Patents

Literature

40results about How to "Effective corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene high temperature resistant corrosion-resistant coating for metallic material and preparation method of graphene high temperature resistant corrosion-resistant coating

InactiveCN108276866AReduce coagulationImprove anti-corrosion performanceAnti-corrosive paintsPolyvinyl butyralPolyvinyl alcohol

The invention relates to a graphene high temperature resistant corrosion-resistant coating for a metallic material and a preparation method of the graphene high temperature resistant corrosion-resistant coating. The graphene high temperature resistant corrosion-resistant coating consists of the following components in parts by weight: 6-12 parts of graphene oxide, 20-45 parts of a phenolic resin,2-6 parts of polyvinyl butyral, 1-4 parts of rare earth chloride, 12-30 parts of graphene quantum dots, 2-5 parts of a heat conduction metallic powder, 3-6 parts of carbon nanotubes, 12-30 parts of asolvent, 2-6 parts of an antioxidant, 5-9 parts of a curing agent and 12-18 parts of a defoaming agent, wherein the graphene quantum dots is 2-4nm in size; the solid content of the phenolic resin is 45-55%. According to the graphene high temperature resistant corrosion-resistant coating provided by the invention, by the virtue of the good dispersibility of the graphene quantum dots in solvents andrelatively good non-covalent functions of the graphene quantum dots with graphene sheets, two-dimensional sheet structures of the graphene can be overlapped layer by layer in the coating, a compact physical insulating layer can be formed, and the corrosion resistance of the coating can be improved.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

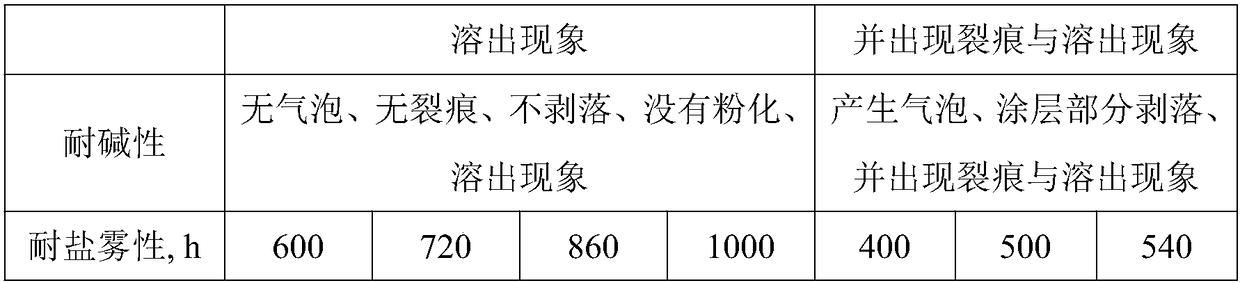

Production method bamboo strip side pressing bamboo board

InactiveCN101417457AJieba XiaoxianIncrease profitCane mechanical workingReed/straw treatmentElectricityResist

The invention relates to a manufacturing method of bamboo boards by side standing pressing of bamboo chips, including the following steps: bamboo chips or bamboo stripes initially processed according to required sizes are put into a kiering pool to be brewed with boiling water or are placed into a kiering pool with insect-resist agents, mold preventing agents, bleachers or coloring agents to be brewed with boiling water or placed into a dip bleaching pool with bleachers or coloring agents to be dip-bleached; the bamboo chips or bamboo stripes are directly placed into an autoclave for high temperature steam and sulfuration; a resin adhesive is uniformly coated on bottom surfaces and surfaces of the dried bamboo chips or bamboo stripes; the glued bamboo chips or bamboo stripes are sent into a hot-press to be hot-pressed until the glue is solidified; the chips or stripes are cooled to the normal temperature, then stored in a constant-temperature house for 30 days and then cut into finished products according to needed dimensions. The surfaces of the bamboo boards are natural textures formed by the lamination of sides of slices of bamboo chips and are beautiful without knots; the boards are larger in bearing capacity, little in gel content of finished products, more good for the environmental protection and hard to deform; and compared with the prior art, the method is high in efficacy, saves electricity, improves the utilization efficiency of original bamboos and saves cost.

Owner:赵斌

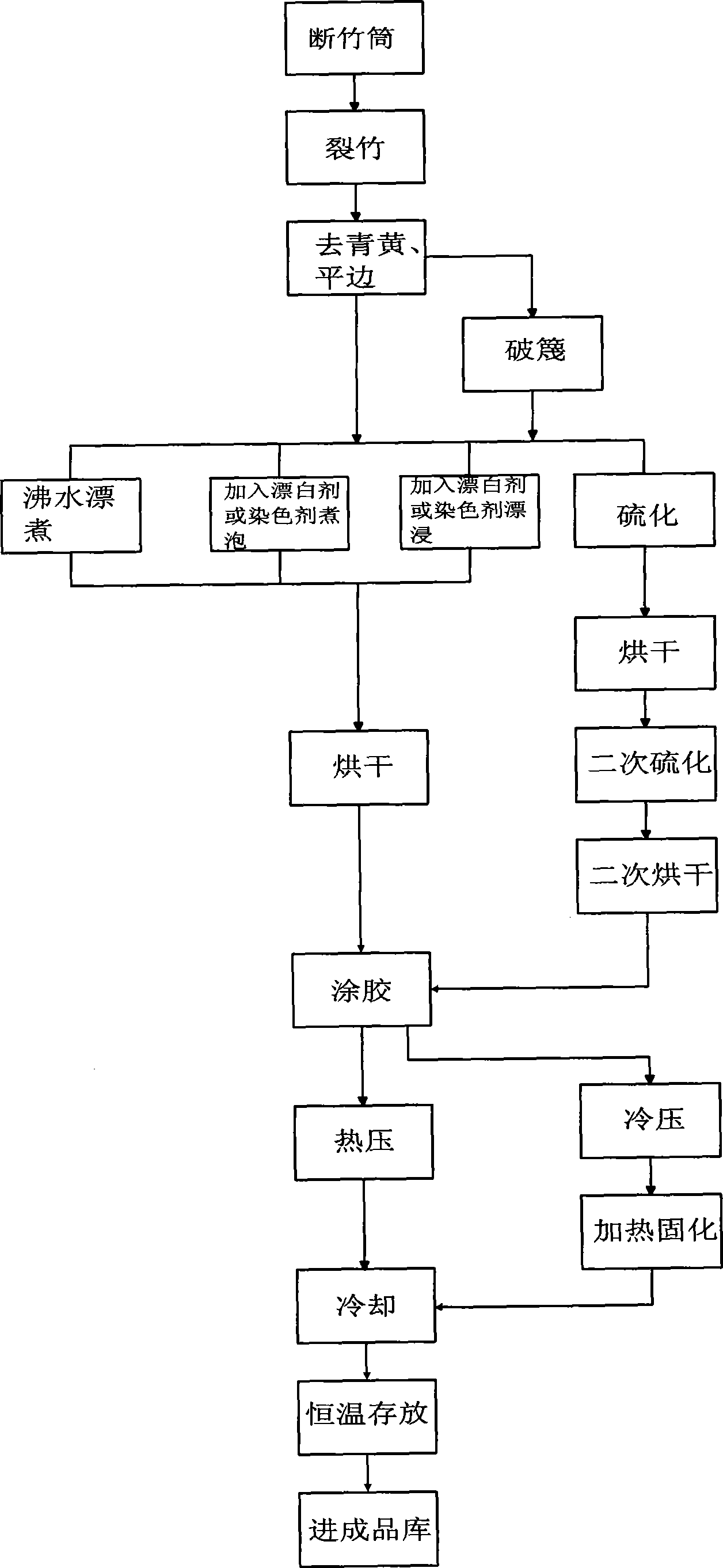

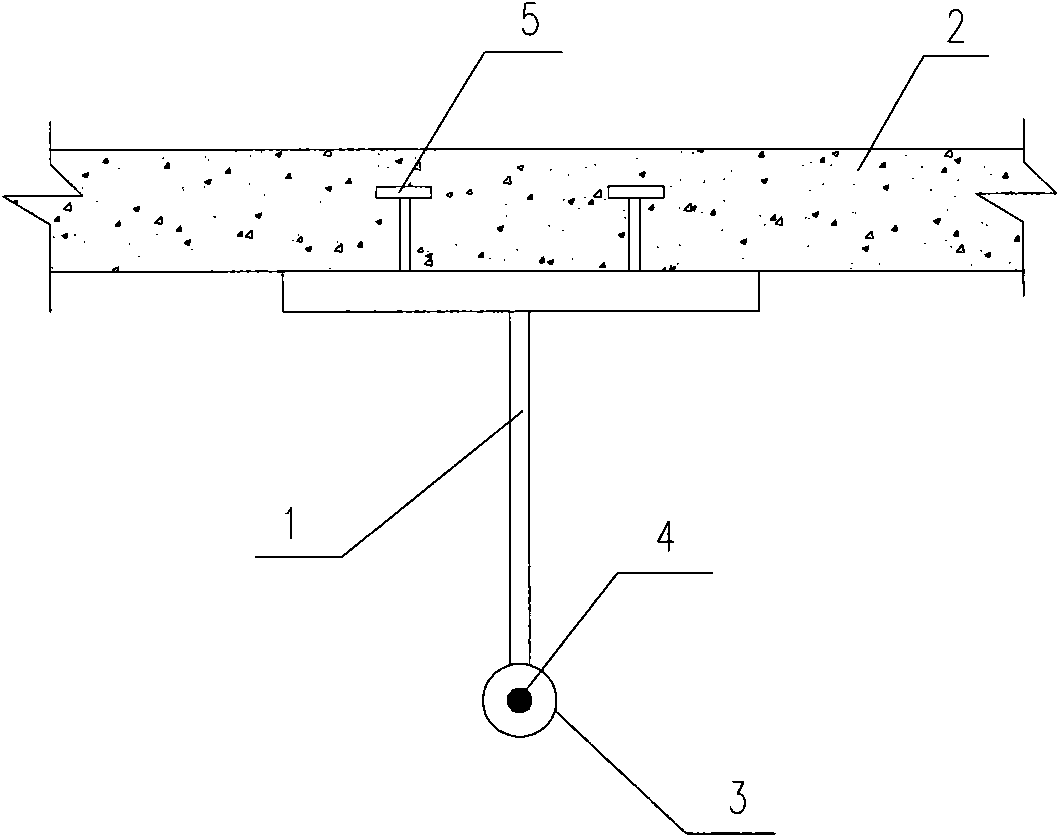

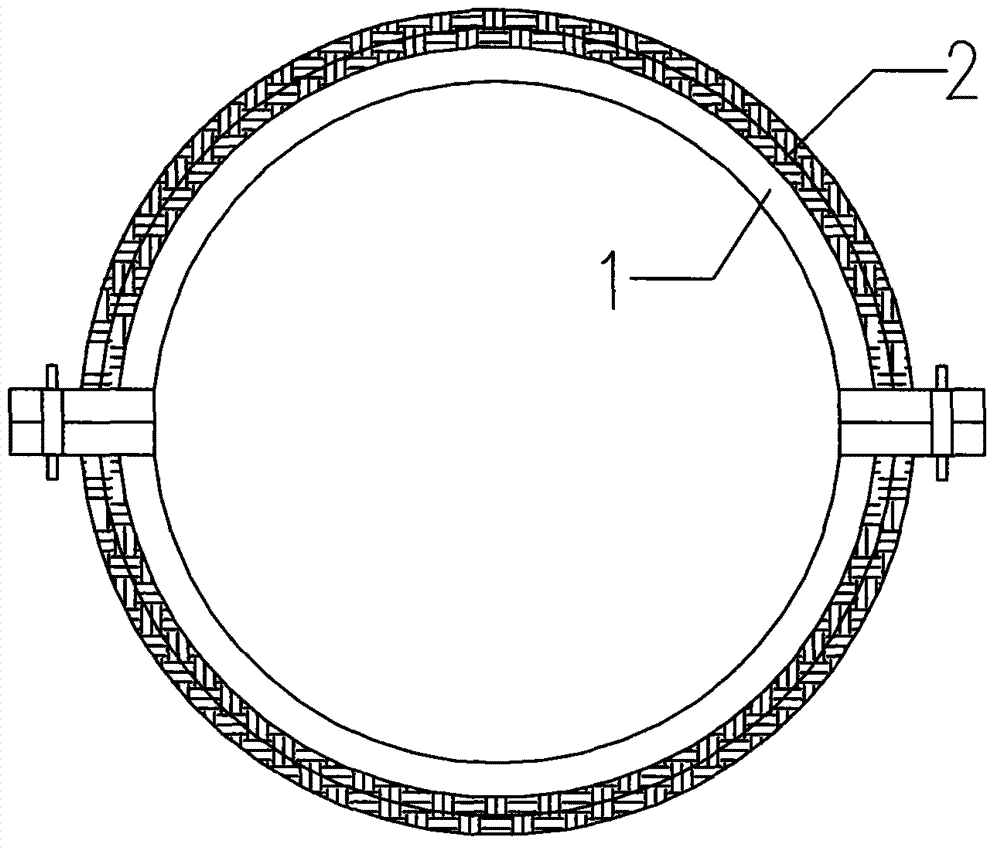

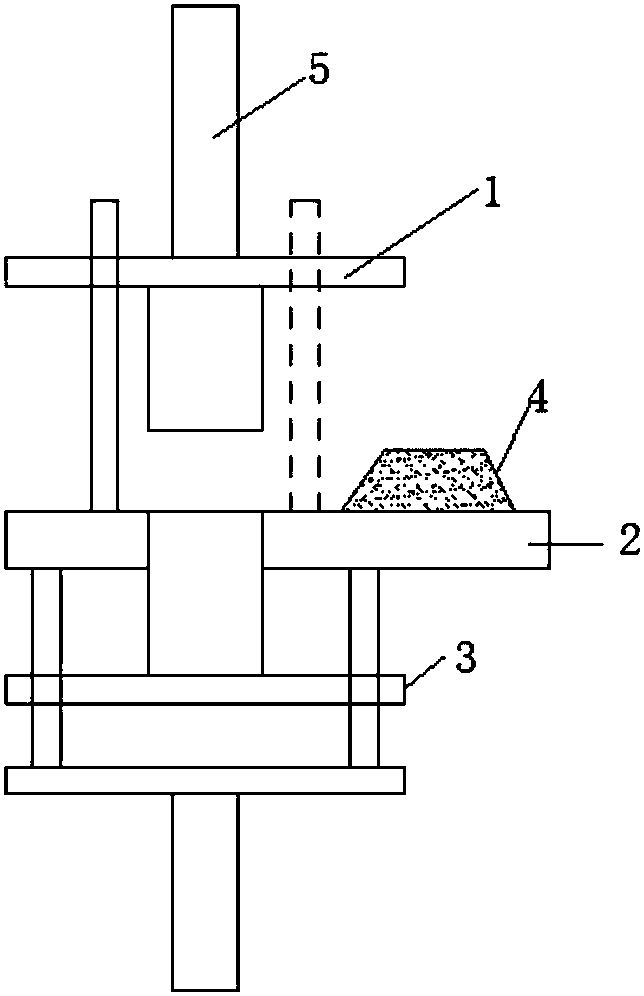

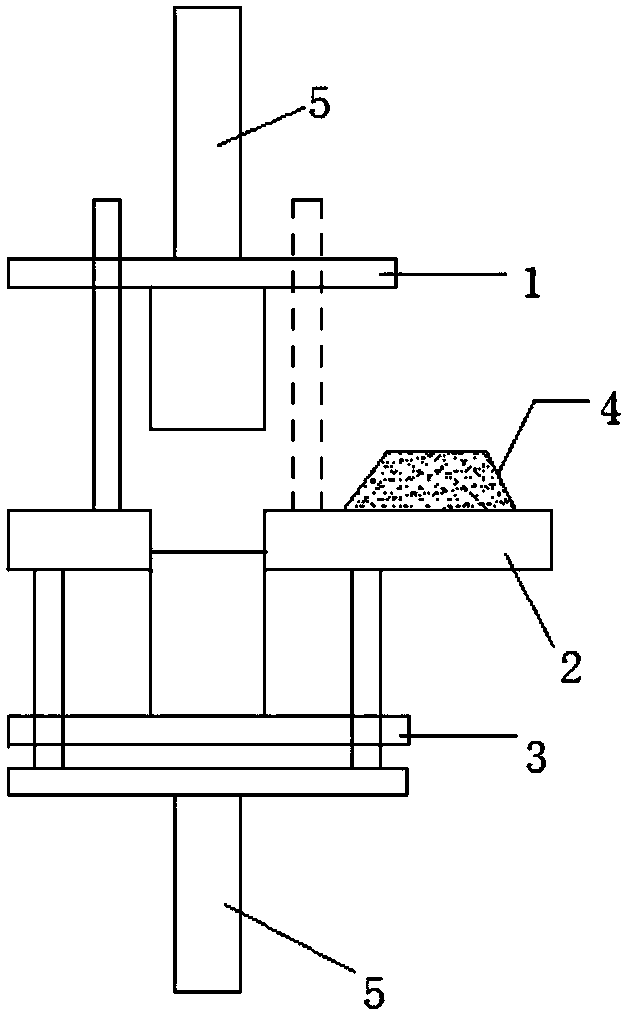

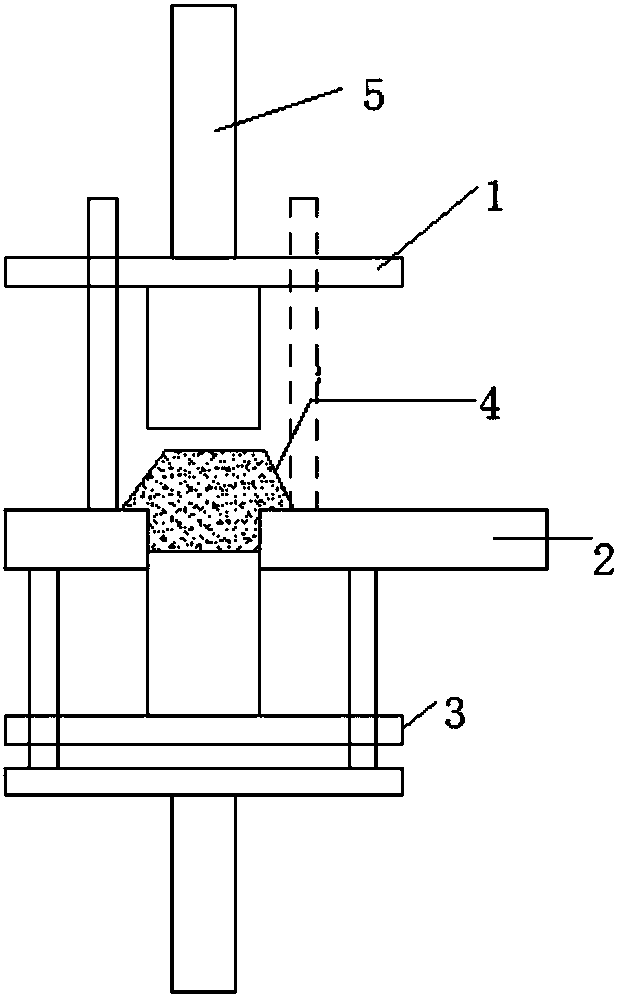

Novel prestressed steel pipe-concrete composite beam

The invention relates to a novel prestressed steel pipe-concrete composite beam, and belongs to the technical field of building structure engineering. The prestressed composite beam mainly comprises a steel beam (1) and a concrete floor slab (2) poured on the steel beam, and is characterized in that: a bottom flange of the steel beam is a steel pipe (3); a plurality of linear steel ropes (4) are arranged in the steel pipe; after the prestressed steel ropes are strained, two ends of the steel pipe (3) are sealed; and the concrete floor slab (2) is poured. Compared with a steel beam and a common composite beam, the novel composite beam has the advantages of great reduction of midspan deflection and steel beam section stress, easy strain of the steel ropes, effective anticorrosion and fire prevention, simple and convenient construction and remarkable economic benefits.

