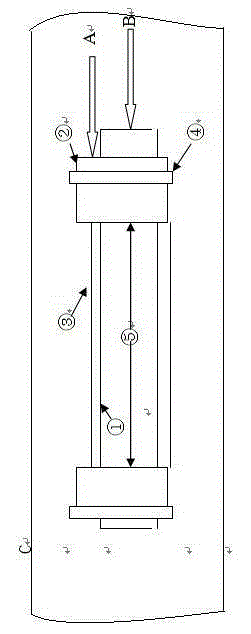

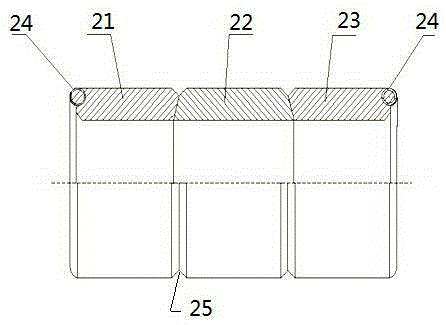

Double-pressurizing-channel packer applied to oil tube sealing and detection

ActiveCN103104214AShort setting timeAdjustable setting timeSealing/packingHydraulic cylinderEngineering

The invention discloses a double-pressurizing-channel packer applied to oil tube sealing and detection. The double-pressurizing-channel packer applied to oil tube sealing and detection comprises a mandrel, a hydraulic cylinder, an outer cylinder, a gauge cutter and rubber sleeves. The outer cylinder is sleeved on the mandrel. The rubber sleeves are respectively arranged at two ends of the outer cylinder and connected with the gauge cutter. The hydraulic cylinder is arranged at one side outside the gauge cutter. A hydraulic oil channel and a high-pressure commingler channel are arranged on the hydraulic cylinder. According to the double-pressurizing-channel packer applied to oil tube sealing and detection, due to the facts that the double-pressurizing-channel packer is small in an inner cavity and low in gas consumption, operation cost is reduced, setting time is short and detection time is saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Cement concrete additive for fast rehabilitating cement concrete road

The invention discloses a formula of a cement concrete additive for fast rehabilitating a cement concrete road. The formula comprises the following raw materials in parts by weight: 12-18 parts of bentonite, 20-23 parts of silicon powder, 0.5-2.5 parts of stearic acid, 2.5-6.5 parts of methylcellulose, 20-25 parts of inorganic matrix material, 13-17 parts of early strength agent, 22-28 parts of water reducing agent, 0.1-10.5 parts of thickening time control agent, 0.2-3.5 parts of corrosion inhibitor, 40-55 parts of slag, 22-27 parts of methacrylic acid, 13-19 parts of polyethylene glycol monoether acrylate monomer, 12-17 parts of sodium allysulfonate, 2.5-4.0 parts of polyether acrylate monomer, 21-24 parts of ferrous sulfate, 13-19 parts of industrial salt, 1.5-3.5 parts of coal ash, 2.5-4.0 parts of calcium carbonate powder, 3.5-5.5 parts of polyacrylamide and 2.0-3.5 parts of lauryl sodium sulfate. The formula of the cement concrete additive for fast rehabilitating the cement concrete road has the characters that cement concrete road maintenance operation time can be greatly shortened, hardening time and solidification time is adjustable, the applicable temperature range is wide, the admixture amount is low, and the like.

Owner:江苏兆佳建材科技有限公司

External-wall door and window rapid waterproof repairing mortar and preparation method thereof

The invention discloses external-wall door and window rapid waterproof repairing mortar and a preparation method thereof. The external-wall door and window rapid waterproof repairing mortar comprisesthe following components in parts by weight: 250-350 parts of ordinary Portland cement, 100-150 parts of sulphoaluminate cement, 7-10 parts of calcium oxide, 150-200 parts of water, 20-30 parts of metakaolin, 30-60 parts of filler, 300-400 parts of quartz sand, 1.5-2.5 parts of cellulose ether, 1.5-2.5 parts of wood fiber, 0.5-1.5 parts of water reducing agent, 5-15 parts of rubber powder, 3-8 parts of calcium formate, and 2-5 parts of retarder. The external-wall door and window rapid waterproof repairing mortar has the advantages of less components, low raw material cost, no shrinkage, micro-expansion function, no cracking, high density, high strength and leakage resistance.

