Antibacterial and anticoagulant coating, functional material with antibacterial and anticoagulant coating and preparation method of functional material

A functional material and coating technology, applied to medical materials with antibacterial and anticoagulant coatings and their preparation, in the field of antibacterial and anticoagulant coatings, which can solve the problem of non-reactive activity or limited activation methods, and the combination of coatings and substrates Low strength and high risk of coating peeling off, to avoid coating dissociation and peeling, long-lasting anticoagulant and antibacterial effects, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

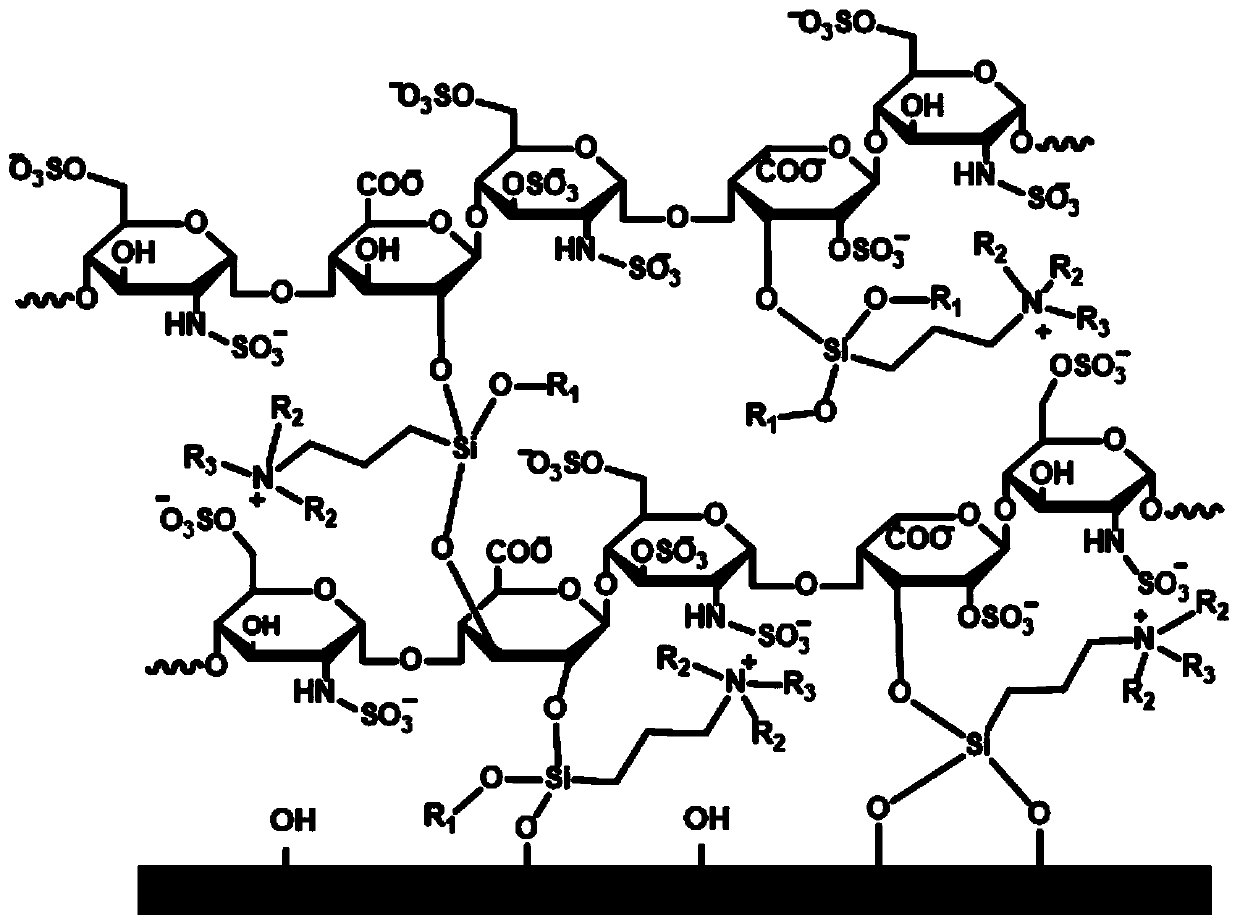

[0102] The present invention also provides a preparation method with an antibacterial and anticoagulant type coating, comprising the following steps:

[0103] 1) after mixing sodium heparin with the organosilicon quaternary ammonium salt solution having the structure of formula (I), obtain organosilicon quaternary ammonium salt / heparin complex solution;

[0104]

[0105] where R 1 and R 2 each independently selected from -CH 3 , -CH 2 CH 3 ;

[0106] R 3 is selected from the alkyl group of C6~C18;

[0107] 2) After thermal curing the organosilicon quaternary ammonium salt / heparin complex solution obtained in the above steps, a coating with antibacterial and anticoagulant type is obtained.

[0108] The present invention compares the structures, materials, specific parameters, specific process parameters, and corresponding optimization principles of the compounds in the above preparation methods with the structures, materials, and specific parameters of the compounds i...

Embodiment 1

[0141] Preparation of antibacterial and anticoagulant medical polyurethane materials

[0142] A) Add 1.0 g of sodium heparin (molecular weight 7500-20000 g / mol) to 5 mL of dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride ethanol solution (0.4 g / mL) , mixed into dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride ethanol / heparin complex solution.

[0143] B) Put the medical polyurethane material into the plasma reaction chamber, pass oxygen at a flow rate of 150cc / min, maintain the working pressure of the reaction chamber at 20Pa, and treat the sample plasma for 15min under 500W power to obtain the surface hydroxylated medical polyurethane material .

[0144] C) The surface hydroxylated polyurethane material obtained in the step B) is obtained in the step A) dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride ethanol / heparin composite It was soaked in the organic silicon quaternary ammonium salt / heparin composite intermediate coating for 5 min...

Embodiment 2

[0147] A) 1.2g of sodium heparin (molecular weight 7500~20000g / mol) was added to 5mL of dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride methanol solution (0.4g / mL) , mixed into dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride ethanol / heparin complex solution.

[0148] B) Put the medical polyurethane material into the plasma reaction chamber, pass oxygen at a flow rate of 200cc / min, maintain the working pressure of the reaction chamber at 30Pa, and treat the sample plasma for 40min under 300W power to obtain the surface hydroxylated medical polyurethane material .

[0149]C) The surface hydroxylated polyurethane material obtained in the step B) is obtained in the step A) dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride ethanol / heparin composite immersed in the compound solution for 3 min to obtain a polyurethane material with a physically loaded organosilicon quaternary ammonium salt / heparin composite intermediate coating.

[0150] D) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com