Patents

Literature

211results about How to "Reduce the amount of glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

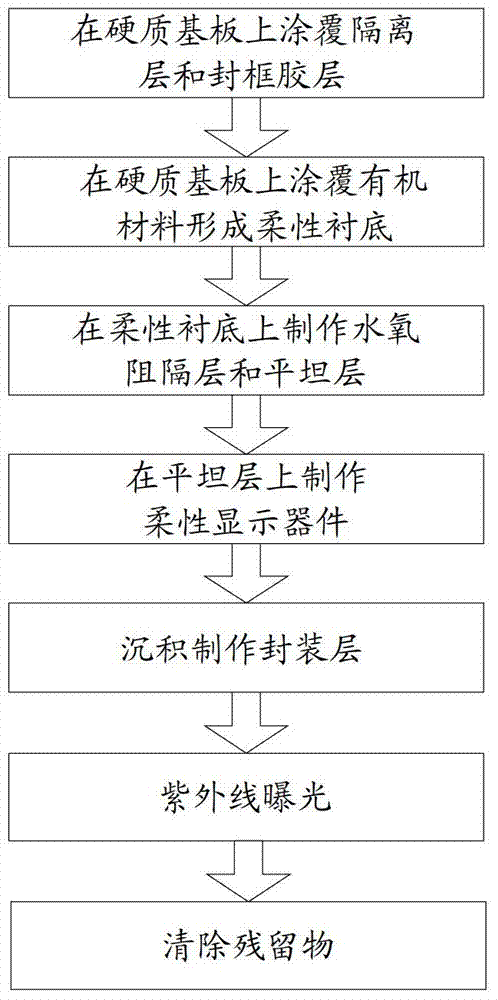

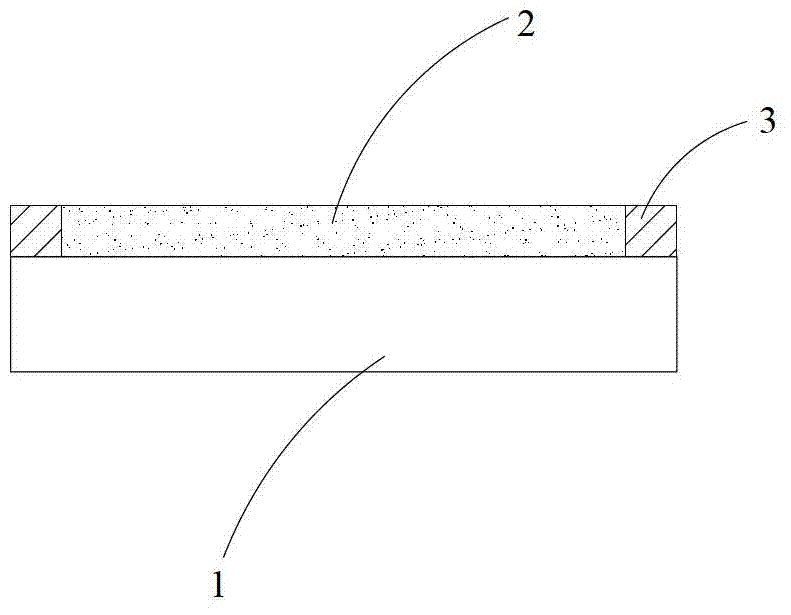

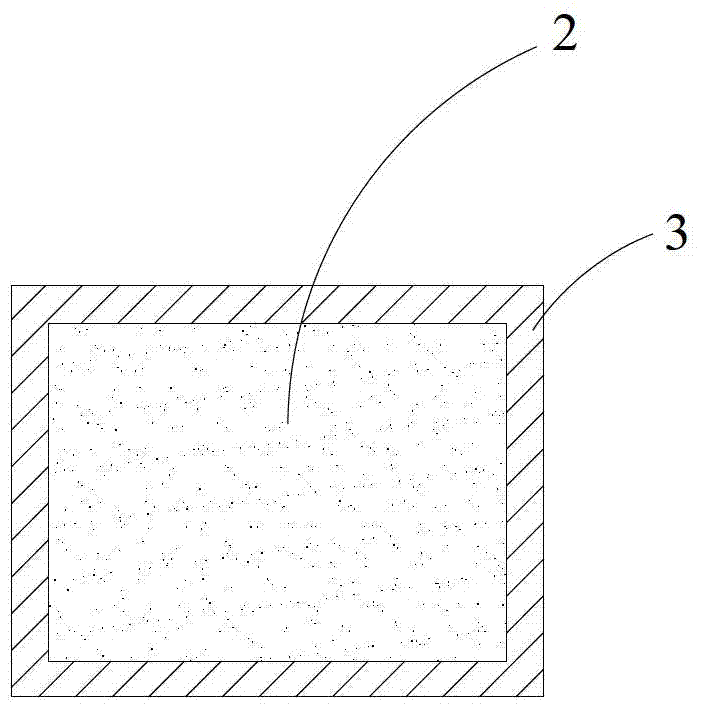

Manufacturing method of flexible display device

ActiveCN103325731AGood flexibilityImprove display qualitySolid-state devicesSemiconductor/solid-state device manufacturingIsolation layerUltraviolet

The invention belongs to the field of displayers, and discloses a manufacturing method of a flexible display device. The manufacturing method of the flexible display device comprises the following steps that a rigid substrate is coated with an isolation layer and a frame sealing glue layer, the rigid substrate is coated with organic materials to form a flexible substrate, a flexible display device is manufactured on the flexible substrate, ultraviolet exposure is conducted, and residues are removed. According to the manufacturing method of the flexible display device, radical group matter is added to enable the isolation layer to have anti-adhesion performance, the periphery of the isolation layer is coated with the modified frame sealing glue layer, the frame sealing glue layer has good anti-adhesion performance, the ultraviolet exposure is conducted, the frame sealing glue layer is resolved, and therefore the flexible substrate is naturally separated from the rigid substrate. According to the manufacturing method of the flexible display device, separating performance is good, the residues are few, technological process is simple, and the manufactured flexible display device is good in flexibility, and good in display quality.

