Titanium three-way tube and production method thereof

A production method and technology of three-way pipes, which are applied in the direction of pipes, branch pipelines, pipes/pipe joints/pipe fittings, etc., can solve the problems of low erosion resistance of weld seams, no advantages in service life, and easy breakage, etc., and achieve water delivery High efficiency, efficient and quick installation, high specific strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

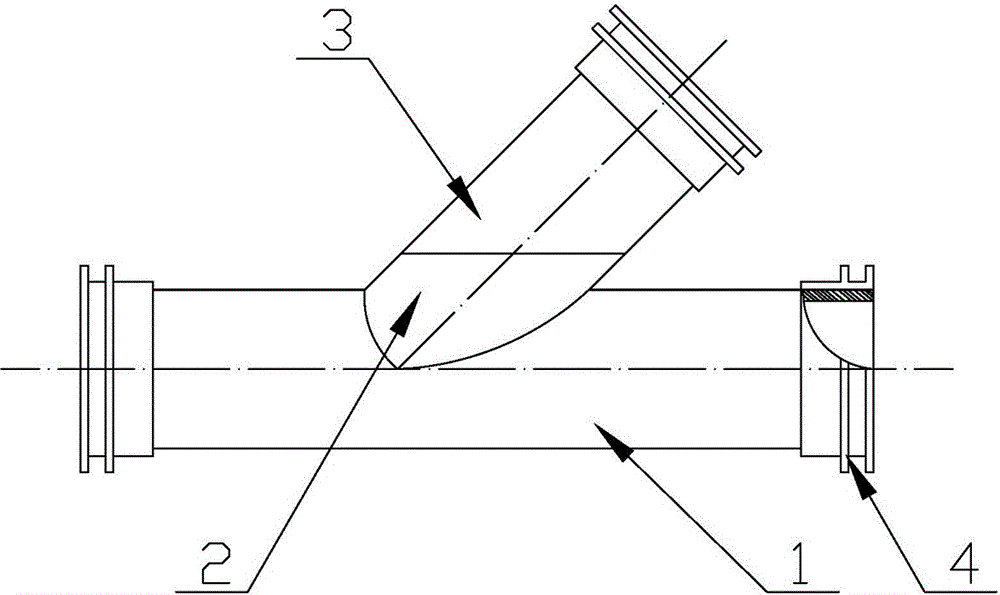

[0024] Depend on figure 1 , figure 2 As can be known, a kind of production method of titanium tee pipe, it comprises the following steps:

[0025] (1) Blank tube: use pure titanium to process the blank tube in the tube end shaping machine as the main tube 1;

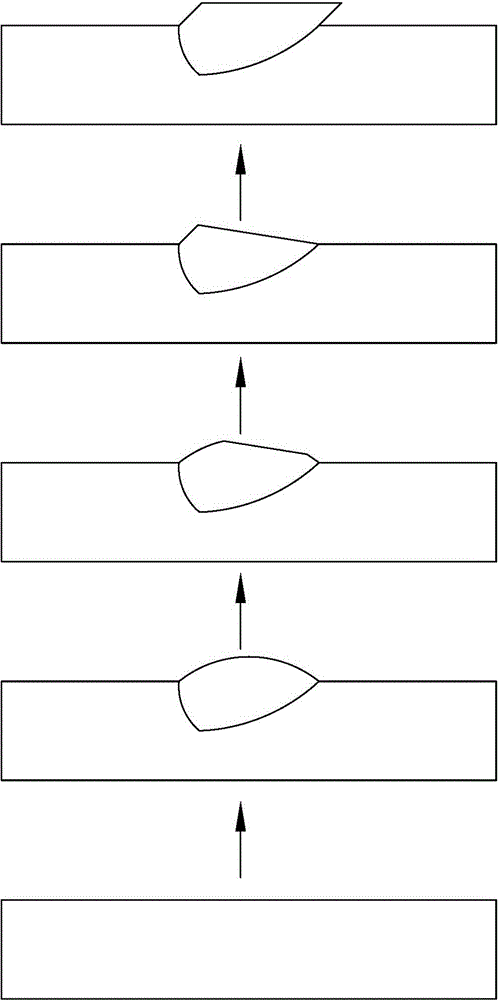

[0026] (2) Cold expansion forming: place the main pipe 1 obtained in step (1) in the mold of the pipe end shaping machine, press the set point on the main pipe 1 under normal temperature conditions, and squeeze out the prototype bubble from the inside to the outside of the pipe wall;

[0027] (3) Hole opening: Cut the top of the prototype bubble in a direction parallel to the central axis of the main pipe 1 to form a branch pipe connected to the main pipe 1;

[0028] ⑷Secondary molding: use the method of step 2 again to expand the opening of the branch pipe blank to the required set size, and adjust the angle of the branch pipe blank at the same time;

[0029] ⑸Reshaping: Trimming the opening of the branch pipe bille...

Embodiment 2

[0038] The thickness of the main pipe 1, the branch pipe 2 and the side pipe 3 in this embodiment is 1.0mm, and the outer diameter is 50.8mm.

[0039] The rest are the same as embodiment 1.

Embodiment 3

[0041] The thickness of the main pipe 1, the branch pipe 2 and the side pipe 3 in this embodiment is 0.75 mm, and the outer diameter is 40.0 mm.

[0042] The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com