Preparation method and application of water glass modified fiber

A technology of modified fiber and water glass, which is applied in the preparation of building board materials and the preparation of water glass modified fiber. It can solve the problems of low strength of finished products, poor heat preservation effect, and large investment in production equipment, so as to improve the quality of boards, The effect of reducing production cost and adjustable setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

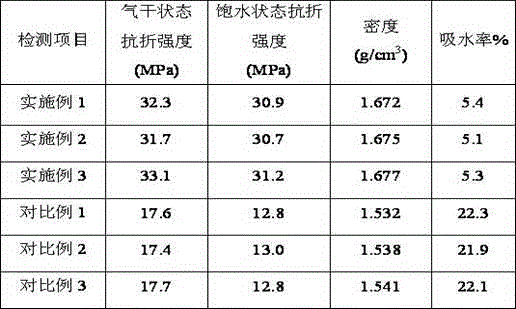

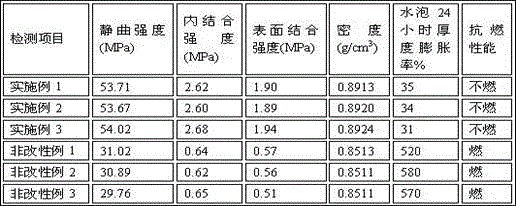

Embodiment 1

[0020] Embodiment 1, this embodiment provides a preparation method of water glass modified fiber and its specific application process. It specifically includes the following steps: coarsely grind dry plant stalks or wood chips with bark into coarse mixed fibers with a length less than 50mm and a diameter less than 2mm; The wood is directly coarsely ground into the fiber, and the stirring is continued for 15 minutes, and then the pressure is increased to 12MPa, and the stirring is continued for 30 minutes. Slowly release the pressure and then evacuate until the vacuum degree reaches below 0.09MPa. Mix 30% water glass by weight of fiber and 1.5% water glass curing agent by weight of water glass and spray it into the plant or wood fiber under vacuum stirring state, continue to stir for 20 minutes, then pressurize to 10MPa, and continue to stir for 30 minutes. After slowly releasing the pressure, the material is dried on a fluidized bed at a temperature of 130 degrees to obtain p...

Embodiment 2

[0023] Embodiment 2, this embodiment provides a preparation method of water glass modified fiber and its specific application process. It specifically includes the following steps: coarsely grind dry plant straw or bark wood chips into coarse mixed fibers with a length of less than 50mm and a diameter of less than 2mm; Plants or wood are directly coarsely ground into fibers, and continue to stir for 22 minutes, then pressurize to 25MPa, and continue to stir for 10 minutes. Slowly release the pressure and then evacuate until the vacuum degree reaches below 0.09MPa. Mix 35% water glass by weight of fiber and 1.5% water glass curing agent by weight of water glass and spray it into the plant or wood fiber under vacuum stirring state, continue to stir for 25 minutes, then pressurize to 15MPa, and continue to stir for 30 minutes. After slowly releasing the pressure, the material is dried on a fluidized bed at a temperature of 140 degrees to obtain a primary modified fiber. Spray 2...

Embodiment 3

[0026] Embodiment 3, this embodiment provides a preparation method of water glass modified fiber and its specific application process. It specifically includes the following steps: coarsely grind dry plant straw or wood chips with bark into coarse mixed fibers with a length of less than 50mm and a diameter of less than 2mm; The plant or wood is directly coarsely ground into the fiber, and the stirring is continued for 30 minutes, and then the pressure is increased to 20MPa, and the stirring is continued for 25 minutes. Slowly release the pressure and then evacuate until the vacuum degree reaches below 0.09MPa. Mix 40% water glass by weight of fiber and 1.5% water glass curing agent by weight of water glass and spray it into the plant or wood fiber under vacuum stirring state, continue to stir for 20 minutes, then pressurize to 10MPa, and continue to stir for 30 minutes. After slowly releasing the pressure, the material is dried on a fluidized bed at a temperature of 145 degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com