Owner:TCL CORPORATION

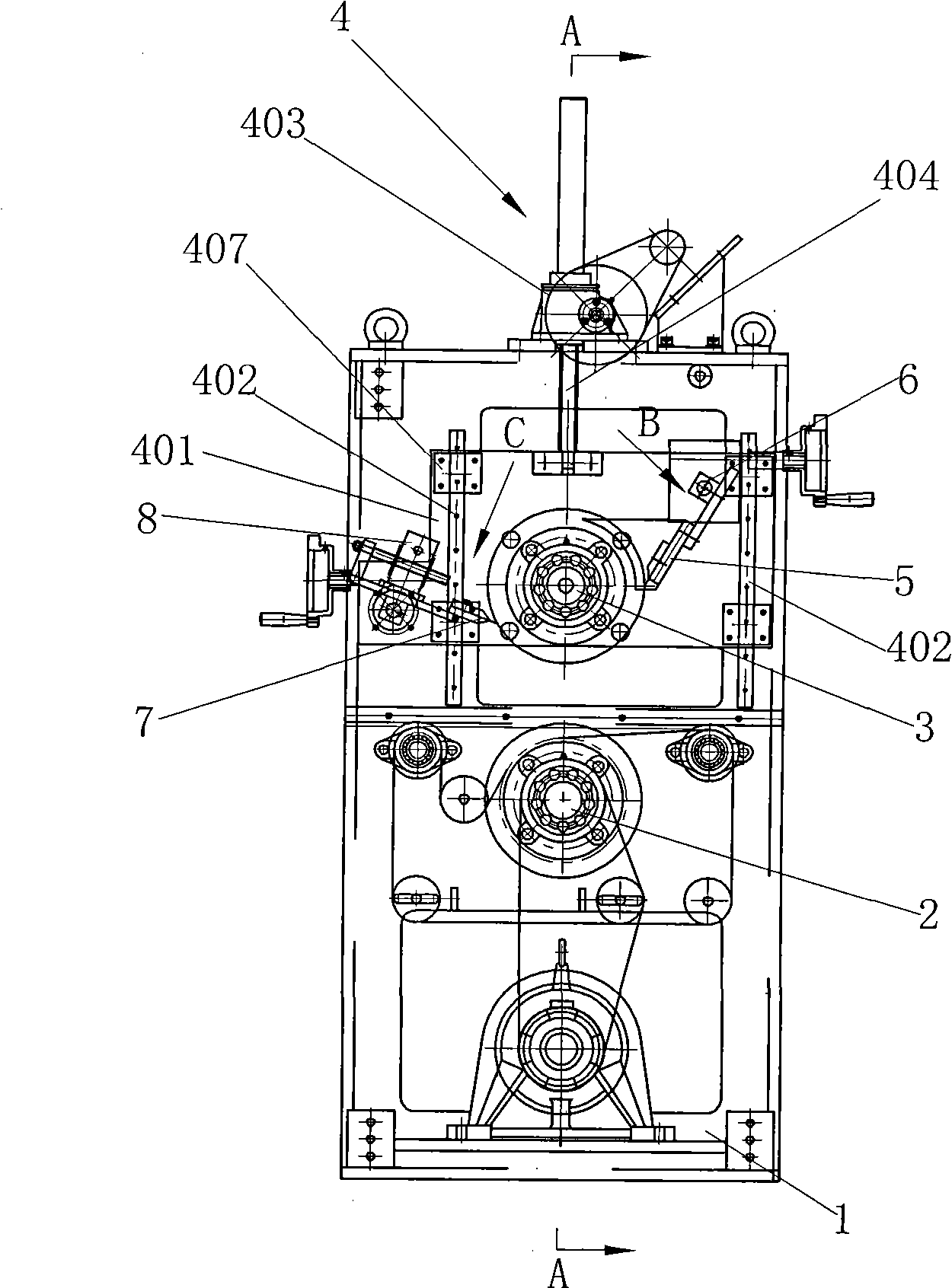

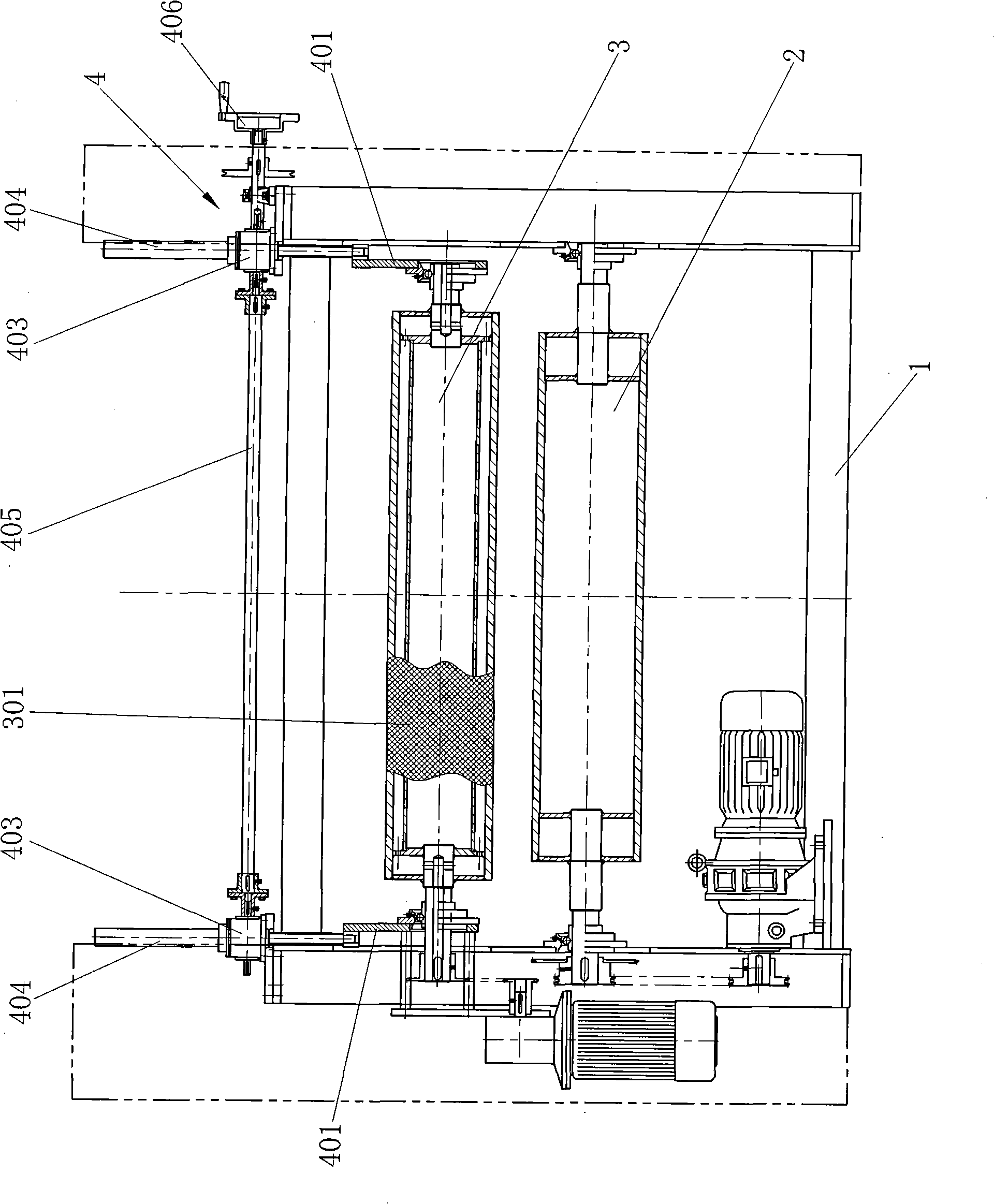

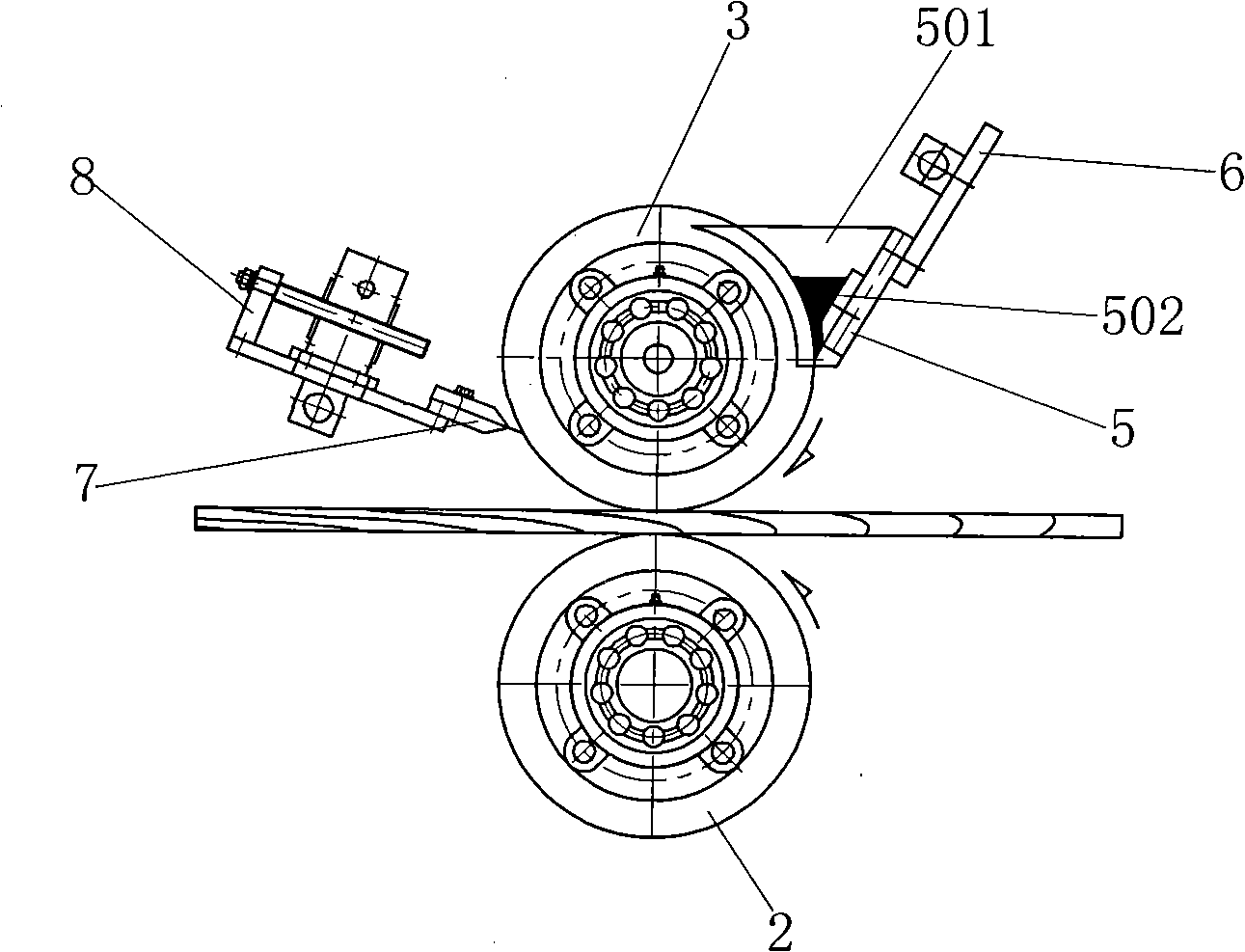

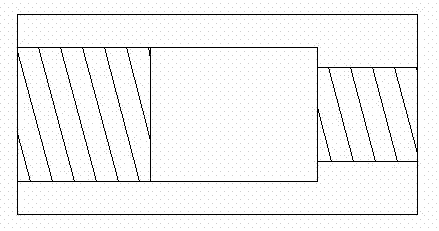

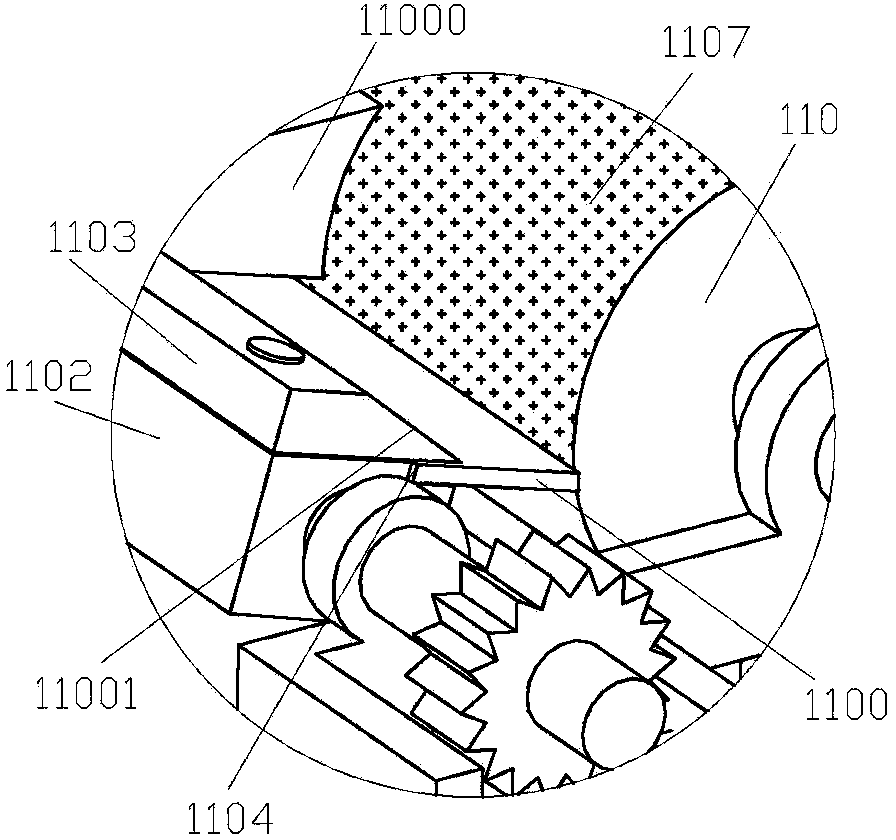

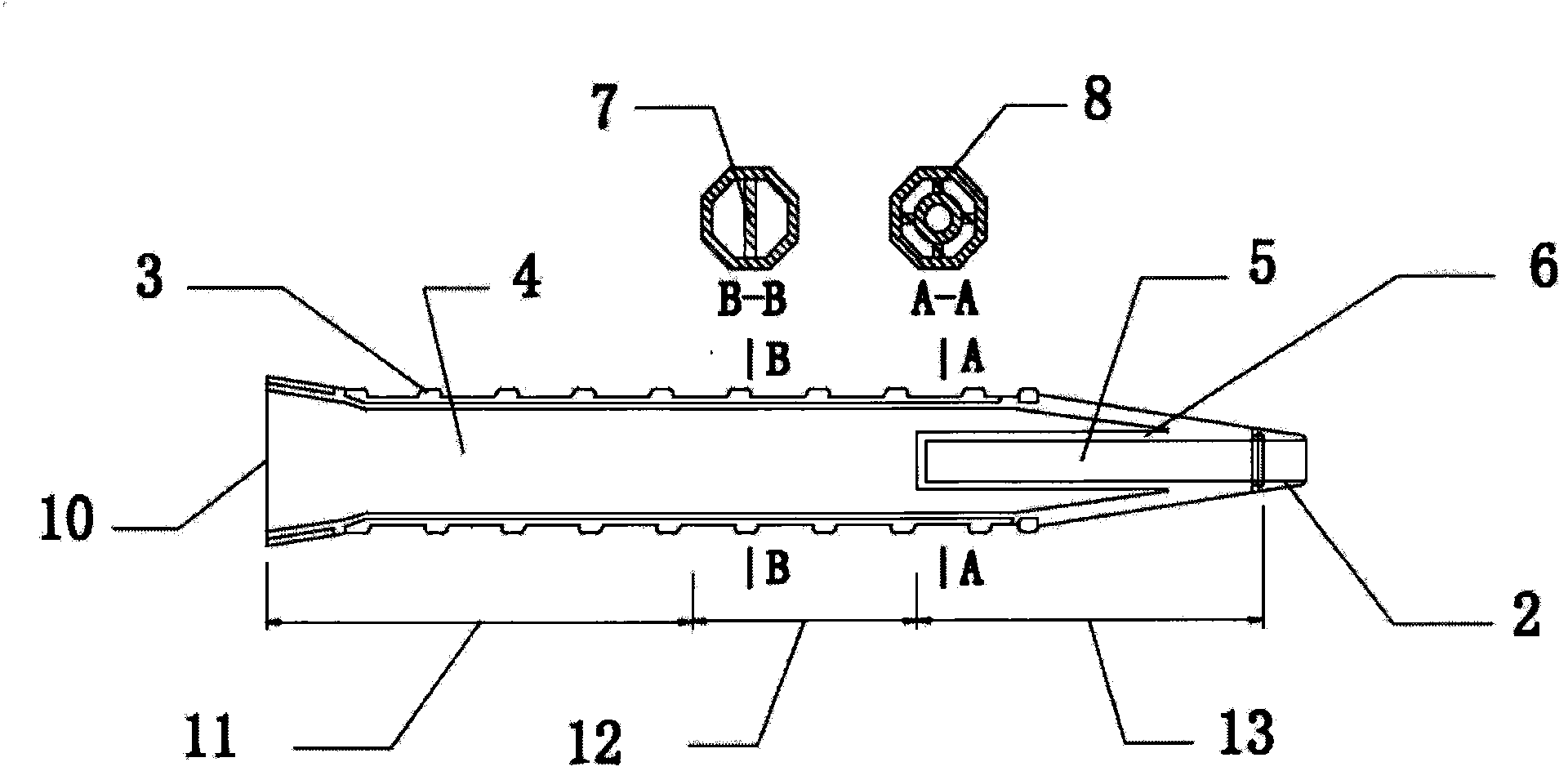

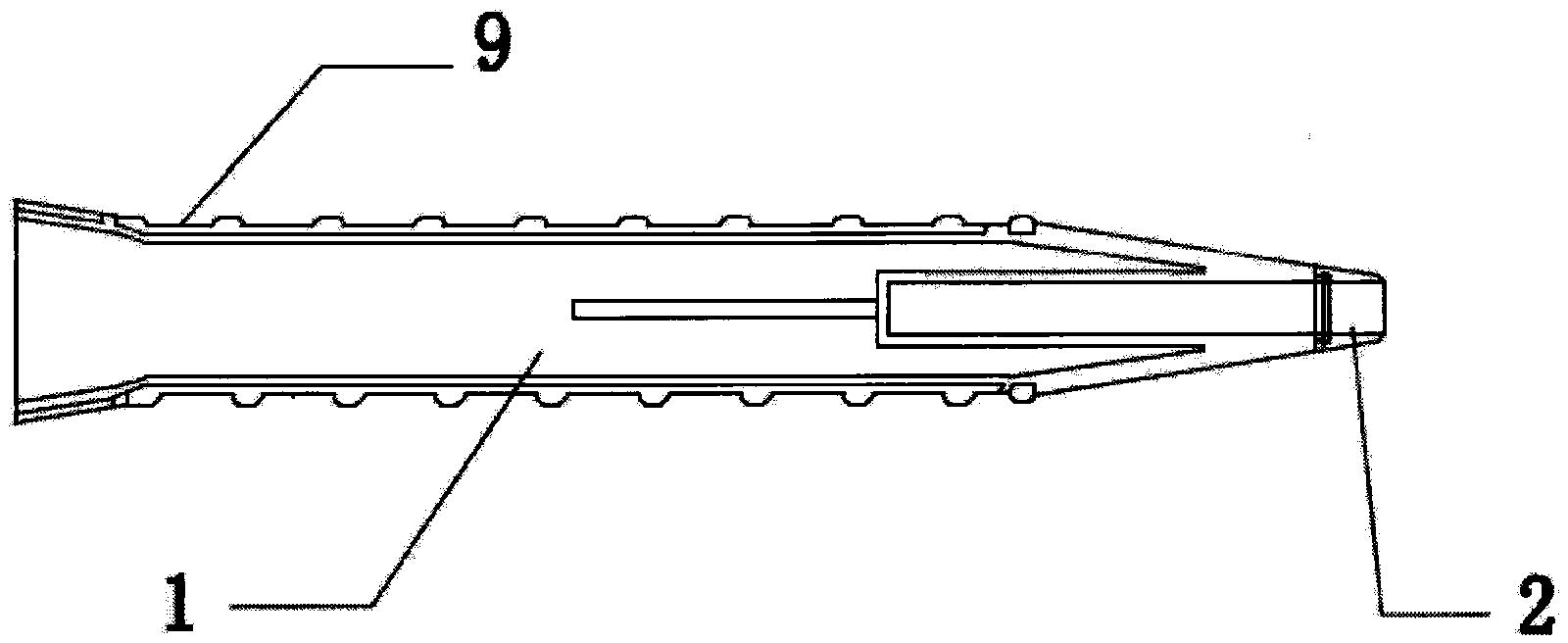

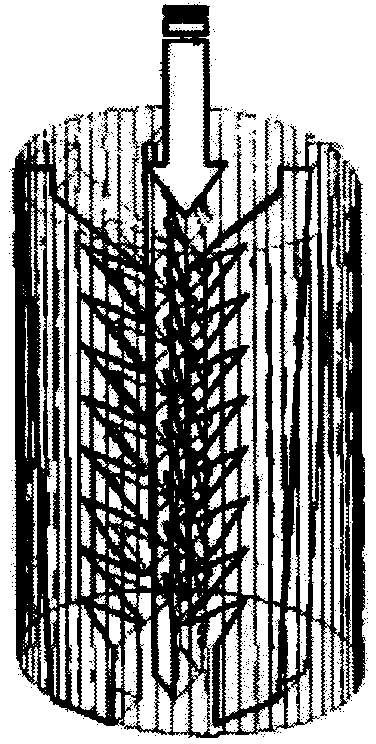

Glue spreader

ActiveCN101862723AGuarantee paste qualityReduce the amount of glueLiquid surface applicatorsCoatingsKnurlingPulp and paper industry

The invention relates to a glue spreader, which comprises a rack. The two ends of a conveying support roller are arranged on the rack. A glue spreading roller is arranged above the conveying support roller. The conveying support roller and the glue spreading roller are respectively connected with a driving mechanism. The invention is characterized in that the two ends of the glue spreading roller are arranged on a lifting mechanism which is arranged on the rack, the surface of the glue spreading roller is provided with hatching knurling, one side of the glue spreading roller is provided with a measurement scraper which is connected with a measurement adjusting mechanism and the measurement adjusting mechanism is arranged on the lifting mechanism. The surface of the glue spreading roller is provided with the hatching knurling. Proper glue volume can be controlled and glue can be spread on the surface of base material evenly. When the surface course pasting quality is ensured, the glue usage amount and the manufacture cost are reduced.

Owner:WUXI SHENGJIN MACHINERY

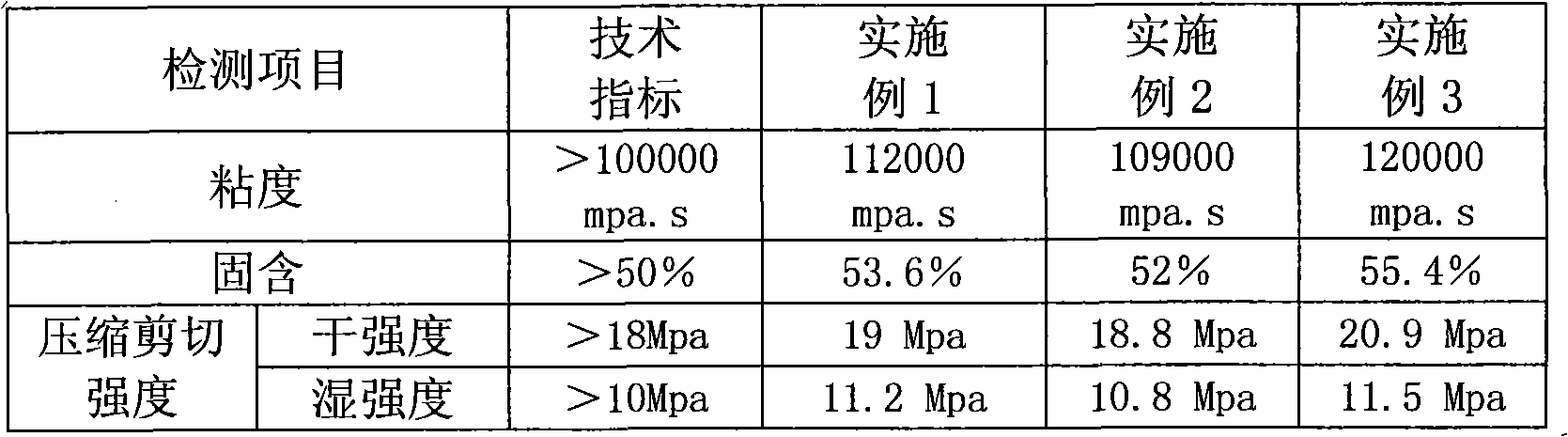

High performance aqueous adhesive composition for artificial lawn back rubber

ActiveCN101475783AImprove wetting propertiesExcellent pull-out forceHydrocarbon polymer adhesivesPolymer sciencePortion size

The invention discloses a high-performance aqueous adhesive composition for gum application in an artificial lawn. The adhesive composition can remarkably improve drawing force, reduce the use amount of gum substantially and reduce cost. The high-performance aqueous adhesive composition for gum application in the artificial lawn comprises the following compositions in portion by weight: 100 portions of carboxylic styrene butadiene latex, 5 to 60 portions of tackifying resin, 50 to 400 portions of filler, 0 to 5 portions of thickening agent and 0 to 3 portions of paint; and the portion of water is used to adjust the viscosity of an adhesive composition system between 5,000 and 50,000 MPa.s.

Owner:COCREATION GRASS CO LTD

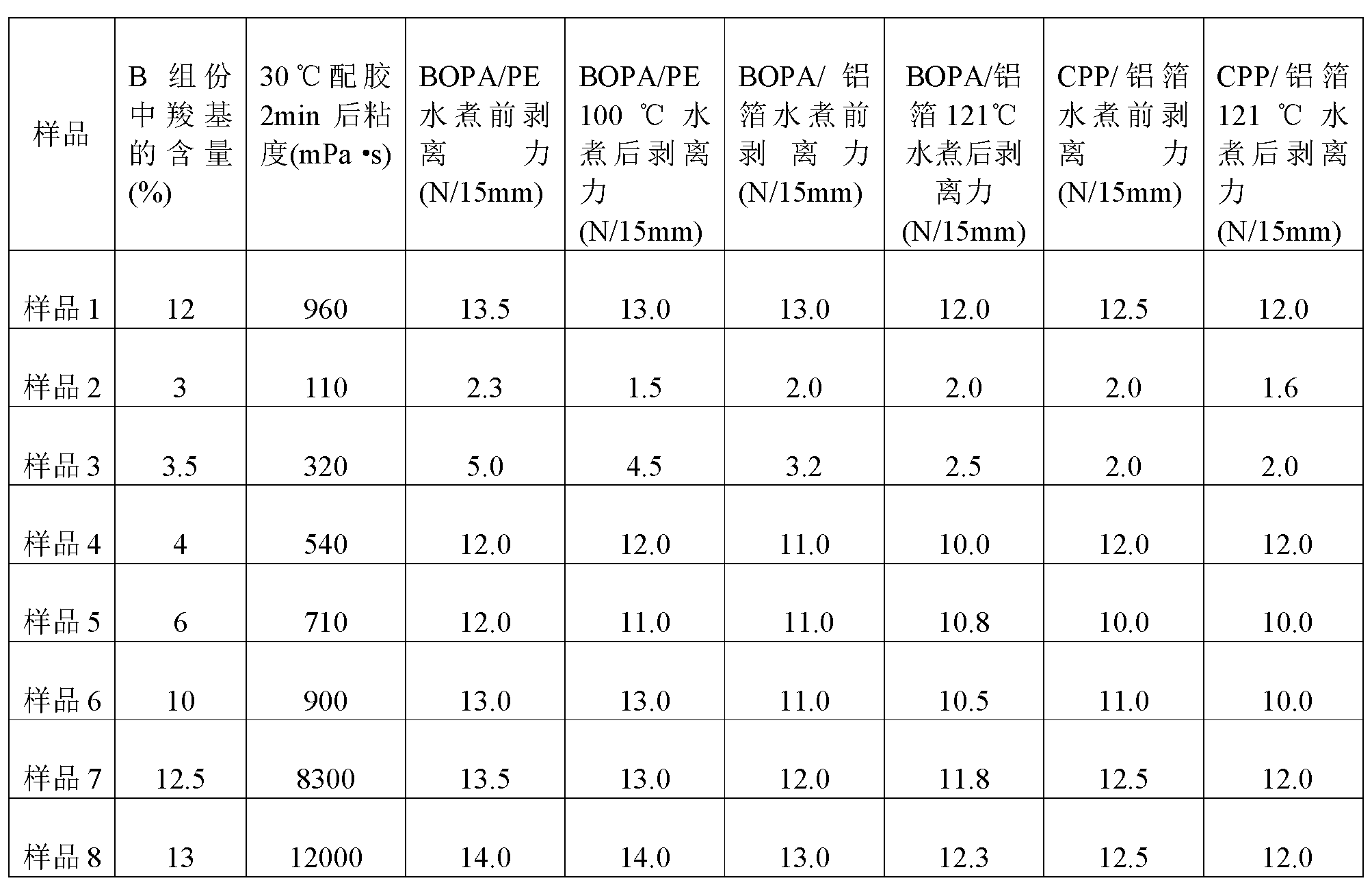

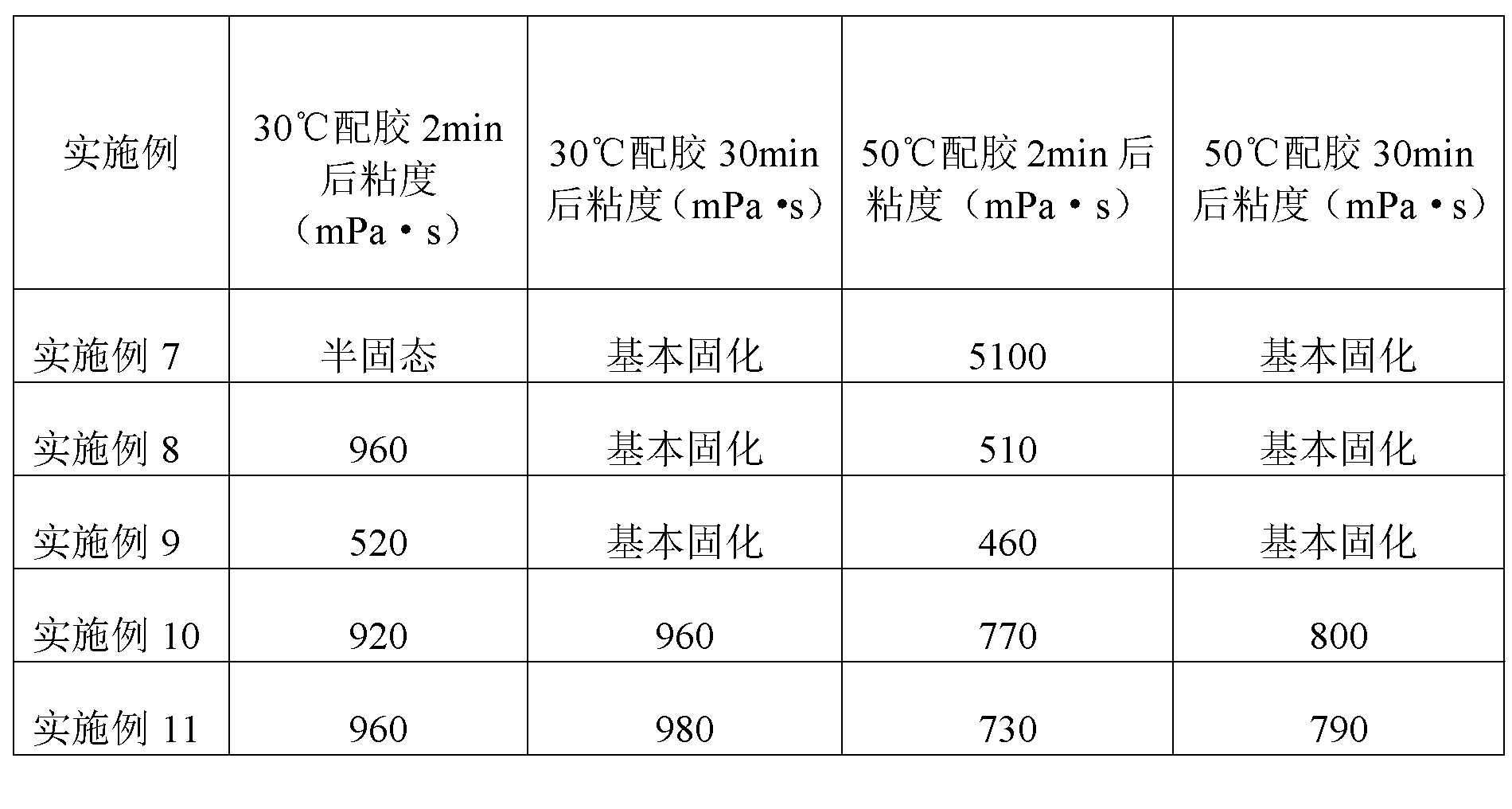

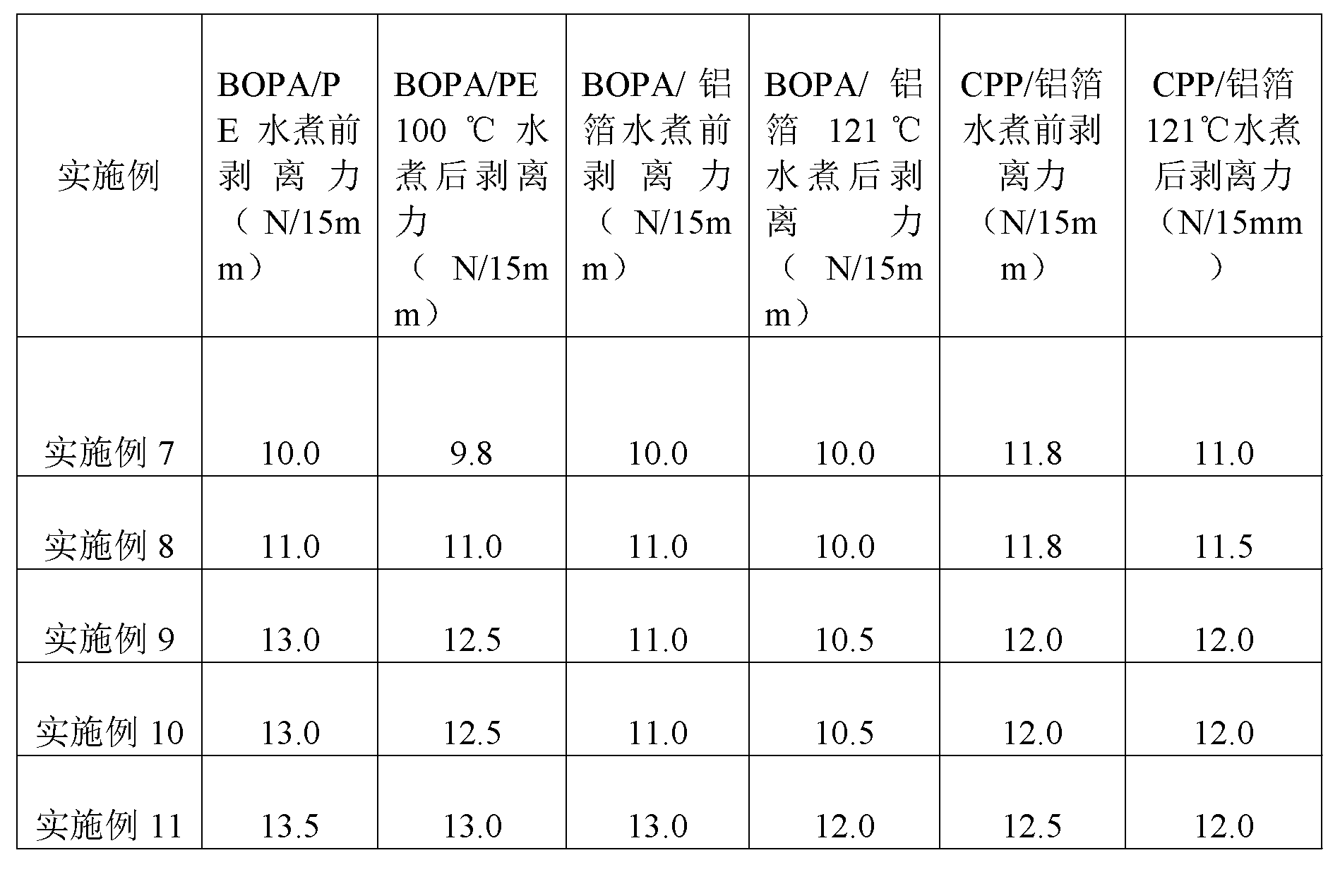

Solvent-free double-constituent polyurethane compound adhesive and preparation method for same

ActiveCN103013417AGood adhesionEliminates undesirable effects of uneven or even non-uniform coatingPolyureas/polyurethane adhesivesPolyolPolyurethane adhesive

The invention provides a solvent-free double-constituent polyurethane adhesive which is composed of a constituent A and a constituent B, wherein the constituent A is end isocyanate-group polyurethane prepolymer, and the constituent B is carboxyl-containing polyether polyol. The solvent-free polyurethane adhesive is strong in compounding fastness, long in service usage period and wide in suitable base material range; and moreover, the compound film prepared from the adhesive can still keep an excellent appearance and excellent adhesion property after high-temperature sterilization treatment.