Owner:北京京诚华宇建筑设计研究院有限公司

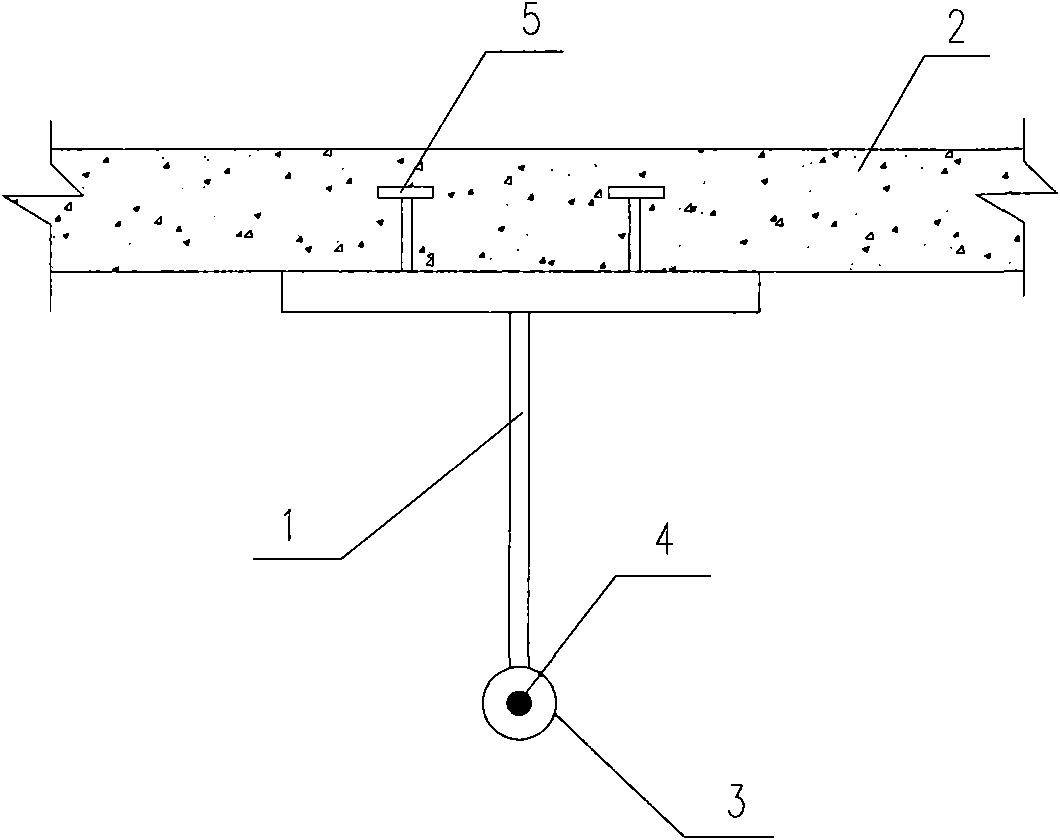

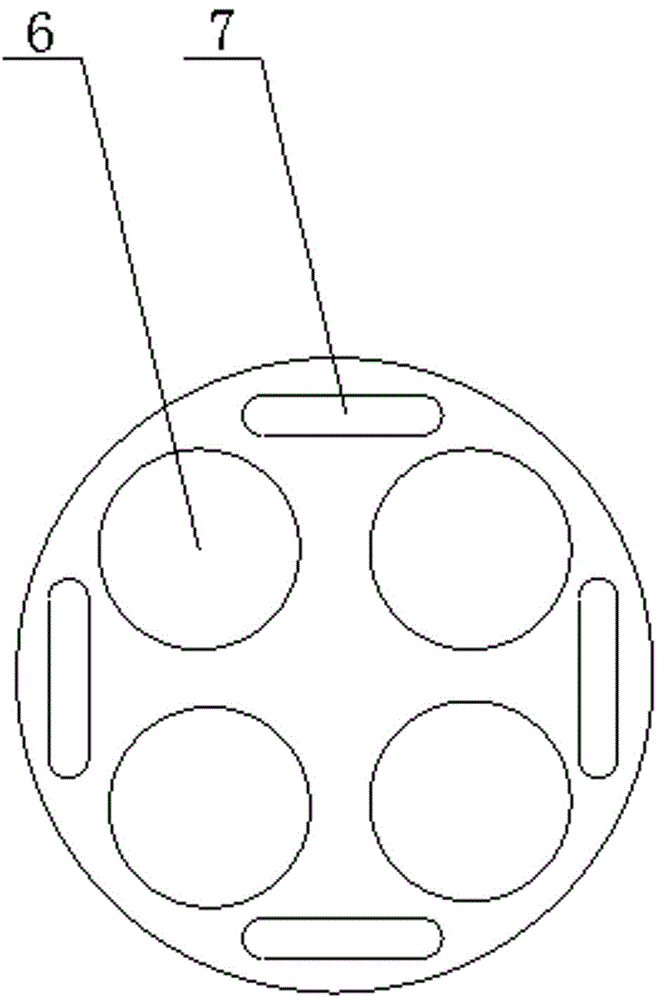

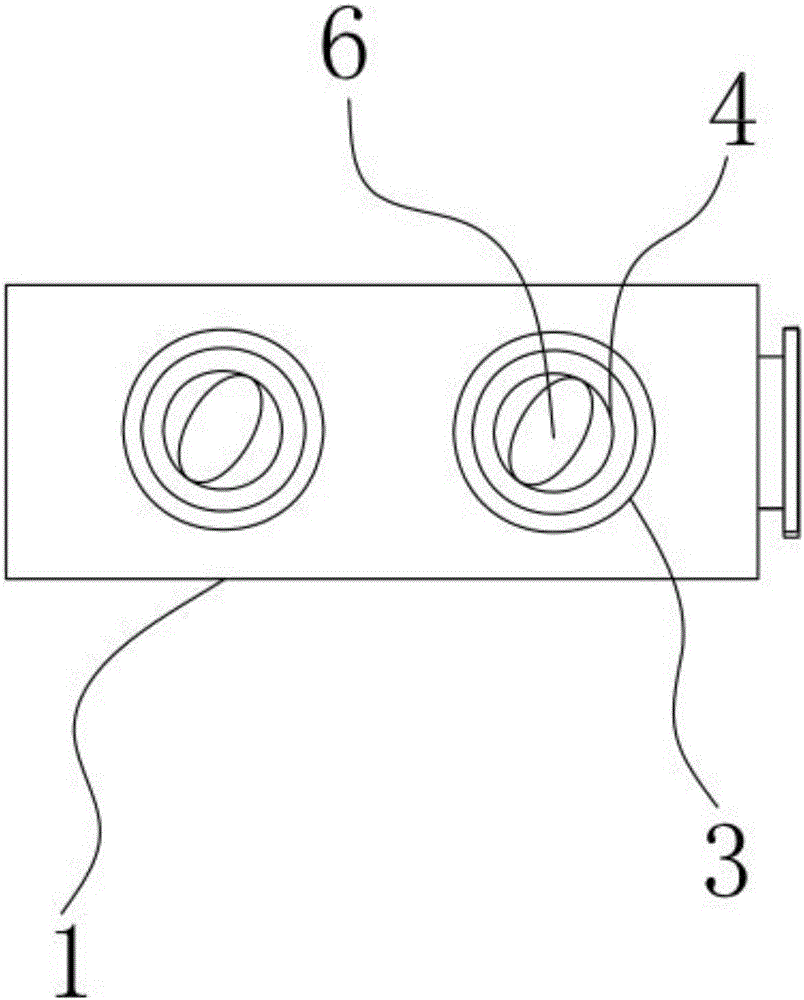

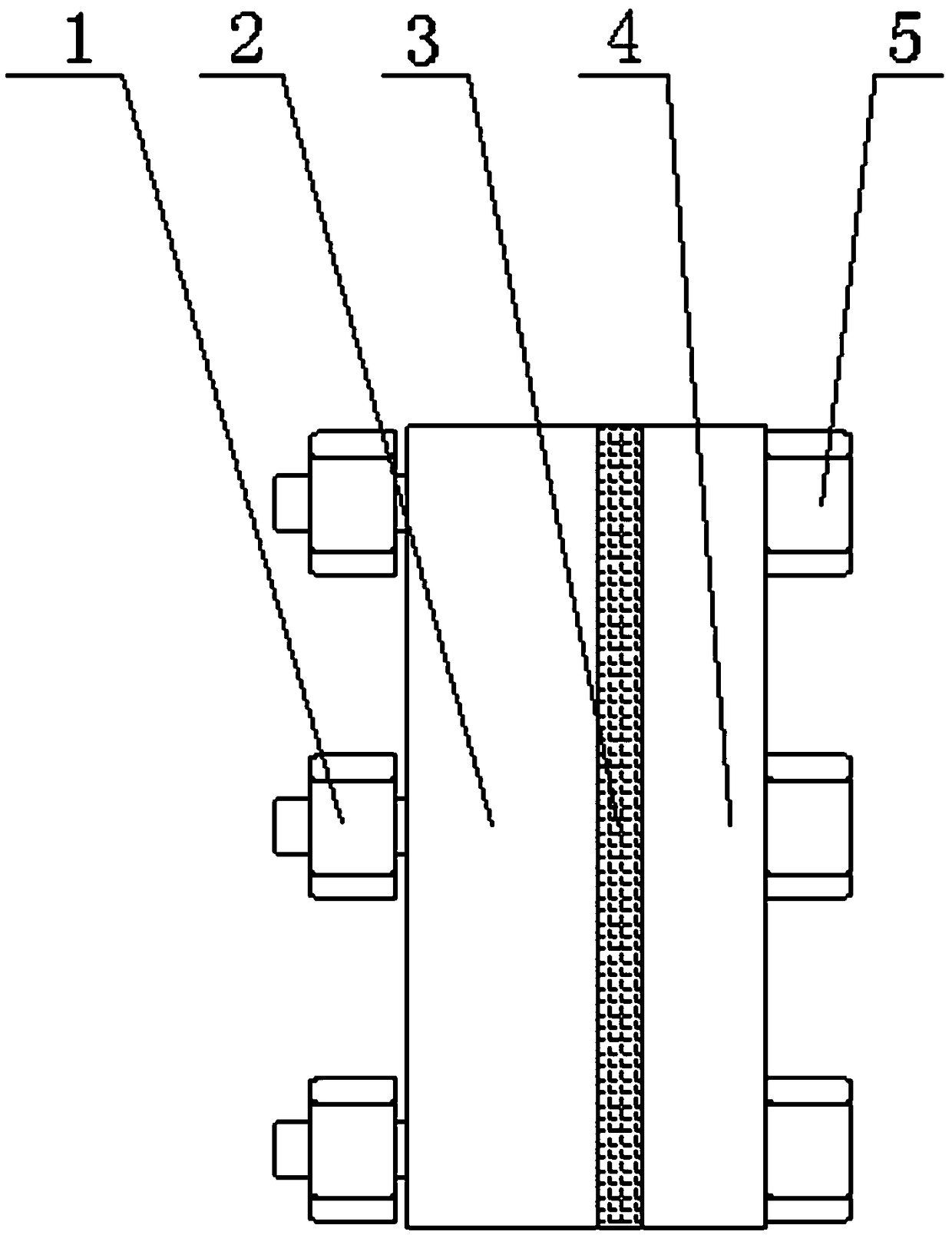

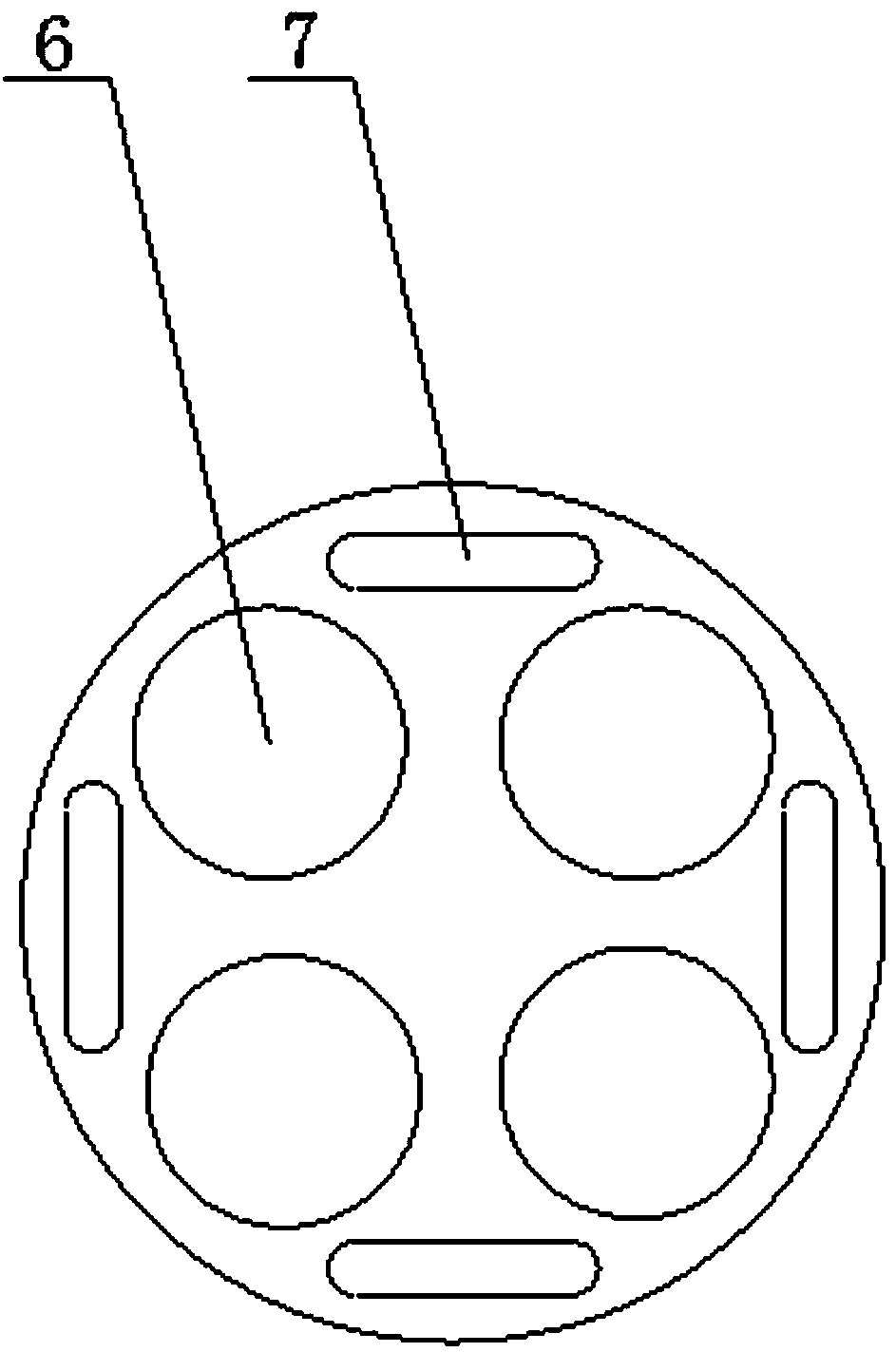

Multi-pipeline connecting flange

ActiveCN106247058AQuick and efficient installationImprove engineering efficiencyFlanged jointsPipe elementsMaterial resourcesEngineering

The invention relates to a multi-pipeline connecting flange which comprises a first flange body, a second flange body, a sealing gasket, fastening bolts and nuts. The sealing gasket is arranged between the first flange body and the second flange body. The corresponding positions of the first flange body and the second flange body are each provided with at least two pipe containing holes and are further each provided with at least two fastening through holes. The fastening bolts sequentially penetrate the fastening through holes of the first flange body and the fastening through holes of the second flange body to be in threaded connection with the nuts. According to the multi-pipeline connecting flange, due to the fact that the corresponding positions of the first flange body and the second flange body are each provided with the at least two pipe containing holes, multiple pipelines can be connected at the same time, the engineering efficiency is greatly improved, manpower and material resources are saved, and the construction progress is accelerated.

