Patents

Literature

56results about How to "Satisfy the carrying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Access system and method

InactiveCN101212398AEliminate problems that are prone to single points of failureSupport smooth upgradeAssess restrictionData switching networksAccess networkInstability

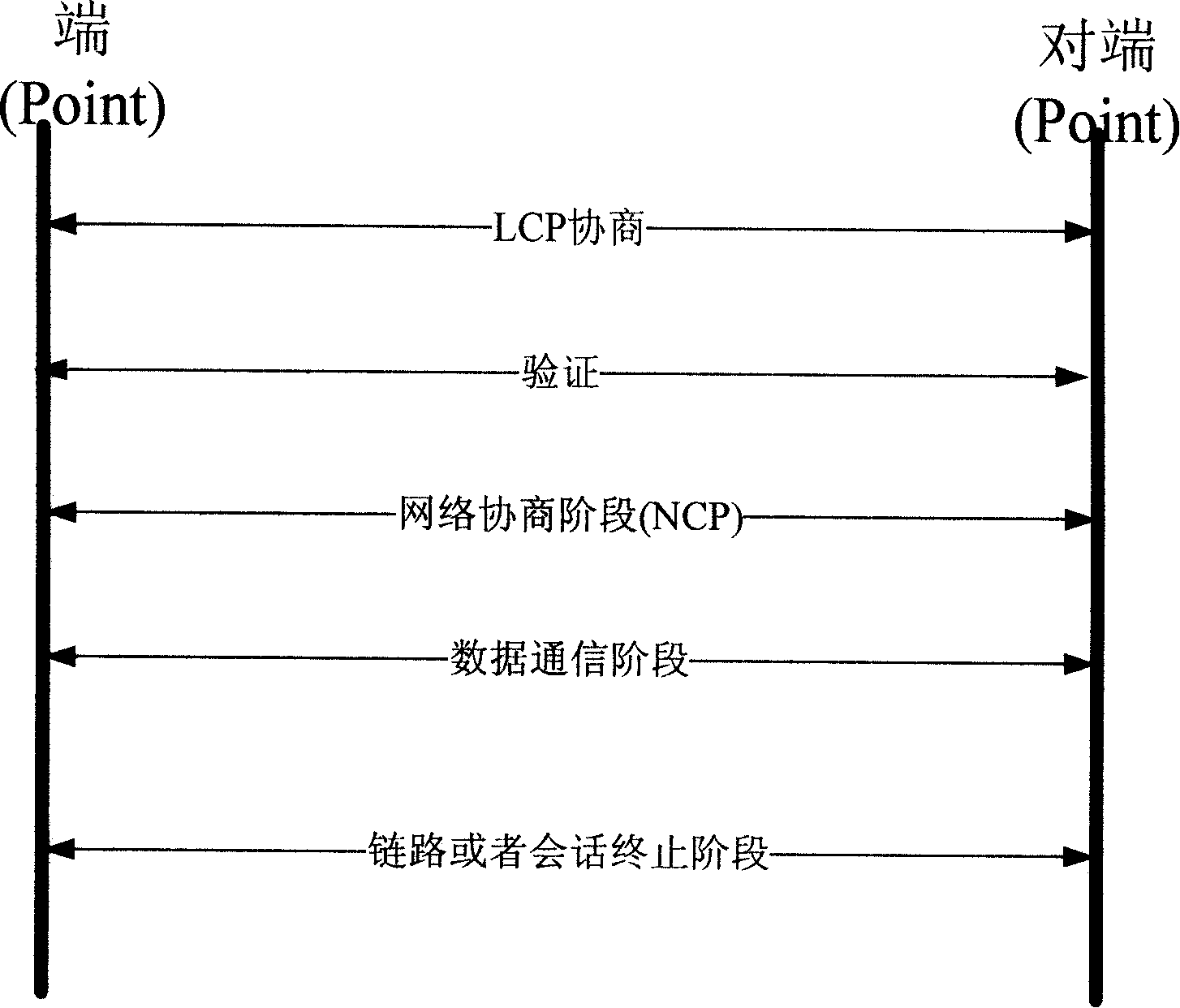

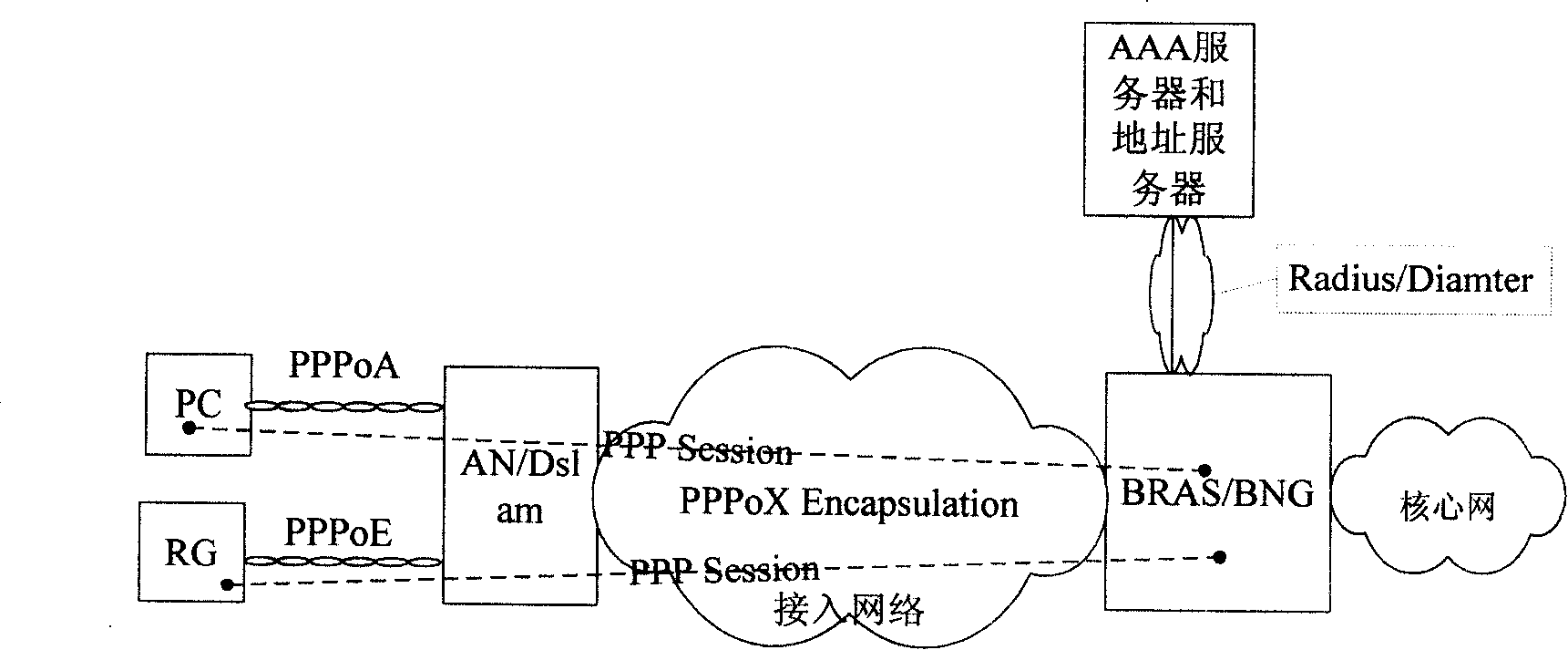

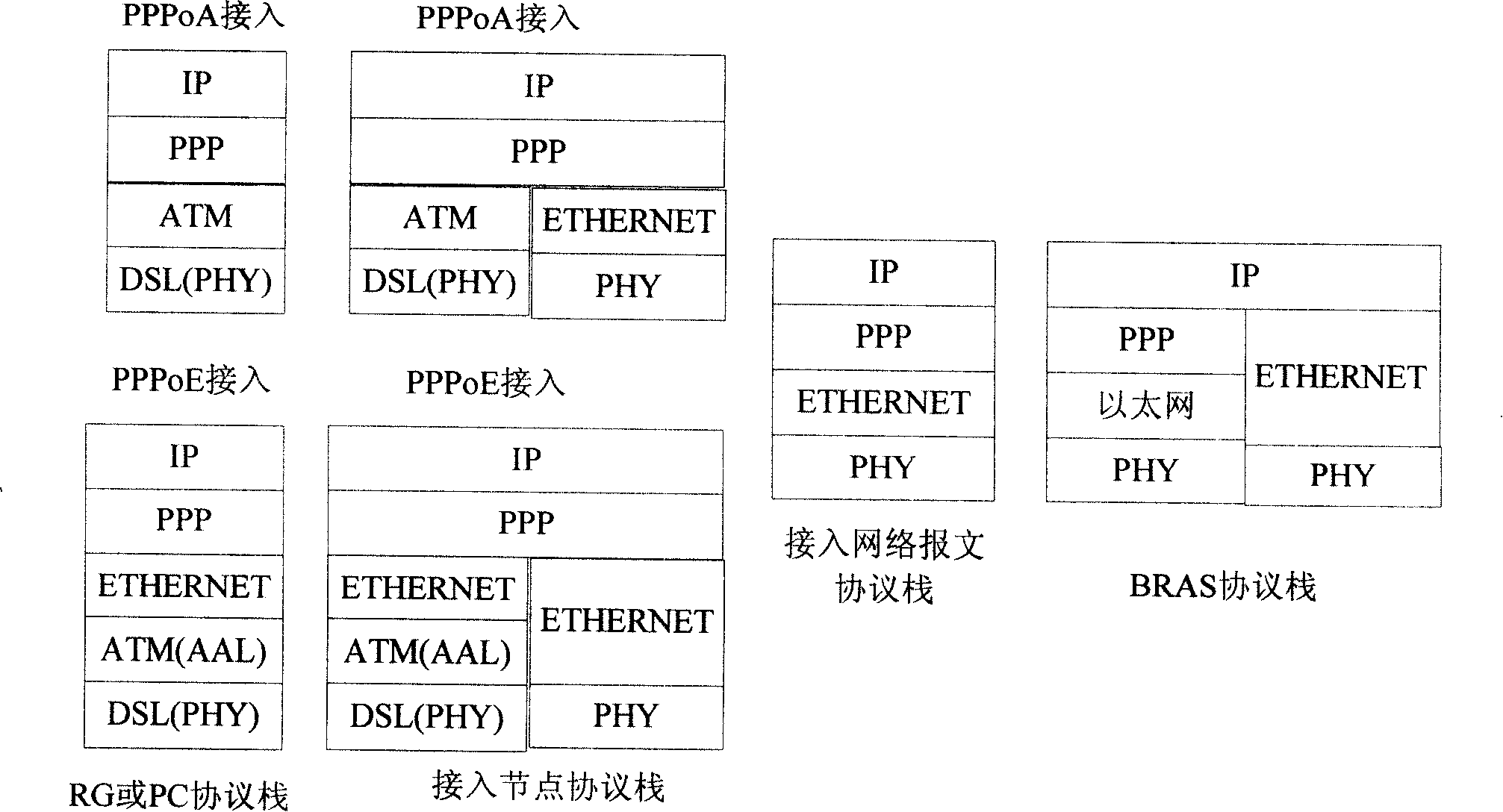

The invention discloses an access system, which comprises a user device, an access node and an access controller. The access controller is connected with the access node and accesses in the user device. The access node accesses in the user device and distinguishes forwarding controlling from a data message. The controlling message is transferred and the user data message is transmitted between the user and the access controller. The benefit resulted from the technology is that the access controller in the invention manages a PPP and the access network realizes isolation between controlling and transmission, thus removing the obstacle of supporting the multicast by the PPP and solving the problems of difficulty and instability existing in the access server.