Owner:苏州博莱特新材料有限公司

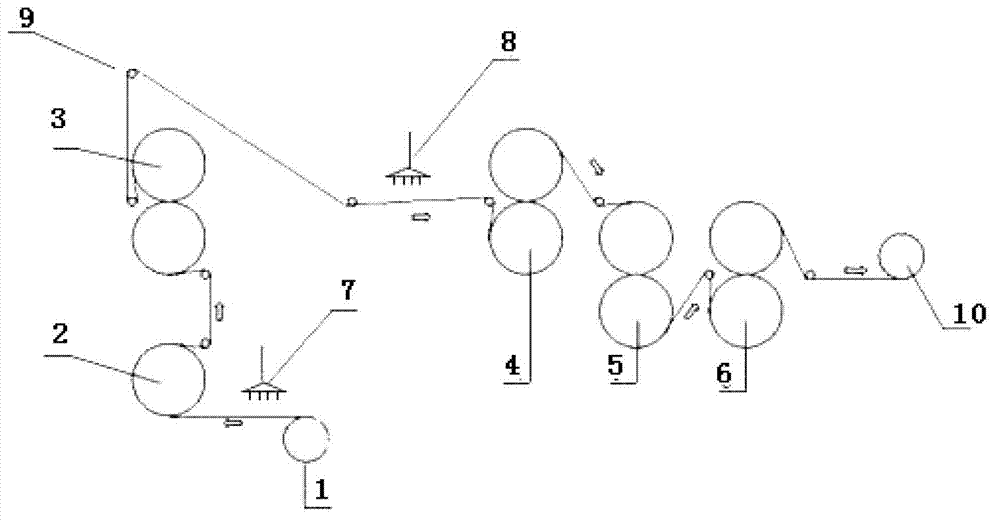

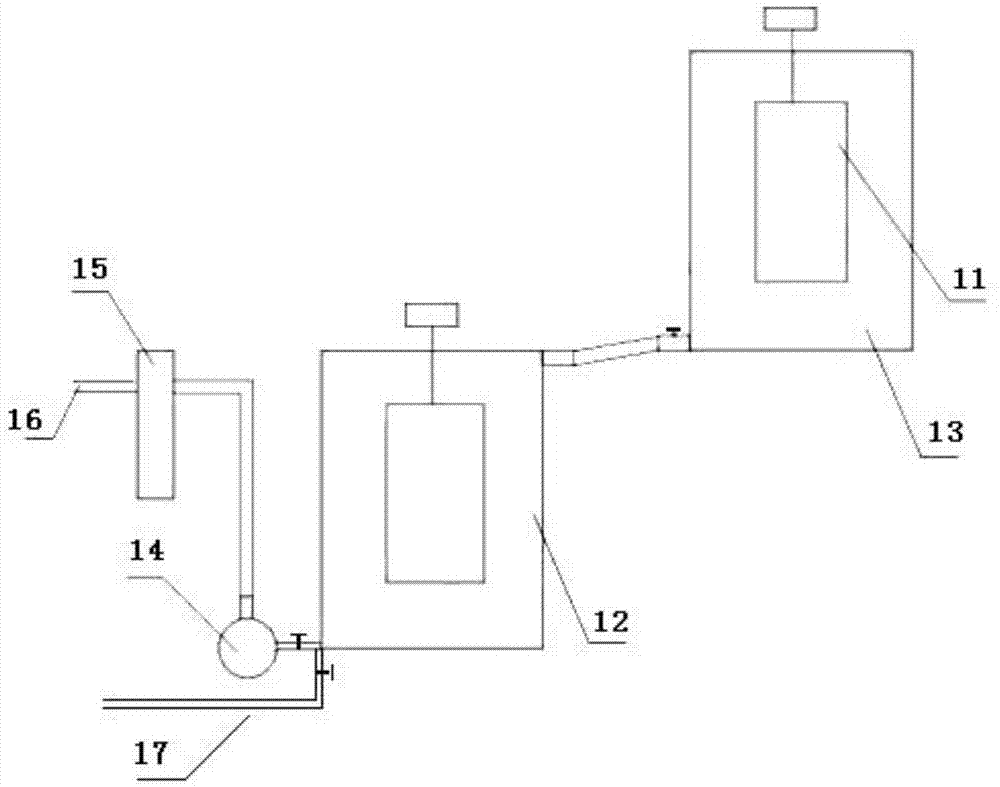

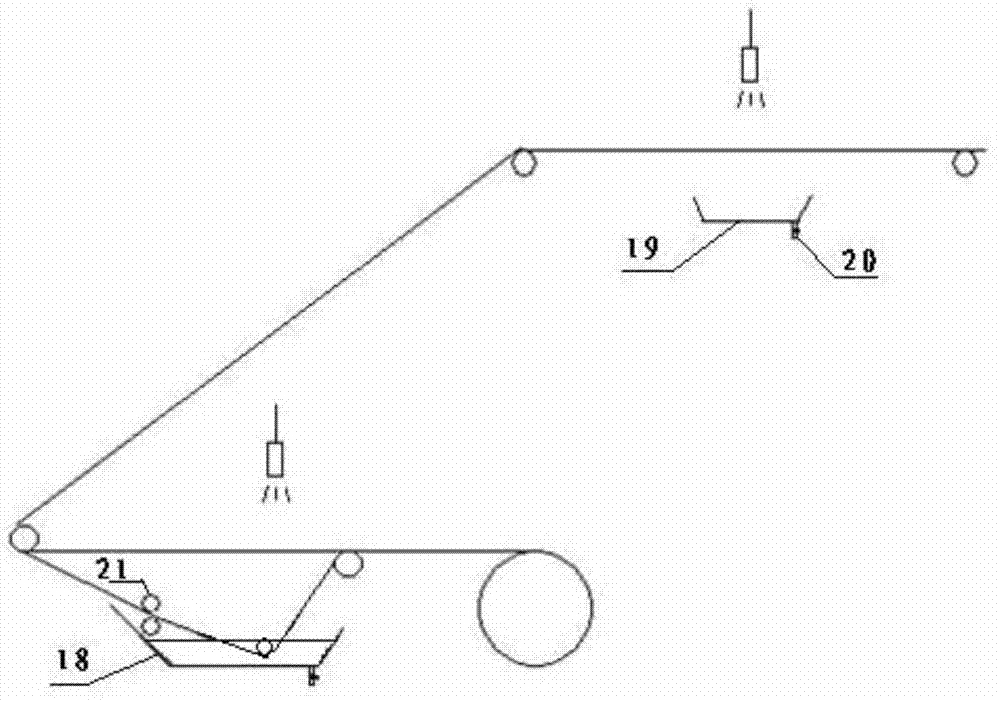

In-situ polymerization composite surface sizing system and surface sizing craft for needle punching non-woven fabrics

ActiveCN103111404AMeet quality requirementsReduce viscosityFibre treatmentPretreated surfacesIn situ polymerizationSynthetic Polymeric Macromolecules

The invention discloses an in-situ polymerization composite surface sizing system and a surface sizing craft for needle punching non-woven fabrics, namely a chemical process that organic monomers are polymerized to form high polymer materials and a flame planting composite process that non-woven fabrics are soaked by the organic monomers are combined in the same production line in a situ mode. The surface sizing system comprises a glue producing device, a glue seeping / flame planting sizing device and a drying device. The surface sizing craft achieved through the surface sizing system comprises the steps of (1) adding an emulsifying agent, a buffer agent and some water inside a burdening pot, stirring, evenly mixing the emulsifying agent, the buffer agent and the water, adding butyl mehtacrylate and methyl metacrylate, stirring, adding an initiating agent, stirring for an hour in a temperature range of 60 to 70 DEG C to form prepolymer, adding remaining water, stirring, evenly mixing the remaining water and the prepolymer, obtaining water miscible liquid, cooling the water miscible liquid to room temperature, introducing the water miscible liquid to a mixing pot, adding a polysaccharide compound into the mixing pot, mixing the polysaccharide compound with the water miscible liquid in a continuously stirred mode, forming suspension liquid; (2) treating the needle punching non-woven fabrics in a sizing mode through the glue seeping / flame planting sizing device; and (3) drying the needle punching non-woven fabrics and finalizing the design.

Owner:SHANDONG UNIV

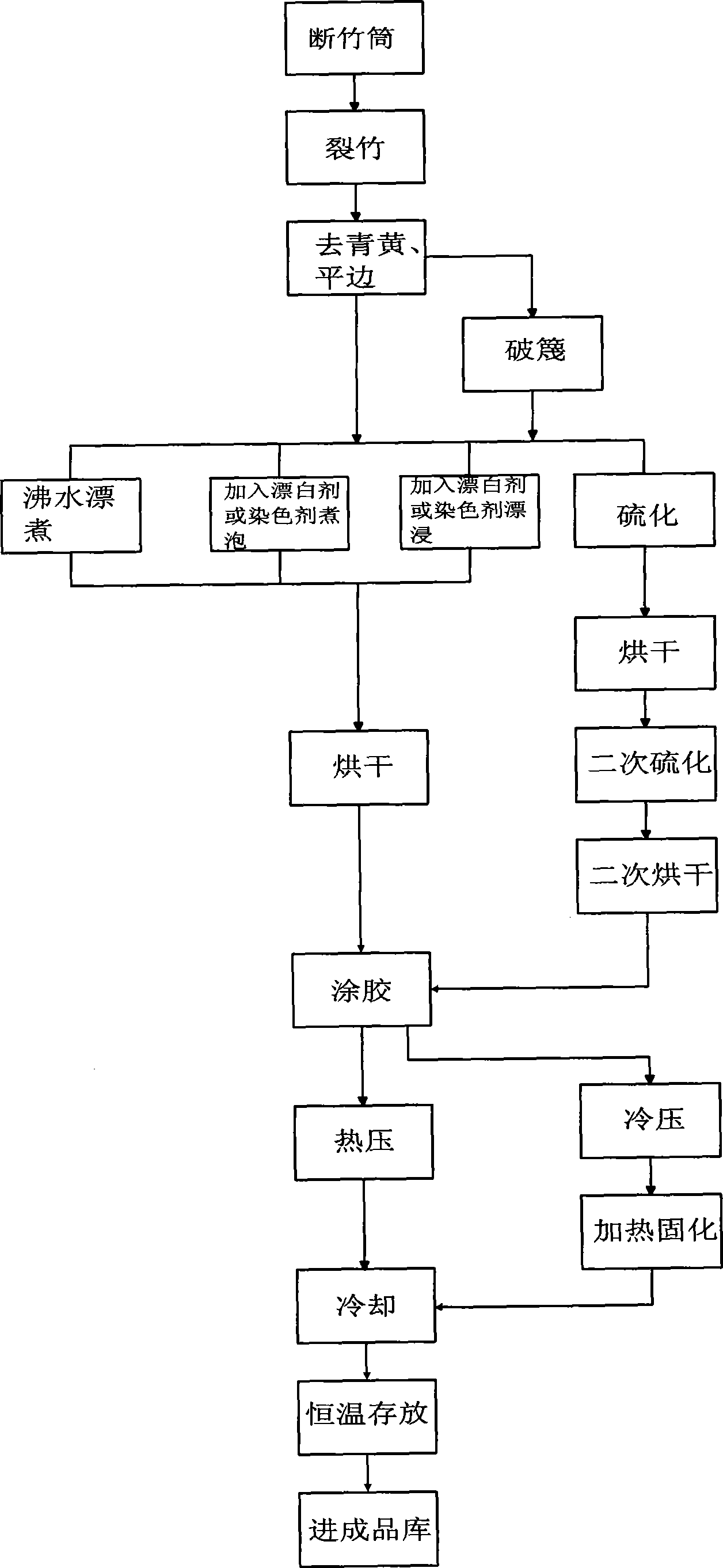

Production method bamboo strip side pressing bamboo board

InactiveCN101417457AJieba XiaoxianIncrease profitCane mechanical workingReed/straw treatmentElectricityResist

The invention relates to a manufacturing method of bamboo boards by side standing pressing of bamboo chips, including the following steps: bamboo chips or bamboo stripes initially processed according to required sizes are put into a kiering pool to be brewed with boiling water or are placed into a kiering pool with insect-resist agents, mold preventing agents, bleachers or coloring agents to be brewed with boiling water or placed into a dip bleaching pool with bleachers or coloring agents to be dip-bleached; the bamboo chips or bamboo stripes are directly placed into an autoclave for high temperature steam and sulfuration; a resin adhesive is uniformly coated on bottom surfaces and surfaces of the dried bamboo chips or bamboo stripes; the glued bamboo chips or bamboo stripes are sent into a hot-press to be hot-pressed until the glue is solidified; the chips or stripes are cooled to the normal temperature, then stored in a constant-temperature house for 30 days and then cut into finished products according to needed dimensions. The surfaces of the bamboo boards are natural textures formed by the lamination of sides of slices of bamboo chips and are beautiful without knots; the boards are larger in bearing capacity, little in gel content of finished products, more good for the environmental protection and hard to deform; and compared with the prior art, the method is high in efficacy, saves electricity, improves the utilization efficiency of original bamboos and saves cost.

Owner:赵斌

Two-component silicone sealant for solar cell modules and its injection process

InactiveCN102268234AImprove injection efficiencyEasy to operateLiquid surface applicatorsOther chemical processesPlasticizerEngineering

A silicone two-component sealant for solar cell modules and a glue injection process thereof. The A component of the silicone two-component sealant for solar cell modules is: basic polymer, plasticizer, filler, and flame retardant; the B component is: crosslinking agent, coupling agent, catalyst, and light stabilizer. This two-component silicone sealant is suitable for adhesive fixing and sealing of solar cell modules, as well as bonding and sealing of junction boxes with glass and TPT / TPE backplanes. Compared with the existing technology, the glue injection process has the advantages of convenience, high efficiency and saving the amount of glue used, and can meet the needs of large-scale and rapid production of solar cell modules.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

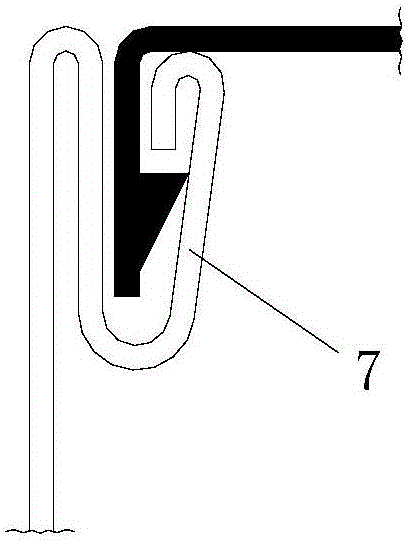

Pressure resisting type air pipe air leakage preventing structure of ventilation air conditioner system and air pipe joint machining method

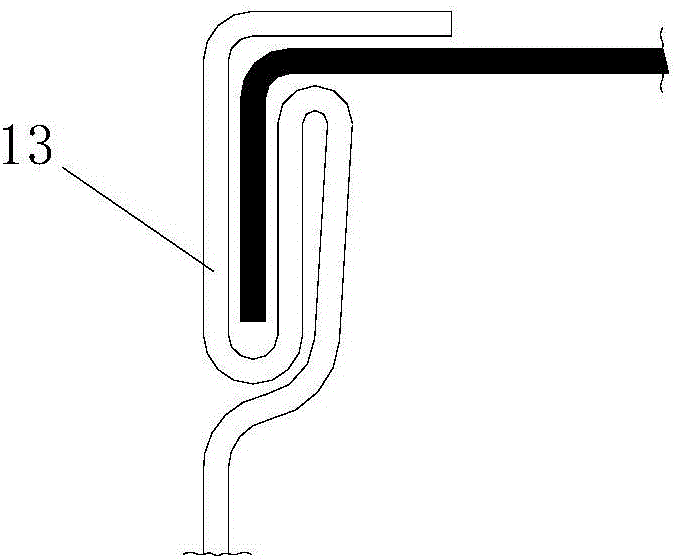

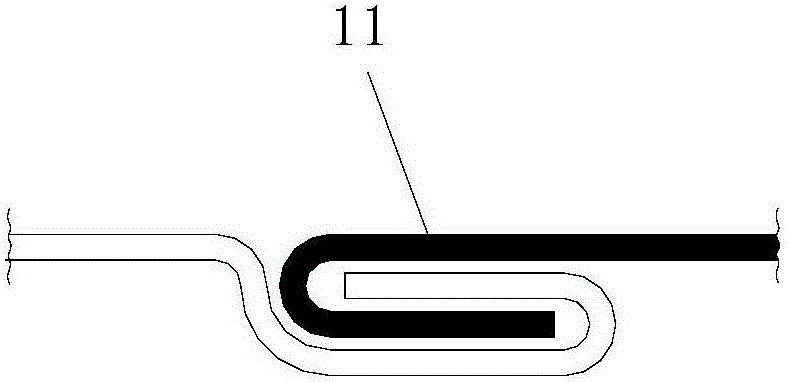

The invention discloses a pressure resisting type air pipe air leakage preventing structure of a ventilation air conditioner system. The pressure resisting type air pipe air leakage preventing structure comprises a pressure resisting type sealing structure and a clamping structure. The pressure resisting type sealing structure comprises a pressure resisting type sealing strip located between two flange edges of an air pipe flange. The clamping structure comprises a clamping piece clamped on the two flange edges. The pressure resisting type sealing strip is a T-shaped sealing strip. The T-shaped sealing strip comprises a clamping strip and a limiting strip located at the bottom of the clamping strip. The pressure resisting type air pipe air leakage preventing structure is simple, reasonable in design, convenient to install, good in using effect and capable of effectively reducing the air leakage amount of an air pipe of the ventilation air conditioner system. Meanwhile, the invention discloses an air pipe joint machining method. The method comprises the first step of metal panel cutting, the second step of seaming machining, the third step of flange machining edge machining, the fourth step of pipe joint body panel bending and the fifth step of seaming joint closing and compacting. The machining method is simple in step, manufacturing is easy and convenient, the using effect is good, and the air pipe joint machining process can be easily, conveniently and rapidly finished.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

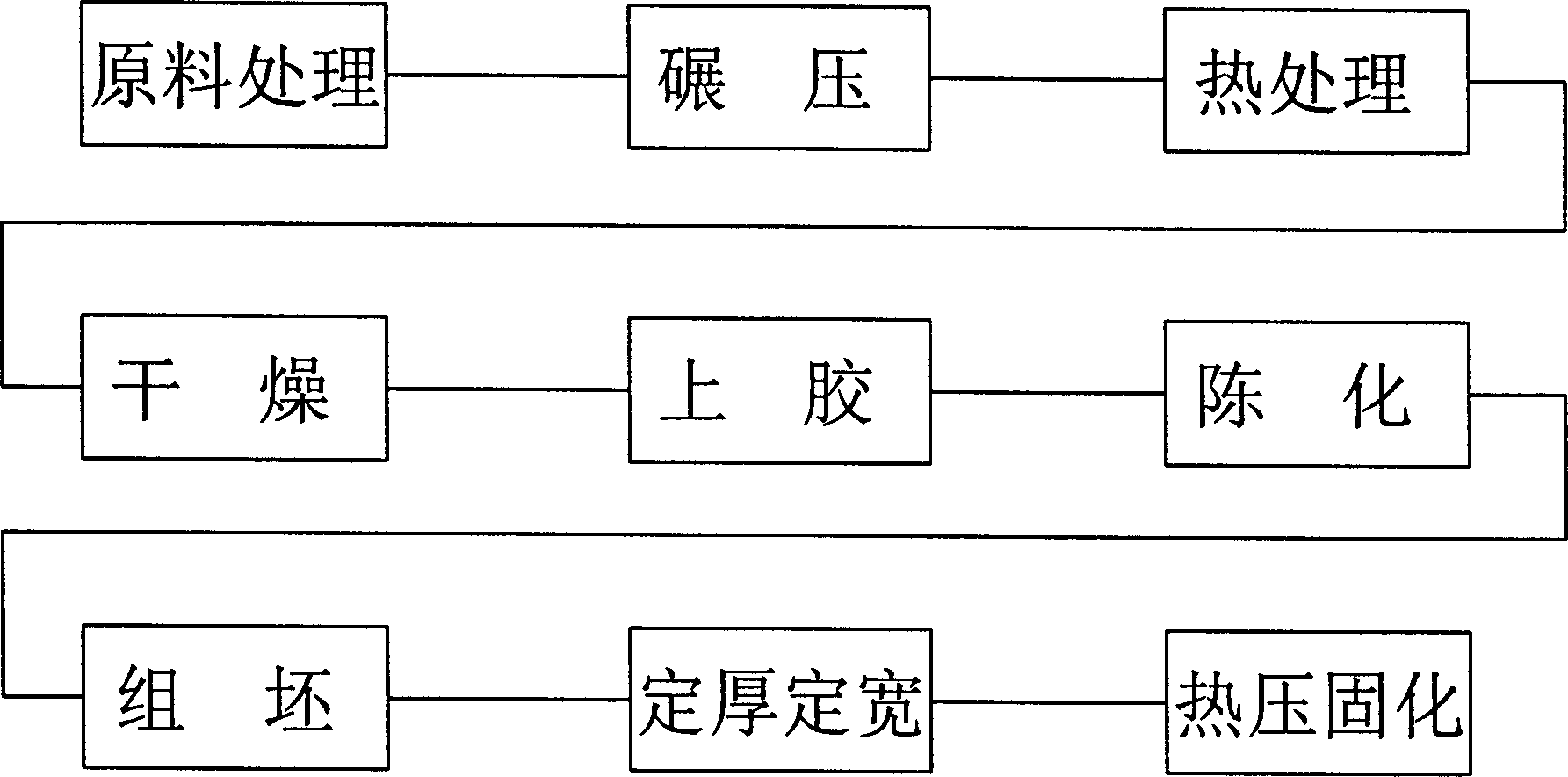

Bamboo-wood composite section bar production method

InactiveCN1788950ASolve bottlenecksIncrease profitSynthetic resin layered productsWood veneer joiningMaterials processingHeat treated

The present invention is timber and bamboo material processing and utilizing method. The present invention features that the timber-bamboo section bar is produced through the following steps: eliminating green part of bamboo, eliminating bark of timber, mechanically rolling into bamboo and timber sheet with glue content of 3-5 %, heat treatment, drying, gluing, ageing, compounding and molding and high temperature hot pressing to solidify and to form the section bar. The present invention well combines timber and bamboo material, and has less damage to their fiber structure and low glue consumption.