Owner:YANCHENG FENGGONG MACHINERY

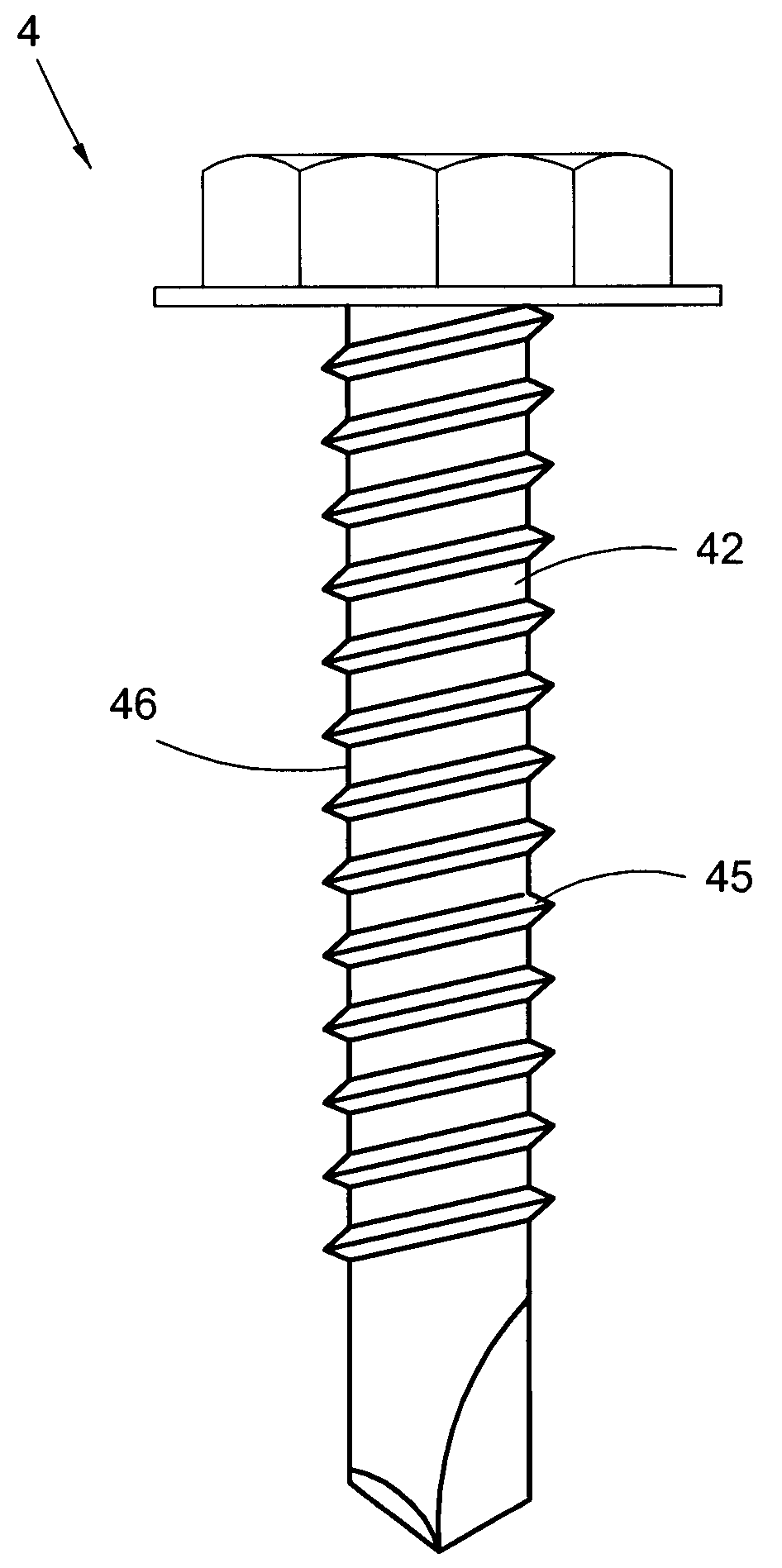

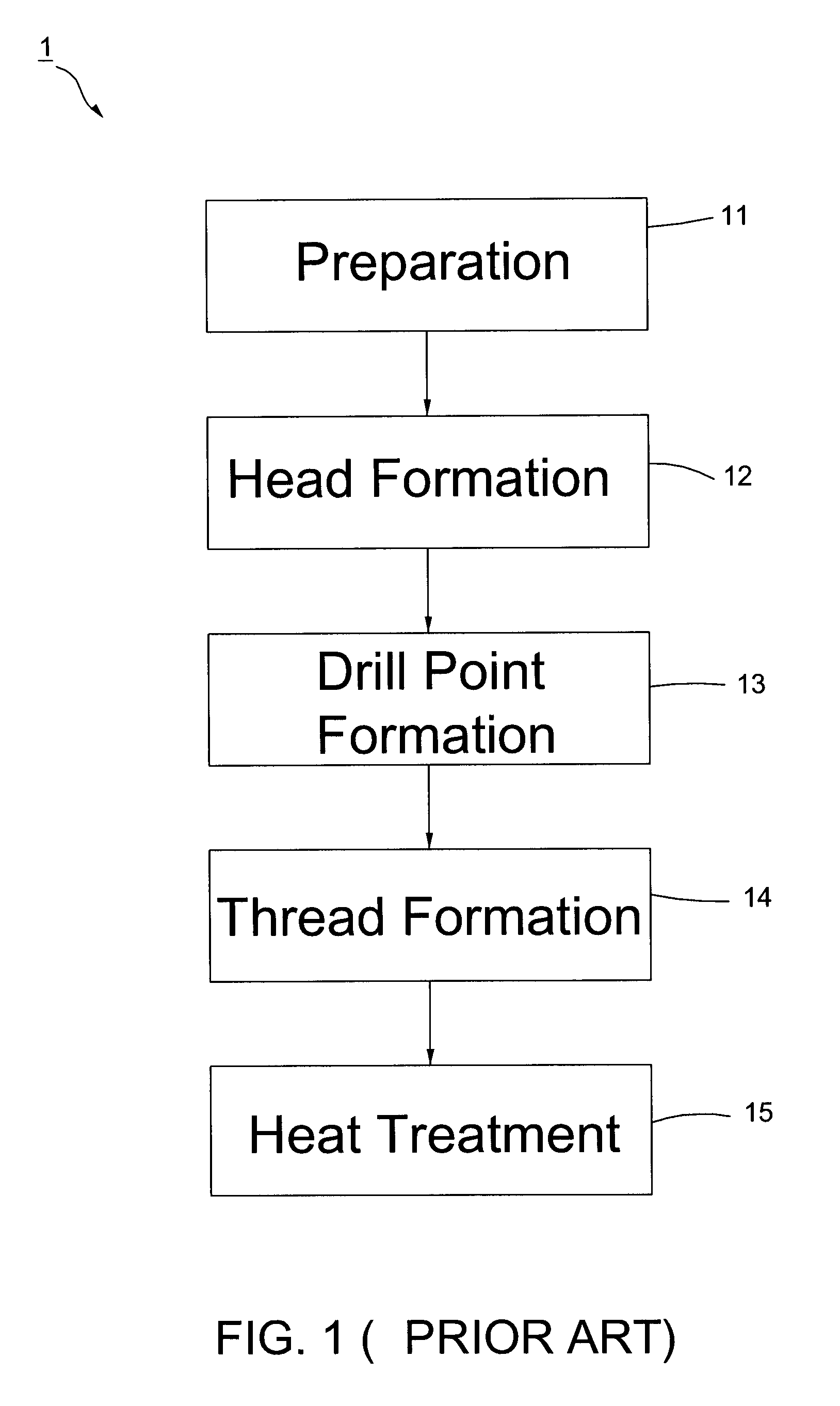

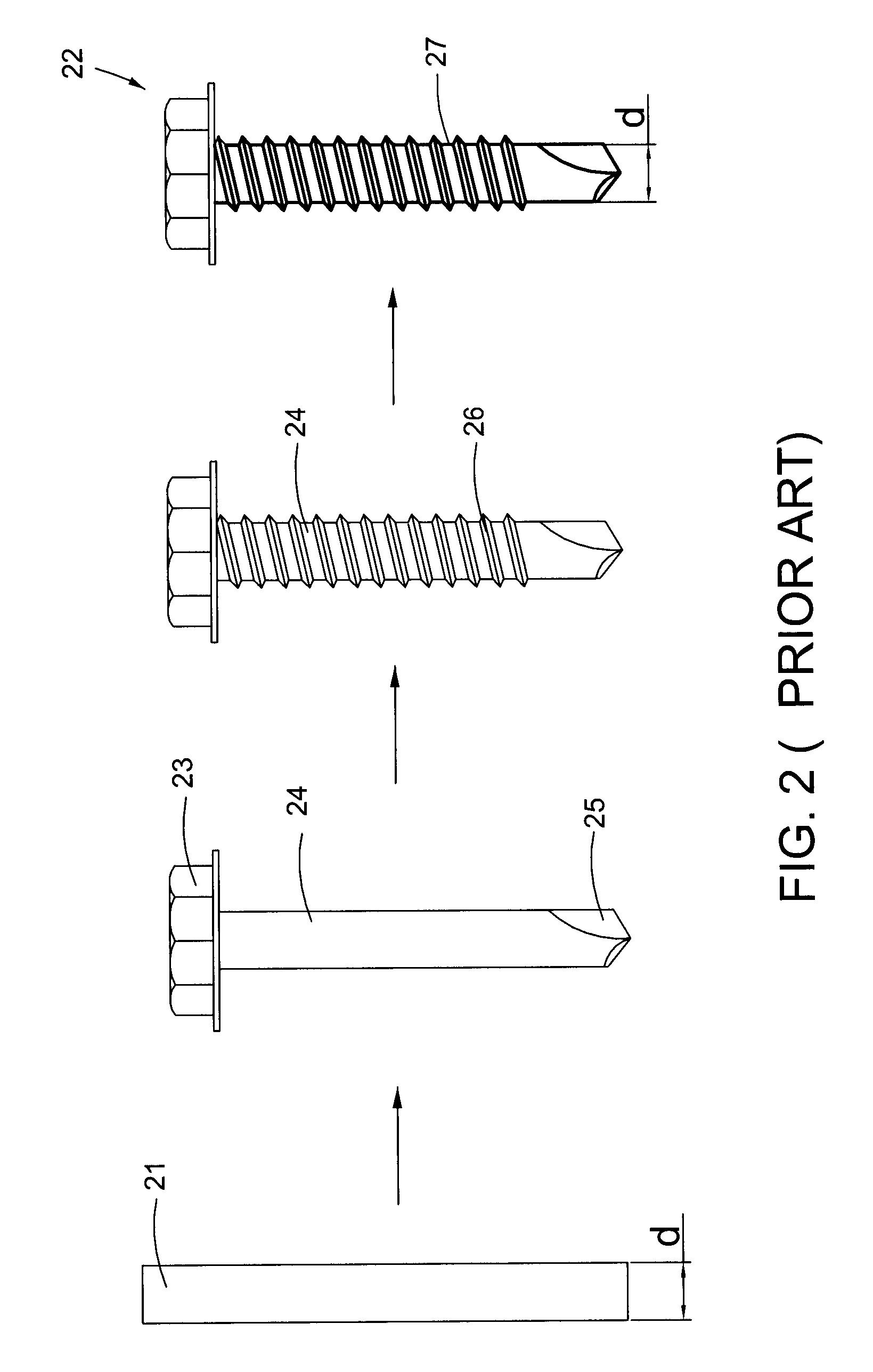

Method for cold forging high strength fastener with austenitic 300 series material

ActiveUS20090183546A1High strengthEffective corrosion resistanceBoltsScrew-threads articlesFastenerCorrosion

The present invention pertains to a method for cold forging high strength fastener with austenitic 300 series material comprising the procedures of initially preparing a raw austenitic shaft and then proceeding through a cold forging method to reduce its diameter for thereafter generating a preliminary shank, which can undertake above ½ force more than the raw shaft; further passing through the following formations of the head, the drilling portion and threads in sequence to build an integral fastener. Thus, the entire cold forging facilitates to fabricate the fastener with high strength and hardness by lower manufacturing cost and with effective corrosion resistance, so as to firmly drill the fastener into objects and increase the screwing security.

Owner:TSENG YU SHENG +1

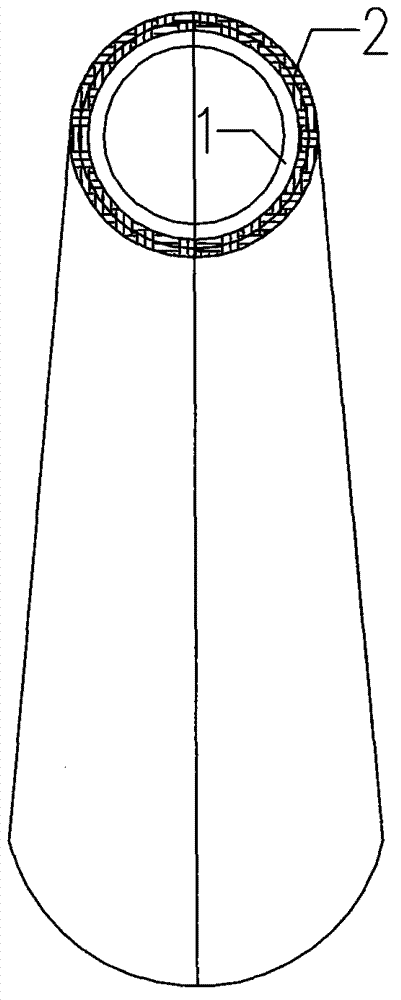

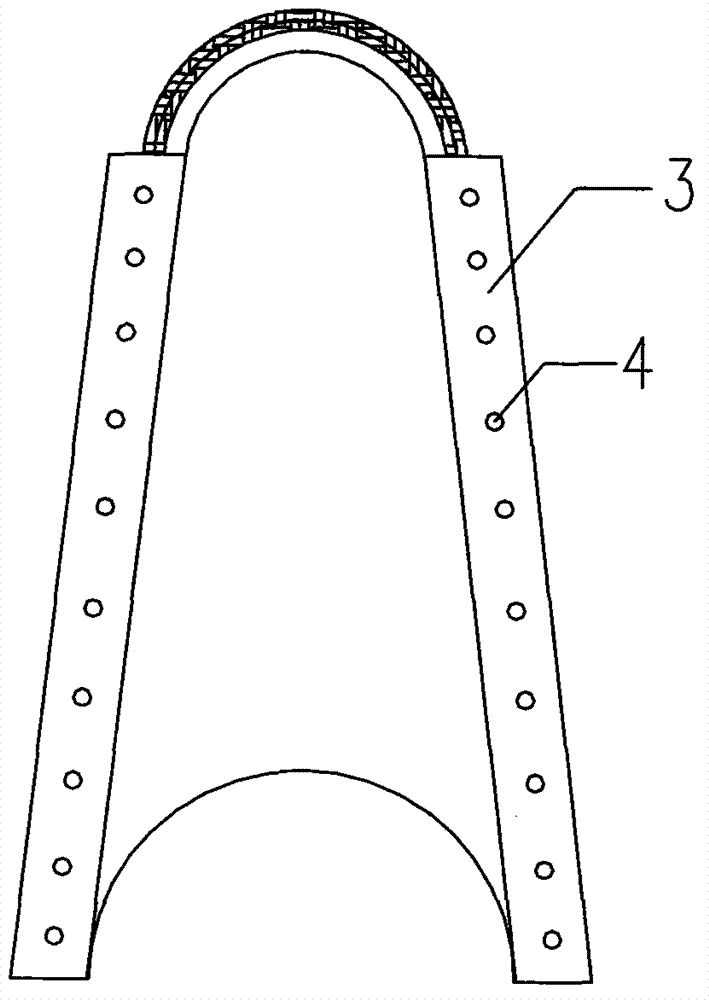

Steel-composite material wind-driven generator tower cylinder

InactiveCN102817795AGuaranteed lifeSolve the problem of the limitation of bridge heightWind energy generationWind motor componentsGlass fiberWind driven

The invention discloses a steel-composite material wind-driven generator tower cylinder, which comprises an internal steel pipe and an external composite material pipe, a plurality of conical steel pipe sections are connected to form the internal steel pipe, and the external composite material pipe comprises a plurality of glass fiber composite material pipe sections; corrosion-resistant E-glass fiber cloth is stuck on the surface of each internal steel pipe, so that the steel-composite material combination section is formed; the steel-composite material combination section is circumferentially divided into two pieces; longitudinal reinforcing ribs are arranged along the longitudinal direction of each piece; each two pieces of steel-composite material combination sections are connected together by adopting high-strength bolts, so that a steel-composite material tower cylinder section is formed in the end; and each two steel-composite material tower cylinder sections are connected together through flanges, so that the steel-composite material tower cylinder for on-site installation is formed. Compared with conventional steel wind-driven generator tower cylinders, the steel-composite material wind-driven generator tower cylinder can effectively resist the hit of wind-blown sand and stormy waves, fatigue and corrosion, so that the life of the tower cylinder can be guaranteed.