Owner:王立刚

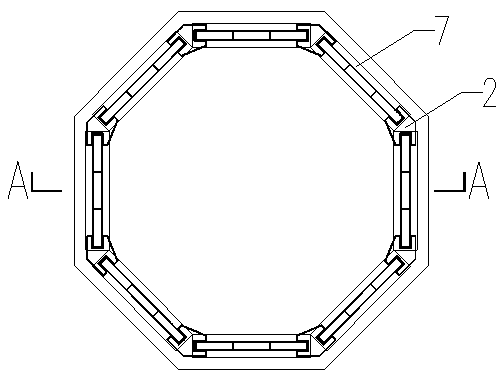

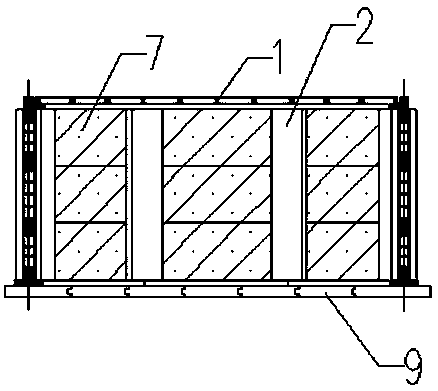

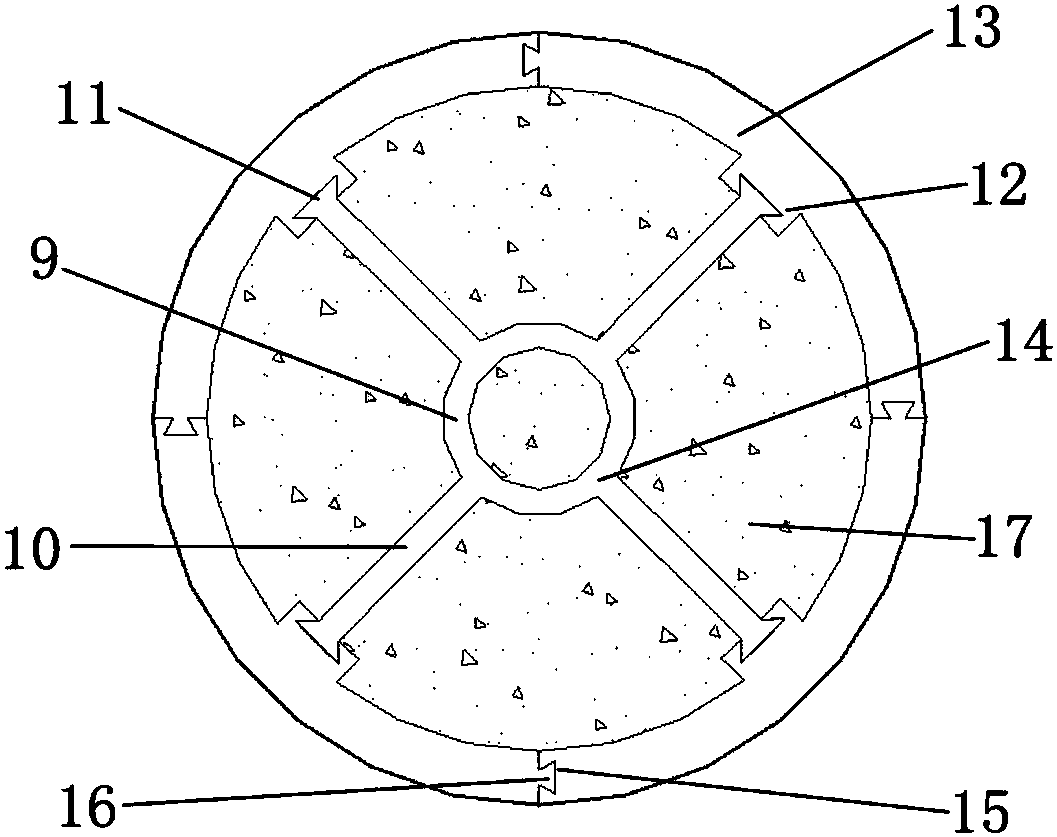

Prefabricated light GFRP octagonal cable well and construction method thereof

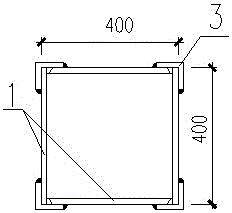

PendingCN110984227AEnsure structural safetyReduce weightArtificial islandsUnderwater structuresStructural engineeringRabbet

The invention discloses a prefabricated light GFRP octagonal cable well. The prefabricated light GFRP octagonal cable well comprises a cover plate, stand columns, a cover plate support, baffles, inverted-T-shaped cross beams and a bottom plate, wherein the eight inverted-T-shaped cross beams are fixed to the bottom plate and arranged in a regular octagon shape; the stand columns are arranged between every two adjacent inverted-T-shaped cross beams, and grooves of the stand columns are tightly matched with the inverted-T-shaped cross beams; the baffles are arranged between every two adjacent stand columns, the bottom ends of the baffles are connected and fixed to the inverted-T-shaped cross beams through rabbets, and the top ends of the baffles are connected and fixed to the cover plate support through rabbets; and the cover plate is fixed to the cover plate support through bolts. According to the prefabricated light GFRP octagonal cable well, by adopting a light GFRP material and a prefabricated assembly mode, the requirements for structural bearing and using functions are met, and the weight of the prefabricated light GFRP octagonal cable well is only 1 / 3 1 / 2 of the weight of a traditional concrete cable well with the same size; and meanwhile, the construction efficiency is improved by 50% or above compared with that of the traditional concrete cable well, and the prefabricated light GFRP octagonal cable well has the characteristics of being economical, reasonable, convenient to transport and convenient and fast to construct.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LIANYUNGANG POWER SUPPLY CO +1

