Multi-pipeline connecting flange

A technology for connecting flanges and multiple pipes, applied in flange connection, pipe/pipe joint/pipe fittings, pipe components, etc., can solve the problems of wasting manpower and material resources, reducing engineering efficiency, slowing down the construction progress, etc., to speed up the construction progress , The effect of improving engineering efficiency and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

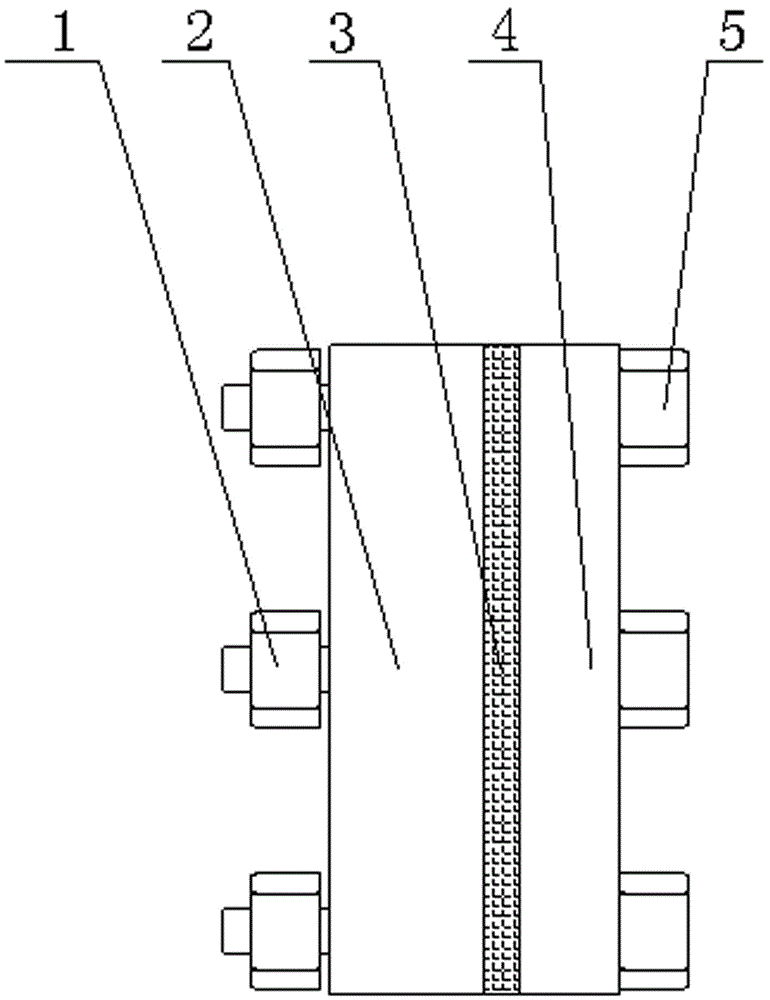

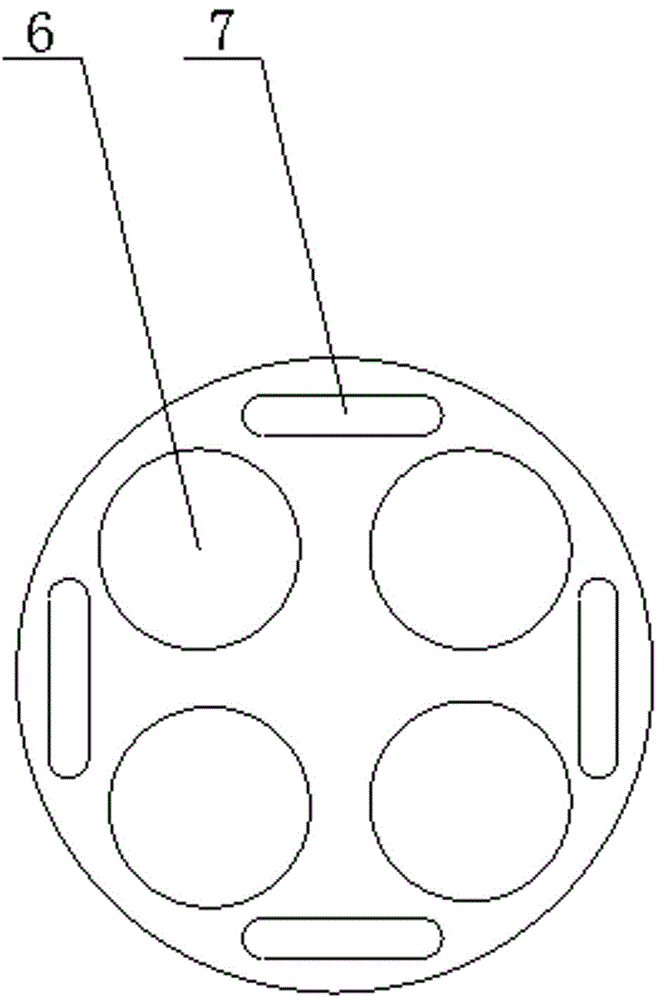

[0055] The multi-pipe connecting flange of the present embodiment, such as figure 1 with figure 2 As shown, it includes a first flange 2, a second flange 4, a sealing gasket 3, a fastening bolt 5 and a nut 1, and the sealing gasket 2 is arranged between the first flange 2 and the second flange 4. The first method Corresponding positions of the flange 2 and the second flange 4 are respectively provided with four tube receiving holes 6 , and the four tube receiving holes 6 are evenly distributed. The corresponding positions of the first flange 2 and the second flange 4 are respectively provided with fastening through holes, the fastening through holes are waist-shaped holes 7, and the fastening through holes of the first flange 2 and the second flange 4 are respectively There are four, and the four fastening through holes are arranged symmetrically in pairs. The fastening bolts 5 pass through the fastening through holes of the first flange 2 and the second flange 4 in turn an...

Embodiment 2

[0094] The multi-pipe connection flange of this embodiment is basically the same as the first embodiment, except that the mass percentages of the components in the first flange and the second flange are: C: 0.11%, Al: 1.25%, Zn: 0.77 %, Si: 0.18%, Mn: 0.72%, S: ≤0.030%, P: ≤0.030%, Cr: 0.17%, Ni: 0.35%, Cu: 0.34%, V: 0.04%, Mo: 0.19%, Ti : 0.56%, B: 0.07%, Pd: 0.19%, Pt: 0.09%, W: 0.31%, Ta: 0.02%, Nd: 0.09%, Ce: 0.07%, Eu: 0.03%, Lu: 0.43%, Au : 0.18%, Ag: 0.73%, Ga: 0.17%, Y: 0.04%, Sn: 0.68%, Zr: 0.13%, Re: 0.04%, Bi: 0.17%, calcium oxide: 0.72%, calcium carbonate: 0.45% , Talc: 0.59%, Magnesium Oxide: 0.27%, Copper Oxide: 0.38%, Iron Oxide: 0.84%, Manganese Dioxide: 0.16%, Potassium Hydroxide: 0.15%, Potassium Nitrate: 0.36%, Calcium Chloride: 0.15 %, Potassium chlorate: 0.19%, the balance being Fe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com