Owner:NANJING UNIV OF TECH

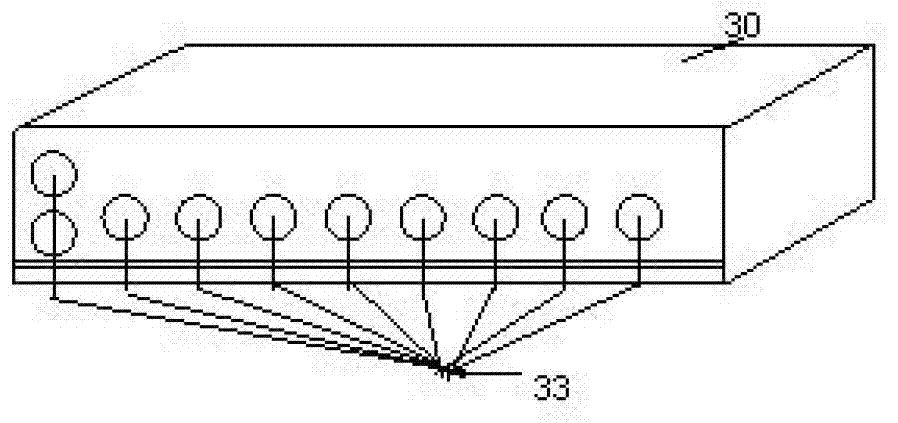

Combined firework conformation body adopting foamed material

The invention discloses a combined firework conformation body adopting a foamed material, which is used for fixed setting off of device firework inner barrel. The combined firework conformation body comprises a conformation body and barrel holes; the conformation body is processed and formed from foamed material; a plurality of closed barrel holes are formed in the conformation body, in which firework inner barrel can be fixedly connected; the quantity of barrel holes in the conformation body and the shape of the arrangement of the barrel holes are arranged according to the firework setting off requirement; and the outer shape of the conformation body is of a cube, a rounded body, a elliptical body, a fan-shaped body, a triangular body, a polygonal body or a specific body shape; and the conformation body is formed through integral molding. The combined firework conformation body adopting the foamed material has the advantages of simplicity in process technology, lightness, water-proofness, moisture-proofness, vibration-proofness and corrosion-proofness, is suitable for the one-step integral conformation of various firework outer barrels or inner barrels, can be processed into various shapes or specific shapes as needed, and is particularly suitable for mechanical manufacture and process.

Owner:杨伦伟

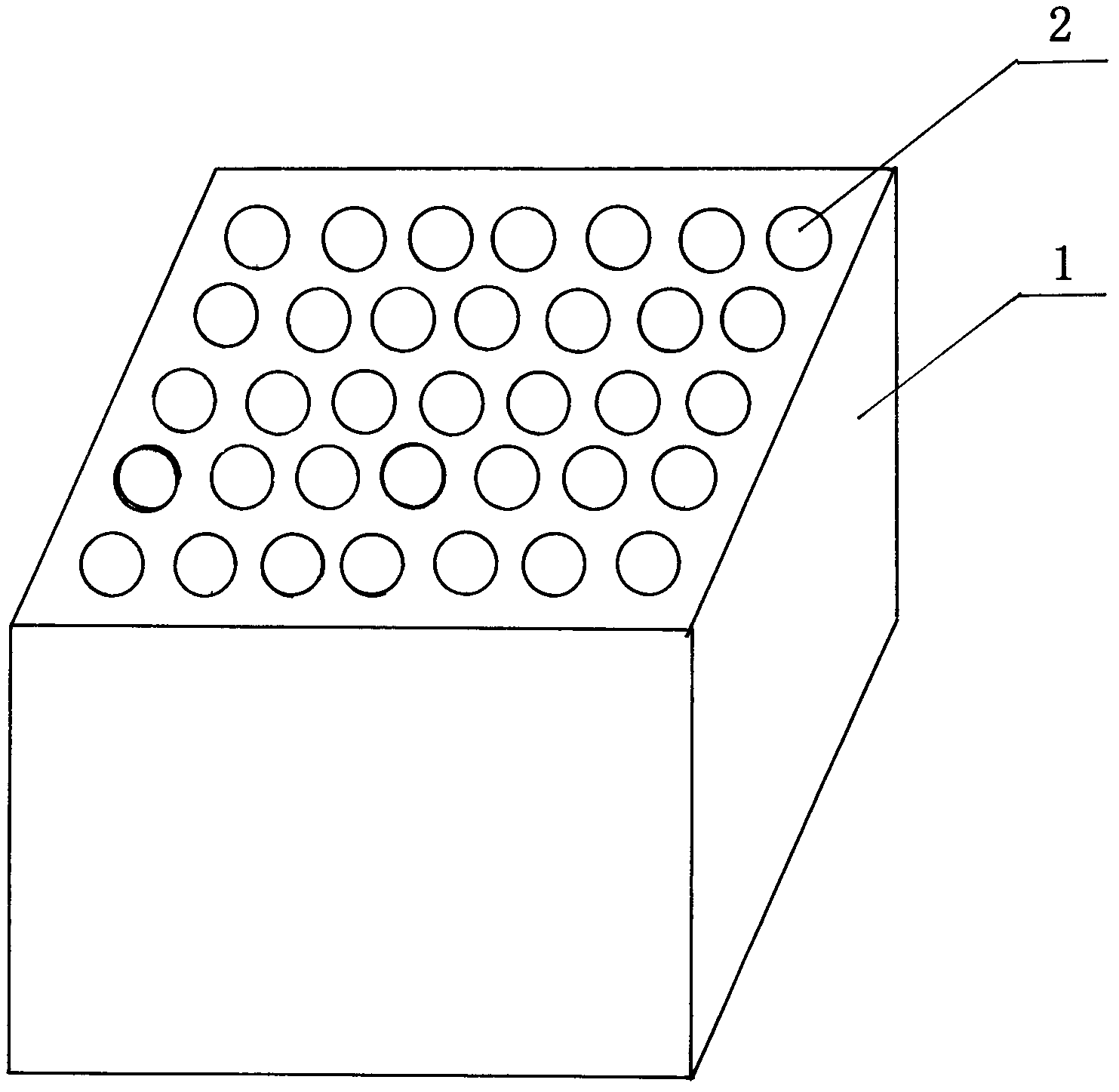

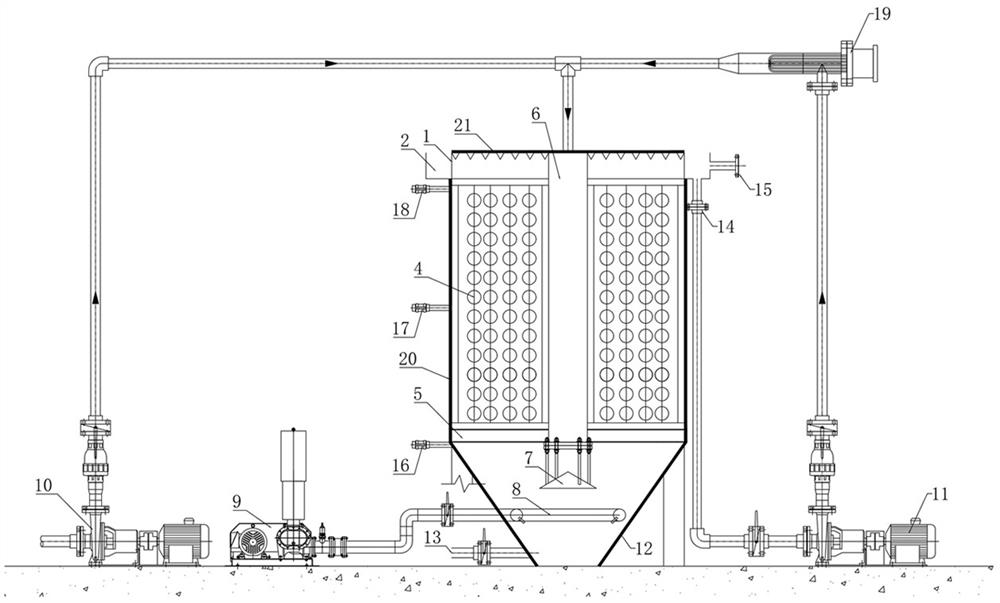

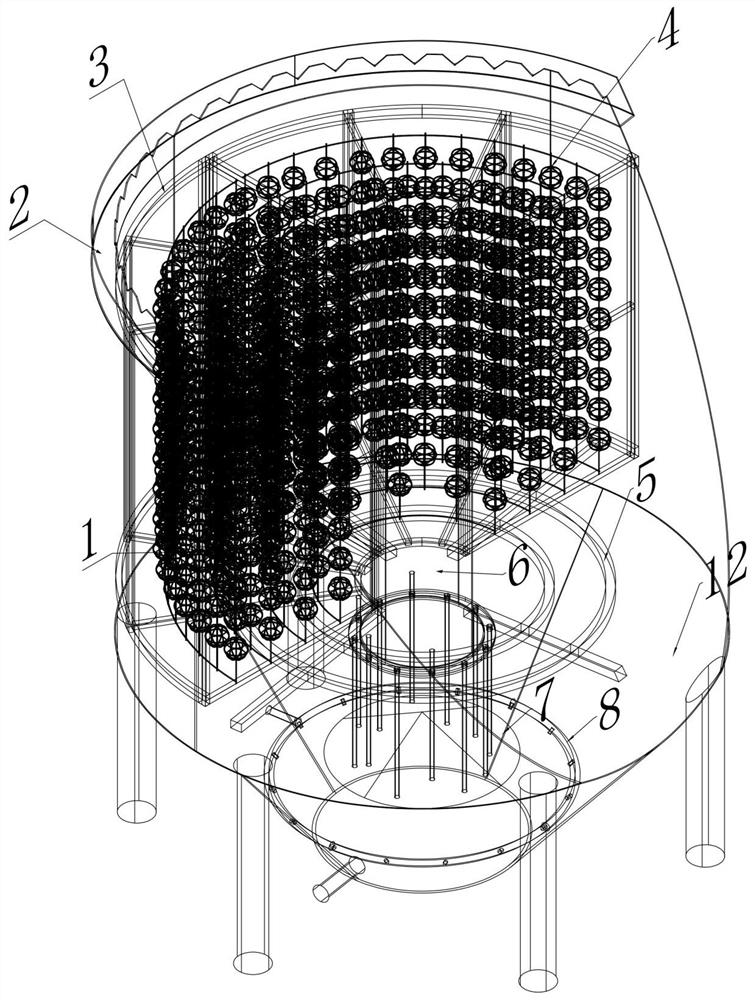

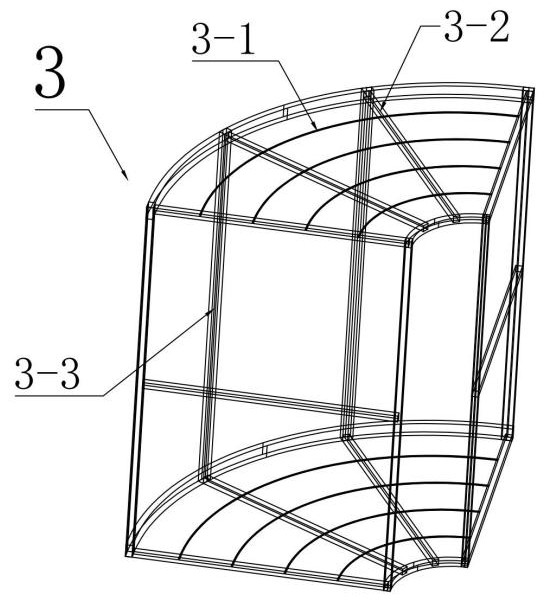

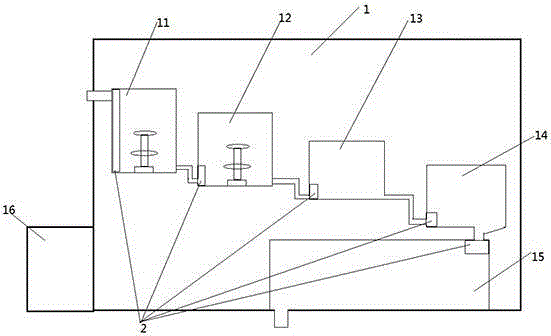

Short-cut nitrification and denitrification coupled anaerobic ammonia oxidation denitrification reactor and integrated equipment

PendingCN114314835AReduce shockImprove mass transfer effectWater contaminantsTreatment with aerobic and anaerobic processesSewage treatmentIntegrated devices

The invention discloses a short-cut nitrification and denitrification coupled anaerobic ammonia oxidation denitrification reactor and complete equipment, and belongs to the field of sewage treatment. The device comprises a tank body, a filler module and a circulating pipeline, the tank body comprises a lower-section sludge hopper, a middle-section central water inlet pipe and a filler area which are arranged from bottom to top in the vertical direction, and a heater is mounted on an upper-section circulating pump water inlet pipe; an aerator pipe is arranged in the sludge hopper; a sludge discharge pipe is arranged at the lower section; the central water inlet pipe is fixed on the filler module bracket; an annular water distributor is mounted at the lower section of the central water inlet pipe through a flange; the spherical mounting fillers are made into strings and fixed in the filler frame, and the filler frame is placed on the filler module support. And an insulating layer, a sampling port and a top cover plate are arranged outside the tank body. By strictly controlling the dissolved oxygen concentration and temperature in the reactor, short-cut nitrification and denitrification coupled anaerobic ammonia oxidation high-efficiency denitrification can be realized, so that the aim of purifying water is fulfilled.

Owner:佛山市绿能环保有限公司 +1

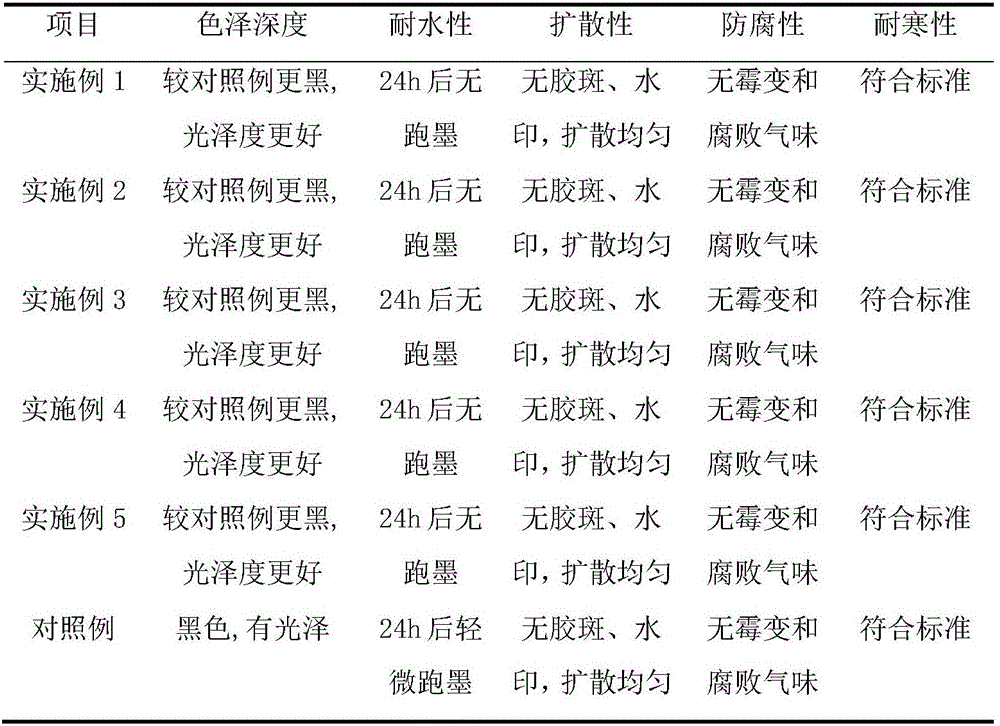

Waterproof and environment-friendly ink and preparation method thereof

InactiveCN106752365AReasonable ratioReduce ink toxicityInksSurface-active agentsEnvironmental resistance

The invention discloses waterproof and environment-friendly ink which is prepared from the following raw materials in parts by weight: 100 parts of fermentation liquor, 10-20 parts of carbon black, 0.2-0.5 parts of gamma-polyglutamic acid, 0.5-2 parts of a dispersing agent and 0.5-2 parts of a preservative. The invention further discloses a preparation method of the waterproof and environment-friendly ink. The waterproof and environment-friendly ink and the preparation method thereof disclosed by the invention have the benefits that in the waterproof environment-friendly ink prepared by the invention, as the proportion of the fermentation liquid to other materials is reasonable, a large quantity of other chemical substances like a brightening agent, an adhesive, a surface active agent, a stabilizing agent, a wetting agent, a color protection agent and an oxidizing agent is reduced, so that the ink toxicity is significantly reduced, and the harm to a human body and the pollution to the environment are reduced; meanwhile, the waterproof environment-friendly ink is bright in ink trace and smooth in writing, can effectively prevent water and resist corrosion to enable the ink to keep bright and not to fade for a long term, and is low in cost, thereby being environment-friendly ink suitable for production and application.