Owner:郎妙金

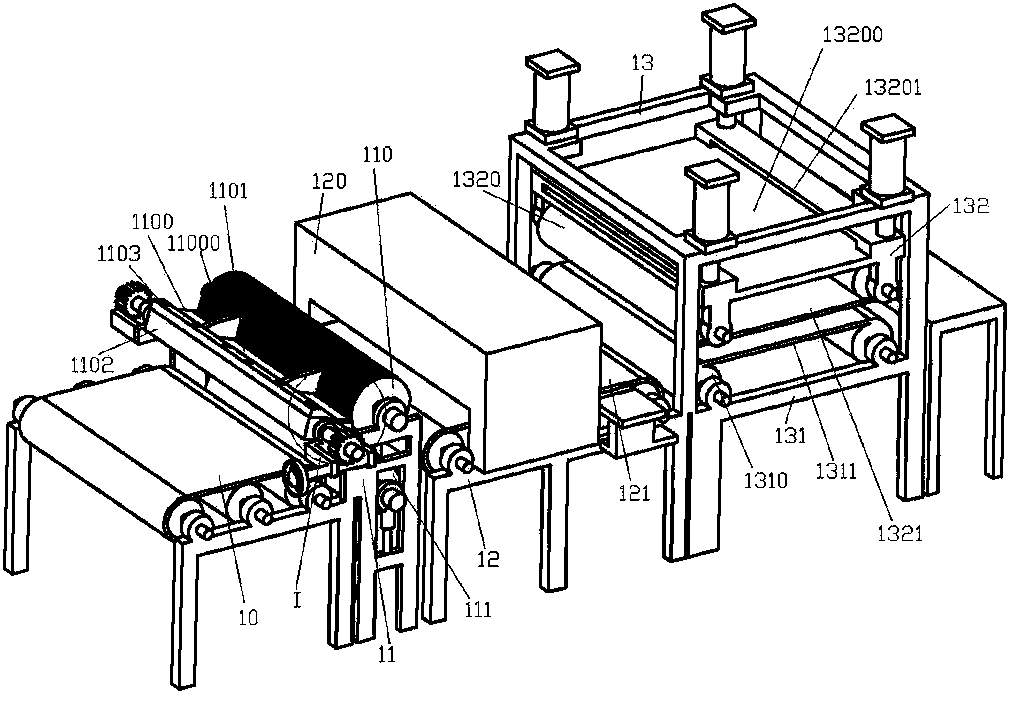

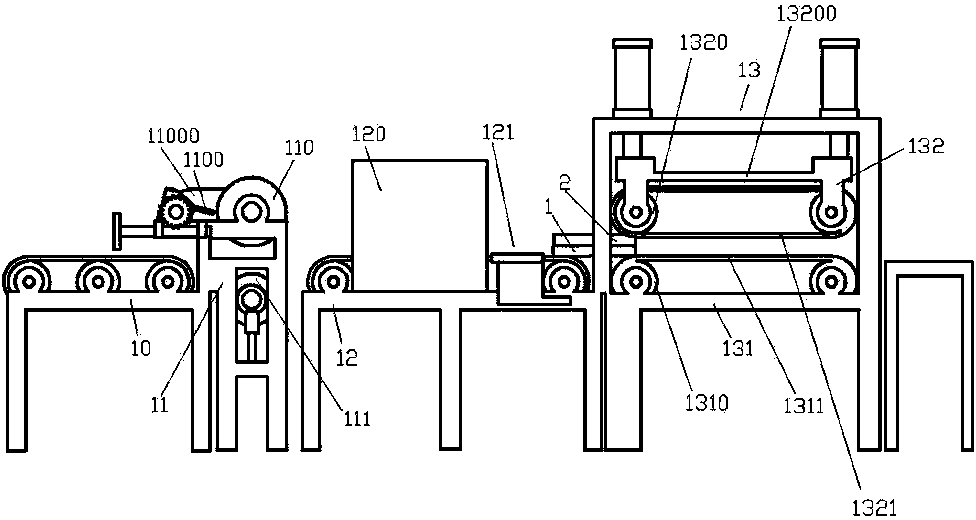

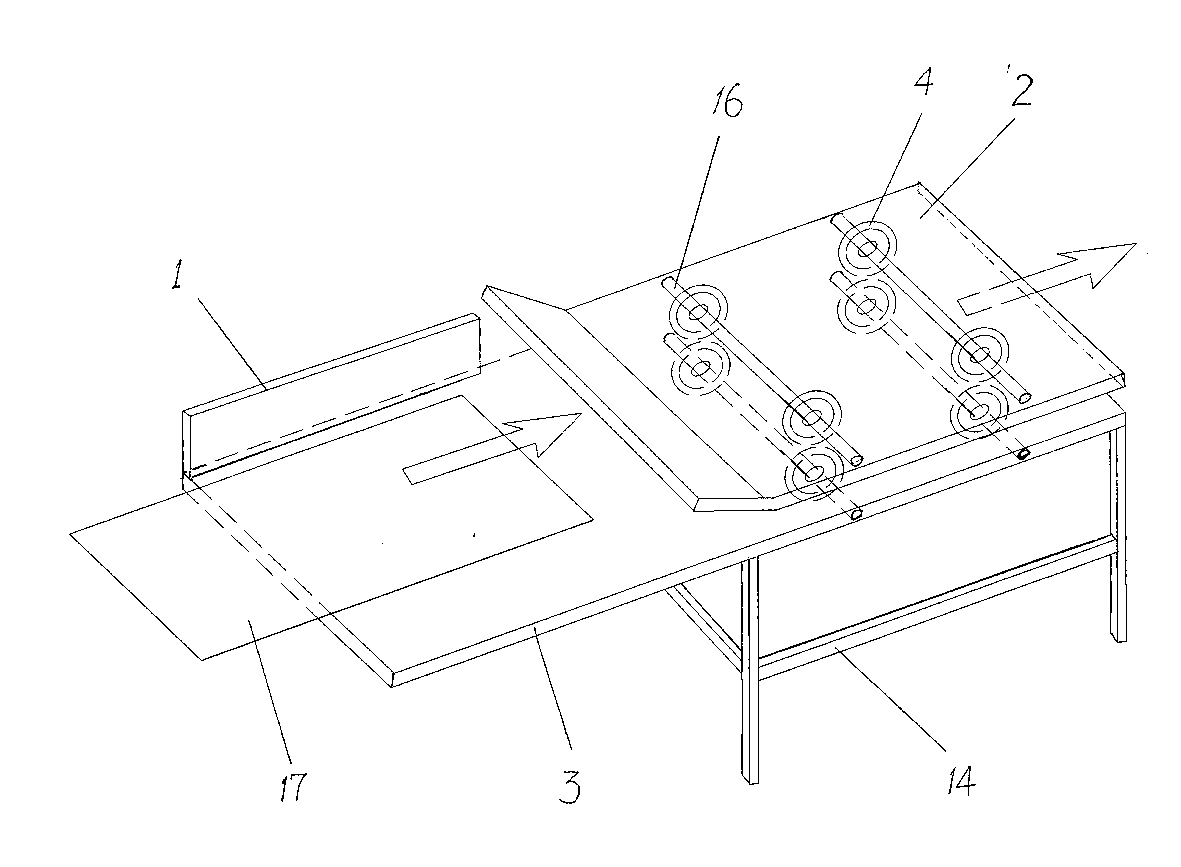

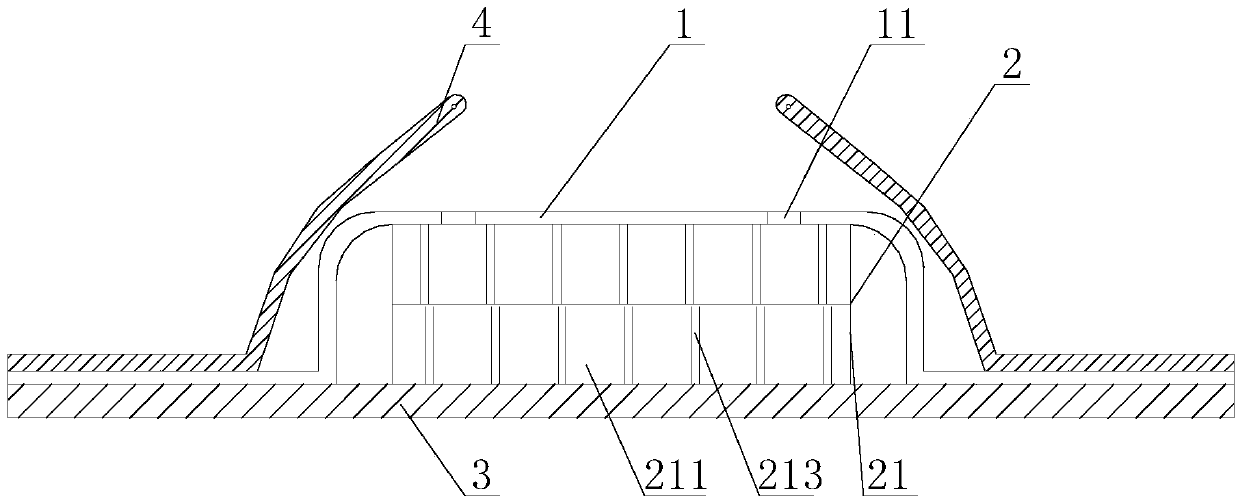

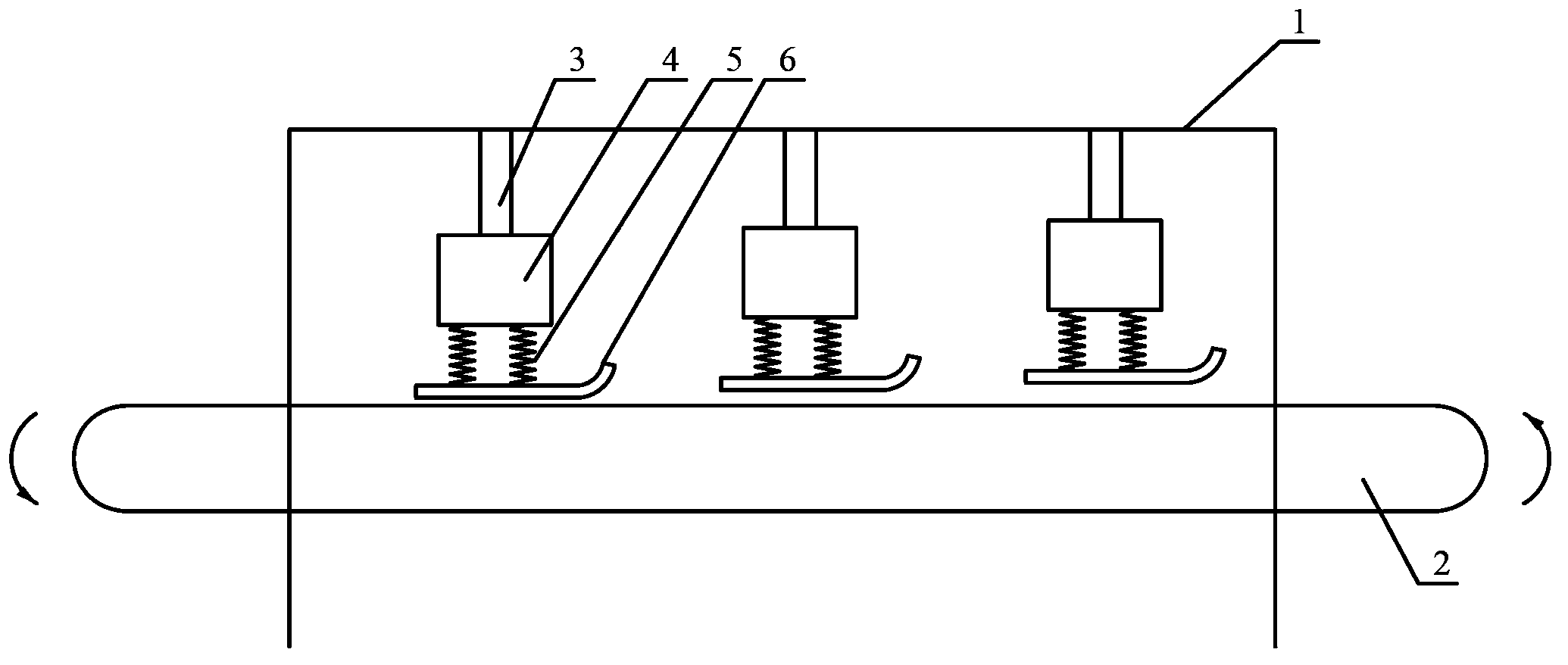

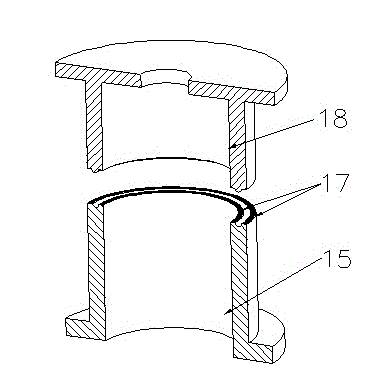

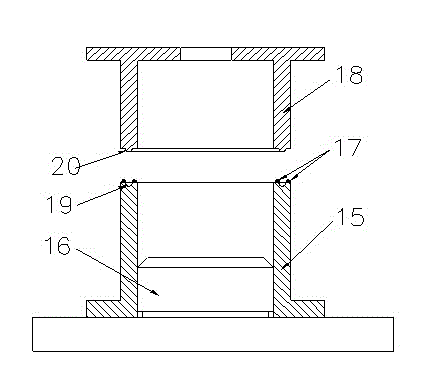

Device for producing composite cushion core of mattress

ActiveCN103935106AFine manipulationReduce the amount of glueLamination ancillary operationsLaminationEngineeringMaterials science

The invention relates to the technical field of composite machines and particularly relates to a device for producing a composite cushion core of a mattress. The device comprises a feeding table and a gluing table, wherein the feeding table is used for conveying a composite layer I, and the gluing table is located at an outlet of the feeding table and is used for gluing the composite layer I; a baking table is arranged at the outlet end of the gluing table and comprises a baking box and a transition region, wherein the baking box is close to the gluing table, the composite layer I can pass through the baking box, the transition region is located at an outlet of the baking box and is used for stacking the composite layer I and a composite layer II in a counterpoint manner, a composite table is arranged at the outlet end of the transition region and comprises a pressed conveying base frame and a press-down frame, the pressed conveying base frame is located below the composite table, the press-down frame is matched with the pressed conveying base frame and can be lifted, more than two pressed rolls rowed up along the conveying direction are mounted on the pressed conveying base frame, a pressed conveying belt is arranged along the peripheries of the rowed pressed rolls, more than two press-down rolls rowed up along the conveying direction are mounted on the press-down frame, and a press-down conveying belt is arranged along the peripheries of the rowed pressed rolls. The device has the energy-saving and environmentally-friendly effects and is high in efficiency and good in compositing effect.

Owner:HEYE HEALTH TECH CO LTD

Method and special fixture for compensating UV gum in Mobile telephone CCD camera assembling process

InactiveCN101140345ASave glueReduce the amount of reworkTelevision system detailsColor television detailsCamera lensCcd camera

The present invention discloses a method and a special clamping fixture for UV glue repair in the process of mobile phone camera assembling. Wherein, the method includes steps below: (1) Spreading UV glue between a lens base and a flexible printed circuit board; (2) Vertically arranging products with finished UV glue and keeping the flexible printed circuit board downward; (3) Taking a group of products processed in step (2) into a UV machine for UV solidification. In addition, the clamping fixture comprises a group of arranging boards to conveniently fix and withdraw product fastening pieces. After UV glues are spread between the lens base and the flexible printed circuit board, the method of the present invention vertically arranges products with finished UV glue and keeps the flexible printed circuit board downwards. Thus, gravity of the glue is utilized to balance glue penetration, thus reducing loss due to UV glue penetration and quantity of products returned for reworking.

Owner:BYD CO LTD

Four-edge board cutting machine for cutting carpentry veneer and four-edge cutting method of carpentry veneer

InactiveCN103009439AImprove finished product qualityNo gapsProfiling/shaping machinesEngineeringEnergy consumption

The invention relates to a four-edge board cutting machine for cutting a carpentry veneer, and a four-edge cutting method of the carpentry veneer. The four-edge board cutting machine comprises a rack, a rectangular bearing platform used for supporting the carpentry veneer, a rectangular bottom press bench used for implementing a flatting action on the supported carpentry veneer, a movable knife rest encircling the outside of the bottom press bench, cutting knifes fixedly mounted on an inner side wall at the periphery of the movable knife rest, a roller oppositely-grinding type veneer conveying mechanism used for conveying the carpentry veneer, a bottom press bench lifting control mechanism, a movable knife rest lifting control mechanism and a veneer feeding mechanism. According to the four-edge board cutting machine, a full frame of the carpentry veneer is compressed and flatted firstly, and then the four edges of the carpentry veneer are cut at the same time, so that joint opening or lamination of butting edges of the four cutting edges of the carpentry veneer are avoided in subsequent links such as assembling and prepressing, and the production efficiency of a core-board or a plywood is improved; the energy consumption is reduced; and the quality of a finished product is ensured.

Owner:河北北方绿野居住环境发展有限公司

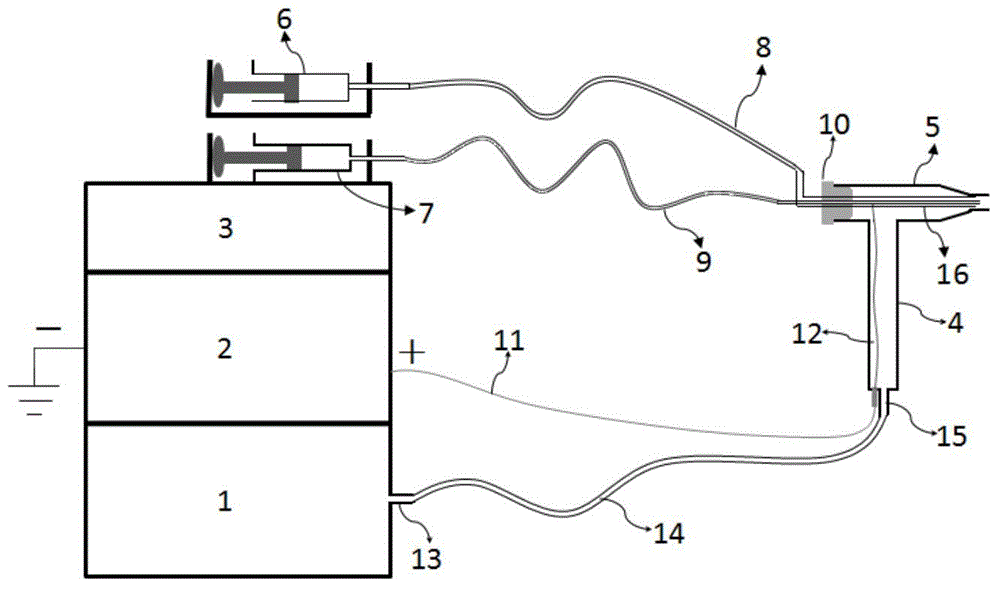

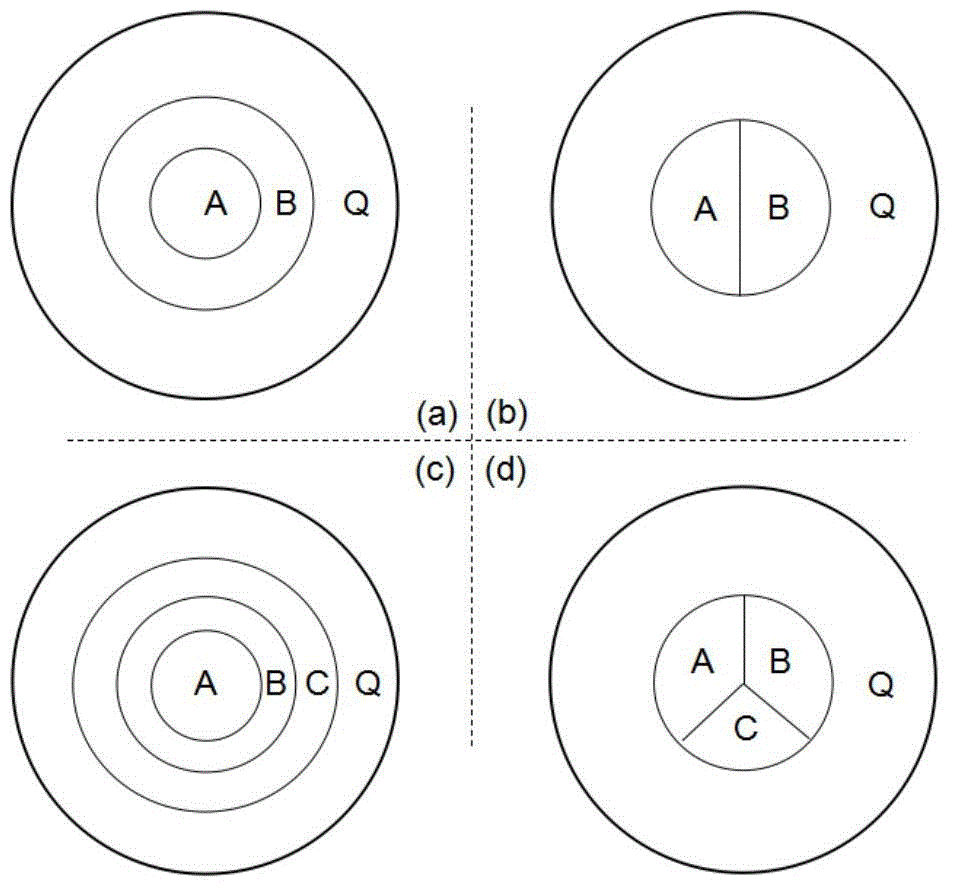

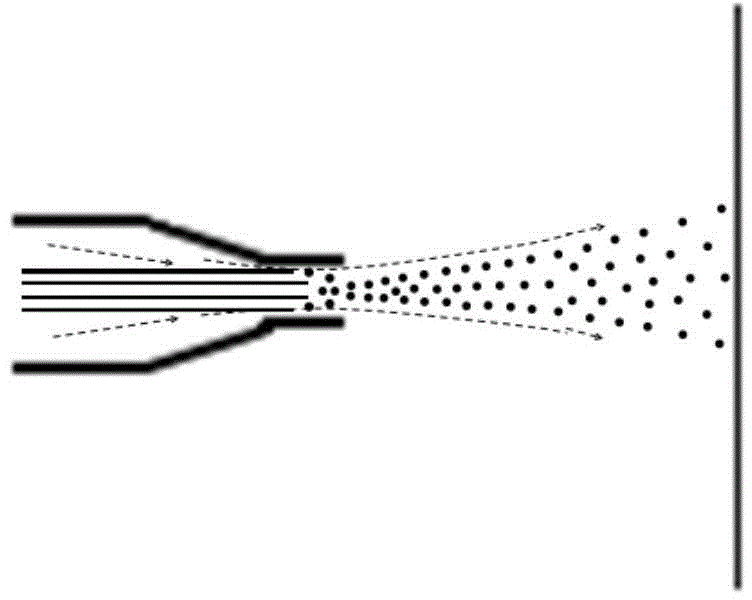

AB glue dispensing device based on electrostatic spraying principle

InactiveCN104084329APrecisely control the dosage ratioUniform depositionLiquid spraying plantsLiquid supply arrangementsBond qualityAir pump

The invention belongs to the technical field of AB glue dispensing equipment, and relates to an AB glue dispensing device based on an electrostatic spraying principle. A spraying gun handle is arranged under a spraying gun pipe, an air pump and a boost pump are electrically connected with a high-voltage electrostatic generator, the positive electrode of the high-voltage electrostatic generator is electrically connected with the spraying gun handle, and the negative electrode is grounded; an electric spraying needle head is arranged in the spraying gun pipe, an inserting port is formed in the lower end of the spraying gun handle, an air flow guide pipe inserting port is formed in one side of the air pump, and the two ends of an air flow guide pipe are inserted into the air flow guide pipe inserting port and the inserting port respectively; the electric spraying needle head is connected with an external guide wire through an internal wire inside the spraying gun handle, the front portion of the spraying gun pipe is a spraying gun spraying head, a pipe plug is arranged on the rear portion of the spraying gun pipe, one end of a first injector and one end of a second injector are connected with the boost pump, and the other end of the first injector and the other end of the second injector are communicated with the electric spraying needle head respectively through a first liquid inlet pipe and a second liquid inlet pipe. The AB glue dispensing device based on the electrostatic spraying principle is simple in structure, convenient to operate, uniform in glue mixing, capable of saving glue, high in bonding quality and wide in application range.

Owner:QINGDAO UNIV

Manufacturing process method of flame-retardant bamboo board

InactiveCN105459223APromote sustainable developmentAchieve sustainable developmentWood treatment detailsWood veneer joiningEngineeringMaterials processing

The invention discloses a manufacturing process method of a flame-retardant bamboo board, and relates to the technical field of bamboo material machining. Bamboo and boards are adopted as main raw materials of the flame-retardant bamboo board. The method comprises the following steps of 1, material selecting, 2, drying, 3, grinding, 4, secondary drying, 5, maintaining and 6, flame-retardant paint smearing. The bamboo and the boards are organically combined, the situation that adopted materials are too single is avoided, the bottleneck problem of existing raw materials is effectively solved, the inherent fiber structure of the raw materials is not destroyed basically, and the amount of glue adopted between the materials is lowered. In addition, flame-retardant paint is smeared to the surface of the bamboo board, the good flame retarding function can be achieved well, the fire resistance of bamboo and board machining pieces is improved, and the safety of the boards is improved.