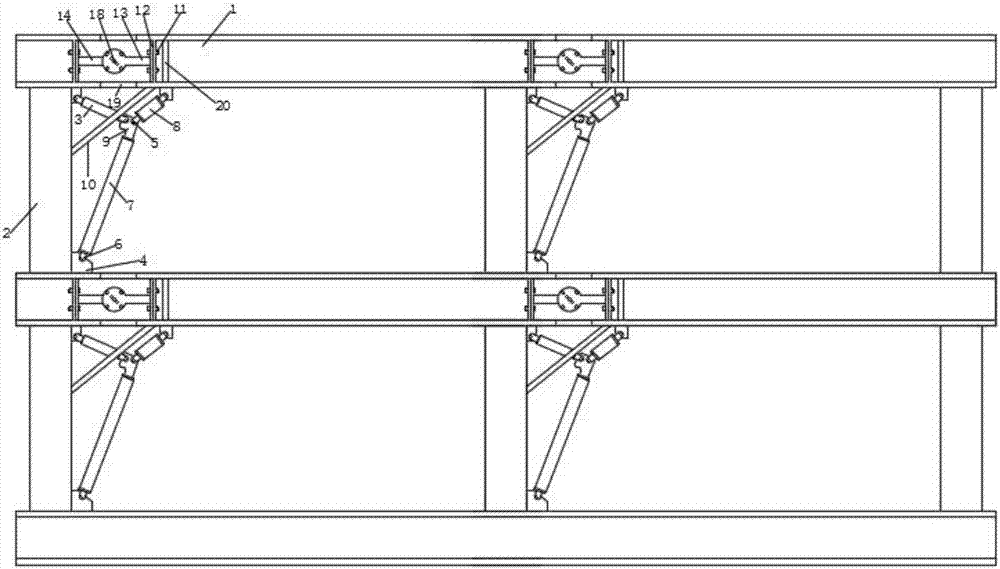

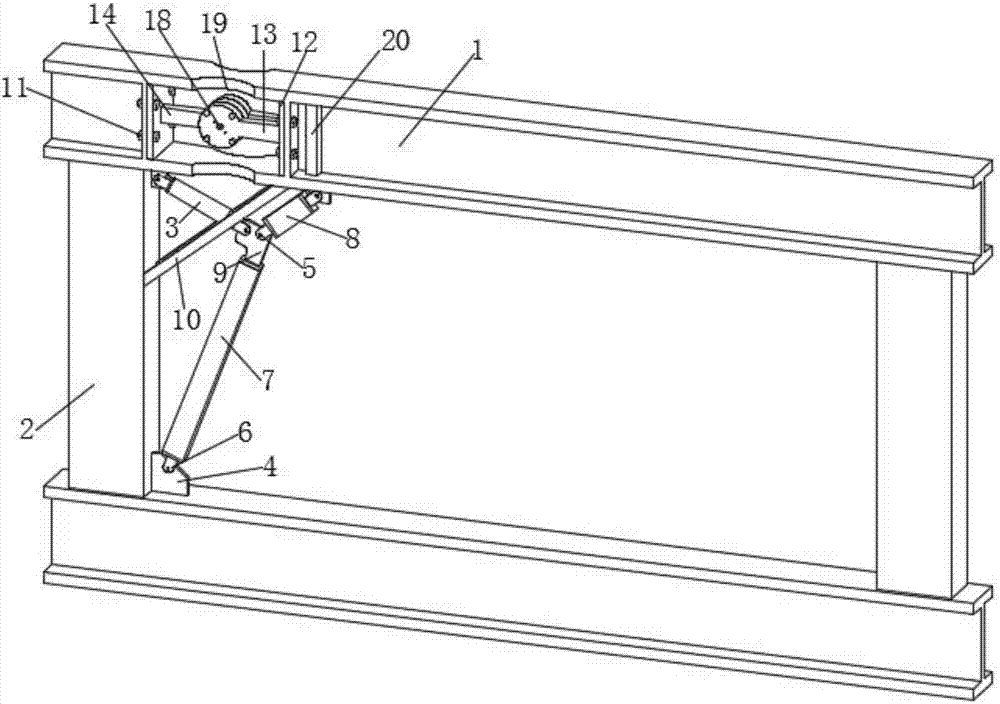

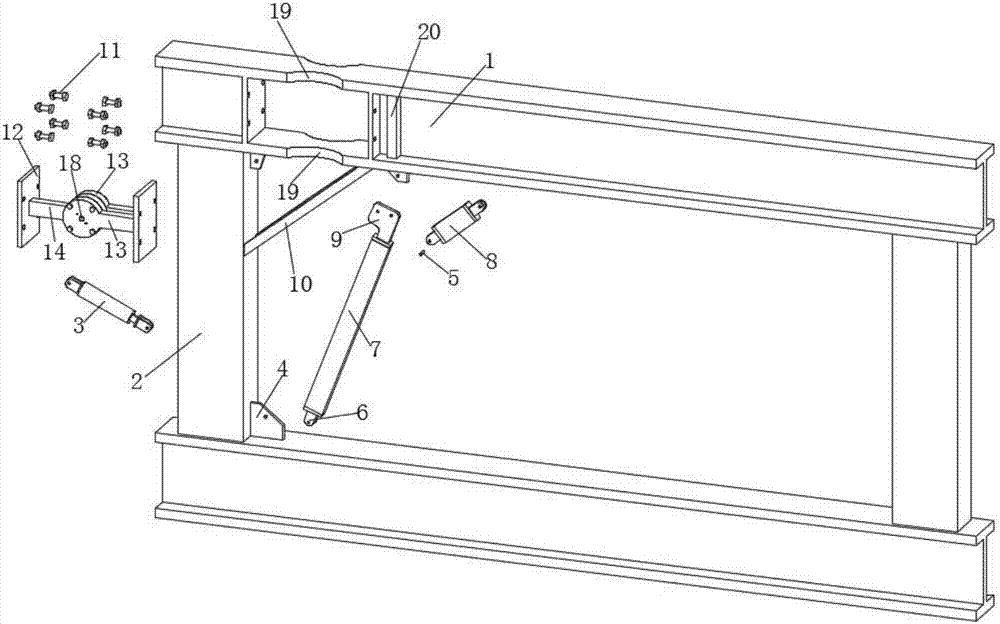

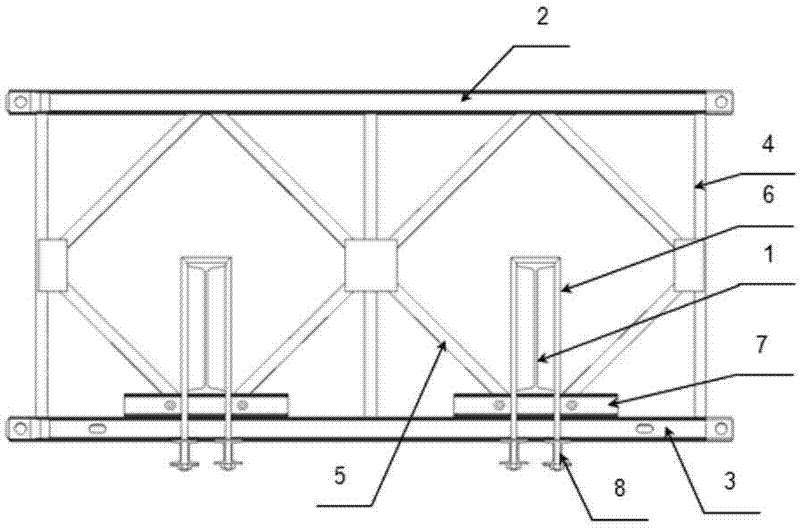

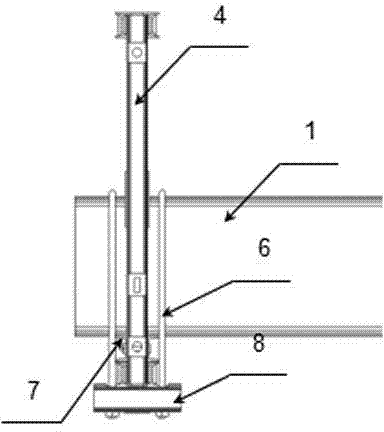

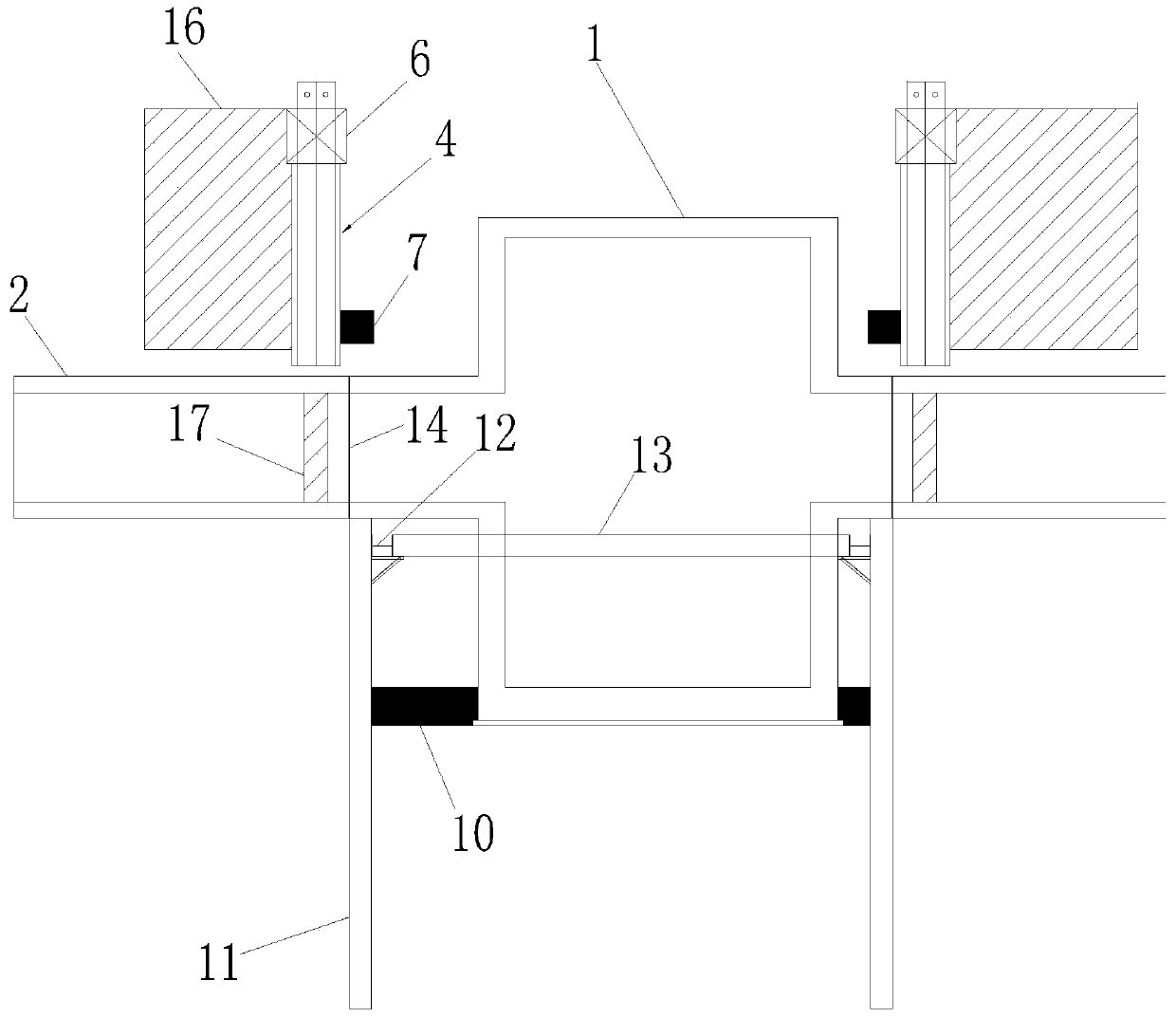

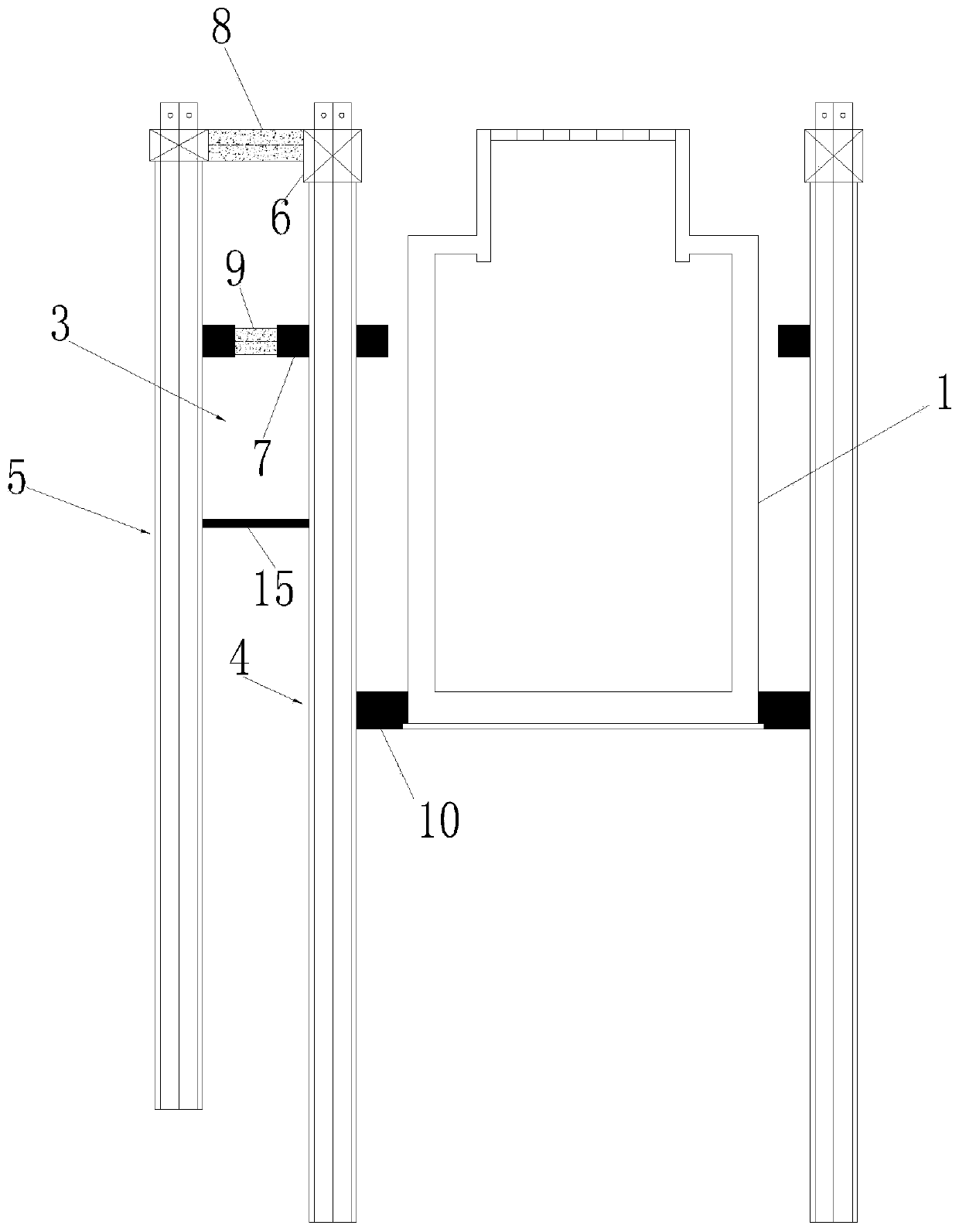

Fabricated steel structure containing replaceable beam end rotating energy dissipation hinge and small inclined-span lariat

InactiveCN106948484AAvoid damageRealize shock absorption and energy consumptionProtective buildings/sheltersShock proofingLateral stiffnessEngineering

The invention discloses a fabricated steel structure containing a replaceable beam end rotating energy dissipation hinge and a small inclined-span lariat. The fabricated steel structure comprises fabricated steel beams, fabricated steel columns, dampers, joint plates, bolt pins, lug plates, lower connecting rods, upper connecting rods, ladder type haunched beams, bolts, end plates, front and rear cover plates, rotating plates, annular grooves, shearing blocks, shearing keys, rotating shafts, flange notches and web rib strips. A plastic-hinge region is locally weakened through the beam end rotating energy dissipation hinge of the fabricated steel structure; not only is the design concept of strong columns and weak beams reflected, but also the energy of the structure is dissipated through shearing deformation; while providing resist lateral stiffness for the structure, a small inclined-span lariat energy dissipation device conducts full energy dissipation of the dampers by enlarging horizontal displacement; and the fabricated steel structure is definite in energy dissipation mechanism and has strong energy dissipation capacity under the moving action of an earthquake, main damage and destroy of the steel structure can be alleviated, and the structure is easy to replace after the earthquake or the damage.