Owner:QUFU NORMAL UNIV

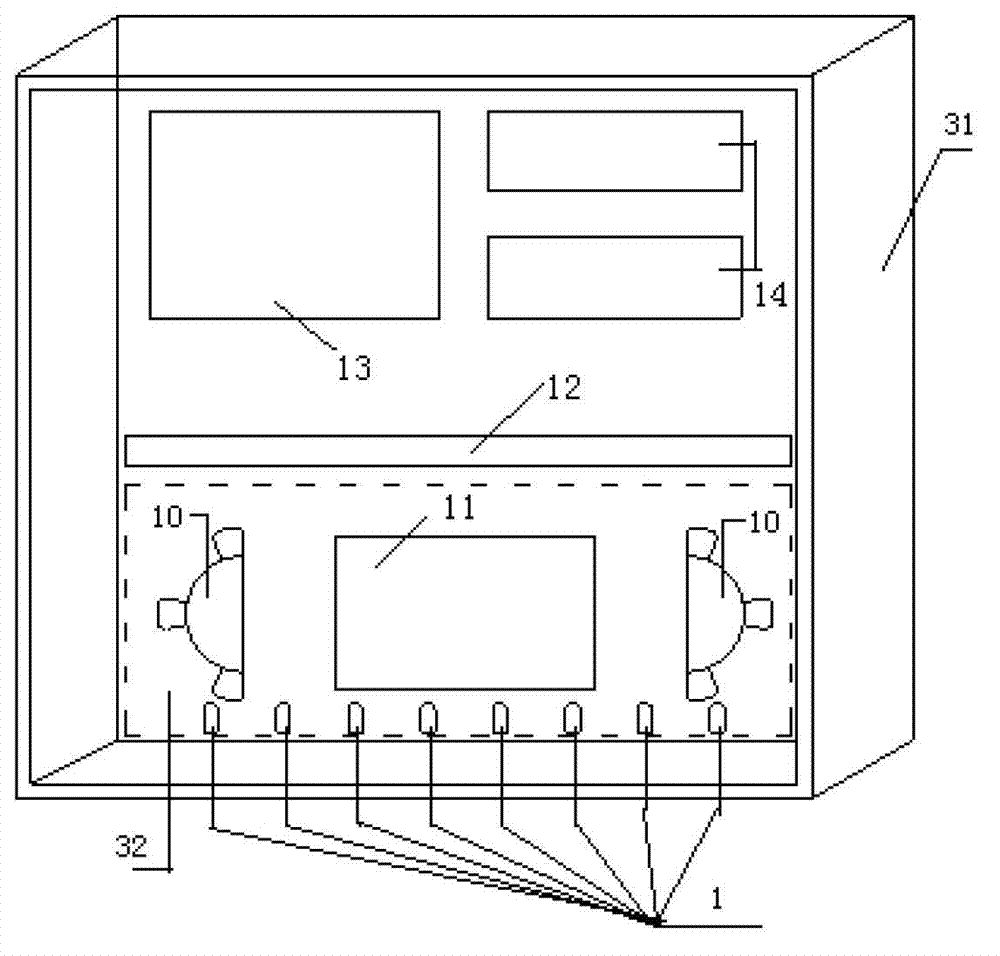

Air injection device for low-noise classroom

InactiveCN106765834AStrong impact resistanceImprove heat resistanceDucting arrangementsLighting and heating apparatusLow noiseFresh air

The invention relates to an air injection device for a low-noise classroom. The air injection device for the low-noise classroom comprises a box body and an air pipe connector. A plurality of adjustable ball-shaped nozzles are installed on the side wall of the box body, the air pipe connector is installed at one end of the air pipe connector, and a silencing material layer is paved on the inner side wall of the box body. The air injection device for the low-noise classroom is easily combined combine with a building and can inject purified fresh air out, supplied air jets can reach all positions in the classroom after spreading, and noise is lowered.

Owner:DONGHUA UNIV

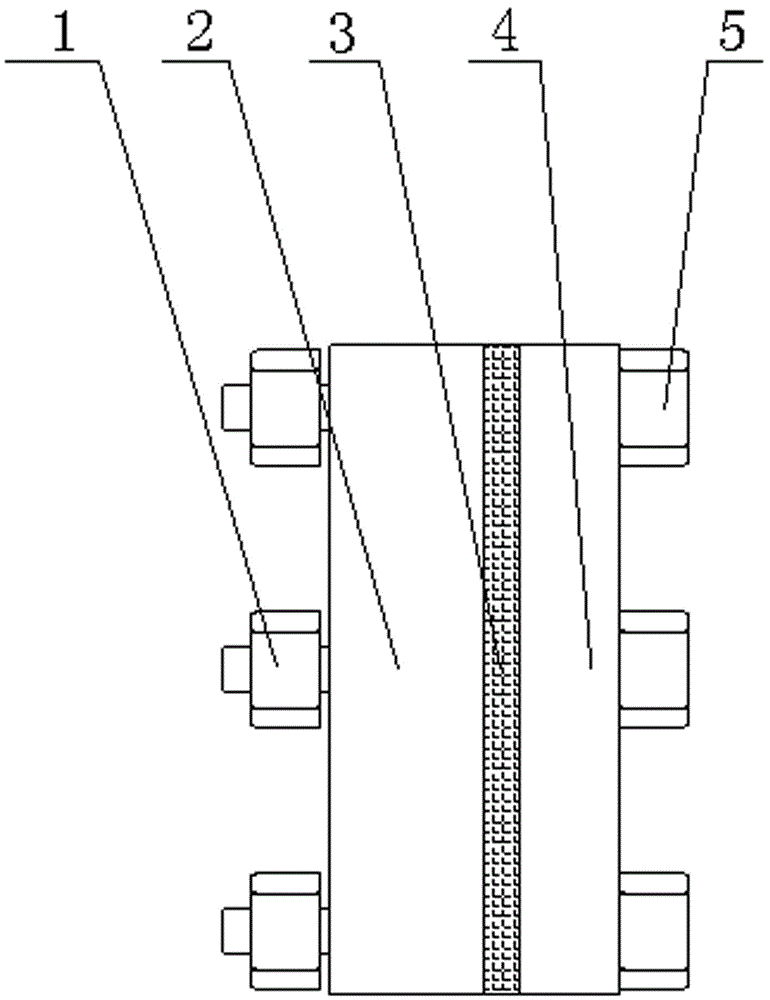

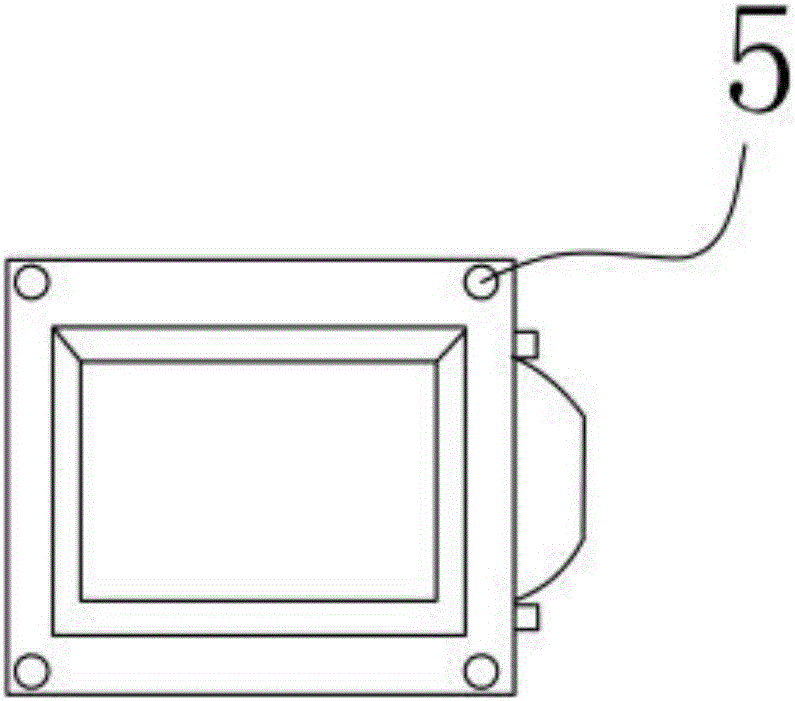

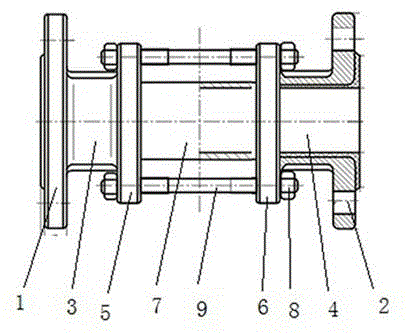

Corrosion-resistant pipe sight glass

InactiveCN104819358AGuaranteed withstand voltageExtended service lifePipe elementsPipe fittingEngineering

The invention discloses corrosion-resistant pipe sight glass and belongs to the field of pipe fittings. The corrosion-resistant pipe sight glass comprises a first flange, a second flange, a first pipe, a second pipe, a first end cap, a second end cap, a glass tube, nuts and a screw. One end of the first pipe is connected to the first flange and the other end is connected to the first end cap. One end of the second pipe is connected to the second flange and the other end is connected to the second end cap. The glass tube is arranged between the first end cap and the second end cap. A polytetrafluoroethylene piece is arranged in the glass tube. The screw is arranged between the first end cap and the second end cap. The nuts are arranged at both ends of the screw. The corrosion-resistant pipe sight glass is simple in structure, easy to use, long in service life, wide in application range, high in practicability and capable of being used for effectively observing the situation inside the pipes.