Owner:湖南大迈新材科技有限公司

Slow-seepage-resistant waterproof plugging mortar and preparation method thereof

The invention discloses slow-seepage-resistant waterproof leaking stoppage mortar and a preparation method thereof. The formula and the manufacturing process of the mortar are reasonable in design and convenient to use; cement, sand and mineral admixtures serve as composite gel components, and a water-borne epoxy resin emulsion and a water-borne epoxy curing agent can adjust the setting time of the mortar, so the strength, anti-permeability and other properties of the mortar are improved, and the mortar has good waterproof and anti-permeability properties; and in addition, a super absorbent polymer is wrapped by a water-soluble polymer to form a microcapsule, the super absorbent polymer does not participate in a reaction during stirring, mixing and cement solidification in virtue of the characteristic of slow dissolution of the water-soluble polymer, but the surface of the microcapsule is dissolved when mortar cracks and water flows into the microcapsule, so the water-absorbent polymer can quickly block cracks by utilizing the water absorption expansibility of the water-absorbent polymer, and a certain leakage self-repairing function is obtained.

Owner:河南省禹志建设工程有限公司

Underground double liquid grouting process and underground double liquid grouting machine thereof

ActiveCN102080552BEliminate the evil effect of cloggingAdjustable setting timeUnderground chambersFlushingSlurryPulp and paper industry

The invention relates to an underground double liquid grouting process, which comprises the following steps: (1) making preparations for implementing the double liquid grouting process and judging whether the grouting conditions are met; and (2) implementing the double liquid grouting process. The invention also discloses an underground double liquid grouting machine. An underground double liquidgrouting machine comprises an inner grouting tube and an outer grouting tube which are nested together, wherein the inner and outer grouting tubes are two independent airtight tubes. According to theinvention, a drill rod and a drill hole water-stopping casing pipe are respectively used as a grout conveying pipeline, the double pipeline grouting is realized, and the position for mixing two grouts and the running time of the grouts in the drill hole after the grouts are mixed are both adjusted by changing the depth of the grouting tubes in the drill hole, thus achieving the purpose of adjusting the coagulation time of the double grouts in the deeper drill hole and eliminating the disastrous effect of blocking the drill hole with the grouts, thereby ensuring a better grouting effect.

Owner:SHANDONG UNIV

A prefabricated prefabricated component inorganic bonding material, preparation method and application

ActiveCN109896830BLow acquisition energy consumption costEmission reductionBridge structural detailsBuilding constructionsFiberPhosphate

The invention provides an inorganic bonding material for prefabricated prefabricated components and its preparation method and application. The inorganic bonding material is prepared from component A and component B; wherein, component A consists of the following raw materials in parts by weight Composition: 50-100 parts of magnesium compound, 15-35 parts of fly ash, 0.5-1.5 parts of high-efficiency superplasticizer, 6-12 parts of composite retarder; component B is composed of the following raw materials in parts by weight: phosphate 15- 30 parts, 50-120 parts of quartz sand, 0.5-5 parts of fiber, 1-3 parts of water resistance agent, 3-6 parts of pH stabilizer. The inorganic bonding material for assembled prefabricated components prepared by the present invention has adjustable solidification time, high bonding strength, high tensile strength, good bonding durability, low shrinkage, good weather resistance, good high temperature resistance, and low cost , Environmental friendliness and so on.

Owner:山东塔罗斯智能装备有限公司

Dual pressurized channel packer for tubing leak detection

ActiveCN103104214BShort setting timeAdjustable setting timeSealing/packingHydraulic cylinderEngineering

The invention discloses a double-pressurizing-channel packer applied to oil tube sealing and detection. The double-pressurizing-channel packer applied to oil tube sealing and detection comprises a mandrel, a hydraulic cylinder, an outer cylinder, a gauge cutter and rubber sleeves. The outer cylinder is sleeved on the mandrel. The rubber sleeves are respectively arranged at two ends of the outer cylinder and connected with the gauge cutter. The hydraulic cylinder is arranged at one side outside the gauge cutter. A hydraulic oil channel and a high-pressure commingler channel are arranged on the hydraulic cylinder. According to the double-pressurizing-channel packer applied to oil tube sealing and detection, due to the facts that the double-pressurizing-channel packer is small in an inner cavity and low in gas consumption, operation cost is reduced, setting time is short and detection time is saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Controllable grouting liquid for coal mining and tunnel engineering and preparation method thereof

