Preparation method of anti-corrosion and anti-impact PE composite pipe

A composite pipe and impact-resistant technology, applied in the field of PE composite pipes, can solve problems such as inconvenience of use, and achieve the effects of being easy to use, overcoming high water absorption and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below.

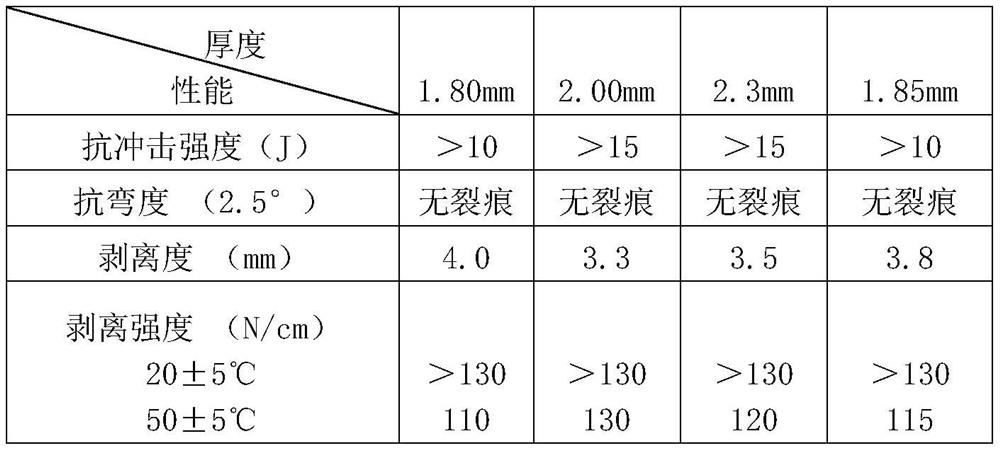

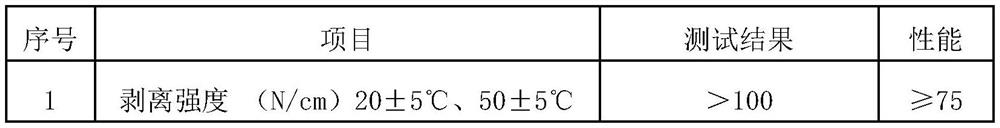

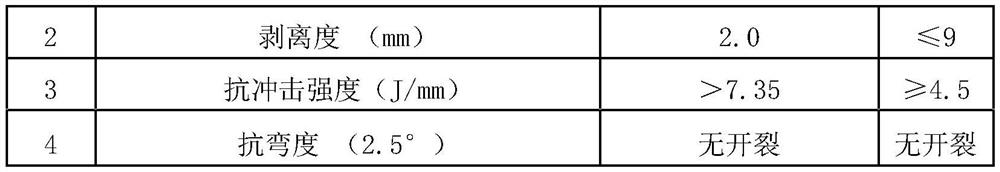

[0026] A preparation method for anti-corrosion and impact-resistant PE composite pipe, comprising: polyethylene, color masterbatch, ceramic particles, compatibilizer, rare earth porcelain sand, polyolefin fiber fabric and filler; the content of polyethylene is 70-90%, The content of the color masterbatch is 1-2%, the content of the ceramic particles is 3-7%, the content of the compatibilizer is 0.5-0.8%, and the content of the rare earth porcelain sand is 1-3% , the content of the polyolefin fiber fabric is 10-20%, the content of the lubricant is 1-10%, the content of the filler is 10.5-15%, and the content of the filler is 5-20%.

[0027] Among them, the pipe preparation materials include by weight: polyethylene 30-50%, color masterbatch 1.2-2%, ceramic particles 2.5-5%, compatibilizer 0.6-0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com