Owner:JIANGSU JINSHENGYUAN SPECIAL VALVE

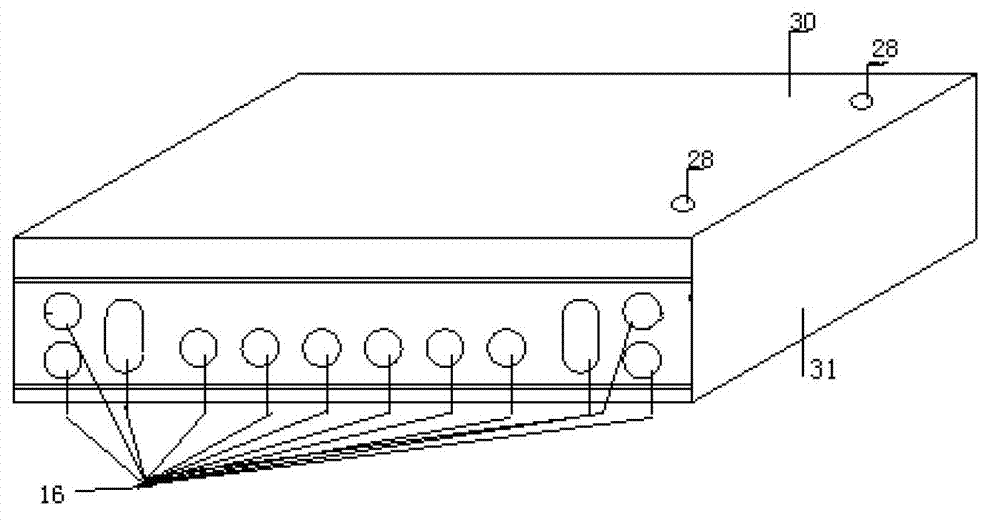

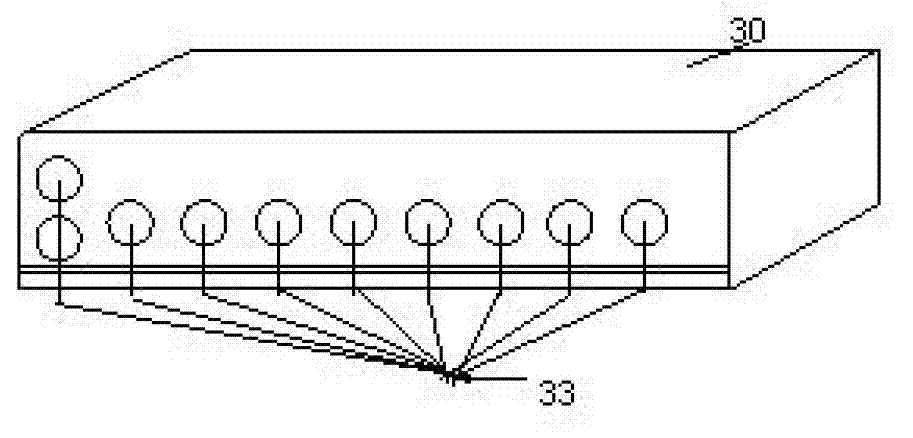

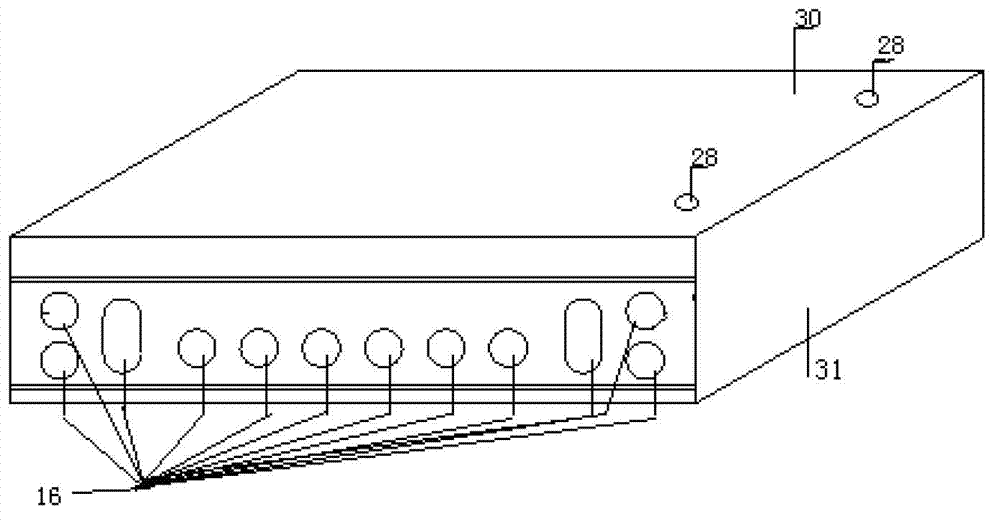

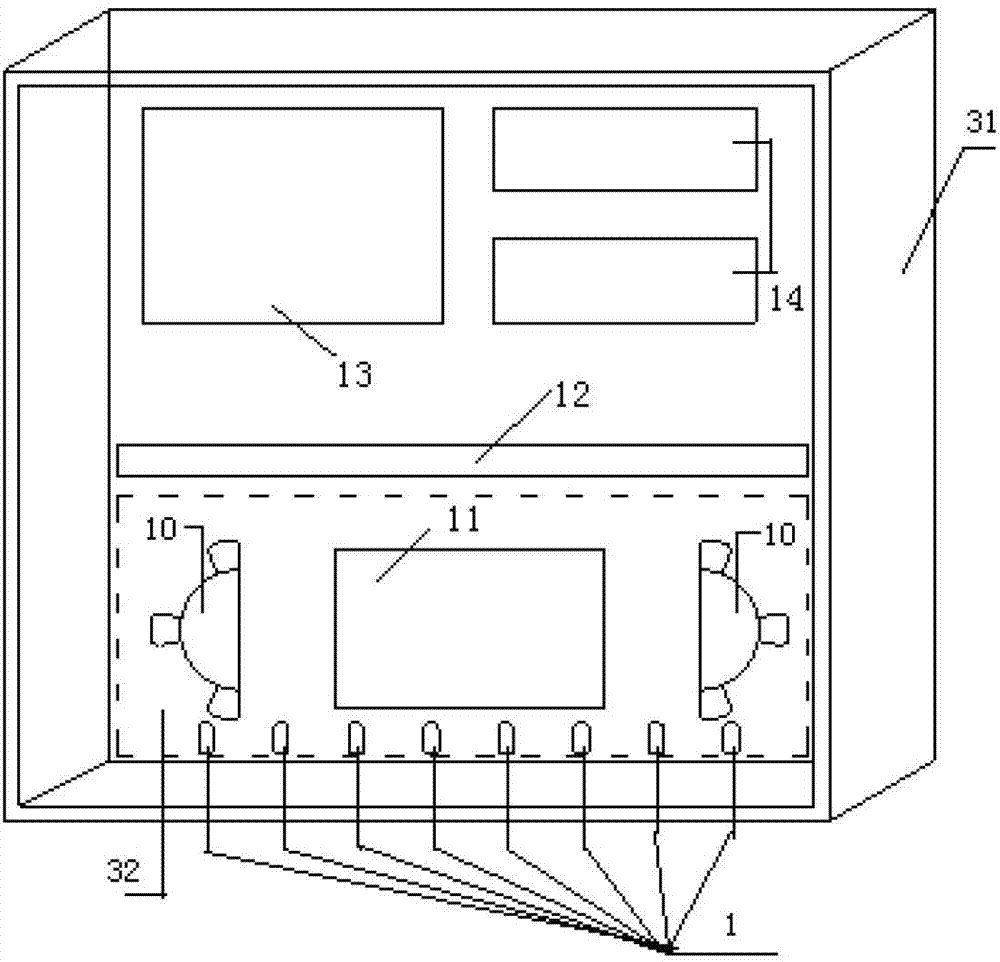

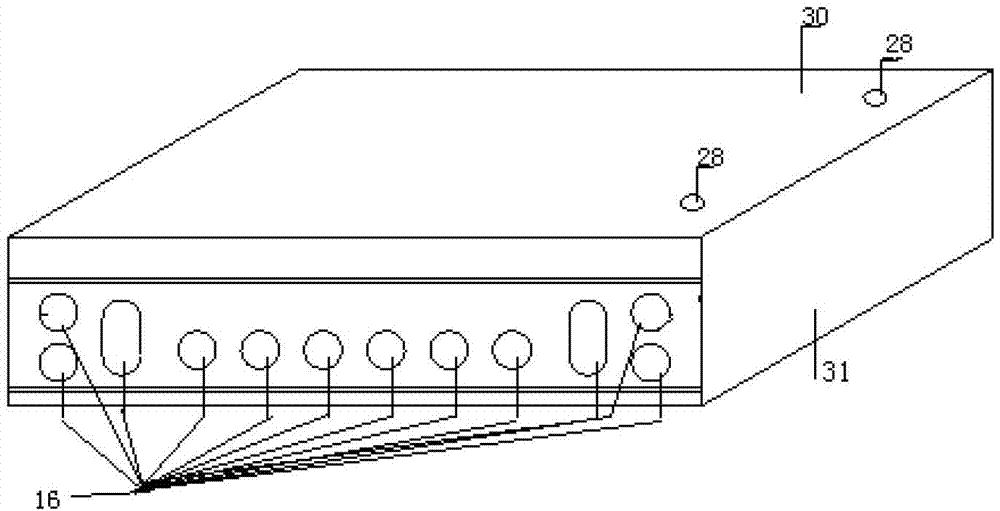

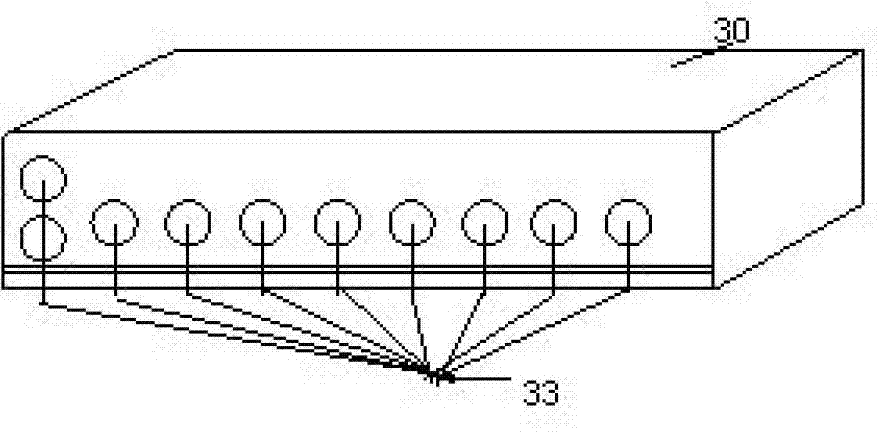

Optical fiber distribution case

InactiveCN103091801ATaking into account installation needsAchieve accessFibre mechanical structuresFiberEngineering

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

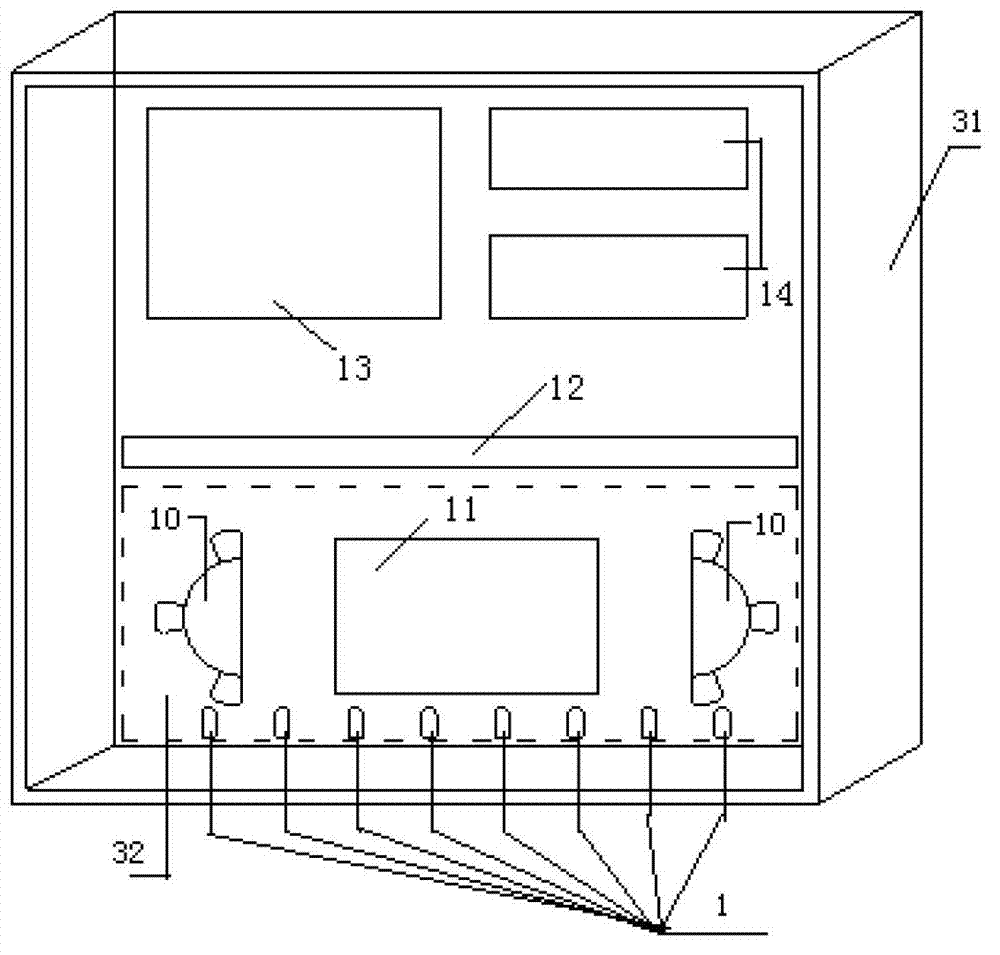

Optical fiber distribution box

InactiveCN103048754ATaking into account installation needsAchieve accessFibre mechanical structuresEngineeringFusion splicing

The invention discloses an optical fiber distribution box, which comprises a box body and a cover plate, wherein the cover plate can be buckled on the box body to form a cavity, an optical adapter is arranged in the box body, one side of the optical fiber adapter is provided with an optical fiber fusion splicing disc, a direct fusion plate and a fiber winding disc are arranged on the optical fiber fusion splicing disc, the fiber winding disc is arranged at two sides of the direct fusion plate and is used for winding and storing remaining optical cables, optical cables enter the box body through a wire inlet and are in fusion splicing with distribution tail fibers on the direct fusion splicing plate, the distribution tail fibers are connected with jumper wire tail fibers through the optical fiber adapter, the jumper wire tail fibers are output of the box body through a wire outlet, and the other side of the optical fiber adapter is provided with an XPON optical fiber access device and an optical divider. The optical fiber distribution box has the advantages that partial equipment of operators and power communication are integrated arranged in the optical fiber distribution box, and the communication equipment installation equipments required by the three-in-one network of the power communication and operation enterprises are taken into considerations. The telecommunication service access can be realized, and the optical fiber distribution box is also suitable for the fiber-to-the-home engineering in small high-rise and high-rise residential areas.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

A shale light perforated brick

InactiveCN104761273AEffective heat resistanceEffective corrosion resistanceCeramic materials productionCeramicwareBrickEngineering

Owner:柳州市永祥建材有限公司

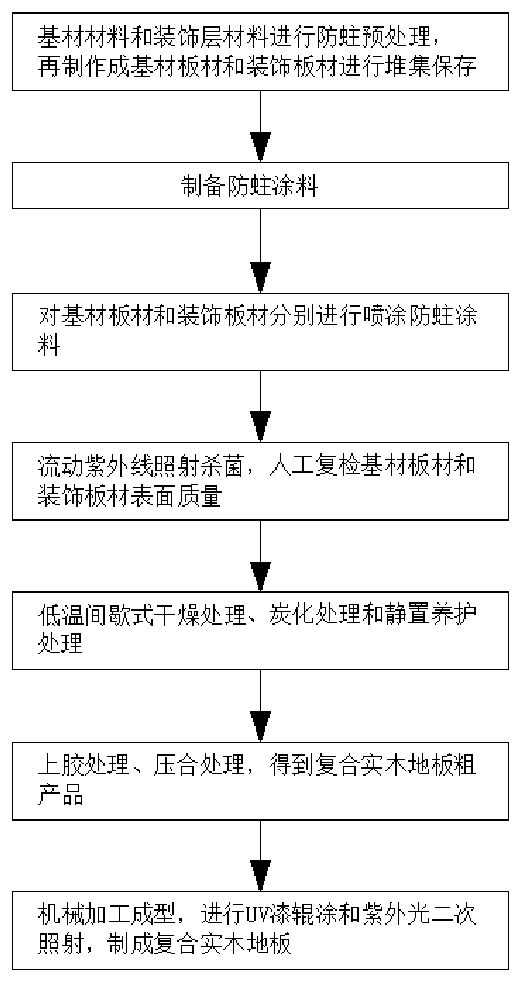

Anti-corrosion and anti-moth manufacturing method for composite solid wood floor

InactiveCN111113617AStable control of moisture contentQuality improvementAntifouling/underwater paintsCovering/liningsSolid woodUltraviolet lights

The invention discloses an anti-corrosion and anti-moth manufacturing method for a composite solid wood floor. The manufacturing method comprises the following steps that a base material and a decorative layer material are selected and subjected to moth-proof pretreatment, and then the base material and the decorative layer material are manufactured into a base material plate and a decorative plate to be stacked and stored; a mothproof coating is prepared; mothproof coating is sprayed on the base material plate and the decorative plate correspondingly; flowing ultraviolet radiation sterilization is carried out, and the surface quality is manually re-inspected; low-temperature intermittent drying treatment, carbonization treatment and standing maintenance treatment are carried out; gluing treatment and press-fit treatment are carried out; and processing and forming, UV paint roller coating and ultraviolet light secondary irradiation are carried out. According to the anti-corrosion and anti-moth manufacturing method for the composite solid wood floor, the mothproof coating spraying, the flowing ultraviolet irradiation sterilization, the low-temperature intermittent drying treatment,the carbonization treatment and the standing maintenance treatment are carried out on the base material plate and the decorative plate so that the water content of the base material plate and the decorative plate can be stably controlled, it is guaranteed that the water content is in the most stable state, and corrosion prevention and moth prevention can be effectively carried out.

Owner:来安县扬子地板有限公司

Environmentally-friendly wastewater treatment device

InactiveCN105174560APrevent precipitationImprove filtering effectMultistage water/sewage treatmentPreservativeDeodorant

The invention discloses an environmentally-friendly wastewater treatment device. The device comprises a wastewater treatment system and a purification device arranged inside the wastewater treatment system. The purification device is composed of a filter net and filters. Anticorrosion agents and deodorant are arranged inside the filters. The whole device is simple in structure and convenient to operate, meanwhile, the anticorrosion agents and deodorant are added into the filters, in this way, wastewater can be effectively subjected to corrosion resistance and de-odorizing treatment while the wastewater is purified, it can be effectively prevented that in the process of wastewater treatment, deterioration causes foul smell, and then the requirements of customers can be better met.

Owner:苏州腾辉环保科技有限公司

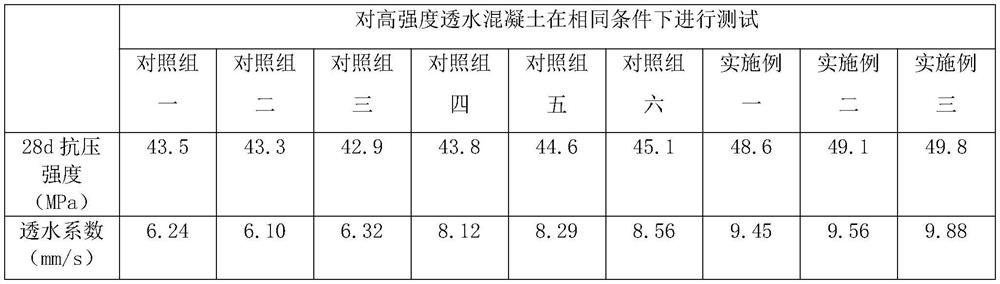

High-strength pervious concrete suitable for sponge city construction and preparation method of high-strength pervious concrete

The invention discloses high-strength pervious concrete suitable for sponge city construction and a preparation method, and particularly relates to the technical field of concrete materials, and the high-strength pervious concrete comprises cement, composite fibers, a composite reinforcing agent, water, a water reducing agent, a quick-setting early strength agent and aggregate. The composite fiber and the composite reinforcing agent in the formula are matched for use, so that the strength and the water permeability of the concrete can be effectively enhanced; the glass fibers, the basalt fibers and the polypropylene fibers are matched for use, so that the internal structural strength of the concrete can be further enhanced, and meanwhile, the composite fibers form a fiber network in the concrete, so that the high water permeability of the concrete can be effectively enhanced; and the nano silicon dioxide, the nano zirconium diboride powder and the nano silicon nitride in the composite reinforcing agent are matched to modify the composite fibers, so that the structural strength and the self performance of the composite fibers can be effectively enhanced, and the structural strength and the water permeability of the concrete are further improved.

Owner:扬州通惠系统集成科技有限公司

High-temperature silicone rubber cable for railway rolling stock current collector

InactiveCN111524650AImprove stabilityGood cooling performanceInsulated cablesInsulated conductorsCurrent collectorEngineering

The invention relates to the technical field of cables. The invention further discloses a high-temperature silicone rubber cable for the railway rolling stock current collector. The cable comprises aflexible memory metal tube with a hollow structure, and a heat insulation layer is arranged on the outer side of the flexible memory metal pipe; six connecting plates which are annularly and uniformlydistributed are fixedly connected between the inner ring of the heat insulation layer and the outer ring of the flexible memory metal pipe; a heat dissipation fiber layer is fixedly filled between the inner ring of the heat insulation layer and the outer ring of the flexible memory metal pipe; a cable core is arranged between two adjacent connecting plates, the cable core is fixedly embedded in the heat dissipation fiber layer, the outer ring of the heat insulation layer is fixedly connected with a shielding layer, the outer ring of the shielding layer is fixedly connected with an insulatinglayer, and the outer ring of the insulating layer is fixedly connected with a silicone rubber protective jacket. According to the high-temperature silicone rubber cable for the railway rolling stock current collector, heat generated by the cable core can be dissipated conveniently, a protective layer outside the cable is effectively prevented from melting, and the conductor of the cable core is not prone to damage due to heating.