Owner:BEIJING UNIV OF TECH

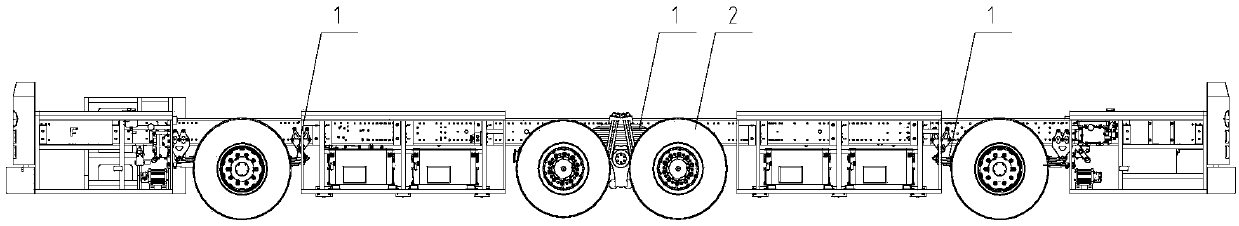

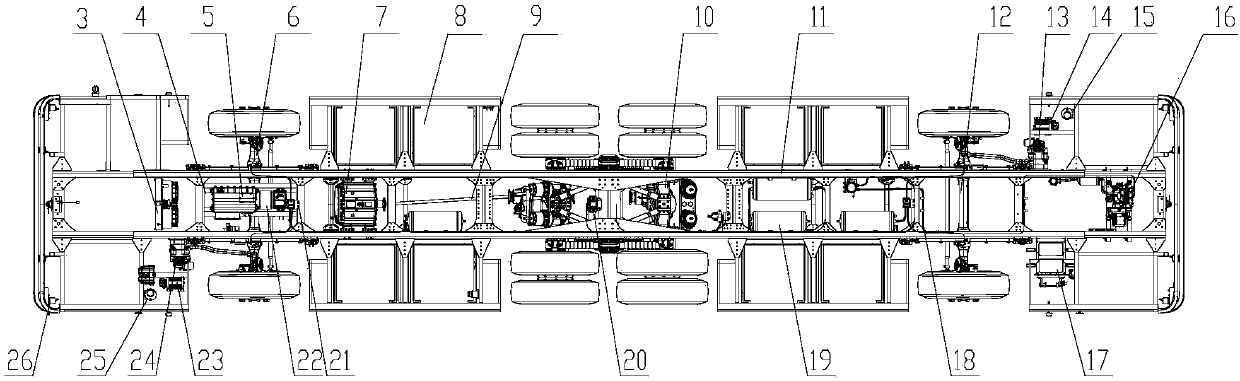

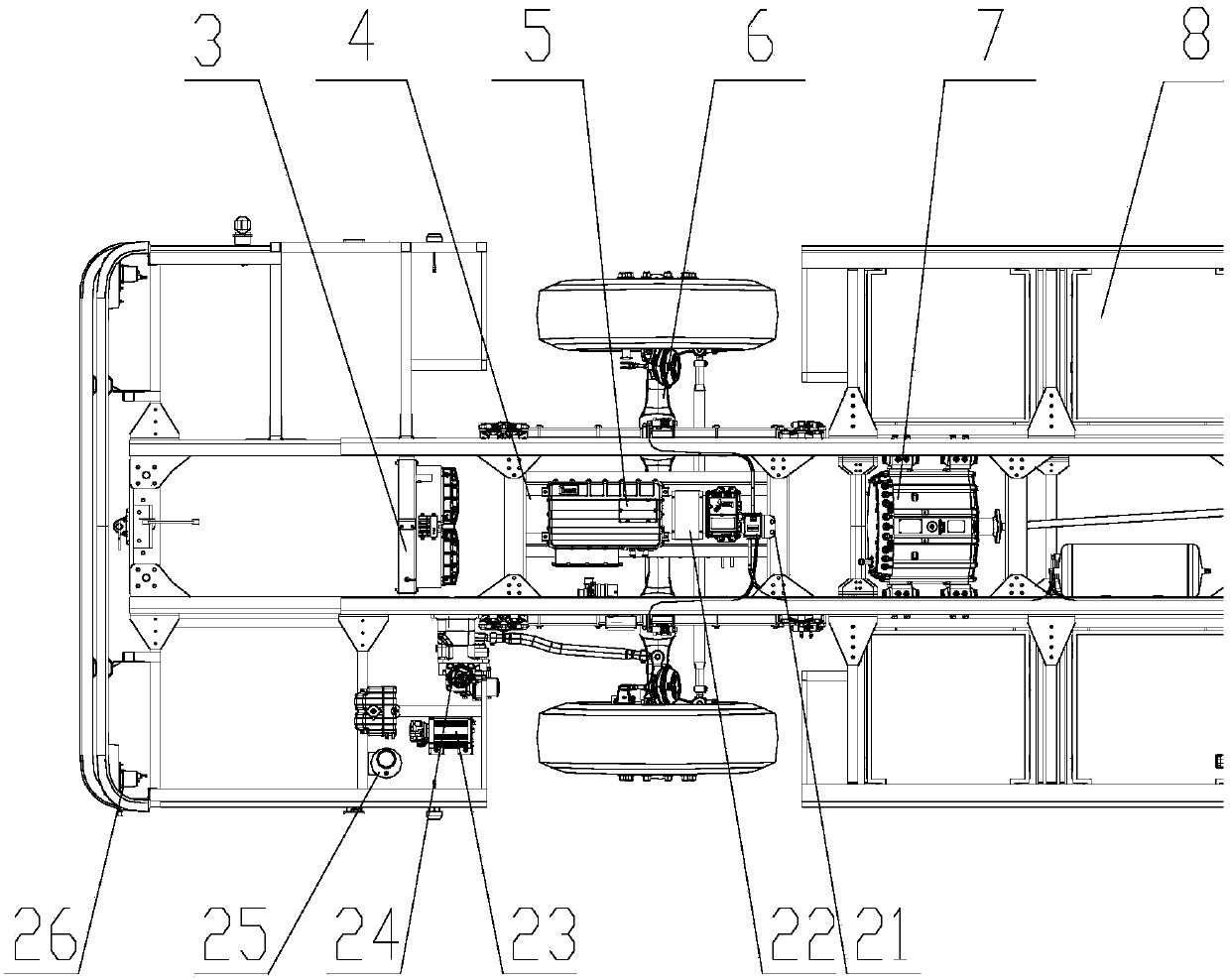

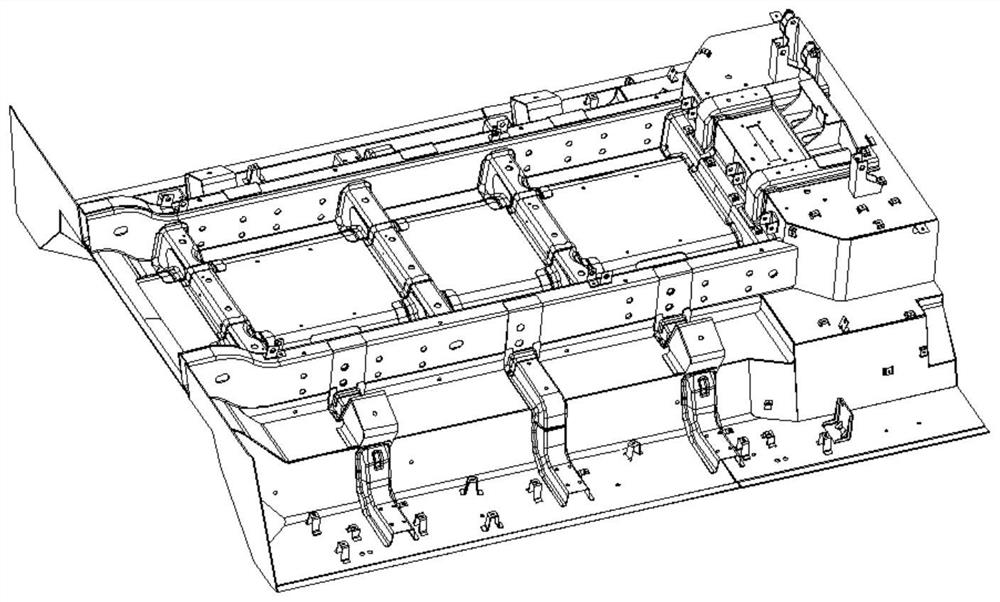

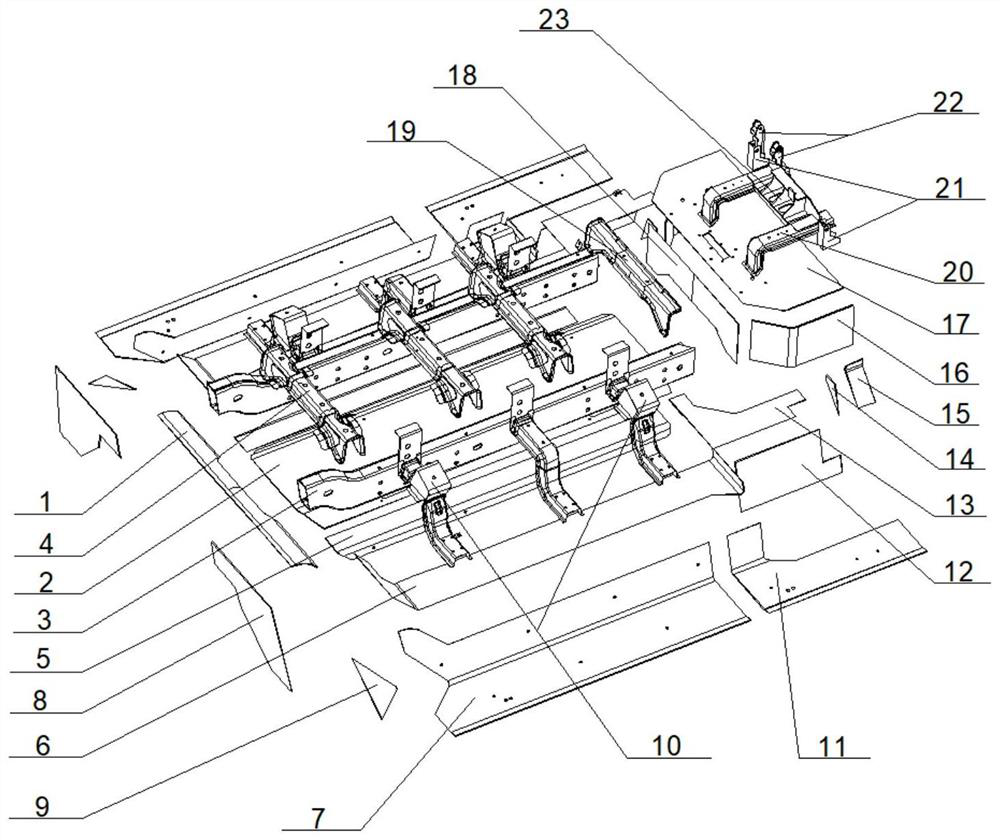

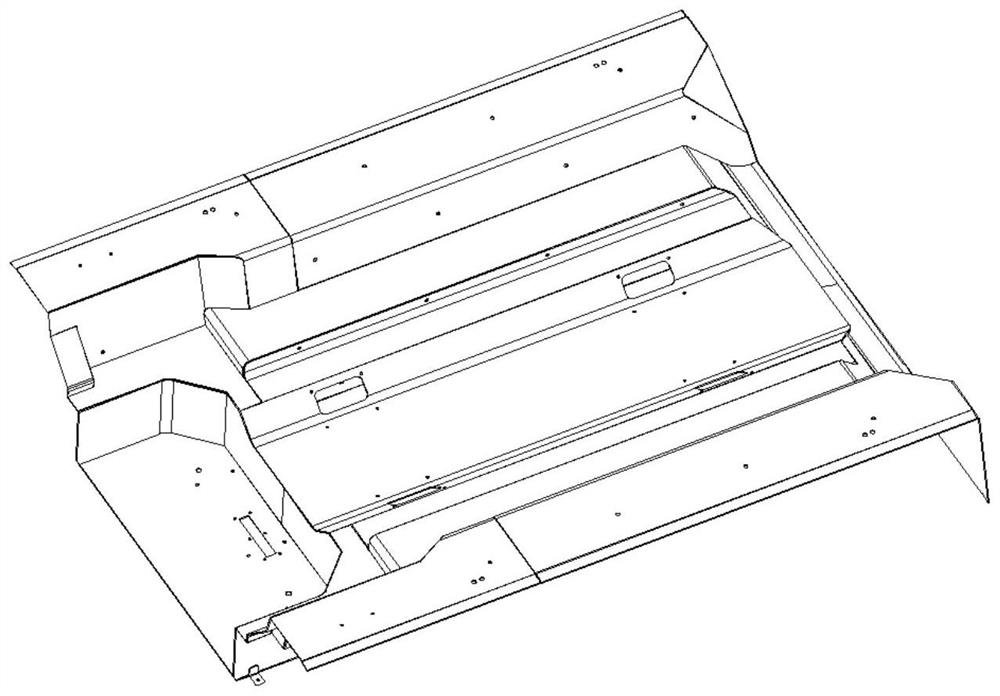

Chassis of automatic container guiding vehicle

PendingCN107791928AImprove mobilityThe positive and negative effects are the sameElectric propulsion mountingFluid steeringAutomated guided vehicleControl theory

The invention provides a chassis of an automatic container guiding vehicle. The chassis is provided with a front steering shaft, a rear steering shaft and two driving axles. The front steering shaft and the rear steering shaft are arranged at the front end and the rear end of the chassis in a mode of being symmetric in the front-rear direction relative to the center of the vehicle. The two drivingaxles are arranged in the middle of the chassis side by side. Single tires are arranged at the two ends of the front steering shaft and the rear steering shaft correspondingly. Double tires are arranged at the two ends of the driving axles correspondingly. The chassis of the automatic container guiding vehicle adopts a 8x4 driving mode, the forward-rotation effect and the reverse-rotation effectof the vehicle are consistent, and distinguishing of advancing or backing-up is not needed; steering of the front steering shaft and steering of the rear steering shaft are coordinated and consistent,so that the turning radius is decreased, and vehicle maneuverability is promoted; and the bearing loads of the tires of the chassis are consistent basically, and thus the large-bearing requirement ismet.