Owner:广德县永彬竹木工艺品厂

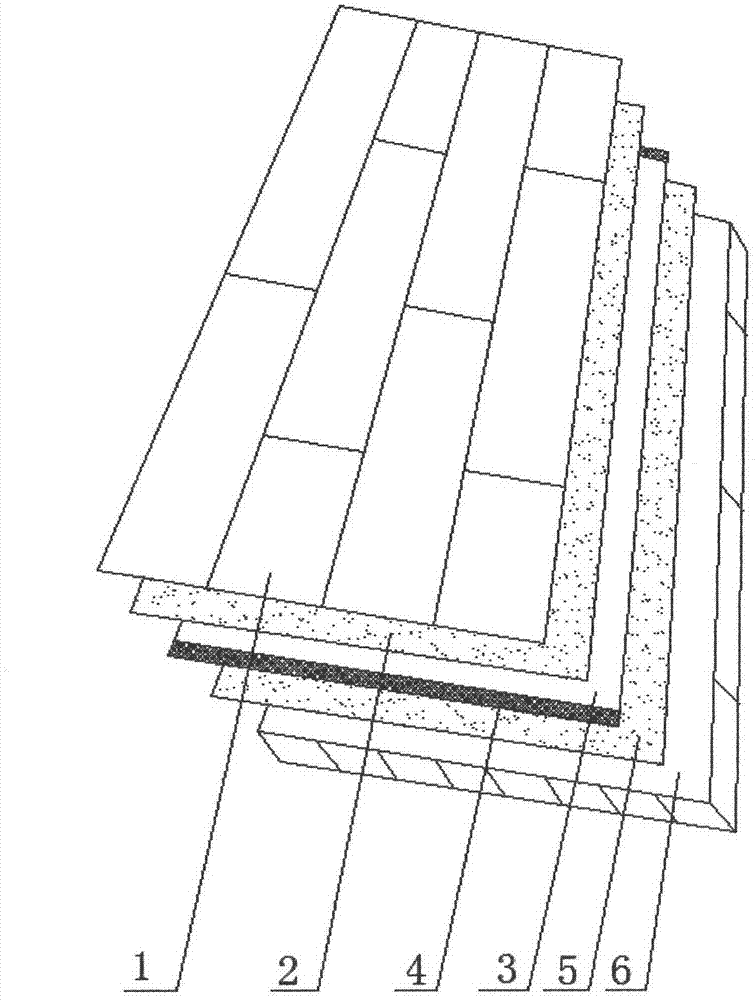

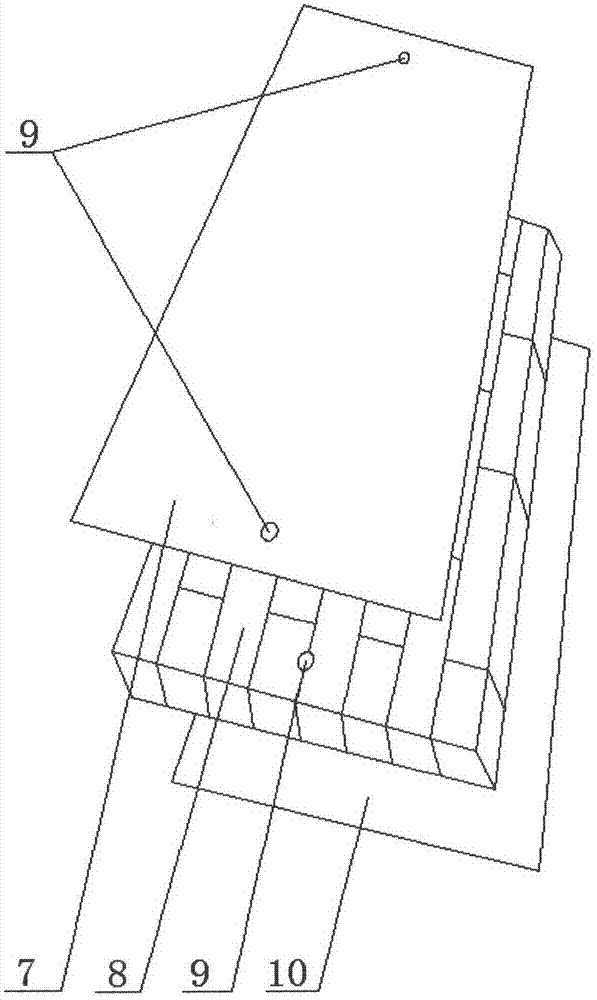

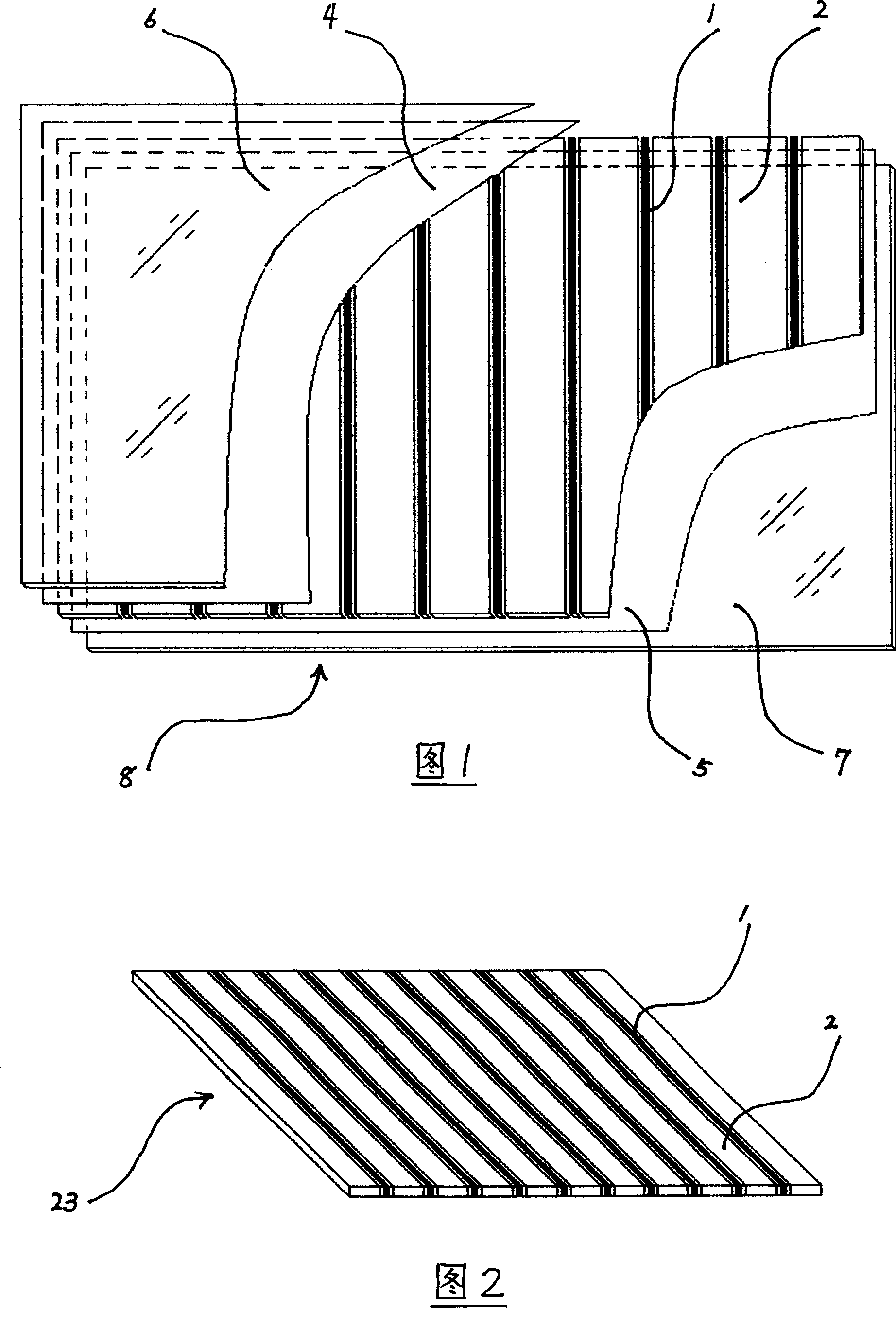

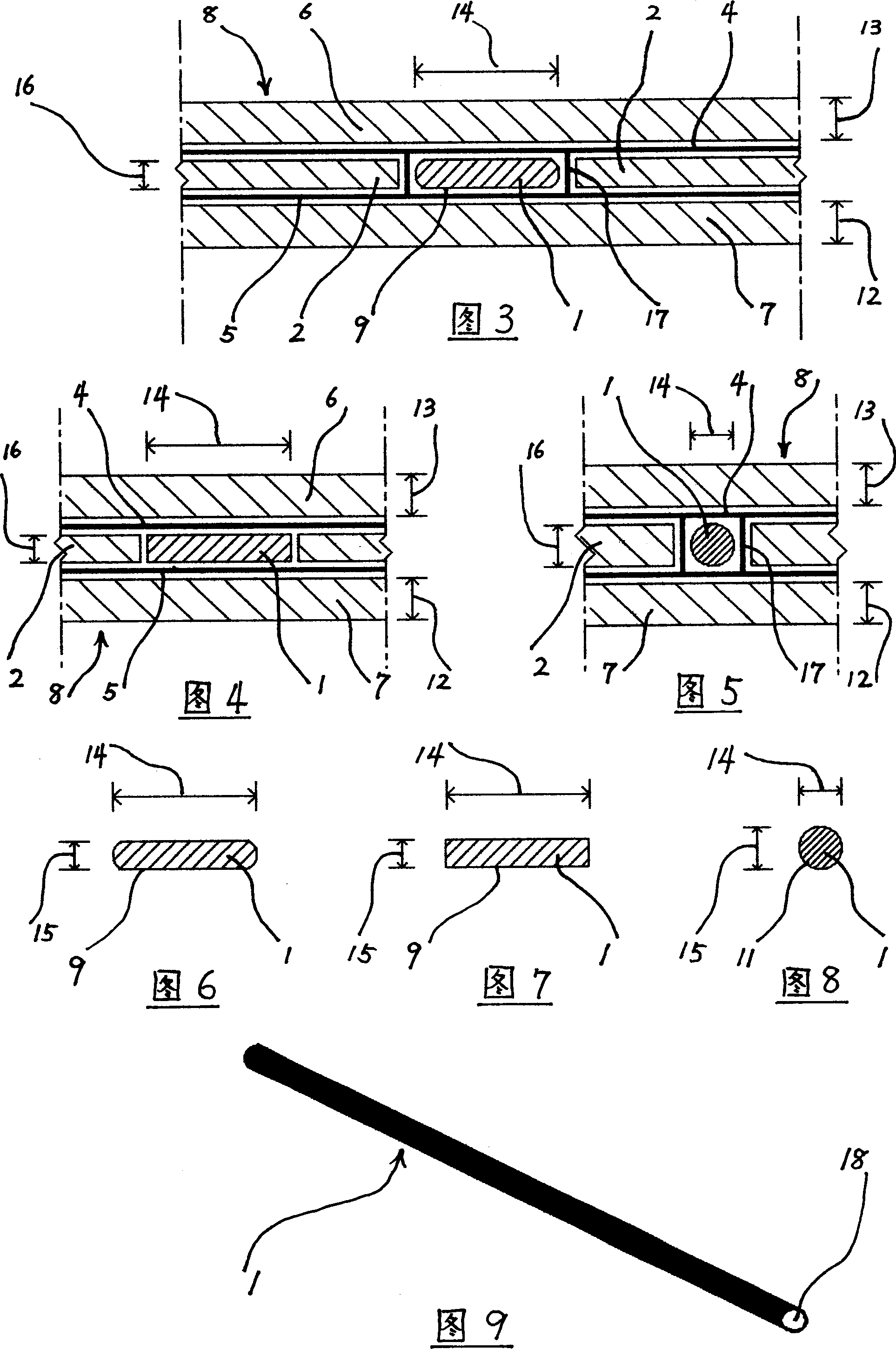

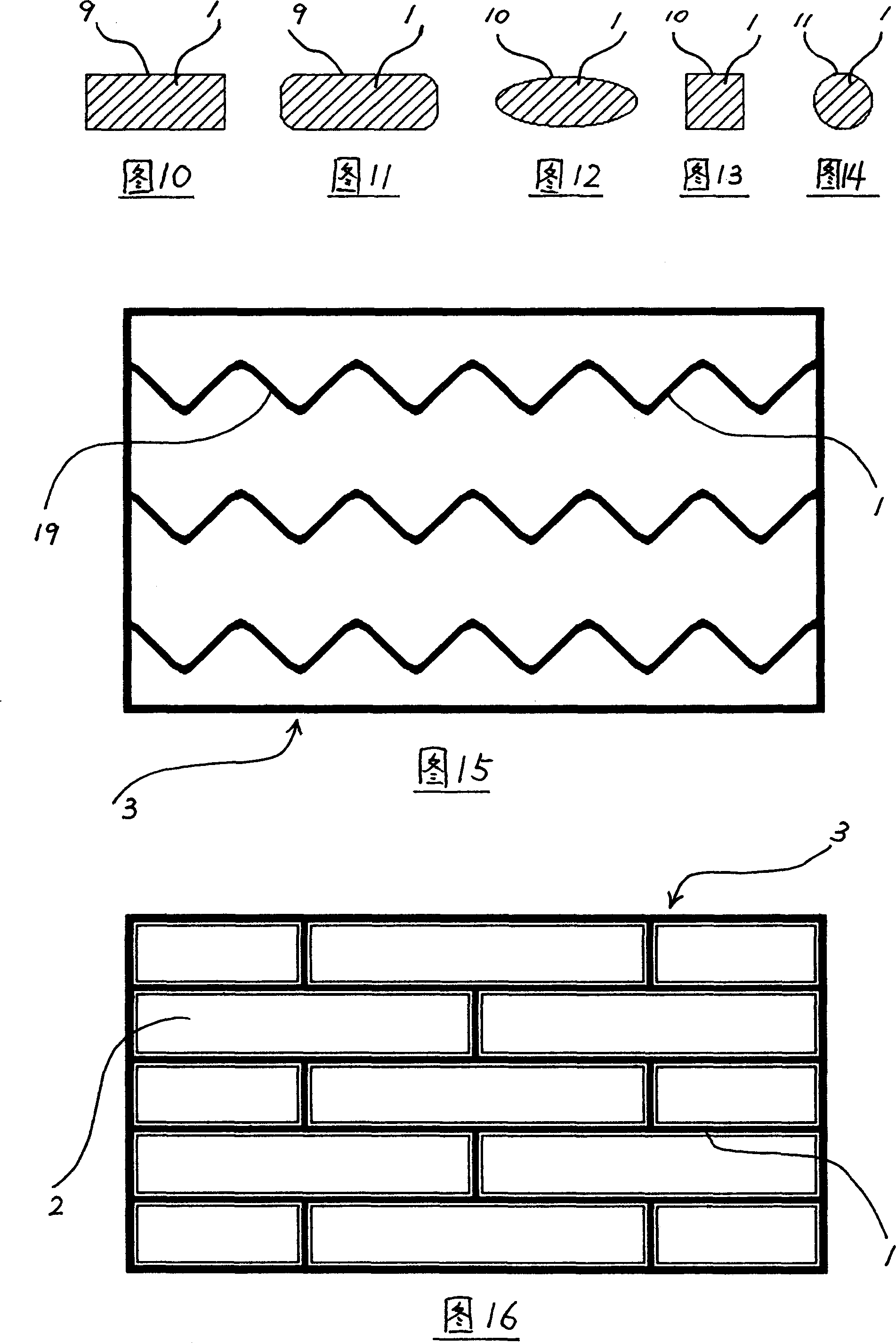

Three-layer solid wood composite electric heating floor and manufacturing method thereof

InactiveCN104712129AReduce the amount of glueSmall degree of deformationLighting and heating apparatusElectric heating systemSolid woodElectricity

The invention discloses a three-layer solid wood composite electric heating floor and a manufacturing method thereof. The three-layer solid wood composite electric heating floor comprises a decoration wood veneer, an upper insulation layer, an electric heating chip, a lower insulation layer and a three-layer solid wood base material layer. The three-layer solid wood base material layer is formed by laminating an upper wood veneer, a lower wood veneer and a solid wood batten base material layer clamped between the upper wood veneer and the lower wood veneer. The decoration wood veneer, the upper insulation layer, the electric heating chip, the lower insulation layer and the three-layer solid wood base material layer are sequentially overlapped and laid from top to bottom and laminated into the complete floor. The lower surface of the decoration wood veneer is coated with insulation resin glue to form the upper insulation layer and is attached to the upper surface of the electric heating chip. The upper surface of the three-layer solid wood base material layer is coated with insulation resin glue to form the lower insulation layer and is attached to the lower surface of the electric heating chip. The electric heating chip is formed by coating the surface of a copper strip used as a power plug with conductive hot melt glue and laying the copper strip on the surface of carbon fiber electric heating non-woven paper. According to the three-layer solid wood composite electric heating floor, the amount of adopted glue is small, the deformation degree is low, and the floor is more environmentally friendly. The electric heating chip and the copper strip are connected firmly, safety is good, and the service life is long.

