Novel prestressed steel pipe-concrete composite beam

A prestressed steel and concrete technology, applied in building components, floors, buildings, etc., can solve the problems of large deformation and easy cracking of composite beams, and achieve the effects of improving bearing capacity, reducing self-weight, and achieving significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

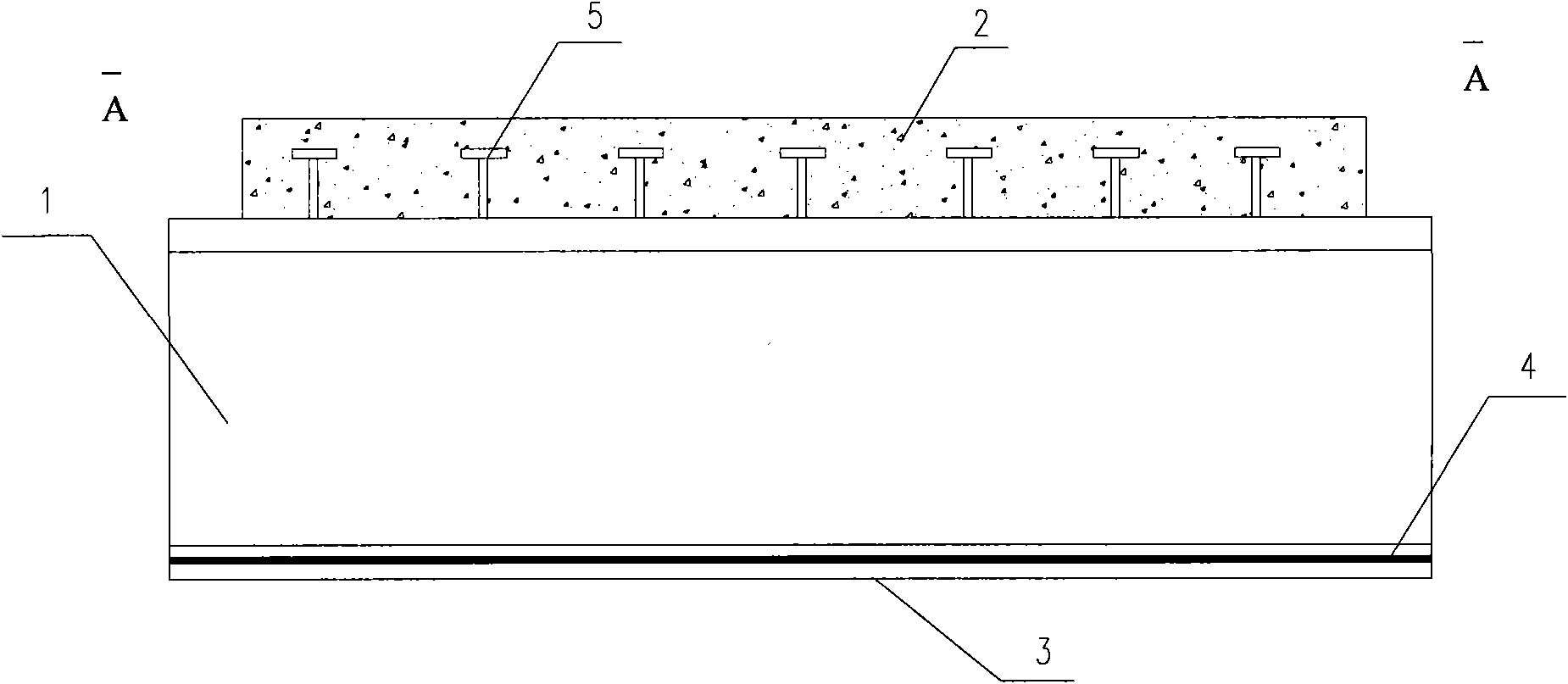

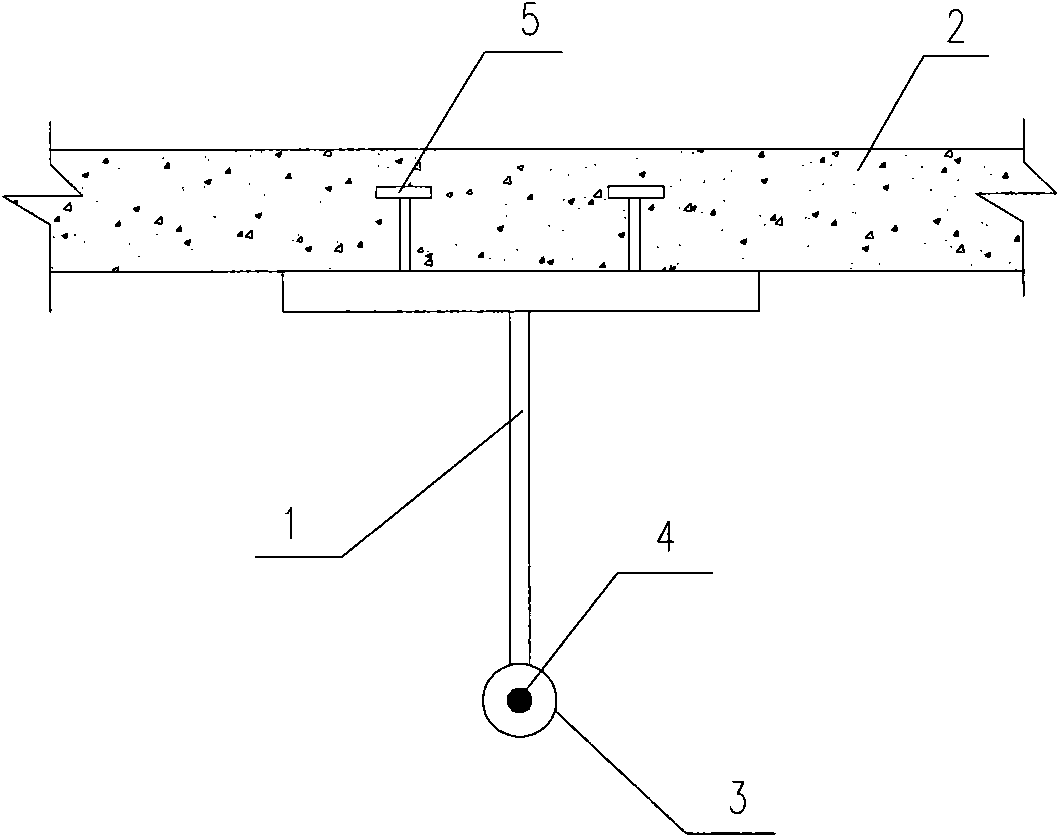

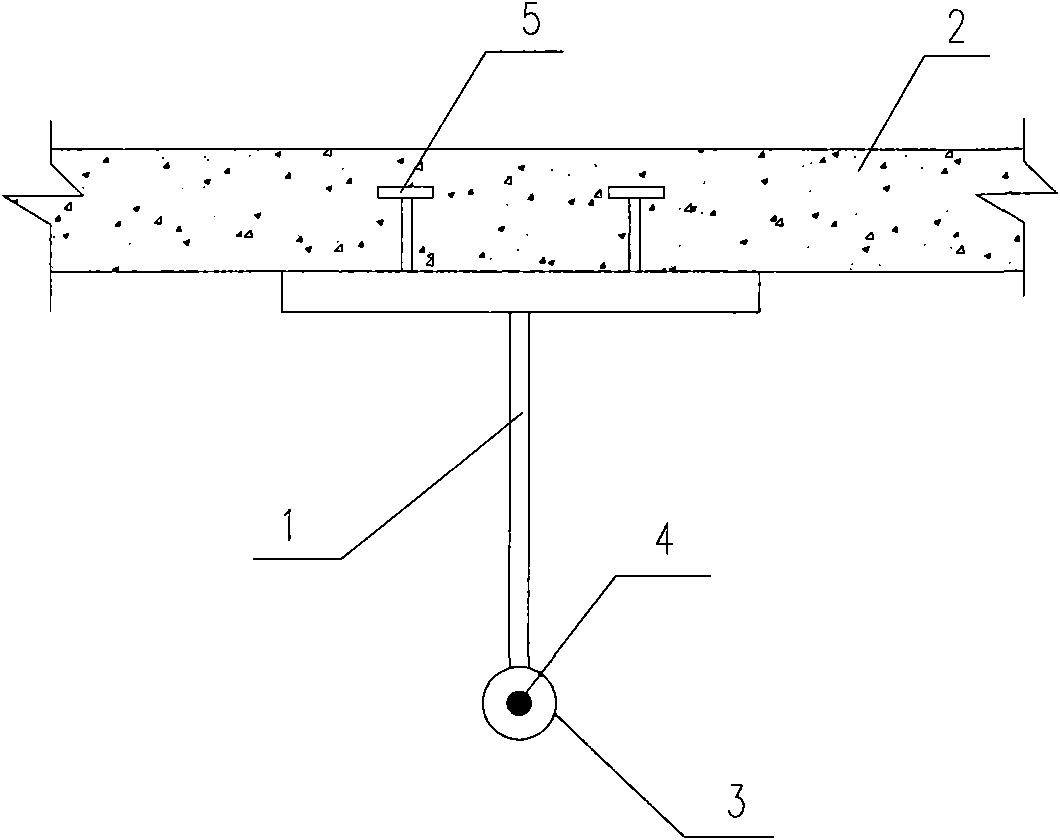

[0014] Embodiment: the lower flange of the steel beam (1) is a steel pipe (3), and several straight steel cables (4) are arranged inside the steel pipe (3), and then the prestressed steel cables (4) sprayed with fireproof and anti-corrosion coatings in advance are stretched After tensioning, both ends of the steel pipe are sealed, shear connectors such as studs (5) are arranged on the top of the steel beam, and finally the concrete slab (2) is poured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com