ActiveCN108715526AGood permeability and pourabilityIncreased Strength and DurabilityUnderground chambersTunnel liningEmulsionHardness

The invention belongs to the technical field of tunnel and coal seam mining, and provides a controllable grouting liquid for coal mining and tunnel engineering and a preparation method thereof for solving the problems that the current grouting liquid is not easy to enter cracks and easy to block grouting holes and the like. The controllable grouting liquid is prepared by mixing ultrafine sulfate cement, redispersible emulsion powder, a high-efficiency water reducer FDN, nano-silica, calcined gypsum, alunite powder, lithium carbonate, wooden calcium and water according to in a certain ratio. The controllable grouting liquid has the advantages that raw materials are easy to obtain, the condensation rate of the grouting liquid is controllable, the workability is good, the pumping effect is good, the water repellency is low, the surface hardness is high, the later strength is stable and does not shrink, the production cost is low, the construction speed is high, the work efficiency is high, and the environment is protected. The grouting liquid can be effectively poured in micro-cracks, is capable of enlarging a grouting radius, and is of great significance for the rapid lining supportreinforcement of a tunnel and the pollution-free, safe and efficient mining of coal. With the adoption of the controllable grouting liquid, emergency rescue projects can be dealt with easily, the construction speed is high, the work efficiency is high and the construction time is saved.