Owner:ANHUI KANGLIYA CO LTD

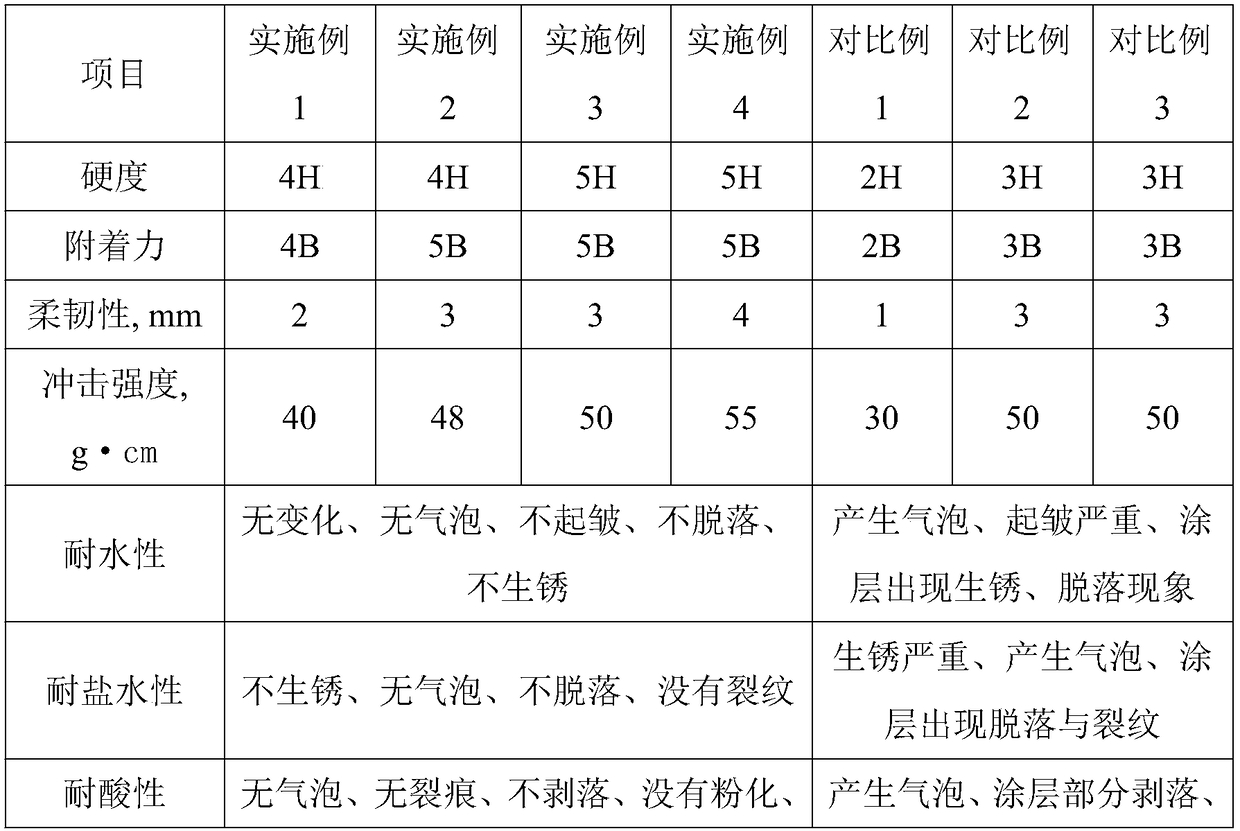

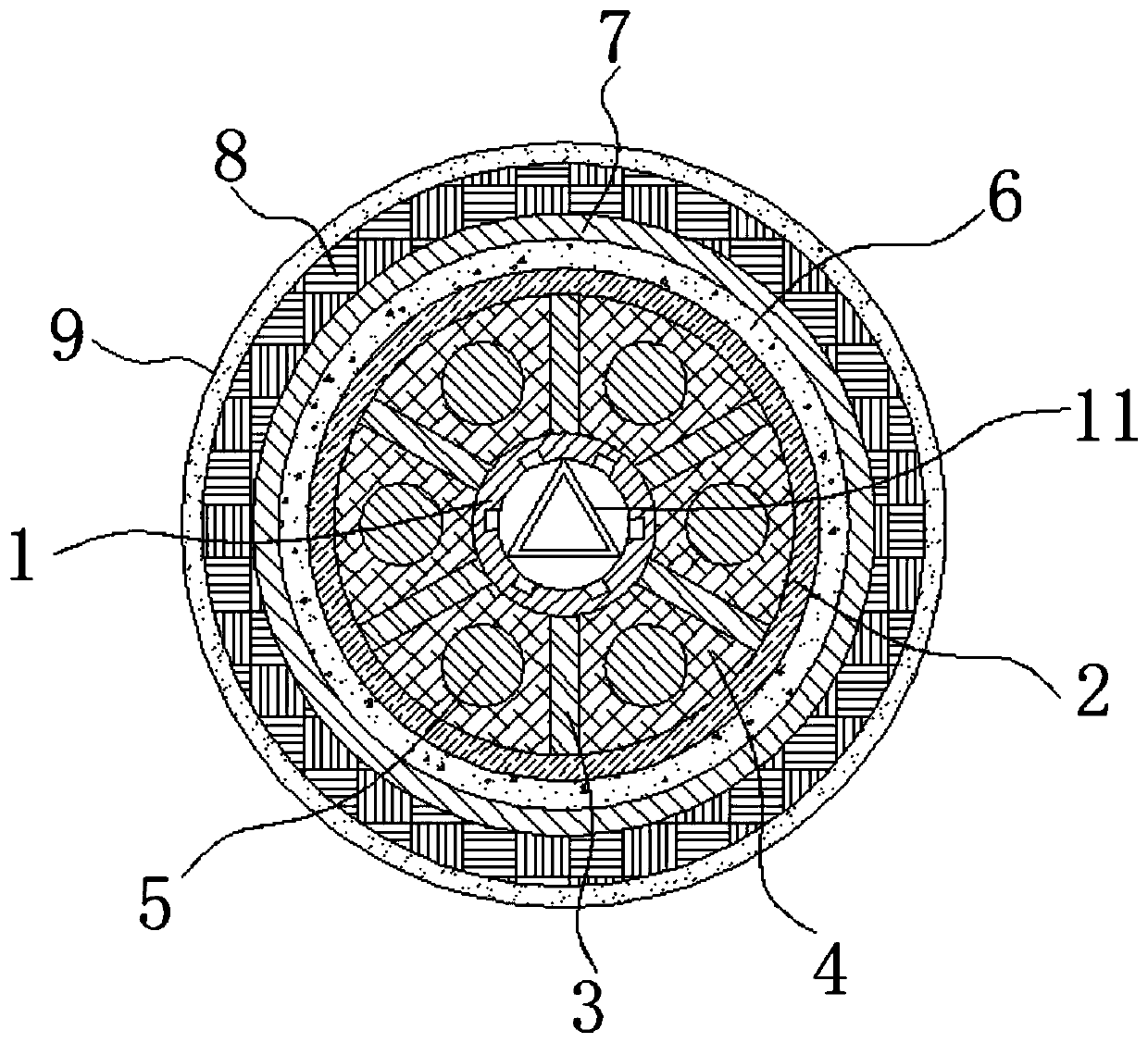

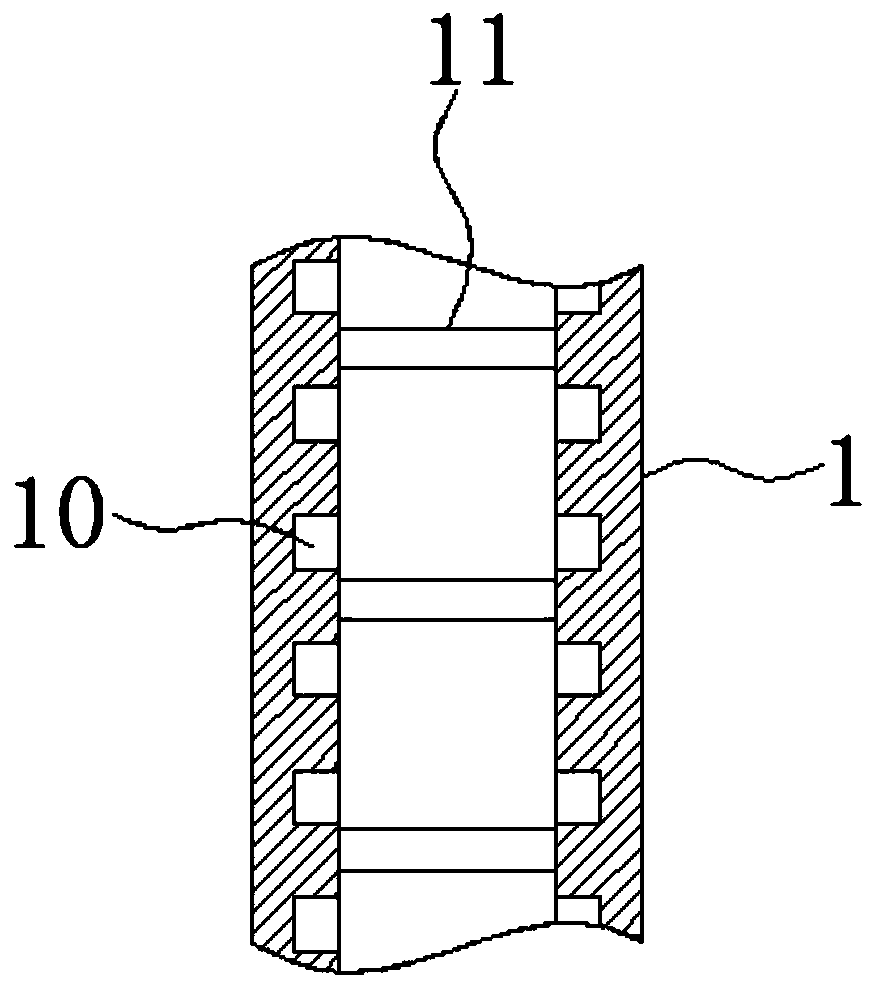

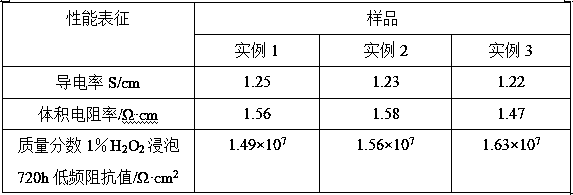

Preparation method of dense anti-corrosion conductive coating

InactiveCN108559365ADense coating structureEffective corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsPhosphateAluminium hydroxide

The invention relates to a preparation method of a dense anti-corrosion conductive coating, and belongs to the technical field of paint. According to the technical scheme, a dense adhesive material isprepared from phosphoric acid and aluminium hydroxide, coating treatment is carried out in an air spraying mode, the surface of the coating is dense and flat, tiny holes exist in part of the internalregion of the coating, the formed coating is dense in structure and has effective anti-corrosion performance, through boric acid modified treatment, as boric acid and phosphoric acid react to generate boron phosphate, meanwhile, boron phosphate and Al(OH)3 react to generate aluminium hydroxide complexing borate, a phosphate adhesive system forms a better net-shaped structure through synergism ofthe two substances, thus, the module mechanical performance strength is improved, and the mechanical performance of the coating material is greatly enhanced.

Owner:FOSHAN LINGXIE ENVIRONMENTAL PROTECTION TECH CO LTD

A multi-pipe connection flange

ActiveCN106247058BQuick and efficient installationGuaranteed tightnessFlanged jointsPipe elementsMaterial resourcesFlange

Owner:YANCHENG FENGGONG MACHINERY

A shale light hollow brick

A shale light hollow brick is disclosed. The hollow brick is prepared from following raw materials by weight: 35-45 parts of shale, 25-30 parts of gangue, 10-14 of straw, 5-7 parts of clay, 3-5 parts of alumina, 2-4 parts of silica, 1-3 parts of magnesium oxide, 4-6 parts of ferrous ferric oxide, 5-7 parts of corundum, 3-6 parts of chromic oxide, 2-5 parts of silicon carbide and 5-8 parts of titanium dioxide. The beneficial effects of the hollow brick are that: after being fired, the hollow brick can be effectively resistant to heat and corrosion, fracture phenomena are prevented, and heat resistance is improved by 2-3 times.

Owner:柳州市永祥建材有限公司

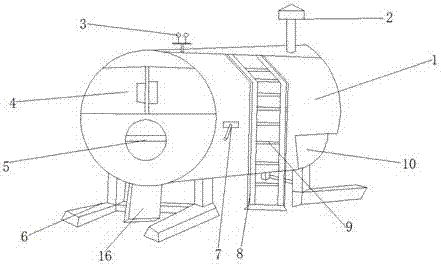

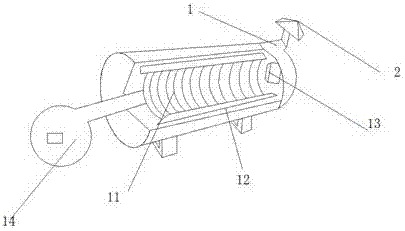

Biomass fuel burning boiler

The invention discloses a biomass fuel combustion boiler, which comprises a bio-boiler body and a burner, a chimney is arranged at the upper end of the bio-boiler body, a boiler door is arranged at one end of the bio-boiler body, and a A fuel door, one side of the fuel door is provided with a fuel tank, one side of the bio-boiler body is provided with a ladder, the outer surface of the ladder is provided with a rubber sleeve, and the other end of the bio-boiler body is provided with a slag remover One side of the burner is provided with a reciprocating fire grate, and one end of the burner is provided with an igniter, and a dust collector is provided below the chimney. A biomass fuel combustion boiler according to the present invention is provided with a rubber sleeve, a fuel tank and a dust collector. The rubber sleeve can prevent slipping and corrosion and play a protective role. It is more convenient to add fuel through the fuel tank. Dust removal, reduce the dust emitted by the smoke exhaust, protect people's health, apply to different working conditions, and bring better prospects for use.

Owner:安吉吉成生物能源科技有限公司

Making method for metal zipper teeth

ActiveCN109396445AEffective anti-agingEffective corrosion resistanceSlide fastenersVolumetric Mass DensityMetal powder

The invention discloses a making method for metal zipper teeth. The making method includes the following steps: S1, a step of material selection, namely the step of selecting metal powder as a raw material; S2, a step of molding, namely the step of calculating required density and pressure during making according to the dimensions of metal zipper teeth, referring to the dimensions of the metal zipper teeth and the raw material characteristics of the metal powder to calculate a contraction ratio, and designing a mold with a required zipper teeth shape; S3, a step of pressing, namely the step ofperforming pressing on the metal powder through the mold so that pressed metal zipper teeth can be obtained; S4, a step of sintering, namely the step of performing sintering on the metal zipper teethobtained by the step S3 through a sintering furnace; and S5, a step of polishing, namely the step of selecting different grinding equipment and grinding materials to perform polishing according to the physical properties of the metal powder material, and finally obtaining a finished product of the metal zipper teeth. The metal zipper teeth made by the method has characteristics of corrosion resistance, exquisite appearance, ageing resistance and long service life.

