Graphene high temperature resistant corrosion-resistant coating for metallic material and preparation method of graphene high temperature resistant corrosion-resistant coating

A technology for anti-corrosion coatings and metal materials, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of adding graphene quantum dots, poor thermal conductivity and anti-corrosion performance of coatings, unfavorable human body and environment, etc., to achieve good thermal conductivity, Improve anti-corrosion performance and reduce the effect of coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

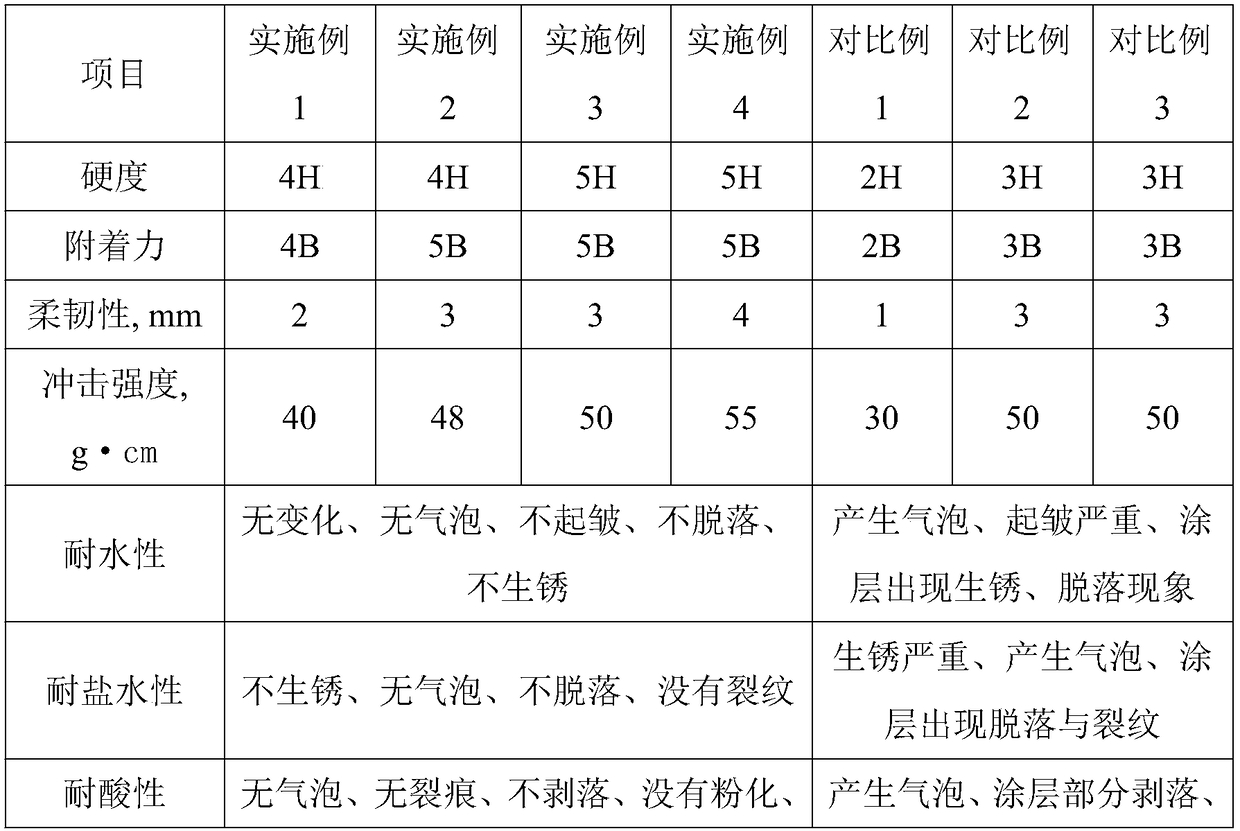

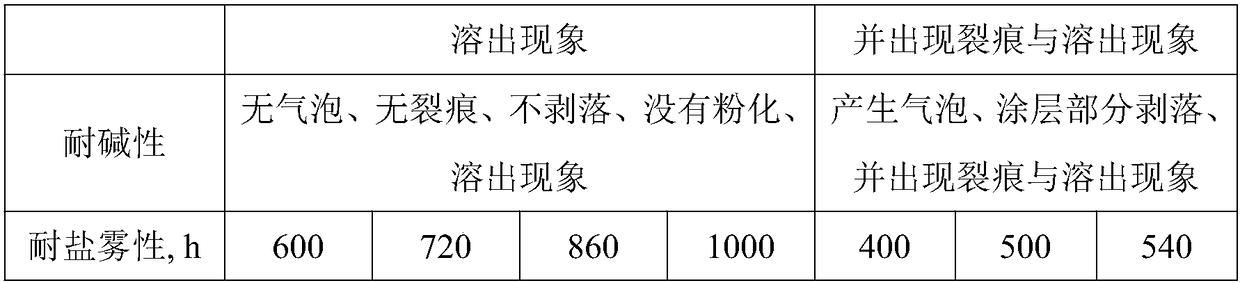

Examples

Embodiment 1

[0033] 1. A graphene high-temperature resistant anti-corrosion coating for metal materials, consisting of the following components in parts by weight: 6 parts of graphene oxide, 20 parts of phenolic resin, 6 parts of polyvinyl butyral, 4 parts of rare earth chloride, graphene 12 parts of quantum dots, 5 parts of heat-conducting metal powder, 3 parts of carbon nanotubes, 12 parts of solvent, 2 parts of antioxidant, 5 parts of curing agent and 18 parts of defoamer;

[0034] The size of the graphene quantum dots is 2nm; the solid content of the phenolic resin is 45%; the heat-conducting metal powder is aluminum powder with a particle size of 5 μm; the purity of the carbon nanotubes is ≥96wt%, and the ash content is ≤0.4wt% , the specific surface area is 100-200m 2 / g.

[0035] In this embodiment, the preferred solvent is butanone, the preferred curing agent is ammonium chloride, the preferred defoamer is emulsified silicone oil, and the preferred antioxidant is ascorbic acid.

...

Embodiment 2