Owner:QINGDAO GRAPHENE CARBON NEW MATERIAL TECH CO LTD

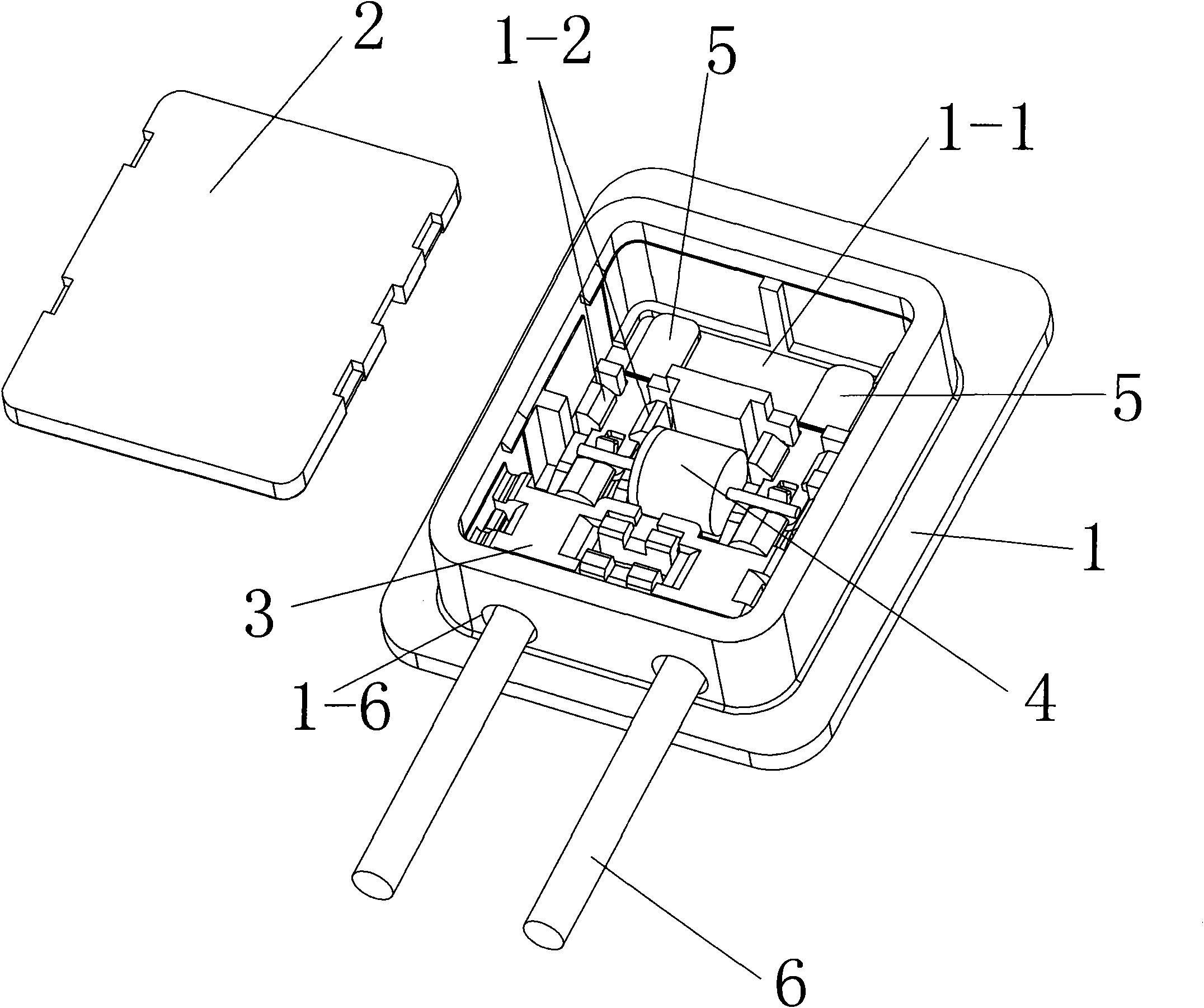

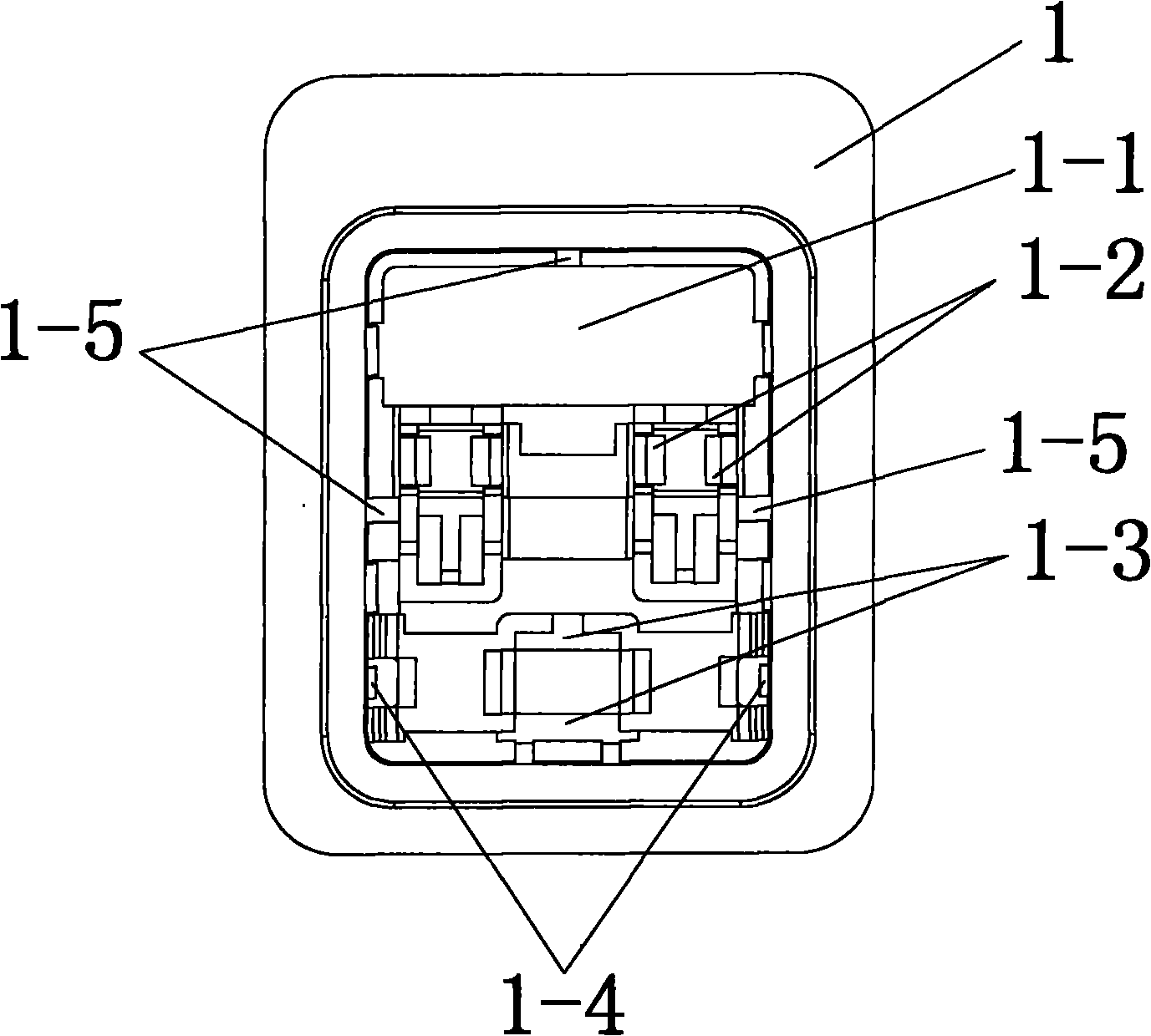

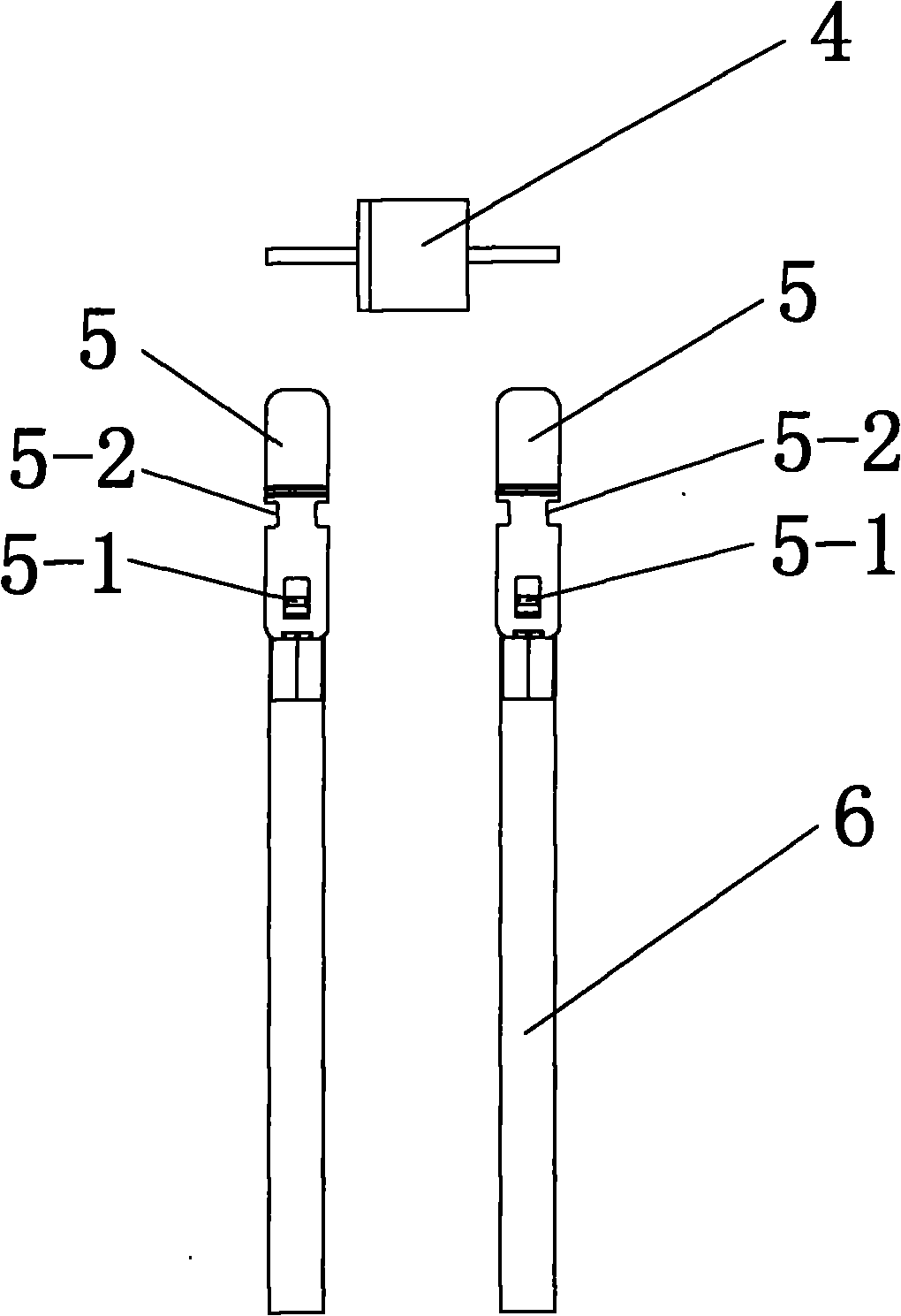

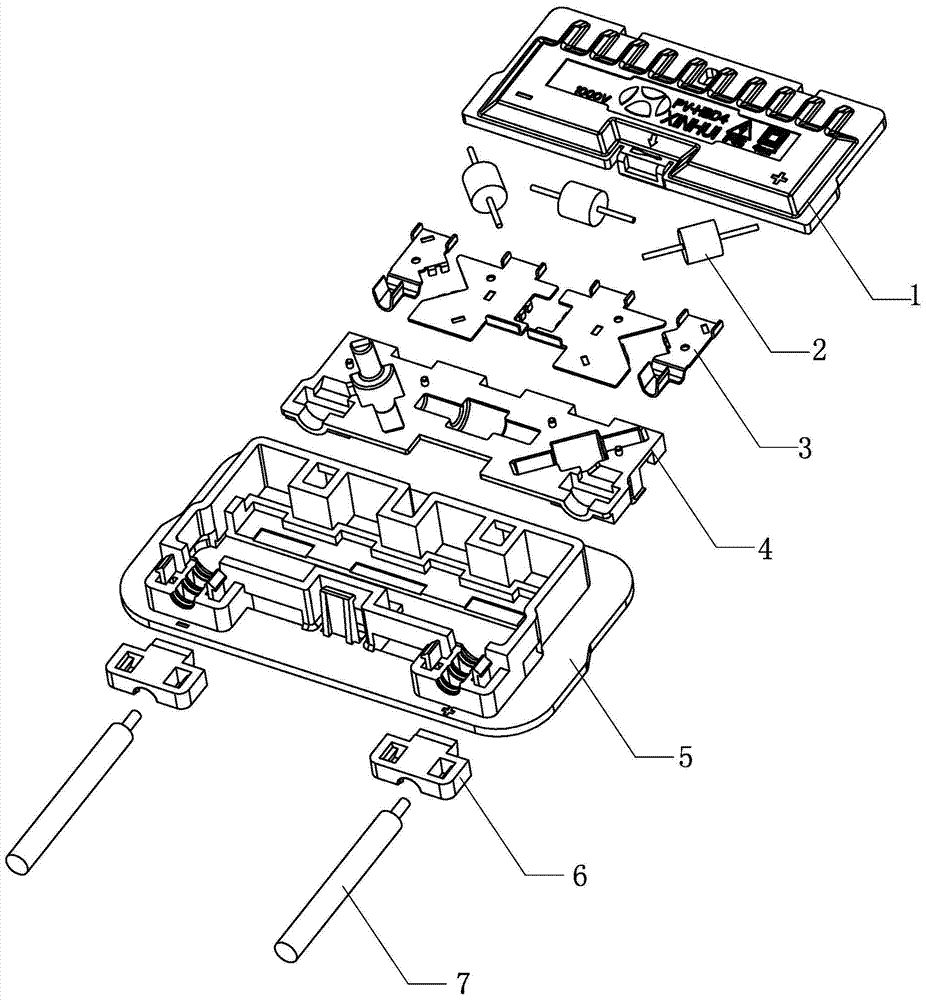

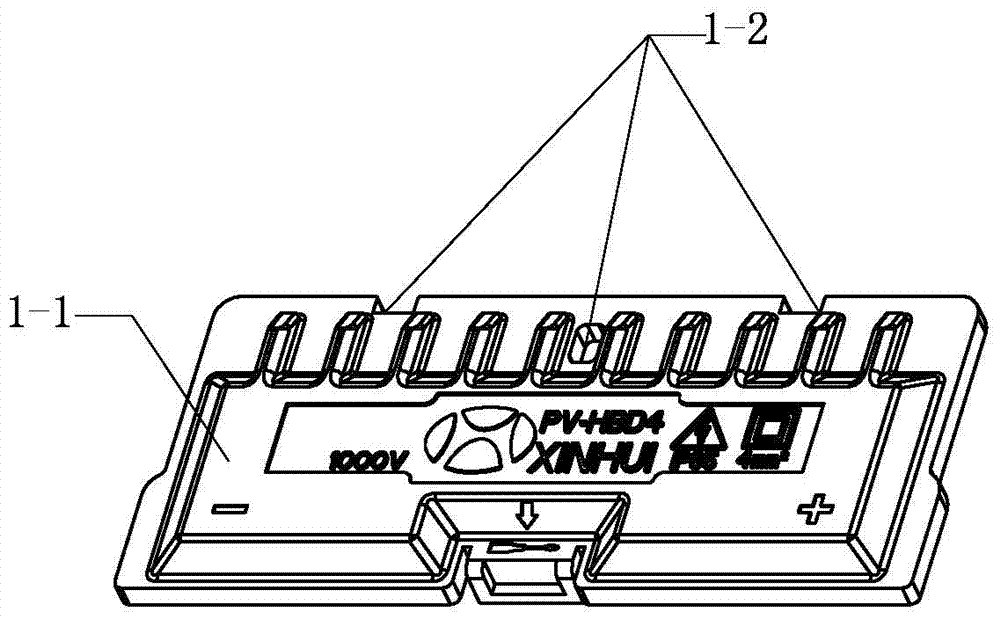

Glue-filling waterproof photovoltaic junction box

ActiveCN101944866AExtended service lifeReduce the amount of glueClimate change adaptationPhotovoltaicsEngineeringEnergy conservation

The invention relates to a junction box, in particular to a glue-filling waterproof photovoltaic junction box which is provided with a box body with a cavity and a box cover, wherein one side of the box body is provided with a connection cable through hole through which a placed cable is penetrated; two clamping modules are arranged in the middle part of the cavity, and buckles are arranged at two sides of the bottom part of the cavity; the two clamping modules are clamped with a metal terminal respectively, a diode is connected between the two metal terminals, and the bottom parts of the metal terminals are connected with the cable; and the two buckles are respectively clamped on two clamping hooks at two sides of a clamping groove, and the clamping groove is pressed on the cable. The glue-filling waterproof photovoltaic junction box adopts a small-volume box design, thus reducing glue-filling quantity and saving cost; pressing and clamping manners among elements are adopted in manufacturing and processing of the junction box, thus avoiding use of mechanical connection and achieving energy conservation and environmental protection; and a glue-filling manner is adopted for sealing the junction box, thus improving tightness and water resistance.

Owner:QC SOLAR SUZHOU CORP

Glass plate with adhesive and interlaid metallic net

The invention discloses a doubling metal net inserting glass board on the building door and window, which is characterized by the following: the metal net is clamped between two transparent glass boards at adhering pattern to reinforce the strength of glass board; the metal net inserted glass board possesses five layer structure, which contains top transparent silicate glass board on the outer surface and bottom transparent silicate glass board; the inner structure is upper layer transparent glue film and lower layer transparent glue film; the metal net layer is clamped by upper and lower transparent glue films; the transparent glass board fills the metal net hole blanking, whose thickness is more than half of metal net thickness and less than 10mm.

Owner:崔建伟

Preparation method of energy-saving, environment-protecting and sag-resistant water-based instant adhesive

ActiveCN101851475ASmall particle sizeImprove stabilityMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesWater basedPolyvinyl alcohol

The invention relates to a preparation method of energy-saving, environment-protecting and sag-resistant water-based instant adhesive. The adhesive is widely applied in self-adhesion or cross-adhesion in the furniture, handicrafts, car interiors and other industries, and is prepared with the following raw materials of certain parts by weight: acetylated polyvinyl alcohol, vinyl acetate, plasticizer, nano-montmorillonite soil, emulsifier, initiator and the like. Instead of the method of preparing the existing product that the common polyvinyl alcohol is filled once into the reactor as the protective colloid, the preparation of the invention adopts the method of dropping the monomers and the initiator through two ports, the acetylated polyvinyl alcohol is filled in batches as the protective colloid, and the monomers, the initiator and the protective colloid are dropped simultaneously through a three-port dropping device, thereby improving the water resistance, stability, adhesive strength and sag resistance; and the reaction rate is controlled and the nano-montmorillonite soil, the environmental protection type plasticizer, the environmental protection type emulsifier and the like are added during preparation, thereby improving the adhesive property, environmental performance and sag resistance.

Owner:JIANGSU HEISONGLIN ADHESIVE FACTORY

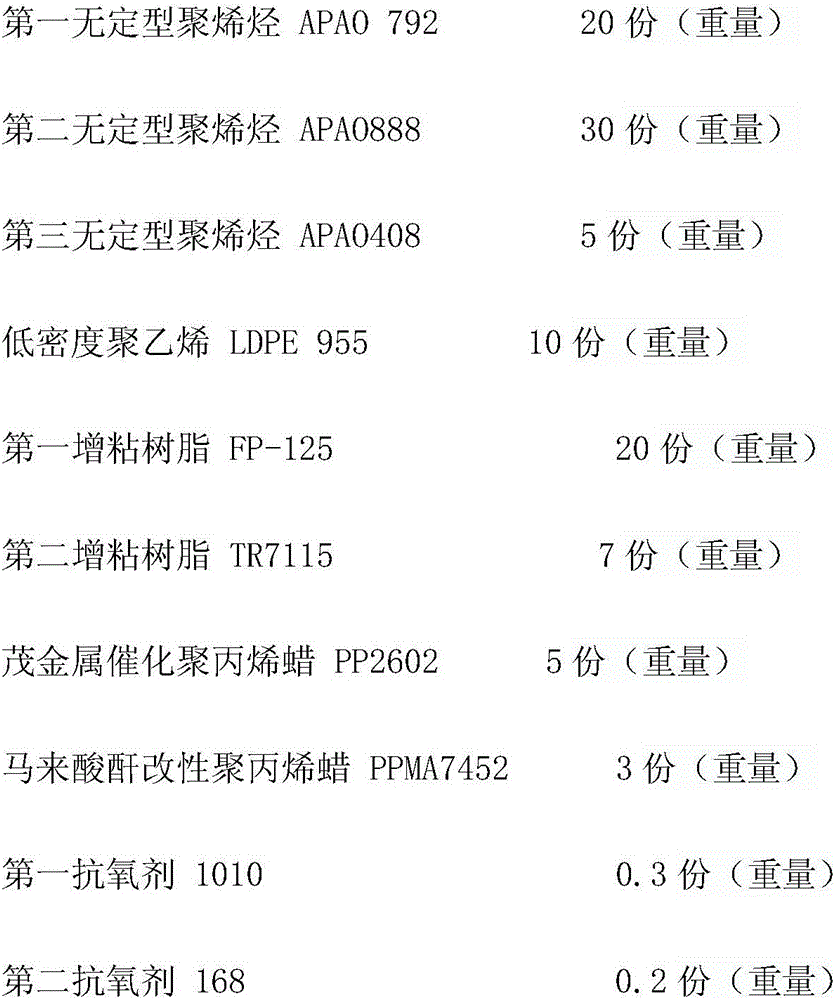

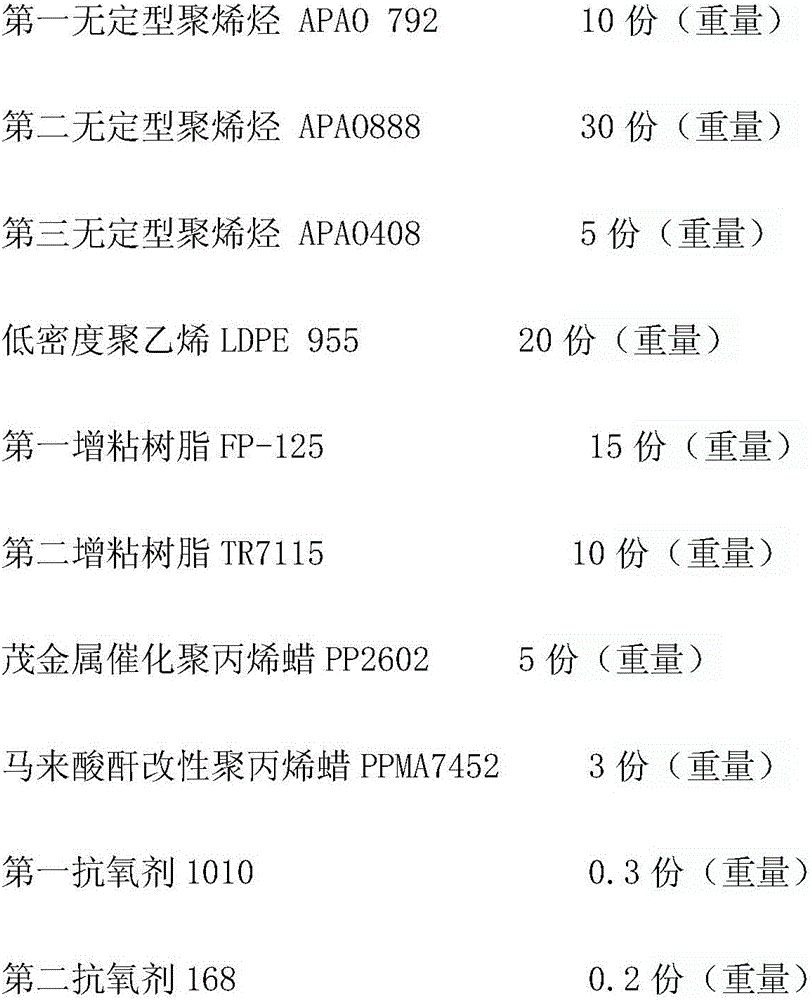

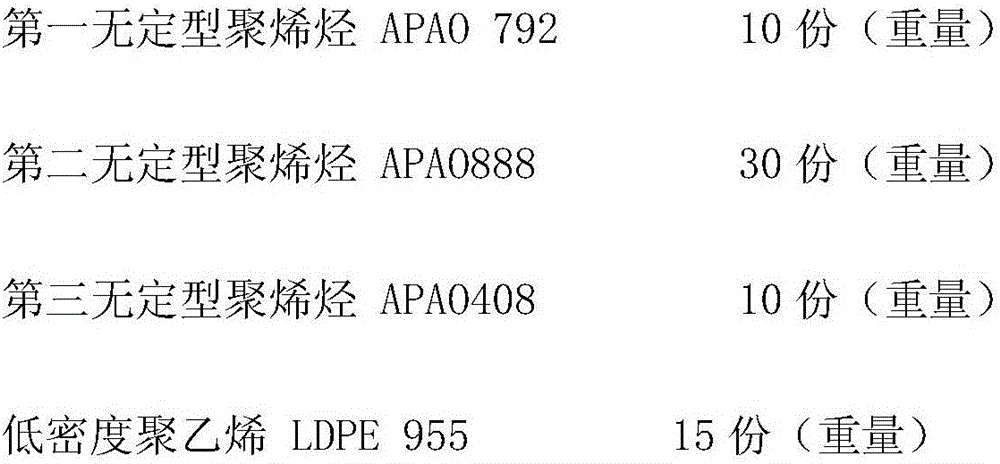

Polyolefin hot melt glue composition for woodworking precoating and edge sealing and preparation method thereof

InactiveCN106118548AReduce the amount of glueReduce glue lineNon-macromolecular adhesive additivesMacromolecular adhesive additivesLow-density polyethylenePolyolefin