Owner:车顺杰

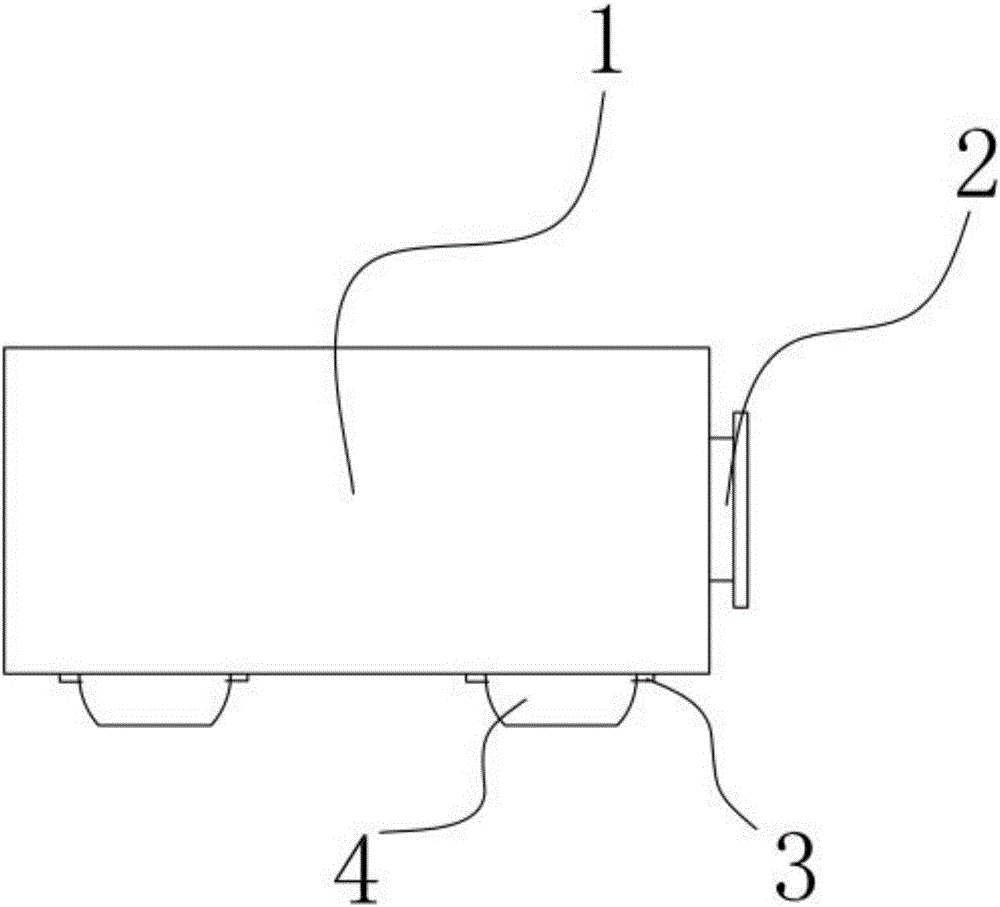

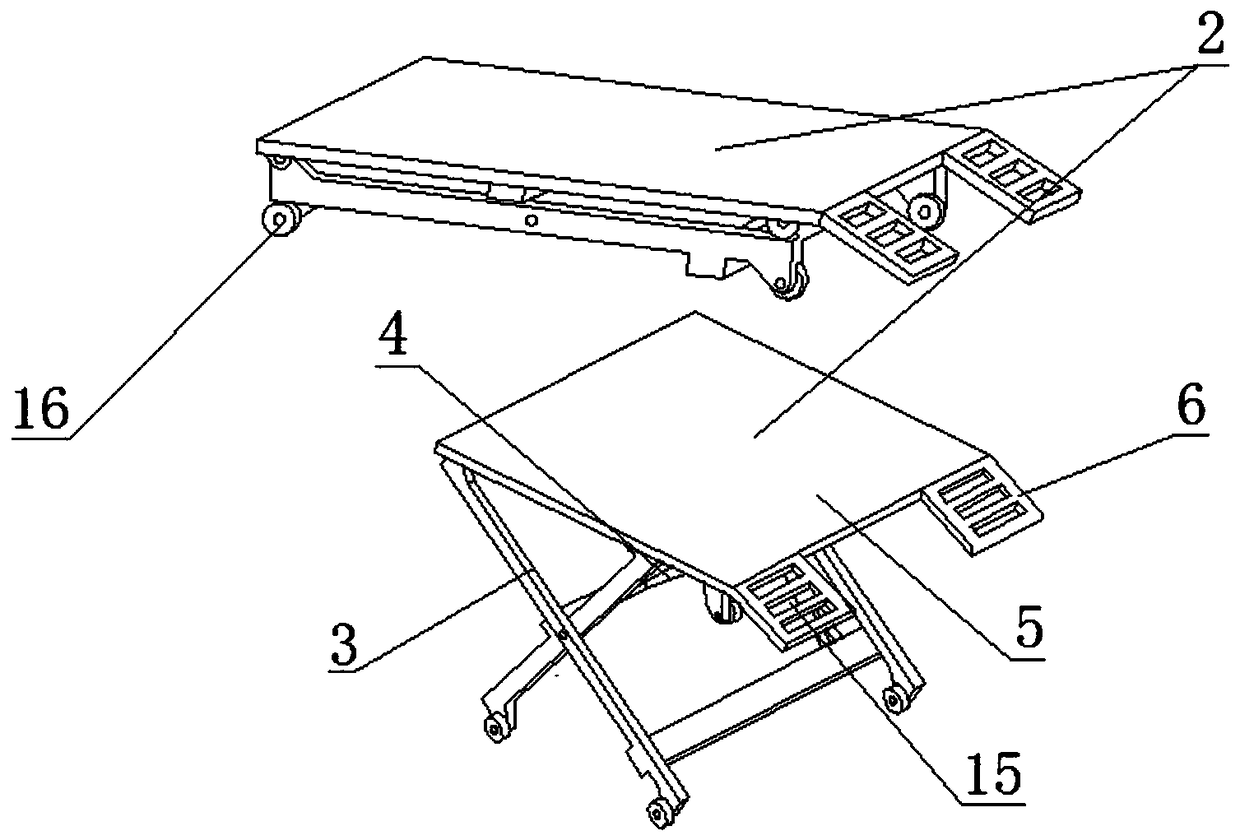

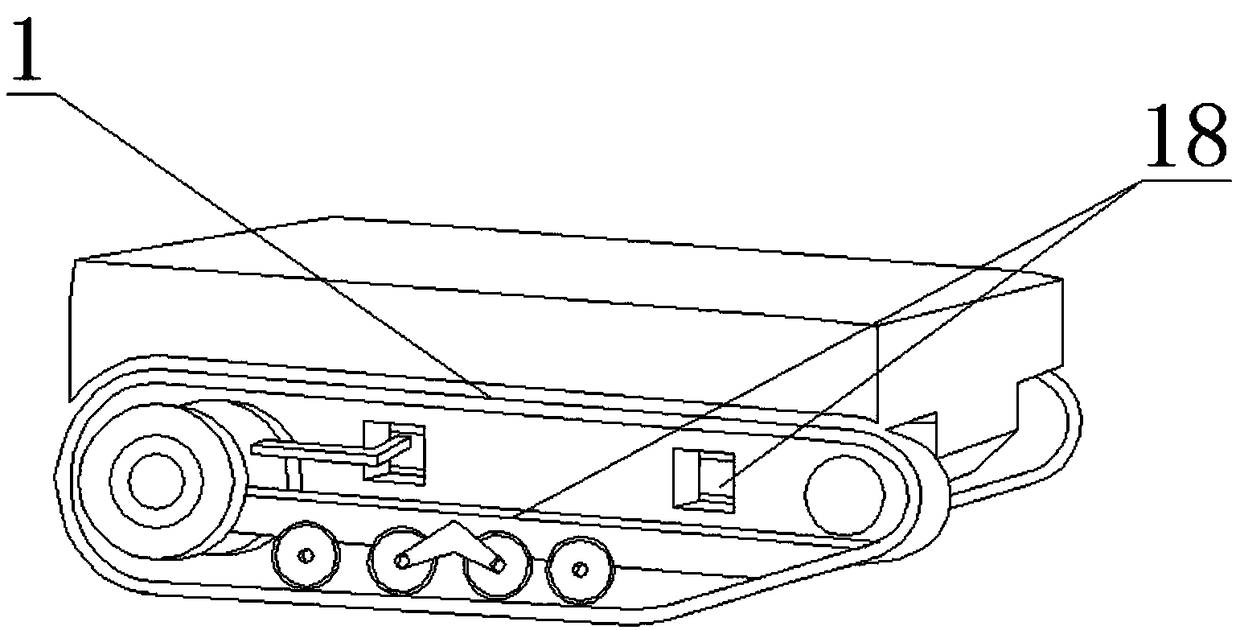

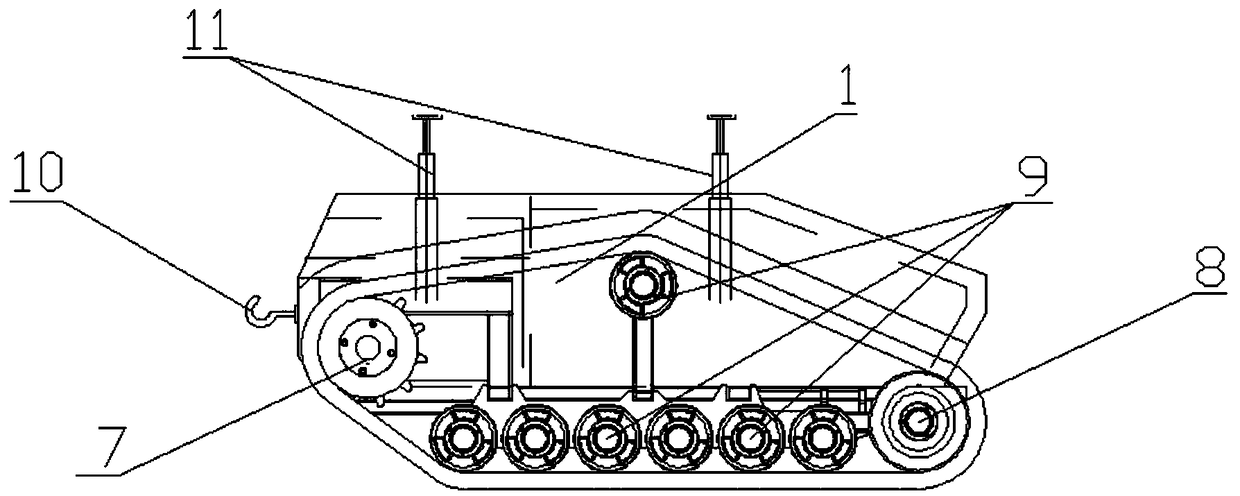

A caterpillar vehicle for a lifting platform with a loading and unloading platform

PendingCN109050692ALower center of gravityImprove stabilityTransmission systemsLifting framesRemote controlMarine engineering

The invention provides a caterpillar vehicle for a lifting platform with a loading and unloading platform. The caterpillar vehicle for the lifting platform is mainly composed of a hydraulic chassis, aloading and unloading platform and a remote controller. The lowest part of the caterpillar vehicle for the lifting platform is a loading and unloading platform, and the upper part of the loading andunloading platform is provided with a hydraulic chassis. A crawler-type operation mode of a common technology is adopted in the invention, suitable for running on all kinds of roads, it 's quite portable, the tracked vehicle can travel on all kinds of roads and 50 cm water depth branches, relying on lithium battery discharge for walking and hydraulic power, Guaranteed power supply, Caterpillar lowcenter of gravity, The utility model has the advantages of good stability, effective corrosion resistance and anti-damage by using the alloy shell and the rubber crawler, convenient transportation and remote control operation by adopting the remote controller, thus improving the safety of the personnel, reducing the workload of the staff, and strong practicability, and can form a mobile intelligent lifting and lowering device with the lifting platform.

Owner:国网安徽省电力有限公司广德市供电公司 +1

Shale high-heat-insulation-modulus brick

InactiveCN104761238AEffective heat resistanceEffective corrosion resistanceCeramic materials productionClaywaresBrickSilicon dioxide

The invention discloses a shale high-heat-insulation-modulus brick, which is prepared from following raw materials, by weight: 35-45 parts of shale, 25-30 parts of coal gangue, 10-14 parts of straws, 8-10 parts of corncob, 5-7 parts of clay, 8-12 parts of fly ash, 3-5 parts of aluminum oxide, 2-4 parts of silicon dioxide, 3-6 parts of chromium oxide, 2-5 parts of silicon carbide and 5-8 parts of titanium dioxide. The shale high-heat-insulation-modulus brick is effective in heat insulation and corrosion resistance after sintering, can be prevented from breaking and is improved in heat resistance by 2-3 times.

Owner:柳州市永祥建材有限公司

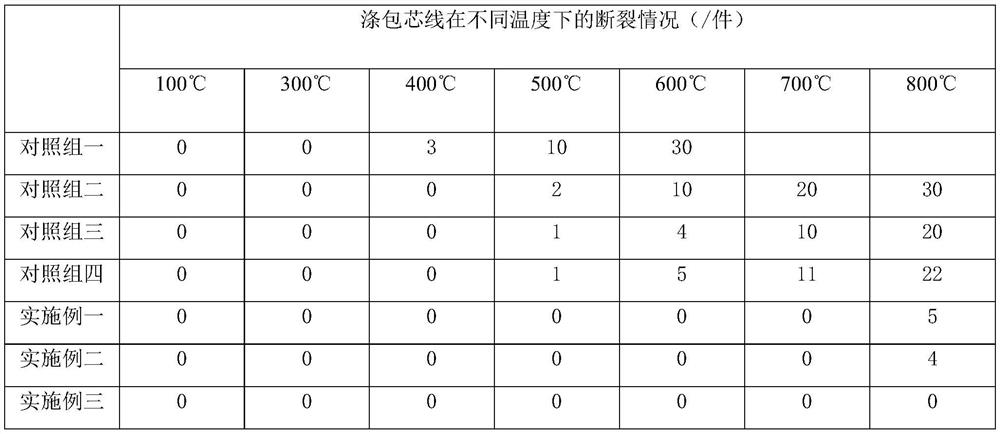

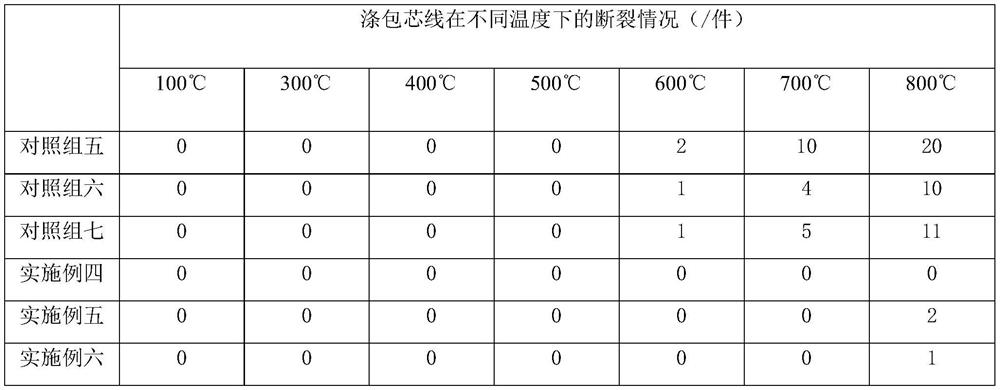

High-elastic wear-resistant antibacterial regenerated polyester core-spun yarn and production process thereof

The invention discloses a high-elastic wear-resistant antibacterial regenerated polyester core-spun yarn and a production process thereof, and particularly relates to the technical field of polyestercore-spun yarns. The core-spun yarn comprises a polyester core-spun yarn A and a polyester core-spun yarn B. The polyester core-spun yarn A comprises boron fibers, carbon fibers and basalt fibers; andthe polyester core-spun yarns B take polyimide filaments as core yarns and take polyester staple fibers as covering yarns. The boron fibers, the carbon fibers and the basalt fibers are used in cooperation, so that the heat resistance and the flame retardance of the polyester core-spun yarn can be effectively enhanced, heat insulation and flame retardance treatment can be effectively conducted atthe sewing position of a garment fabric, and the safety performance is improved. A carbon fiber yarn made of the polyester core-spun yarn A material and polyester staple fibers in the polyester core-spun yarn B are matched to be used as covered yarns, and a composite bulked yarn made of the polyester core-spun yarn A material and polyimide filaments in the polyester core-spun yarn B are matched tobe used as core yarns, so that the heat-resistant strength and the flame retardant property of the polyester core-spun yarn can be further improved, and the safety performance is improved.

Owner:江阴远闻纺织有限公司

A kind of heterojunction metal anticorrosion pigment

ActiveCN113652104BImprove corrosion resistanceInhibit transferInorganic pigment treatmentHeterojunctionOxygen vacancy

The invention belongs to the technical field of material chemistry, and in particular relates to a preparation method of a heterojunction metal anticorrosion pigment. Heterojunction metal anticorrosion pigments are composed of zinc oxide and tungsten oxide, with a two-dimensional nanosheet array structure and photoelectric properties, which effectively inhibit the transfer of water and chloride ions, the interaction between the mass-junction two-component interface and the defect oxygen The existence of vacancies can prevent the contact between corrosive ions and the metal surface, thereby exerting an effective anti-corrosion effect and showing extremely excellent anti-corrosion performance.

Owner:EAST CHINA UNIV OF SCI & TECH

Optical fiber distribution case

InactiveCN103091802ATaking into account installation needsAchieve accessFibre mechanical structuresFiberEngineering

The invention discloses an optical fiber distribution case which comprises a case body and a cover plate. The cover plate can be buckled on the case body to form a cavity body. An optical fiber adapter is arranged inside the case body. An optical fiber fusion welding disc is arranged on one side of the optical fiber adapter and is provided with a straight welding plate and fiber winding discs which are arranged on two sides of the straight welding plate and stores remaining optical cables in a disc mode. Optical cables enter the case body through a cable inlet to be connected with a distribution tail fiber on the straight welding plate in a welding mode. The distribution tail fiber is connected with a jumper tail fiber through the optical fiber adapter, and the jumper tail fiber is output out of the case body through a cable outlet. An X passive optical network (XPON) optical fiber access device and an optical branching device are arranged on the other side of the optical fiber adapter. The optical fiber distribution case can integrally install an operator and part of devices of electric power telecommunication inside the optical fiber distribution case, and considers communication device installation needs needed by a 'three-in-one network' of electric power telecommunication and an operation enterprise. The optical fiber distribution case can achieve telecommunication service access, and is suitable for a fiber to the home project of a small high-rise area and a high-rise area.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Corrosion-resistant cut shot and machining method thereof

InactiveCN110936302AEffective corrosion resistanceThe effect of monobasic acid is obviousAbrasion apparatusMonobasic acidMachining

The invention provides a corrosion-resistant cut shot and a machining method thereof. A compound of the elements such as chromium, molybdenum and tungsten in the formula is effectively resistant to corrosion, is mainly resistant to acid, and particularly has an obvious resisting effect on monobasic acid like hydrochloric acid. The machining method of the corrosion-resistant cut shot is more refined, aerial fog machining is combined with cutting, quenching and tempering are integrated, and all indexes of a cut shot finished product are excellent.

Owner:江苏亿达铸造机械有限公司

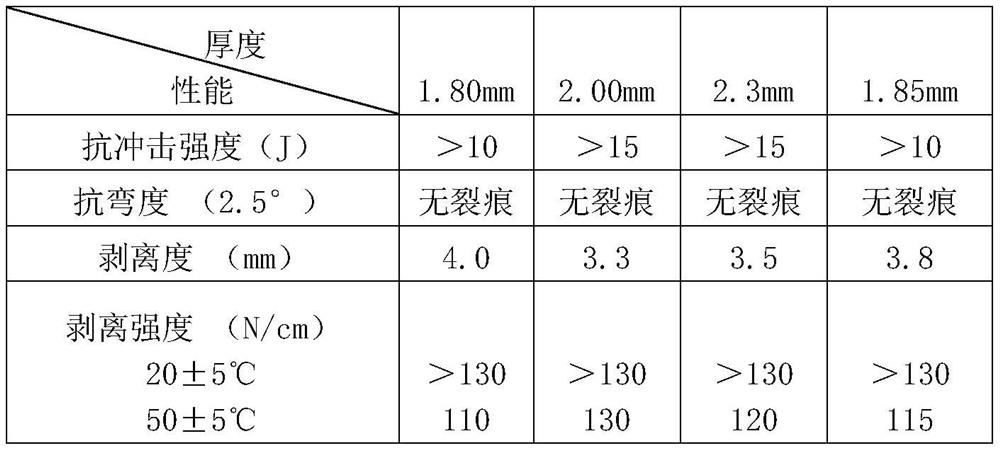

Preparation method of anti-corrosion and anti-impact PE composite pipe

The invention discloses a preparation method of an anti-corrosion and anti-impact PE composite pipe. The anti-corrosion and anti-impact PE composite pipe comprises polyethylene, color master batches, ceramic particles, a compatibilizer, rare earth porcelain sand, a polyolefin fiber fabric and a filler, the content of the polyethylene is 70%-90%, the content of the color masterbatch is 1%-2%, the content of the ceramic particles is 3%-7%, the content of the compatibilizer is 0.5%-0.8%, the content of the rare earth porcelain sand is 1%-3%, the content of the polyolefin fiber fabric is 10%-20%, the content of the lubricant is 1%-10%, the content of the filler is 10.5%-15%, and the content of the filler is 5%-20%. According to the preparation method of the anti-corrosion and anti-impact PE composite pipe, the wall thickness of the pipe body is adjusted for production, in a severe environment, the thickness of the pipe wall is about large, the anti-corrosion degree is higher, meanwhile, the anti-impact degree is also increased, and due to the use of the polyolefin fiber fabric and the ceramic particles of different components, the anti-corrosion and anti-impact PE composite pipe can be better manufactured. The corrosion resistance and the impact resistance of the pipe body are more effective.

Owner:扬中市长龙管业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com