[0041] 1. A graphene high temperature resistant anti-corrosion coating for metal materials, consisting of the following components in parts by weight: 12 parts of graphene oxide, 45 parts of phenolic resin, 2 parts of polyvinyl butyral, 1 part of rare earth chloride, graphene 30 parts of quantum dots, 2 parts of heat-conducting metal powder, 6 parts of carbon nanotubes, 30 parts of solvent, 6 parts of antioxidant, 9 parts of curing agent and 12 parts of defoamer;

[0042] The size of the graphene quantum dot is 4nm; the solid content of the phenolic resin is 55%; the heat-conducting metal powder is silver powder with a particle size of 10 μm; the purity of the carbon nanotubes is ≥ 96wt%, and the ash content is ≤ 0.4wt%. The specific surface area is 100~200m 2 / g.

[0043] In this embodiment, the preferred solvent is ethanol, the preferred curing agent is ethylenediamine, the preferred defoamer is organosiloxane, and the preferred antioxidant is sodium sulfite.

[0044] 2, t...

Embodiment 3

[0047] 1. A graphene high-temperature-resistant anti-corrosion coating for metal materials, consisting of the following components in parts by weight: 8 parts of graphene oxide, 25 parts of phenolic resin, 5 parts of polyvinyl butyral, 2 parts of rare earth chloride, graphene 18 parts of quantum dots, 4 parts of heat-conducting metal powder, 5 parts of carbon nanotubes, 24 parts of solvent, 5 parts of antioxidant, 6 parts of curing agent and 15 parts of defoamer;

[0048] The size of the graphene quantum dots is 3nm; the solid content of the phenolic resin is 48%; the heat-conducting metal powder is silver powder with a particle size of 6 μm; the purity of the carbon nanotubes is ≥ 96wt%, and the ash content is ≤ 0.4wt%. The specific surface area is 100~200m 2 / g.

[0049] In this embodiment, the preferred solvent is isopropanol, the preferred curing agent is ethylene triamine, the preferred defoamer is polyoxypropylene glyceryl ether, and the preferred antioxidant is sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com