Owner:CHINA FIRST AUTOMOBILE

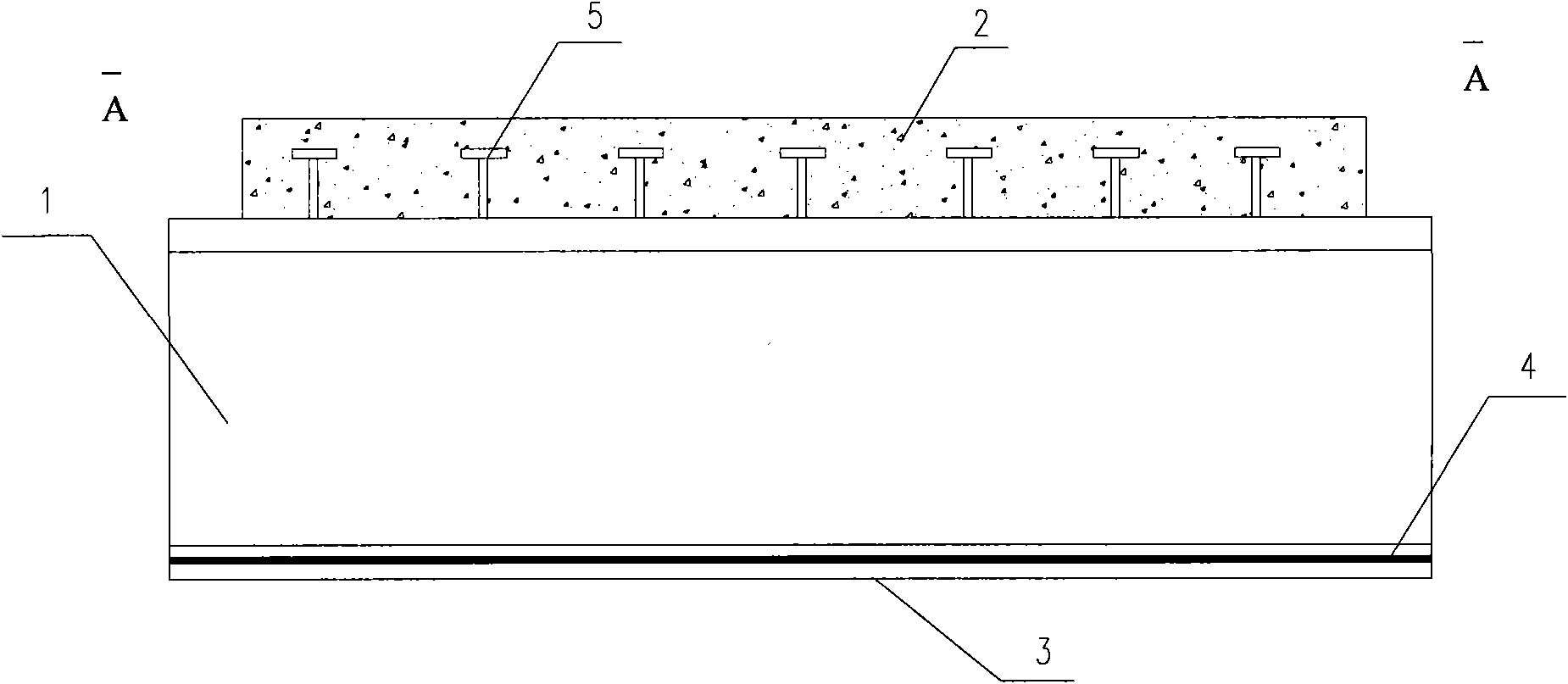

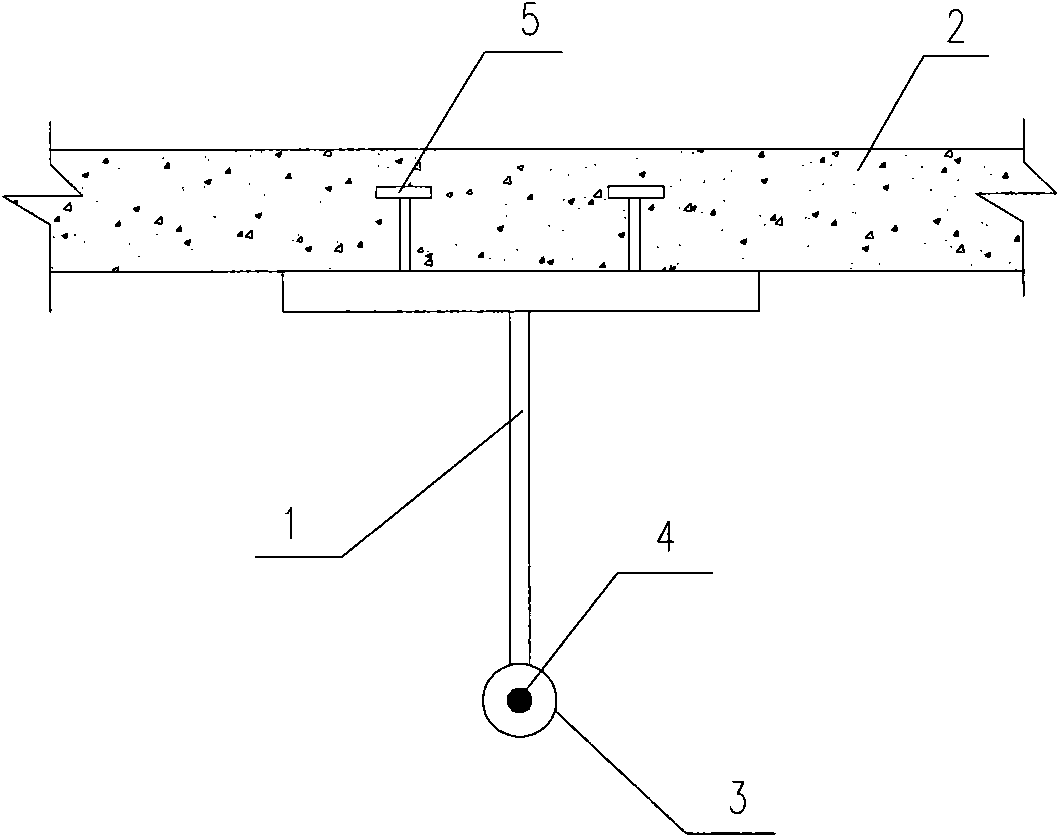

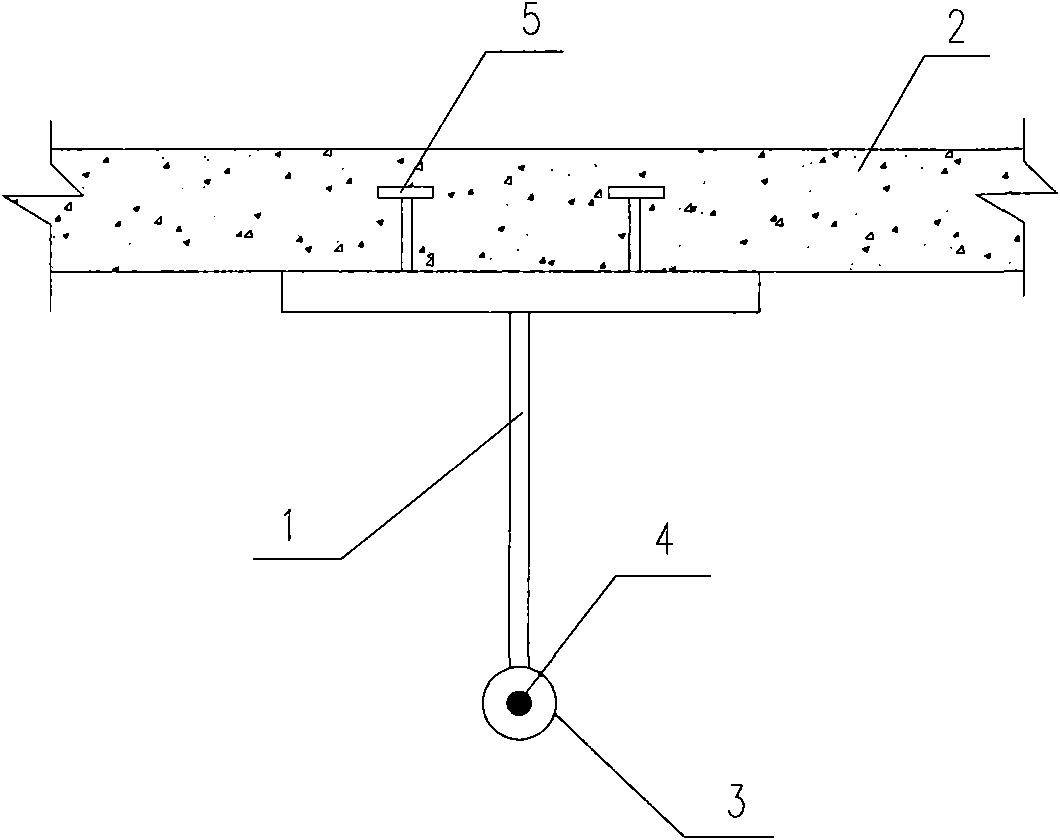

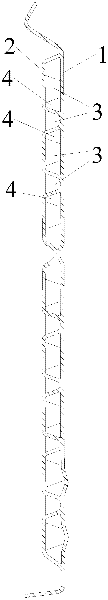

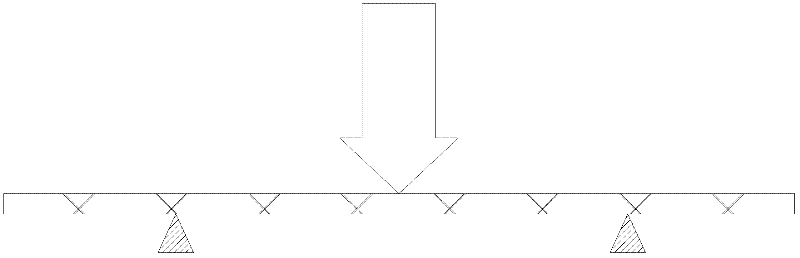

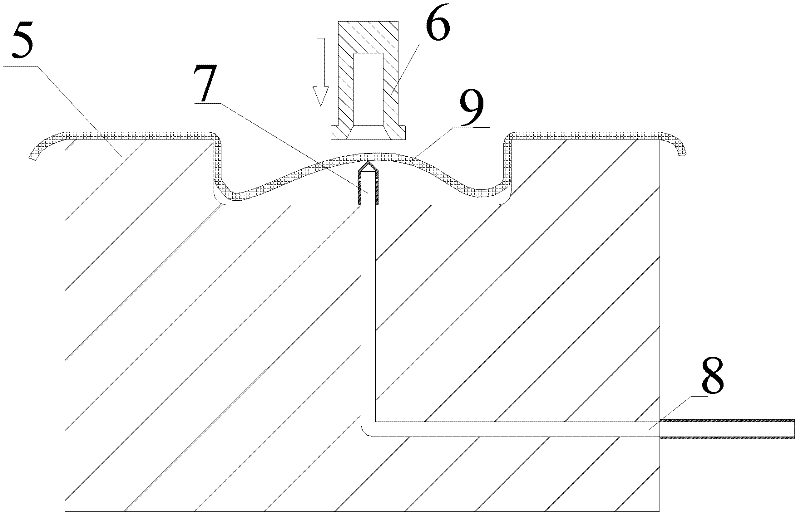

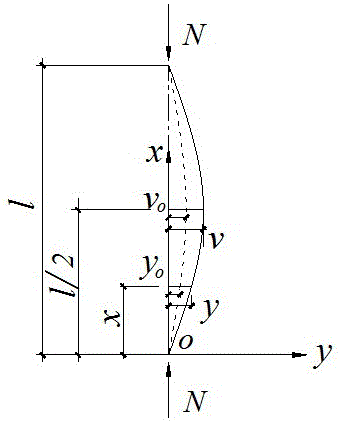

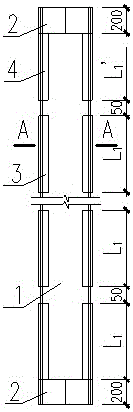

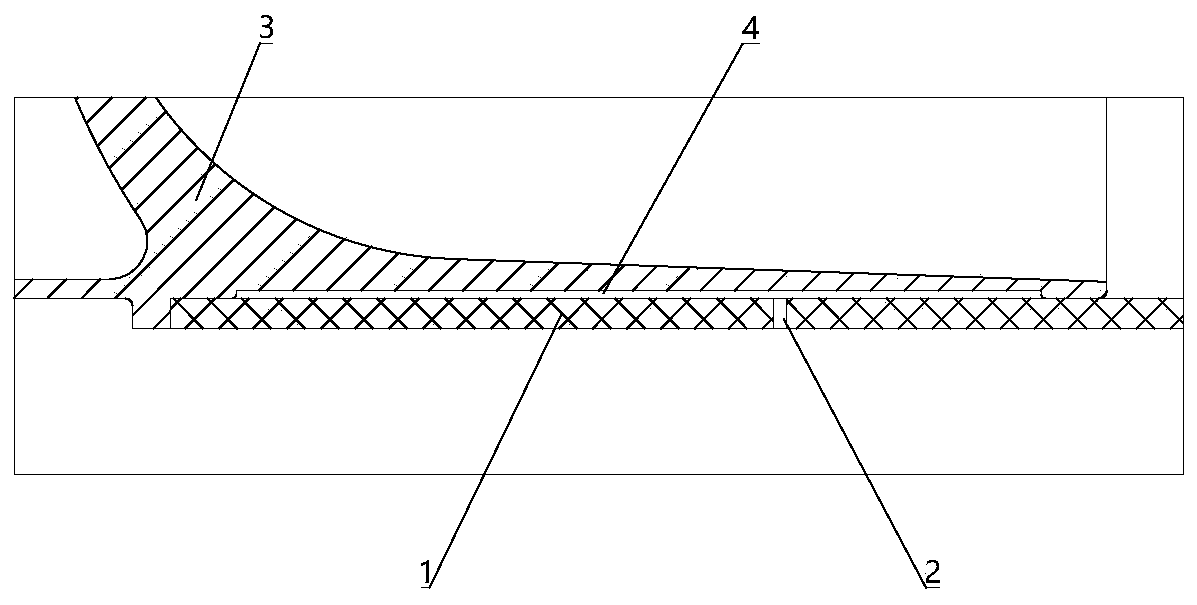

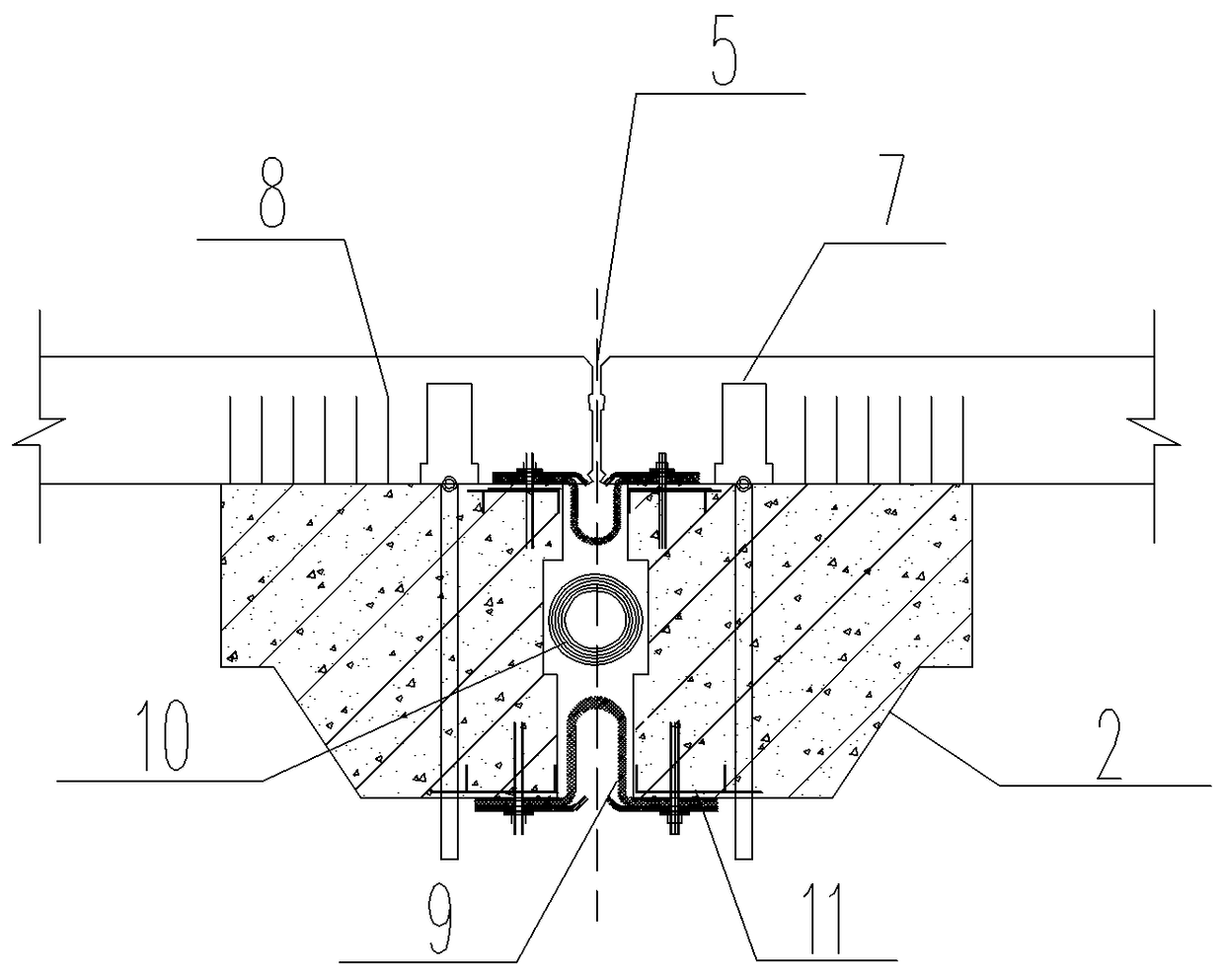

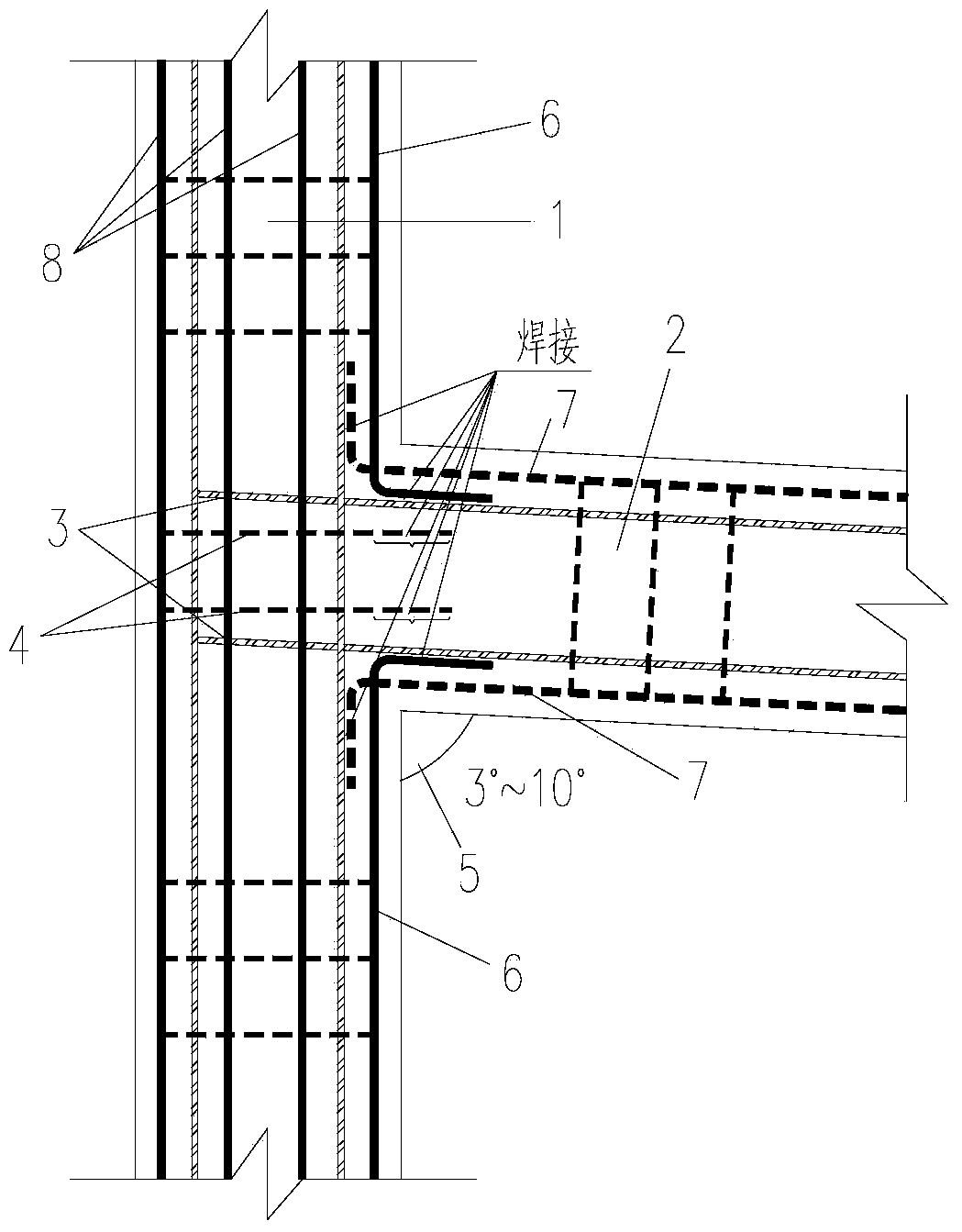

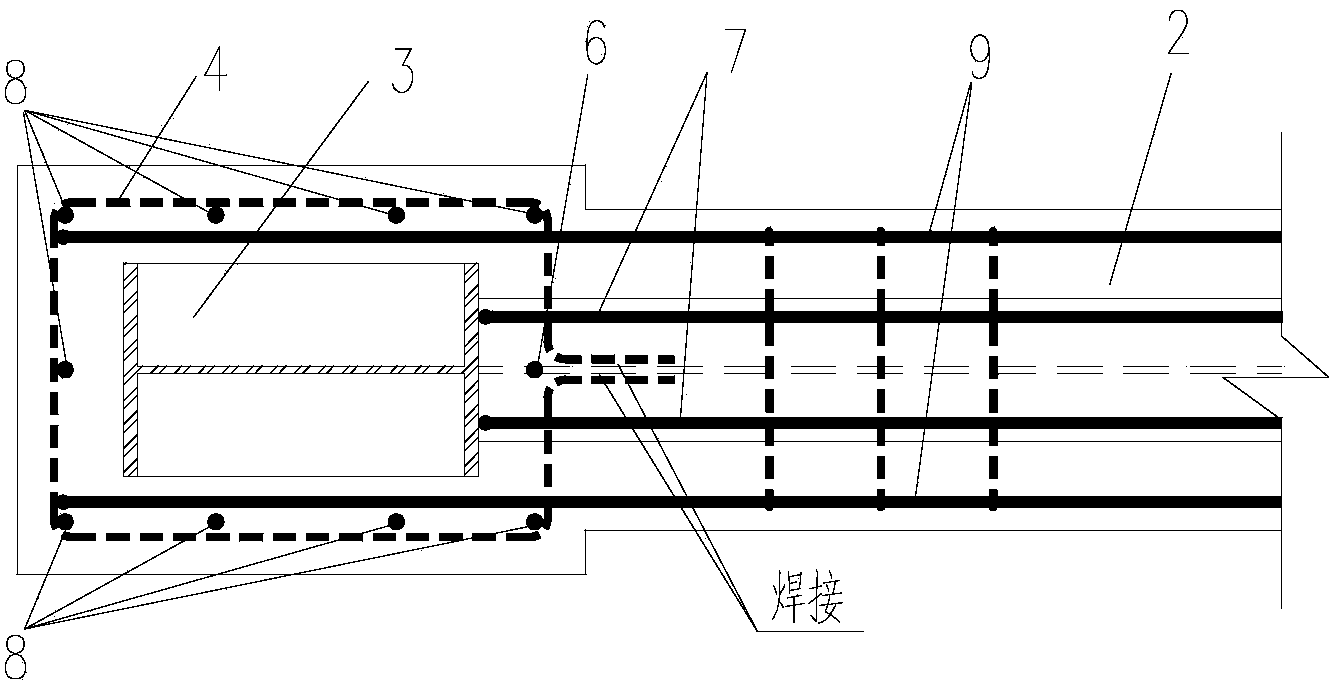

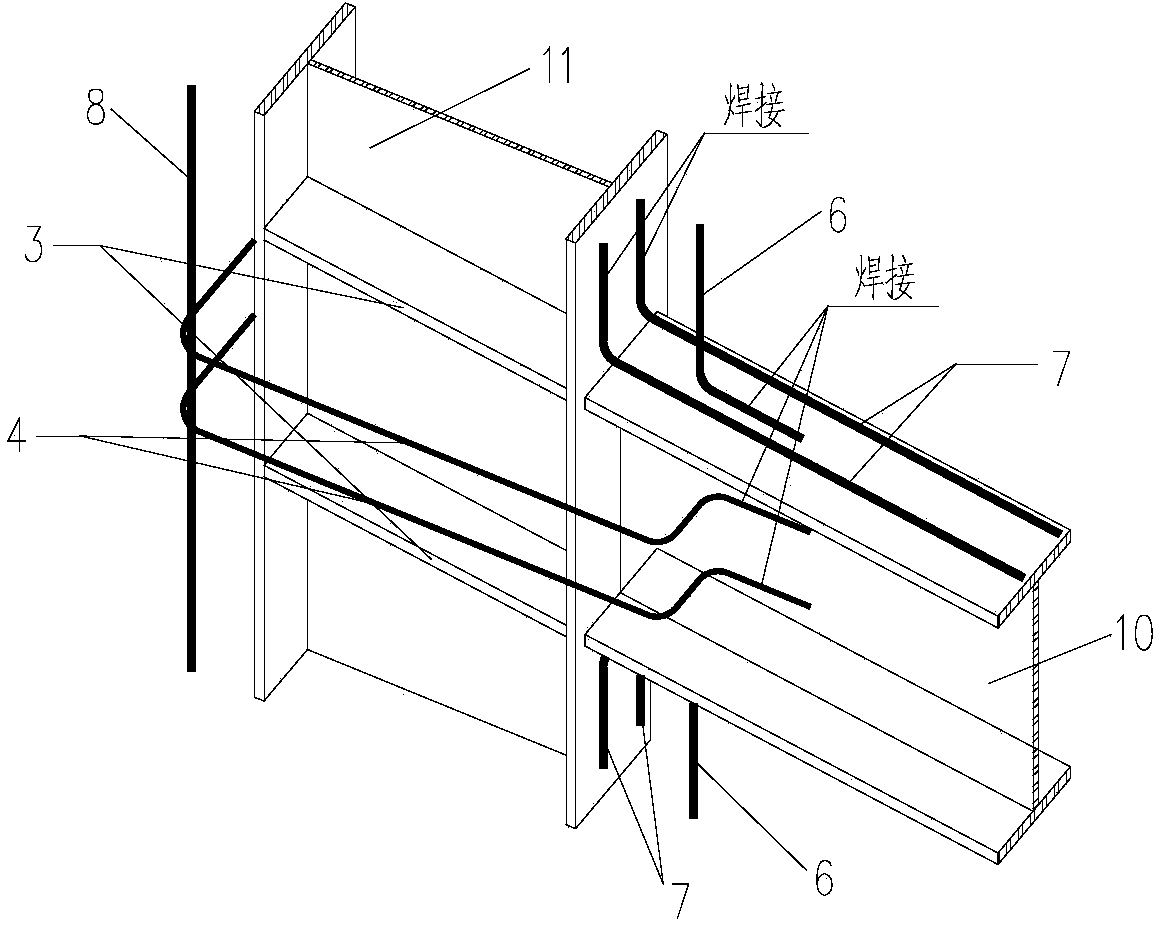

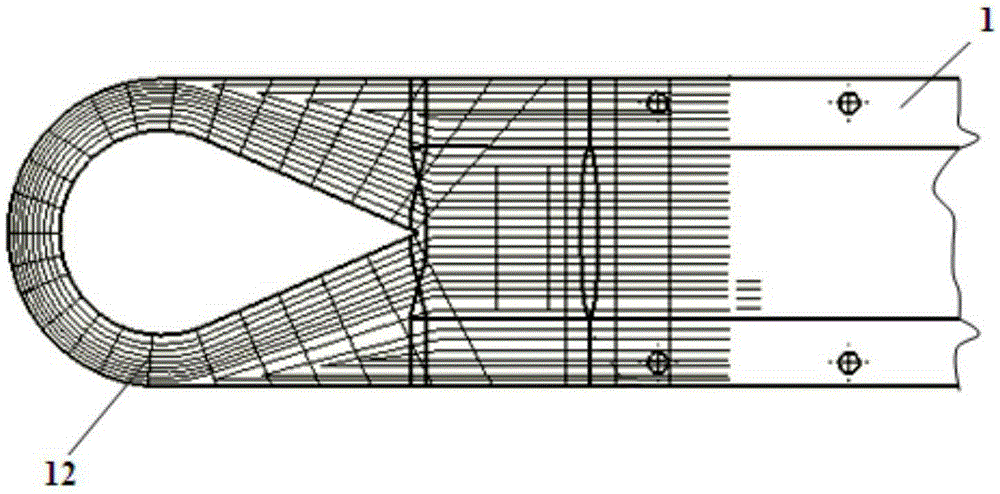

Novel prestressed steel pipe-concrete composite beam

The invention relates to a novel prestressed steel pipe-concrete composite beam, and belongs to the technical field of building structure engineering. The prestressed composite beam mainly comprises a steel beam (1) and a concrete floor slab (2) poured on the steel beam, and is characterized in that: a bottom flange