Owner:WUXI WANLI ADHESION MATERIALS

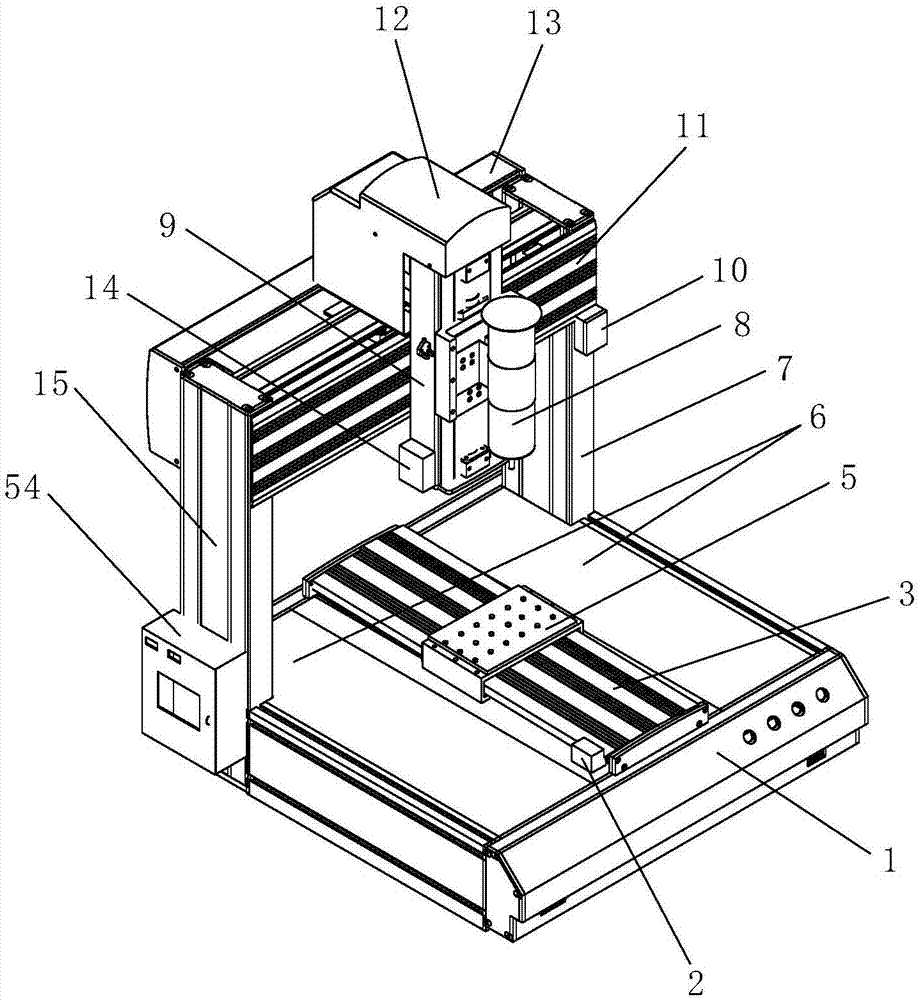

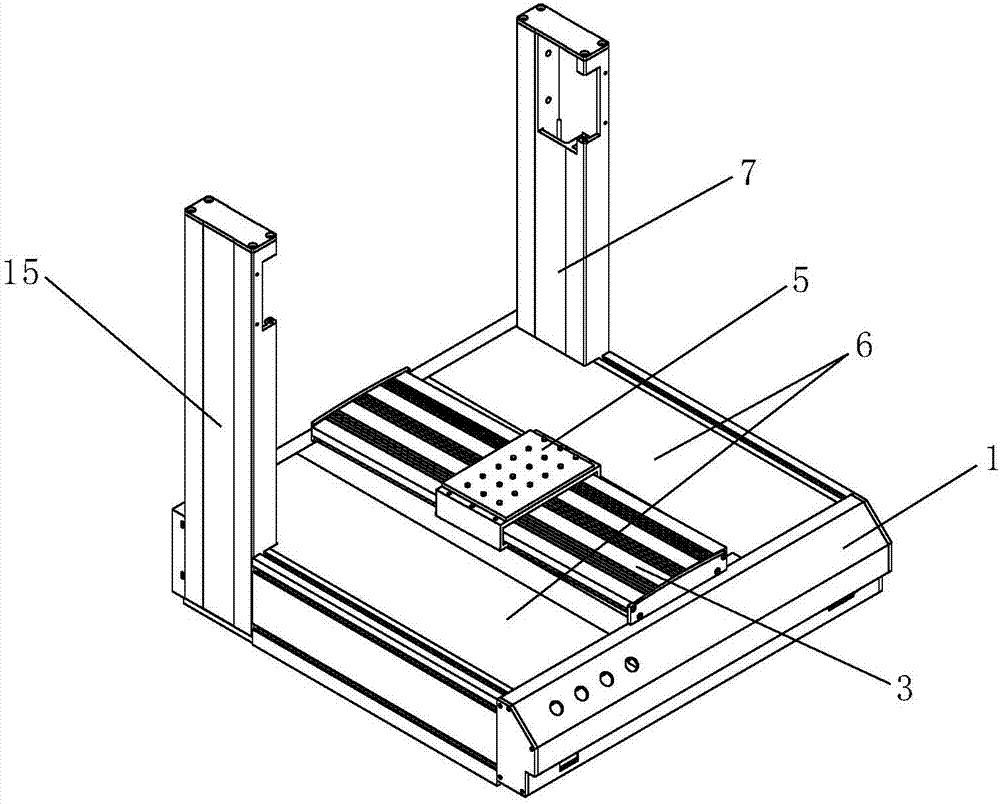

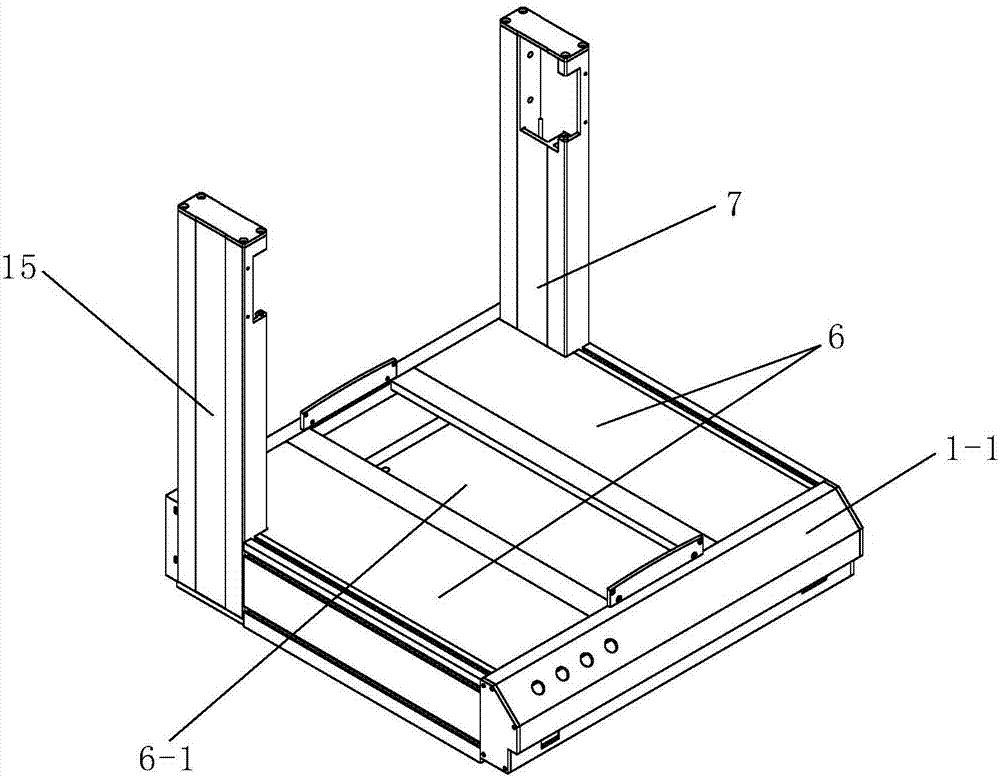

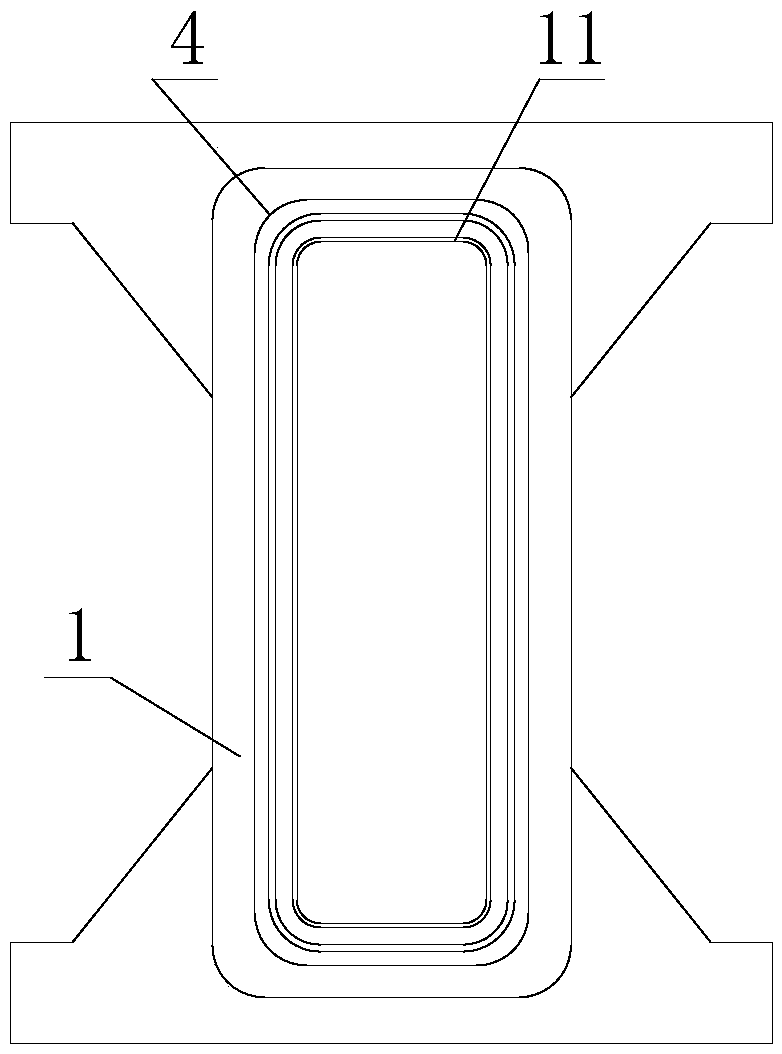

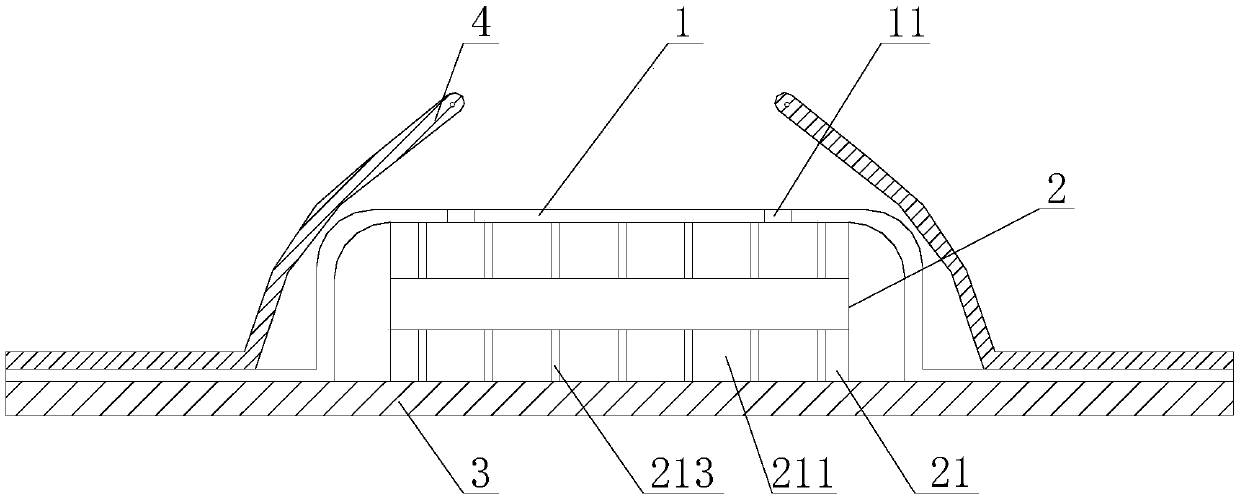

Dispensing machine with accurate positioning performance and consistent dispensing quantity

PendingCN107282370ASimple structureReasonable designLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a dispensing machine with accurate positioning performance and consistent dispensing quantity. The dispensing machine comprises a frame assembly body, an x-axis assembly body, a y-axis assembly body, a z-axis assembly body and a glue outlet assembly body; the frame assembly body comprises a square frame, a left bracket and a right bracket, and the left bracket and the right bracket are mounted on the two sides of the back of the square frame; horizontal operation platforms are mounted on the left and right sides of the square frame, the x-axis assembly body is mounted between the two horizontal operation platforms, the two ends of the y-axis assembly body are connected with the upper end of the left bracket and the upper end of the right bracket respectively, the z-axis assembly body is mounted on the y-axis assembly body, and the glue outlet assembly body is mounted on the front side of the z-axis assembly body; a workpiece platform is mounted on the upper side of the x-axis assembly body, an x-axis displacement sensor is mounted on the left side of the front end of the x-axis assembly body, a y-axis displacement sensor is mounted on the lower side of the right end of the y-axis assembly body, and a z-axis displacement sensor is mounted on the left side of the lower end of the z-axis assembly body. The dispensing machine has the advantages that positioning can be accurate, the dispensing quantity is consistent, the scrap rate of parts is reduced, and the glue is saved.

Owner:XIAN UNIV OF SCI & TECH

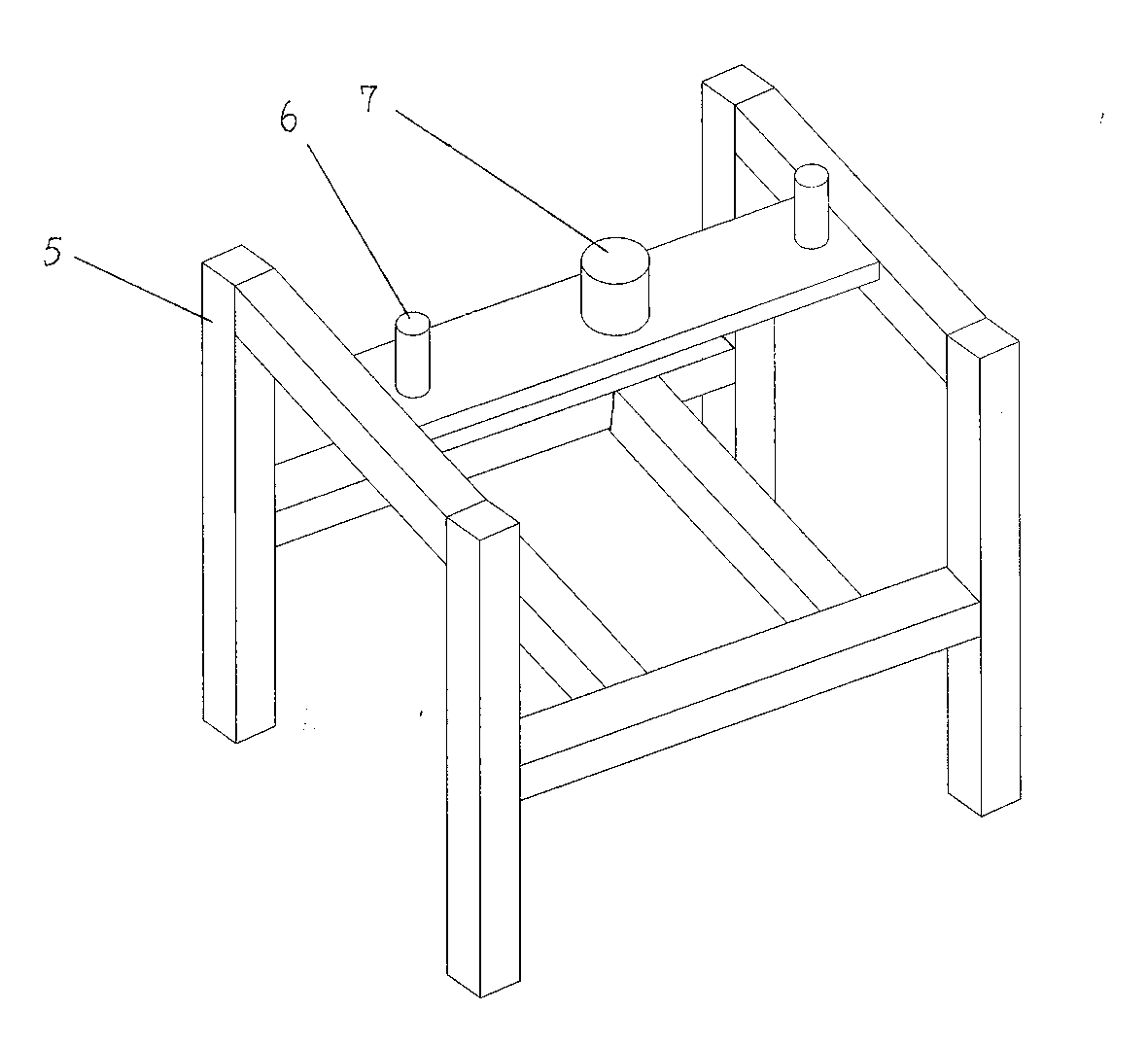

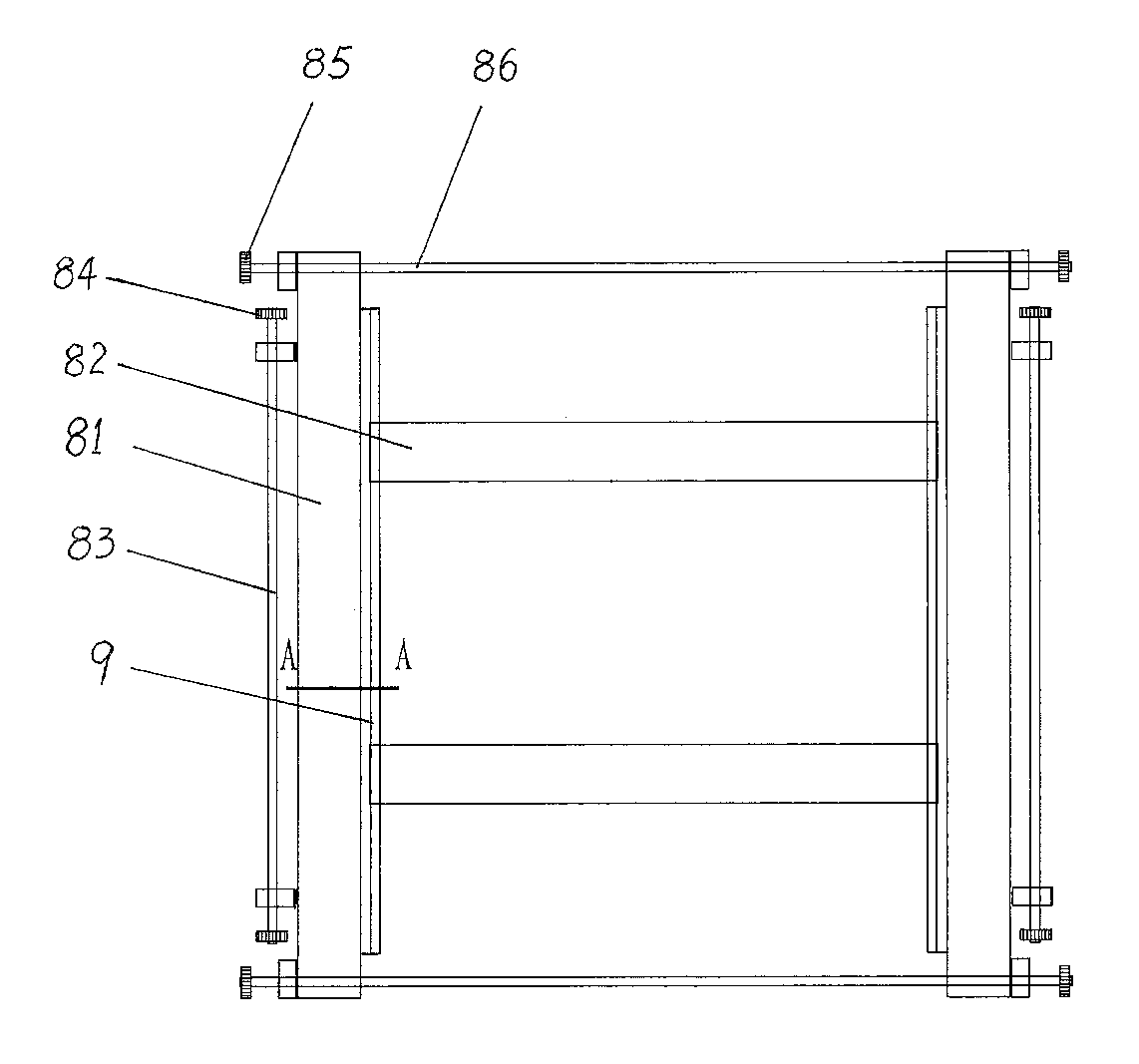

Frame structure and combination method thereof

InactiveCN103365459AHigh strengthImprove yieldDigital data processing detailsProtective devices for lightingEngineeringUltimate tensile strength

The invention discloses a frame structure and a combination method thereof. The frame structure comprises a housing, a first frame, a panel, a polarized plate, a second frame, and a protection plate. The housing is used to support a backlight unit. The first frame is disposed on the backlight unit, and is provided with a first abutting surface and a second abutting surface which are vertical to each other. The first frame is provided with the panel, and the polarized plate is attached with the panel. The second frame is disposed on an outer side of the housing and the first frame, and is abutted with the second abutting surface. The protection plate is attached with the first abutting surface, and an adhesive layer is disposed between the protection plate and the second frame. Thus, the frame structure can reduce gaps between the protection plate and the panel, enhances strength of the protection plate, and has effects of more sensitive and accurate touch control. Glue use amount of the adhesive layer reduces, and integrated yield is improved.

Owner:INTEGRATED DIGITAL TECH

Disposable moisture-absorbing product

InactiveCN105496653ASolve AbsorbencyFix the leakSanitary towelsBaby linensSuper absorbentEngineering

The invention relates to the technical field of personal sanitary products, in particular to a disposable moisture-absorbing product for absorbing liquid excrement. The disposable moisture-absorbing product comprises a liquid-permeable top player, a liquid-tight bottom layer and an absorptive layer, wherein the absorptive layer is arranged between the liquid-permeable top layer and the light-tight bottom layer, and can be used for absorbing and accommodating liquid; at least one absorptive layer comprises multiple absorbing hole layers; the absorbing hole layers are provided with a plurality of absorbing holes; the absorbing holes in adjacent absorbing hole layers are formed in a staggered way. According to the disposable moisture-absorbing product, the absorbing hole layers provided with the absorbing holes are provided, and the plurality of hole layers can be better laminated, so that the glue dosage is reduced, and the softness of the product is increased. Super absorbent polymers are uniformly distributed in the plurality of hole layers, so that the dryness of the product is more uniform. The liquid excrement flows into the absorbing holes, and is temporarily stored in the absorbing holes and absorbed by the absorbing hole layers, so that the problem that a part of excessive liquid excrement is not absorbed and leaks is solved.

Owner:GUANGDONG YINYIN CO LTD

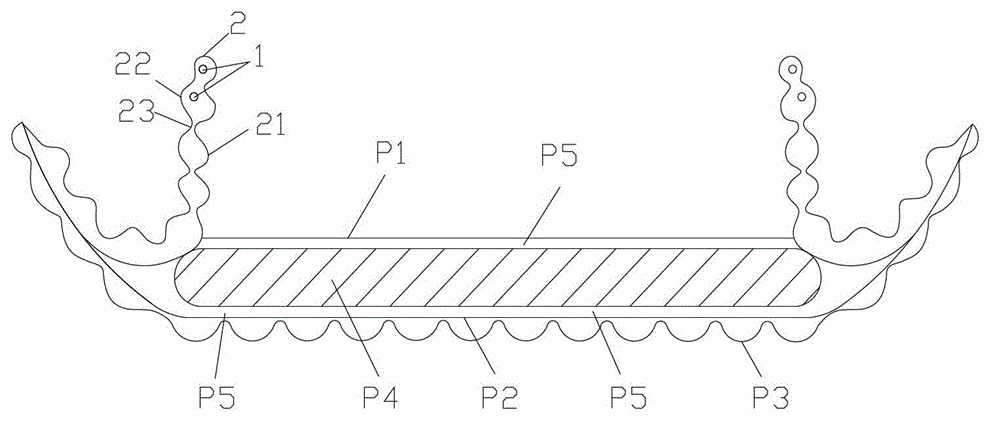

Reining injury prevention three-dimensional protecting surrounding edge for toilet articles

The invention provides a reining injury prevention three-dimensional protecting surrounding edge for toilet articles and relates to the toilet articles. The reining injury prevention three-dimensional protecting surrounding edge is provided with a rubber band and a protecting edge, wherein the protecting edge is a water-repellent non-woven fabric protecting edge and is in a folding double-layer structure, the folding part of the protecting edge covers and surrounds the rubber band and is an upper edge of the protecting edge, corrugated veins are uniformly distributed on the surface of the water-repellent non-woven fabrics, and the water-repellent non-woven fabrics are corrugated vein water-repellent non-woven fabrics. When the reining injury prevention three-dimensional protecting surrounding edge is used for the toilet articles such as paper diapers, other edges of the protecting edge, except the upper edge of the protecting edge, are respectively glued with the surface layer and the bottom layer of the paper diaper, the protecting edge is vertical to the surface layer and the bottom layer of the paper diaper, and the three-dimensional protecting surrounding edge is formed. The protecting edge is the water-repellent non-woven fabric protecting edge, and the water-repellent non-woven fabrics are corrugated vein water-repellent non-woven fabrics, so the glued three-dimensional protecting surrounding edge can keep the fluffy and soft state, the comfort and the air permeability can be obviously improved, in addition, the glue consumption quantity can be obviously saved, the cost is reduced, and the three-dimensional texture is improved.

