Production method bamboo strip side pressing bamboo board

A production method and technology of bamboo chips, which are applied in the pretreatment of molding materials, flat products, manufacturing tools, etc., can solve the problems that users do not like, are not beautiful, and raw bamboo cannot replace floors, decorative panels or handicrafts, etc., and achieve savings. The effect of manpower, electricity saving and less glue consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

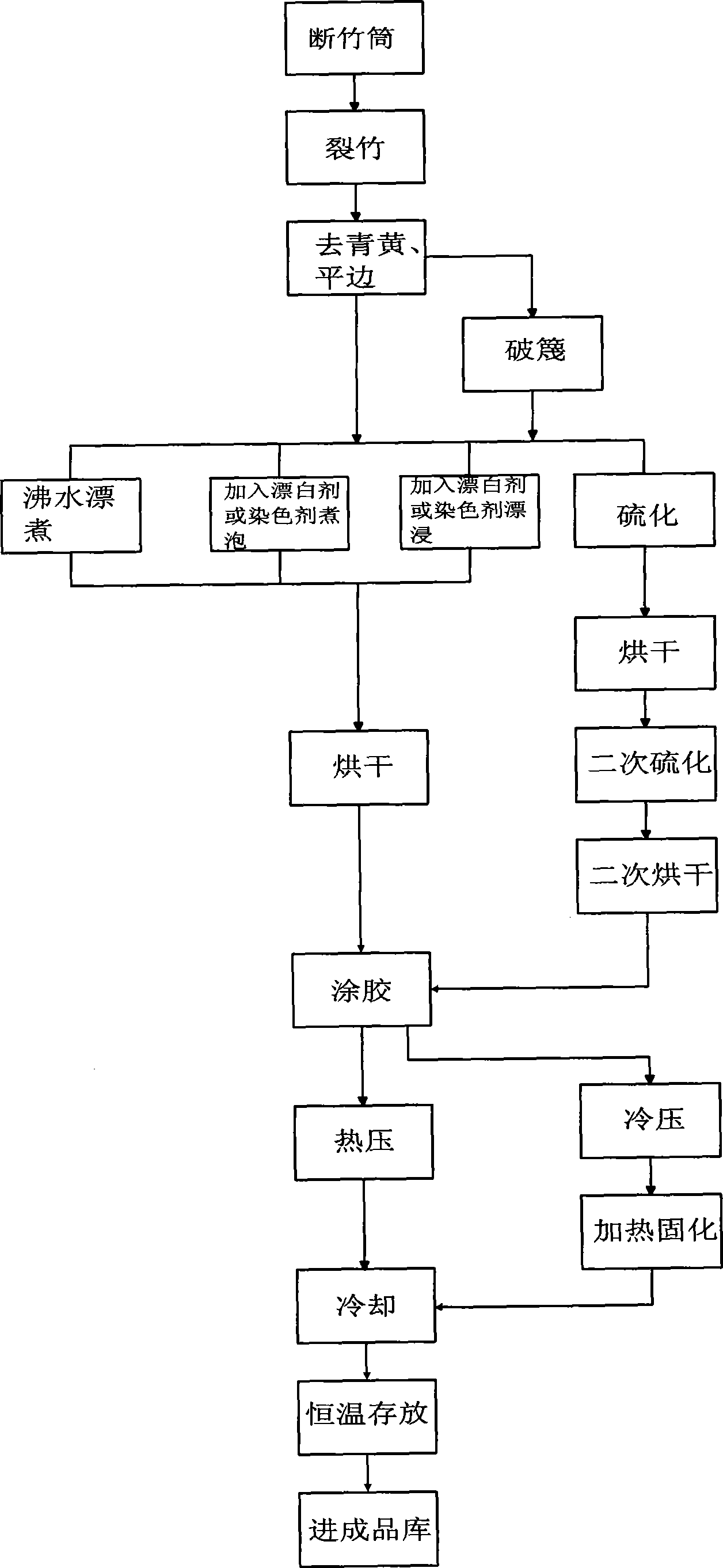

[0026] like figure 1 Shown: a kind of manufacturing method of bamboo slice sideways pressing bamboo plate, including cutting fresh bamboo into bamboo tubes of required length with a bamboo cutting machine and splitting the bamboo tube into equal-width bamboo slice blanks with a bamboo splitter, the process steps for:

[0027] [1] Use a milling machine to remove the bamboo green on the surface of the bamboo slices and the bamboo yellow on the bottom surface, and flatten the two sides of the bamboo slices, and process them into a thickness of 2-15 mm, which can be selected as 8 mm, and a width of 3-3 mm. 19 mm, 15 mm bamboo can be selected;

[0028] [2] Use a cutting machine to cut the bamboo slices into a thickness of 0.5-4 mm along the longitudinal direction parallel to the blue outer surface of the bamboo slices, and choose 4 mm bamboo slices;

[0029] [3] Put the bamboo slices processed in step [1] or the bamboo slices cut in step [2] into the blanching tank, and boil for ...

Embodiment 2

[0035] like figure 1 Shown: a kind of manufacture method of side vertical pressing bamboo plate of bamboo chip, its step [1] and [2] are identical with embodiment 1;

[0036] [3] Put the bamboo slices or bamboo sputum processed in steps [1] and [2] into the bleaching tank with added insect-proof, mildew-proof, bleaching agent or dyeing agent and boil for 1.5-4.5 hours with boiling water, you can choose 3 Hour;

[0037] The following steps [4]-[7] are the same as in Example 1.

Embodiment 3

[0039] like figure 1 Shown: a kind of manufacture method of side vertical pressing bamboo plate of bamboo chip, its step [1] and [2] are identical with embodiment 1;

[0040] [3] put the bamboo chips or bamboo scums of step [1] and [2] into the bleaching tank adding insect-proof, anti-mildew, bleaching agent or dyeing agent and soak for 1-96 hours, 70 hours can be selected;

[0041] The following steps [4]-[7] are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com