of the steel beam is a steel pipe (3); a plurality of linear steel ropes (4) are arranged in the steel pipe; after the prestressed steel ropes are strained, two ends of the steel pipe (3) are sealed; and the concrete floor slab (2) is poured. Compared with a steel beam and a common composite beam, the novel composite beam has the advantages of great reduction of midspan deflection and steel beam section stress, easy strain of the steel ropes, effective anticorrosion and fire prevention, simple and convenient construction and remarkable economic benefits.

Owner:北京京诚华宇建筑设计研究院有限公司

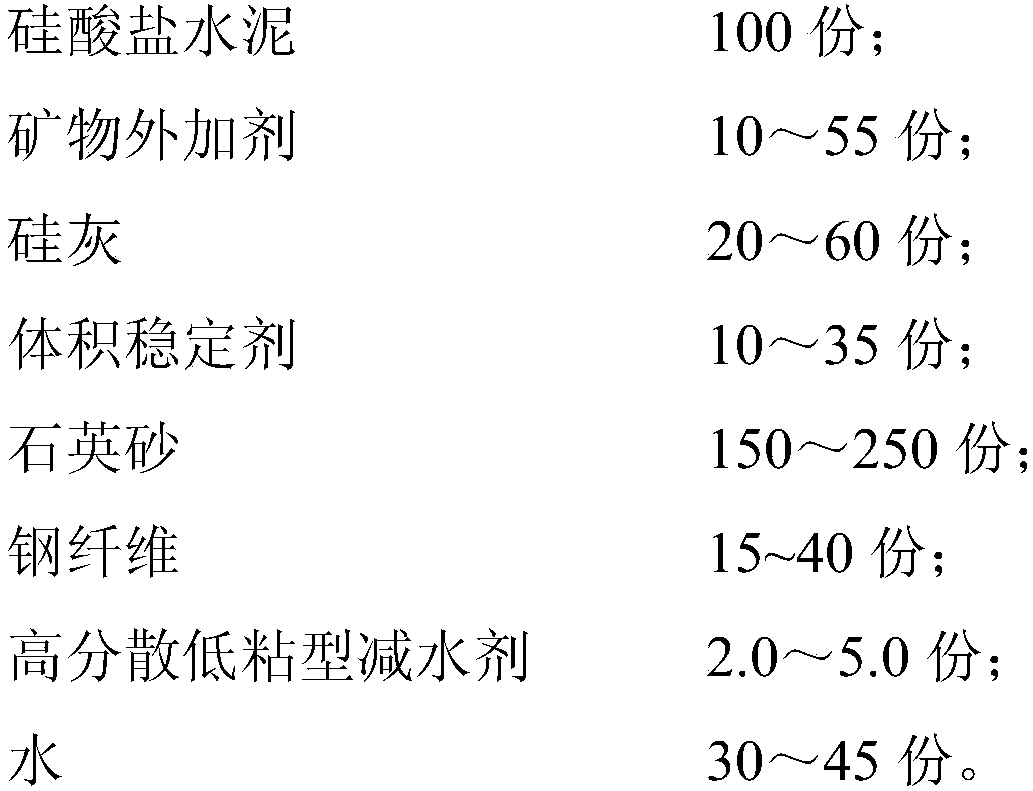

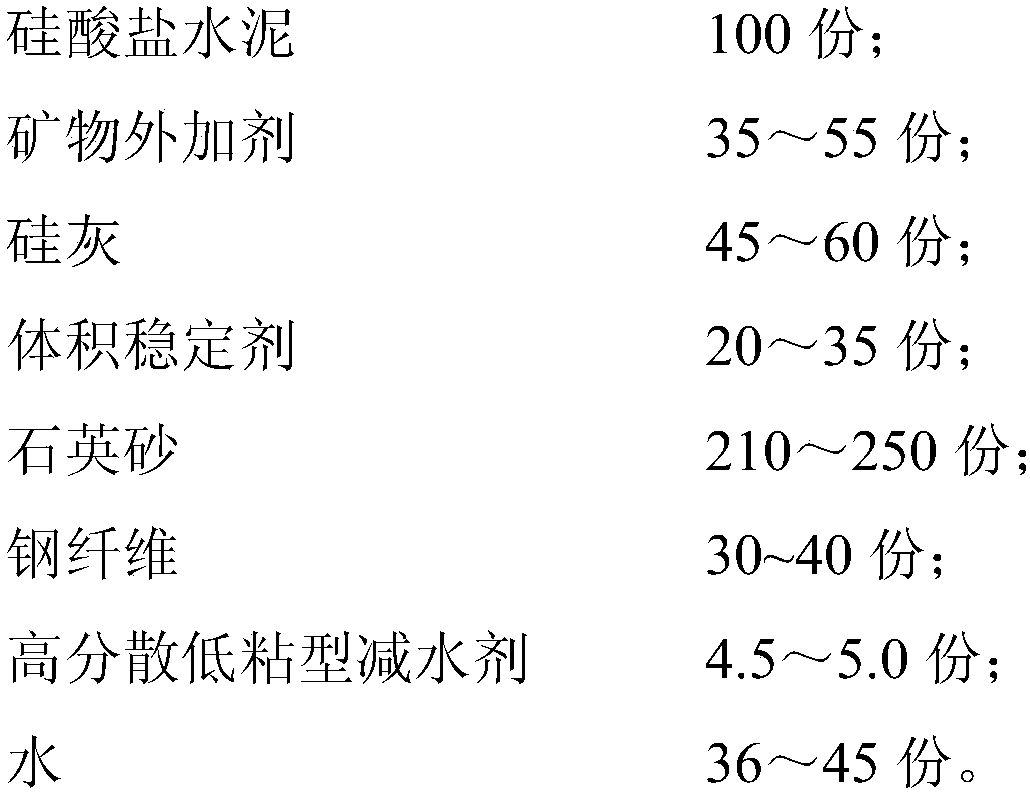

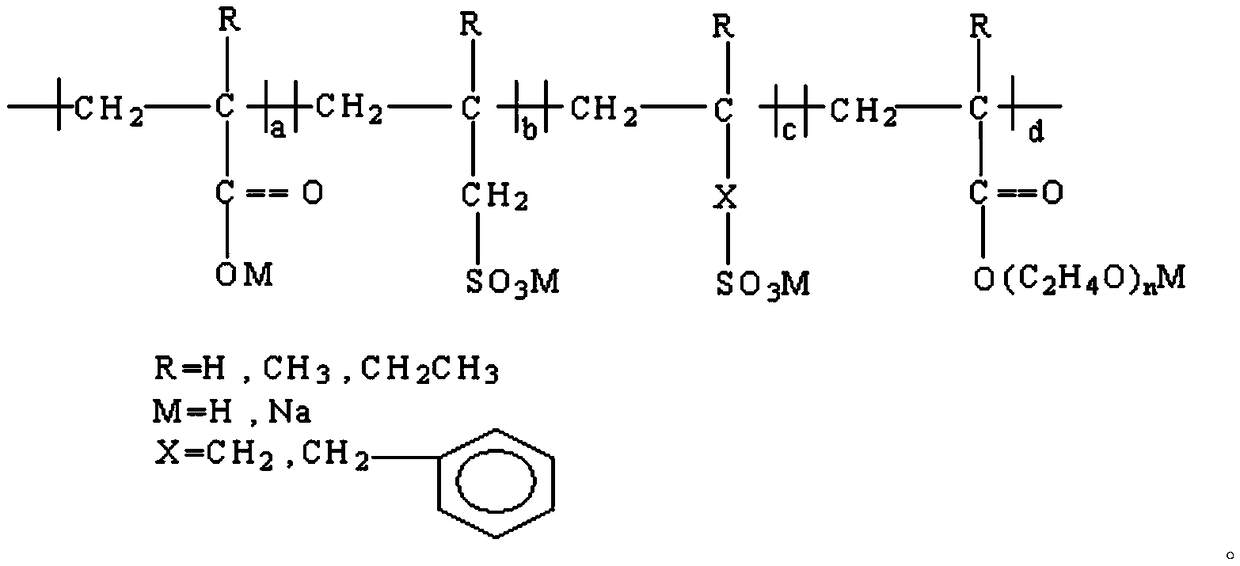

Microexpanded ultrahigh-performance concrete and preparation method

The invention discloses micro-expanded ultrahigh-performance concrete and a preparation method. The concrete is prepared from the following ingredients in parts by weight: 100 parts of Portland cement, 10 to 55 parts of mineral additives, 20 to 60 parts of silicon ash, 10 to 35 parts of volume stabilizers, 150 to 250 parts of quartz sand, 15 to 40 parts of steel fiber, 2.0 to 5.0 parts of high dispersion and low viscosity type water reducers and 30 to 45 parts of water. The micro-expanded ultrahigh-performance concrete replaces a negative bending moment region conventional mechanical tensioning prestress structure to form a non-prestress simple support rotation continuous system; the self-bearing force, interface bonding, micro-expanded expansion performance and durability requirements canbe met; the construction efficiency of the non-prestress simple support rotation continuous system bridge is effectively improved. The concrete has the ultrahigh pressure-resistant and tension-resistant intensity, ultrahigh durability, micro expansion performance, steam curing avoidance, bonding performance and reasonable economic performance; meanwhile, good construction performance is realized.