Owner:厦门造福堂文化传媒有限公司

Method for manufacturing antiskid bamboo-wood composite boards

InactiveCN105397874AAchieve sustainable developmentShorten the growth cycleRosin coatingsDrying gas arrangementsBottle neckMaterials science

The invention discloses a method for manufacturing antiskid bamboo-wood composite boards, and relates to the technical field of composite materials. The antiskid bamboo-wood composite boards are mainly made of bamboos and plates. The method comprises the following steps of (1) material sorting, (2) drying, (3) grinding, (4) afterdrying, (5) recombination of blank pieces, (6) life preserving, and (7) antiskid paint coating. According to the method, due to the organic combination of bamboos and wood, material drawing is prevented from being too simplex in mode, the bottle neck problem of existing raw materials is effectively solved, the inherent fiber structure of the raw materials is basically not destroyed, and the amount of adopted glue between the materials is reduced; in addition, the surfaces of the bamboo-wood composite boards are coated with antiskid paint so that a good antiskid effect can be achieved, and the indoor security is improved.

Owner:广德县永彬竹木工艺品厂

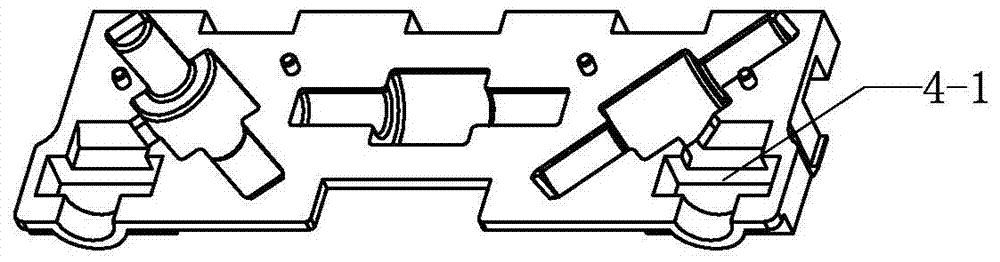

Small sealant filling photovoltaic junction box

ActiveCN103701407ARapid divergenceEvenly distributedPhotovoltaicsPhotovoltaic energy generationEngineeringHeight difference

The invention discloses a small sealant filling photovoltaic junction box. The small sealant filling photovoltaic junction box comprises a base and an upper cover which are buckled with each other; a bottom plate is mounted in the base; terminals are mounted on the bottom plate; diodes are mounted on the terminals; photovoltaic cables pass through wire fasteners in the base and are connected with the terminals; the upper part of the bottom plate in the base is filled with sealant. The hottest part of the photovoltaic junction box is not in direct contact with a solar rear panel, a convection cavity is formed in the bottom of the base, a height difference exits between the bottom surface of the base and the bottom plate, and vent holes are formed in the upper cover, so that a good radiating effect is achieved; the inner cavity of a box body is filled with metal parts, the radiating area of the photovoltaic junction box filled with the sealant is large, and the heat distribution is uniform; the periphery of the base is bent to form coamings, and cavities are defined by the coamings, so that the radiating speed is increased while the sealant filling amount is reduced.

Owner:浙江正泰鑫辉光伏有限公司

Corrugated paper board bonding device

InactiveCN103419409AImprove adhesionSimple structureMechanical working/deformationCardboardPulp and paper industry

The invention provides a corrugated paper board bonding device which comprises a support, a plurality of sequentially-arranged compositing devices fixed on the support, and a conveying belt positioned below the compositing devices. Each compositing device comprises an adjusting rod fixed on the support, a vibrating device fixedly mounted below the adjusting rod, and a pressing plate connected with the vibrating device through springs. The corrugated paper board bonding device has the advantages of simple structure, simplicity in operation and good paper board bonding effect.

Owner:天津市大港巨龙造纸厂

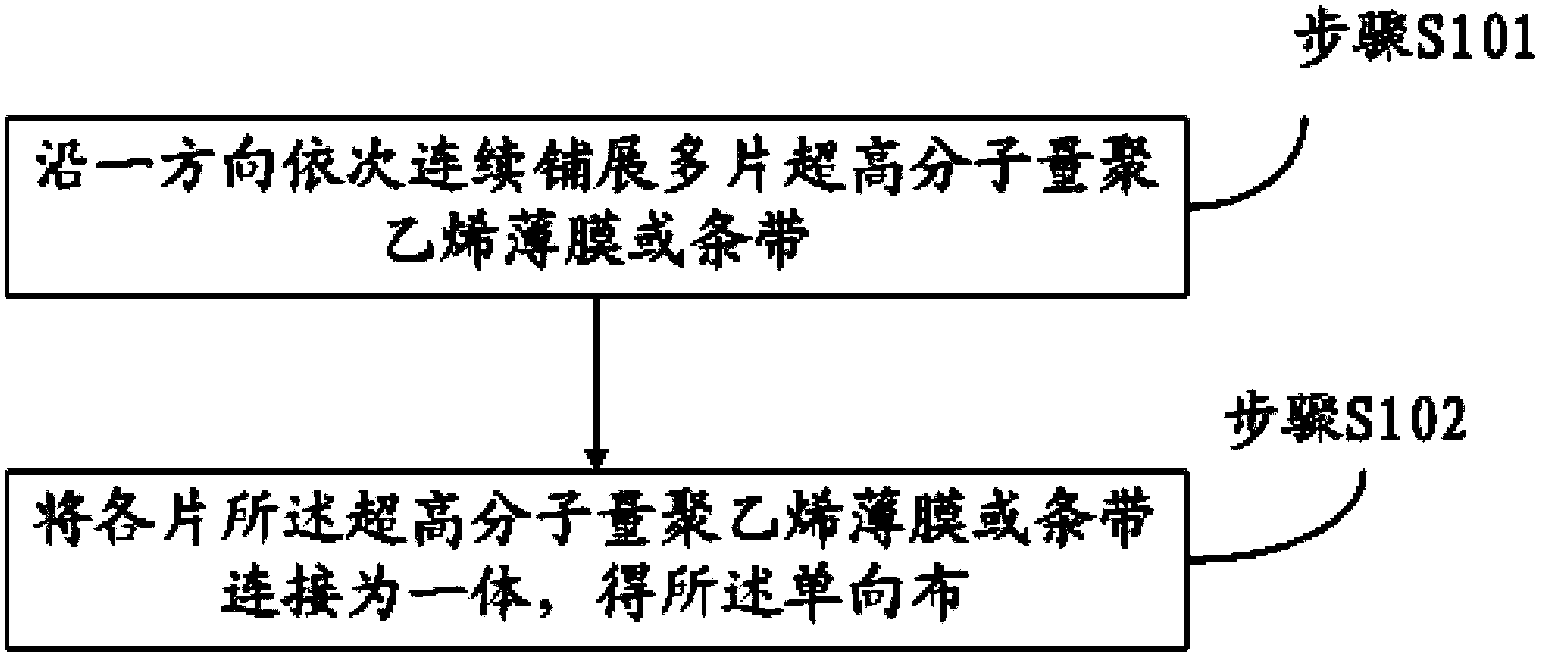

Unidirectional fabric, non-woven fabric, preparation methods of fabrics and non-woven fabric product

InactiveCN104228062AReduce damage rateReduce the amount of glueSynthetic resin layered productsLaminationWhole bodyEngineering

The invention provides a unidirectional fabric, a non-woven fabric, preparation methods of the fabrics and a non-woven fabric product. The preparation method of the unidirectional fabric comprises the following steps: sequentially continuously spreading a plurality of ultra high molecular weight polyethylene films or strips along one direction; and connecting the ultra high molecular weight polyethylene films or strips to form a whole body to obtain the unidirectional fabric. The non-woven fabric prepared on the basis of the unidirectional fabric and the product prepared on the basis of the non-woven fabric are high in strength and excellent in bulletproof property; the preparation method are simple and are low in cost.

Owner:ZHENGZHOU ZHONGYUAN DEFENSE MATERIAL

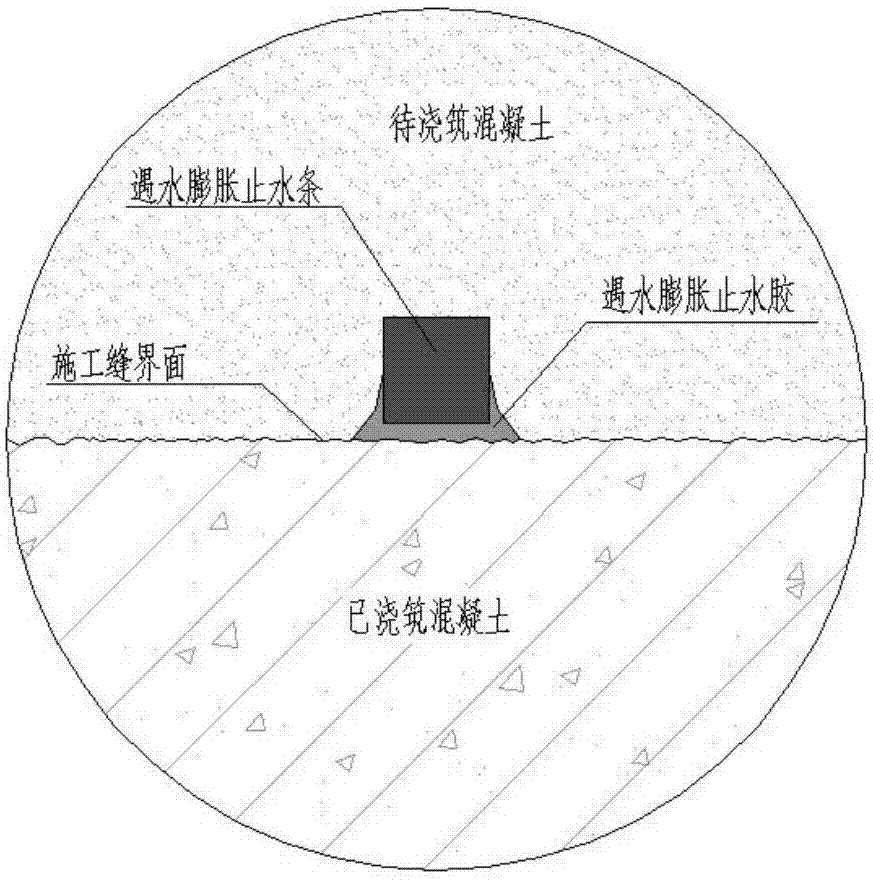

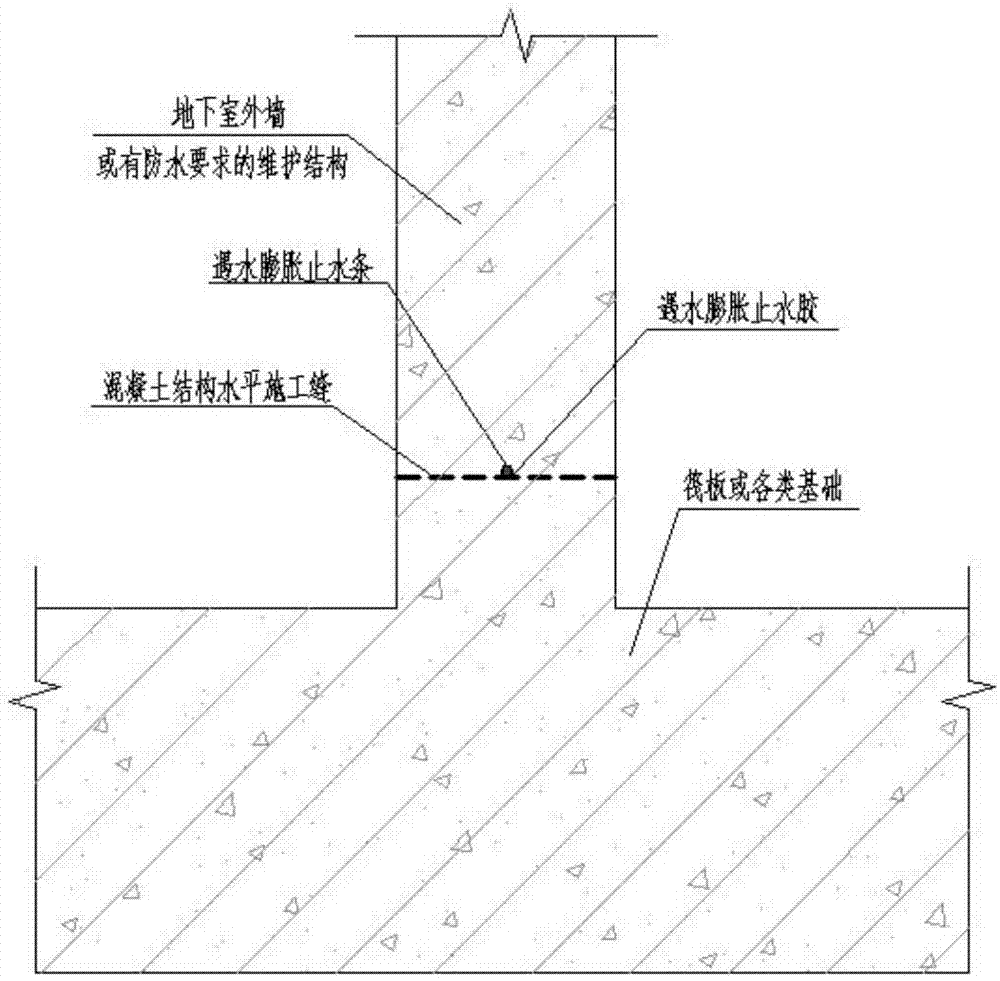

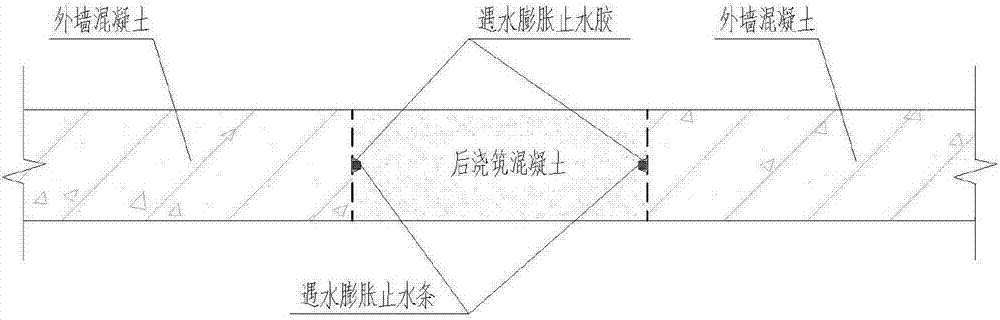

Construction method for combination of water swelling sealing rod and water swelling glue

ActiveCN107143046ARepair operation is simpleQuality improvementArtificial islandsUnderwater structuresSocial benefitsBuilding construction

The invention discloses a construction method for combination of water swelling sealing rod and water swelling glue, which relates to the technological field of waterproof construction. In the construction method for combination of water swelling sealing rod and glue, the water swelling sealing rod is used as a main water stopping material and the water swelling glue is used as a bonding and fixing material as well as an auxiliary water stopping material on a lap joint. At the same time, the combination of water swelling rod and water swelling glue is applied to the construction of the waterproof part in a building. The construction method for combination of swelling sealing rod and water swelling glue can be extensively applied to concrete construction joints, late poured bands, wall pipes, pile crowns in underground projects and other joints which is suitable for the waterproof method. The construction method for combination of water swelling sealing rod and water swelling glue has much more polarization and application value. Besides, the economic and social benefits of the construction method for combination of water swelling rod and water swelling glue are extremely notable.

Owner:王军

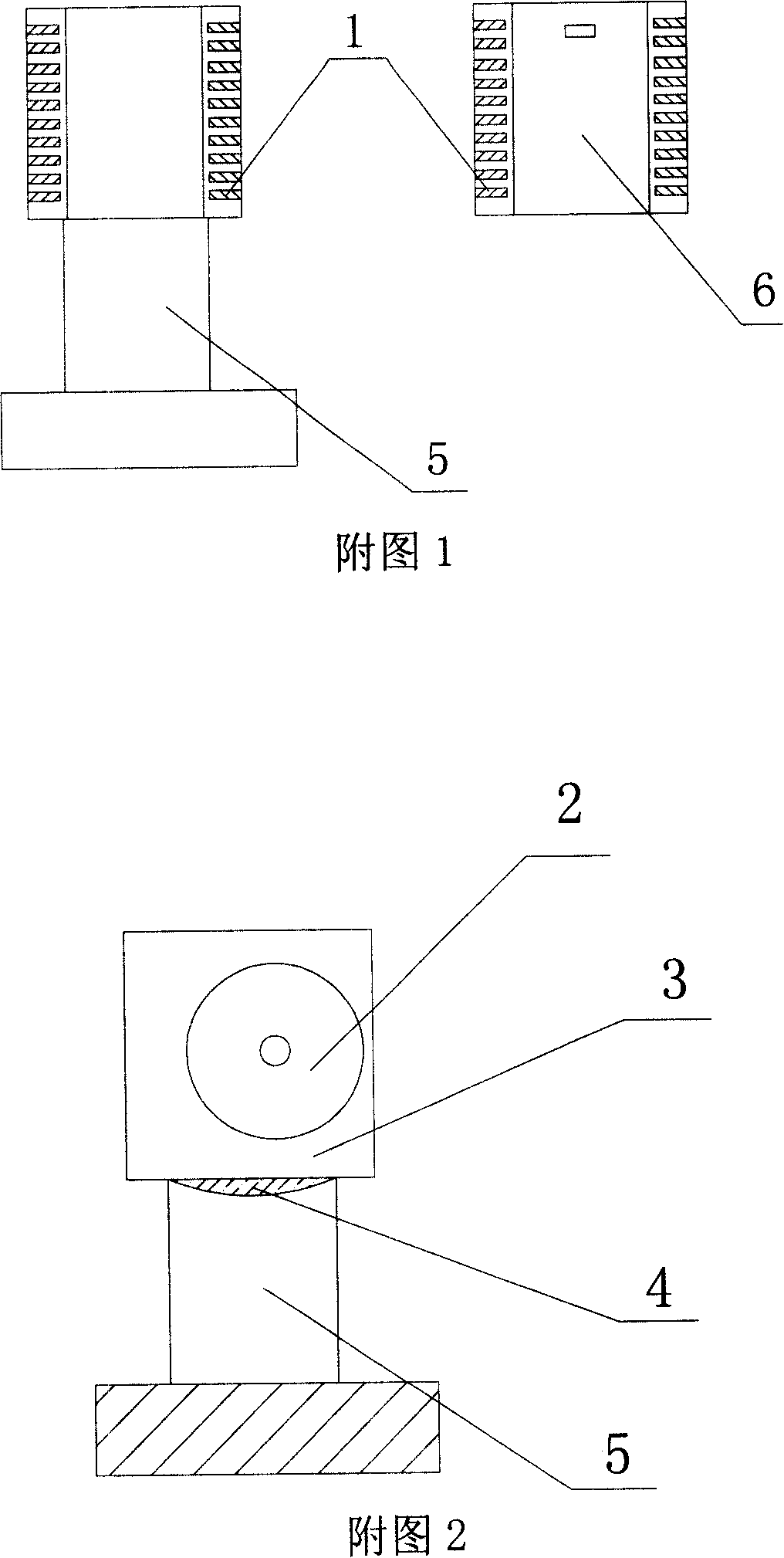

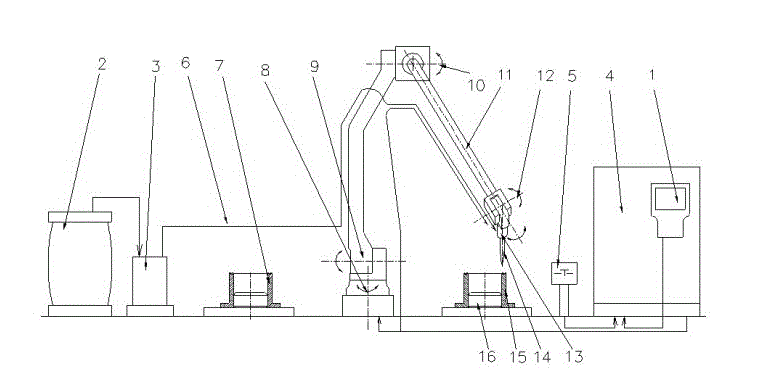

Automatic pattern piece gluing device for evaporative pattern for casting

InactiveCN103331237AAvoid deformationHigh bonding strengthLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention relates to an automatic pattern piece gluing device for an evaporative pattern for casting. The automatic pattern piece gluing device comprises an automatic evaporative pattern piece bonding glue transmission system, a numerical-control operating system and a pattern piece locating tool, wherein the numerical-control operating system is customized with demonstration programming software; bonding glue is automatically and uniformly coated on a butting face of a second coating pattern piece, a matching pattern piece and the second coating pattern piece are manually bonded together so as to form the evaporative pattern, a matching groove is formed in the butting face of the second coating pattern piece, and glue moving loci are formed in the two sides of the matching groove; and a matching convex rib is formed at a corresponding position, butted with the second coating pattern piece, of the matching pattern piece, and the matching convex rib and the matching groove are matched together. According to the device provided by the invention, bonding butting faces are bonded in a manner of adopting concave-convex matching and dispensing glue to the two sides of a concave face, so that the bonding strength is high, the foam pattern difficultly deforms, and the glue consumption is reduced. A glue moving program is customized by the numerical-control operating system, so that the gluing form is stable and smooth, and is not subjected to glue interruption, and the bonding rate is fast.

Owner:解明国 +1

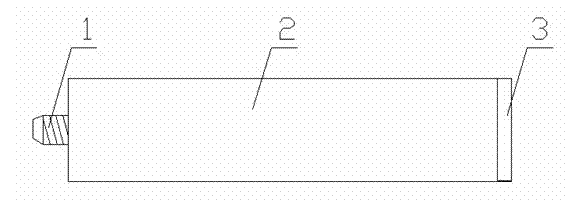

Racket handle

The invention relates to a racket handle which comprises a handle body and a small cap. The handle body comprises an outer hollow cylinder and an inner hollow cylinder integrally nested into the outer hollow cylinder. The handle body comprises a front section, a middle section and a rear section which are sequentially arranged along the longitudinal axis. The small cap fixedly sleeve the free end of the front section. One side, close to the free end, of the front section is a conical hollow body. The connecting end of the conical hollow body and the small cap is provided with an inward cylindrical deep hole. Damping strips are disposed inside the cylindrical deep hole. Reinforcing spokes are disposed in a space formed by the inner wall of the front section and the outer wall of the cylindrical deep hole. Grooves spirally extending along the axis of the handle body is formed in the outer wall of the outer hollow cylinder. By the structure, the racket handle has the advantages that wood and a grip are omitted, environmental protection and consumption reduction are achieved, the racket handle is few in material, capable of being washed at any time, good in touch, good in damping effect, fast in sweat dissipation and good in durability, and a racket with the racket handle is long in service life.

Owner:SHANGHAI DOUBLE HAPPINESS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com