Owner:CHINA RAILWAY 12TH BUREAU GRP +2

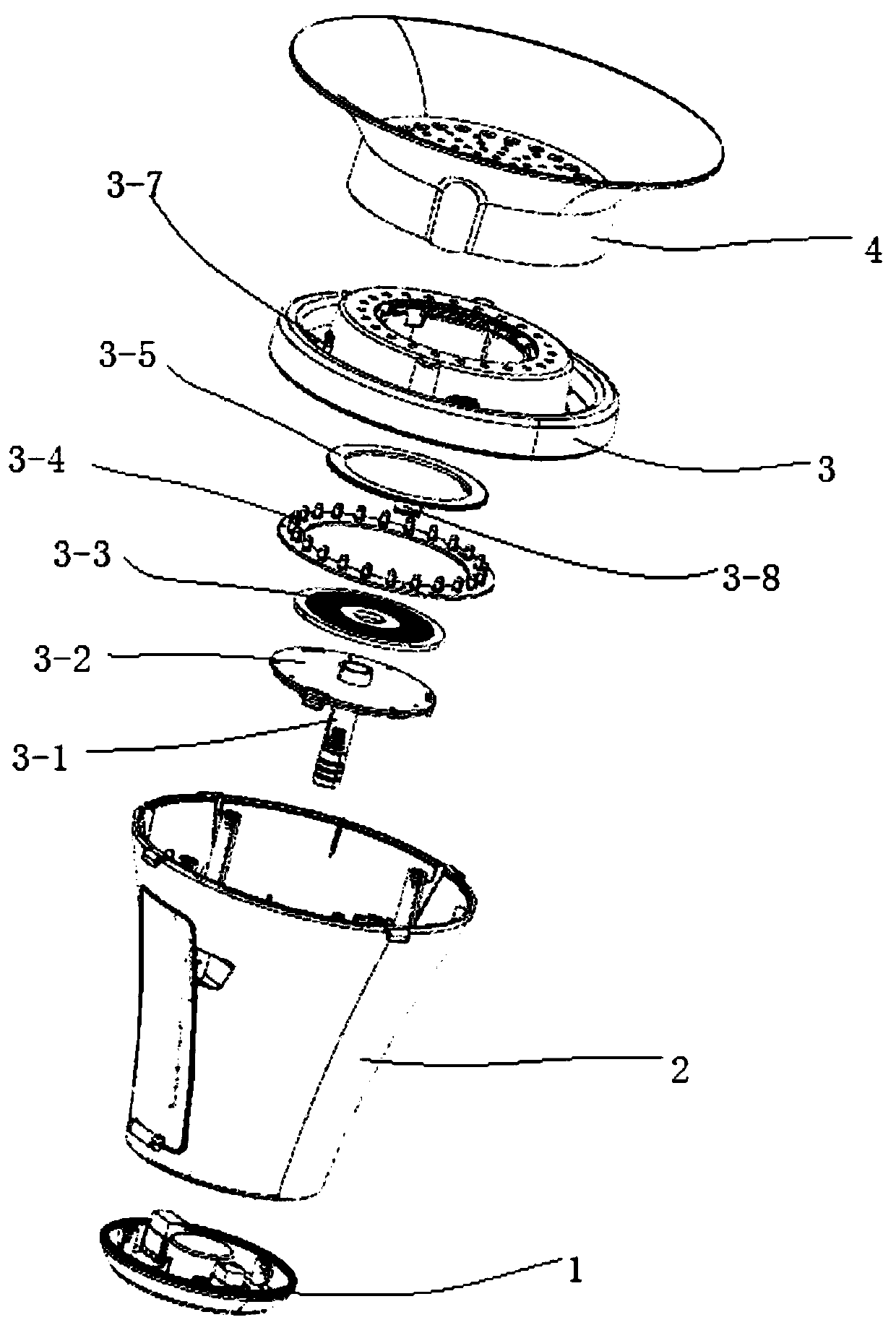

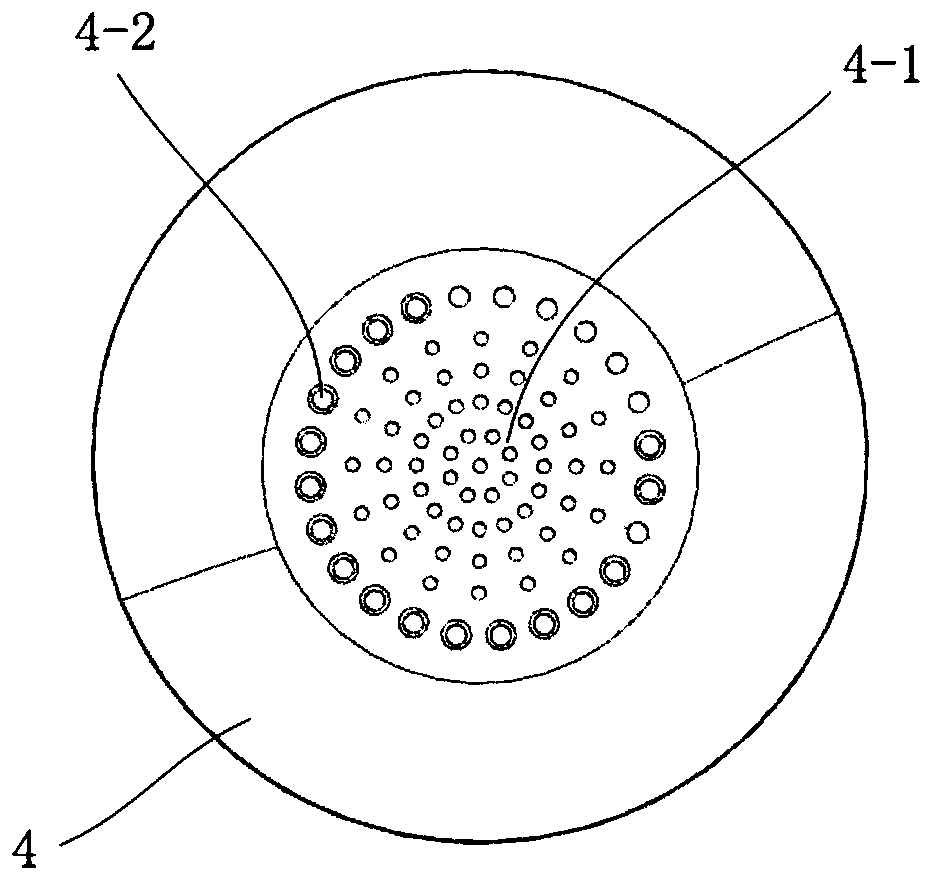

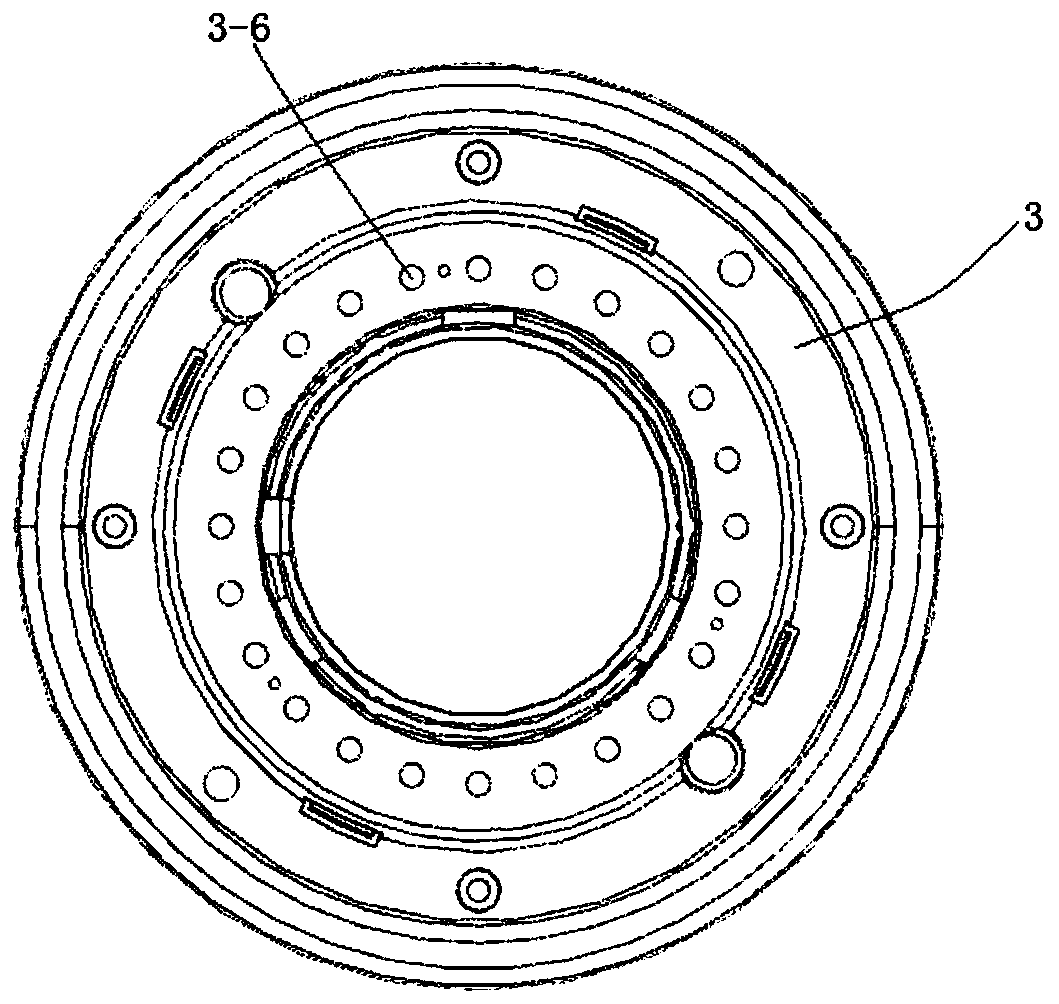

Fumigation therapy handpiece and device with the same

PendingCN109998900AIncrease automatic sprinklerIncrease ceramic heatingMedical devicesBathing devicesEngineeringMedical device

The invention relates to the field of medical devices, and discloses a fumigation therapy handpiece and a device with the same. The handpiece comprises a control box, a bottom plate, a connecting pipe, a fixing pipe and a handpiece body. The handpiece body is fixedly connected with the control box through the connecting pipe. The control box is connected with the bottom plate through the fixing pipe. The fumigation therapy device can be oriented at multiple angles and can rotate by 360 degrees to completely free two hands; the functions of automatic spraying, ceramic heating and the like are added, and the handpiece body is controlled through the control box; the fumigation therapy handpiece can adjust the temperature and set the time.

Owner:深圳瀚方生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com