Owner:宁波市高等级公路建设指挥部 +1

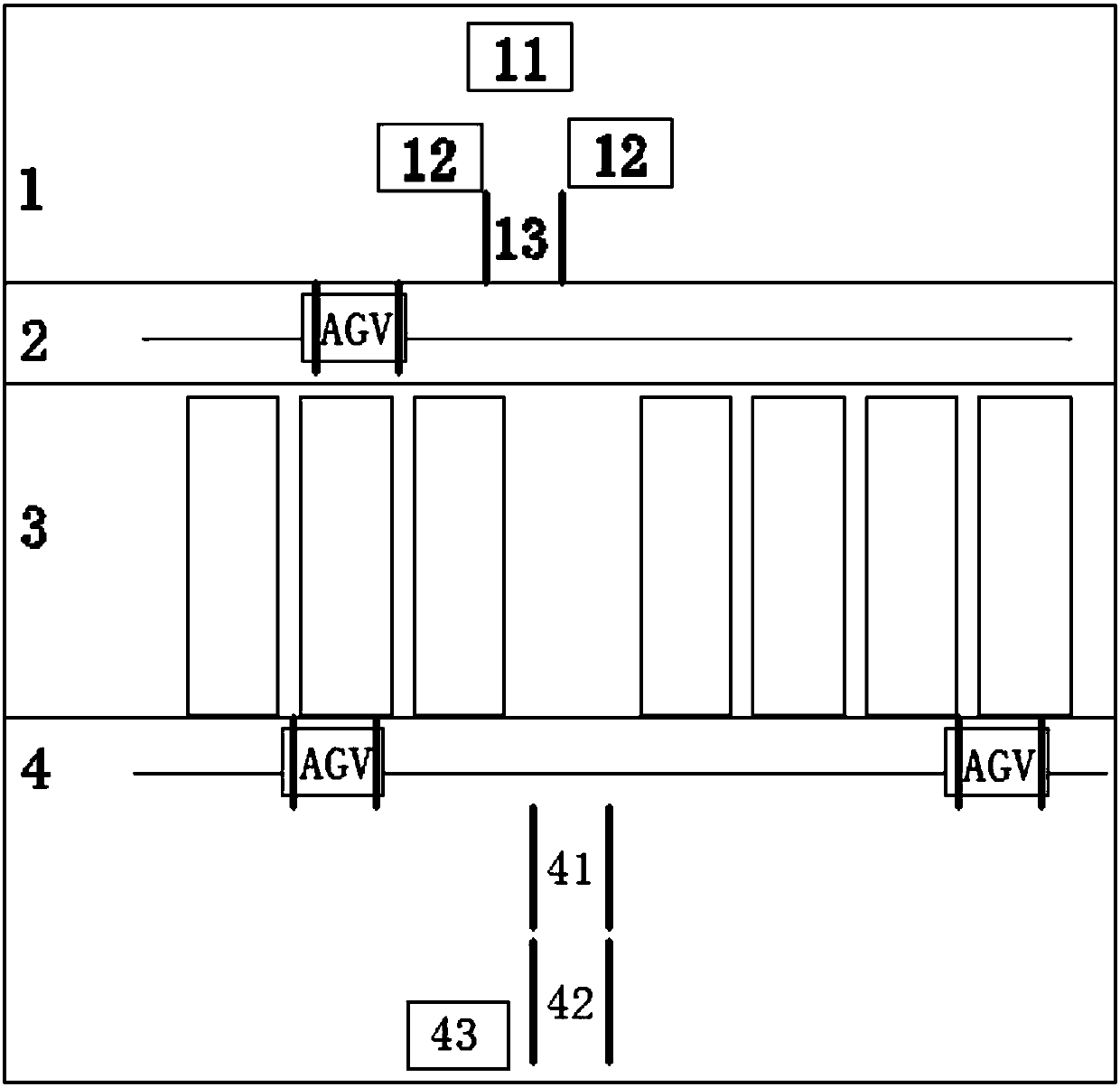

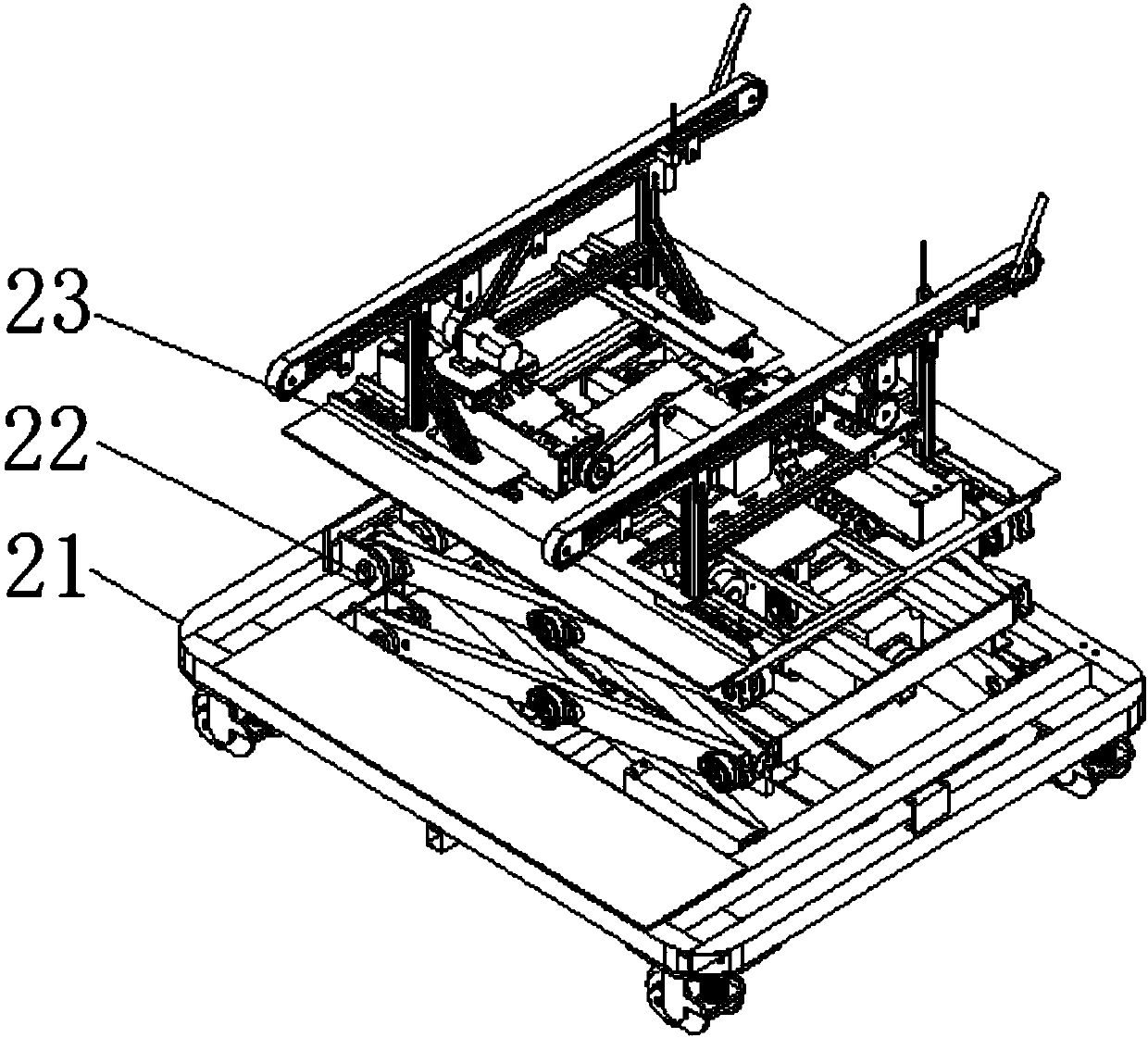

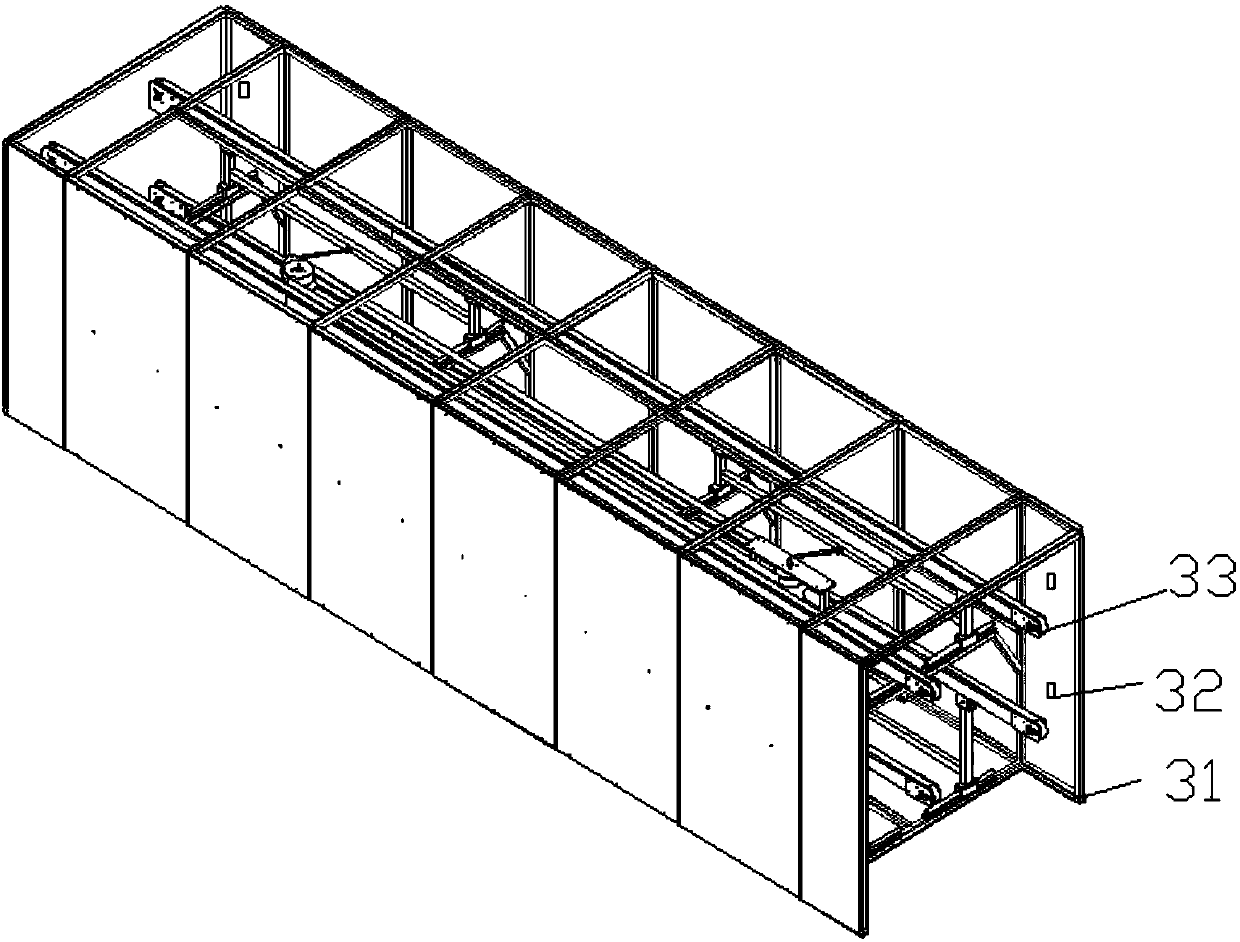

Vehicle bumper repairing, maintaining, carrying and storing system

ActiveCN107685792AIncrease the switching frequencyReduce labor intensityVehiclesProduction lineControl system

The invention discloses a vehicle bumper repairing, maintaining, carrying and storing system which is characterized by comprising a repairing and maintaining region, a conveying region, a storage location region, a guiding and fetching region and a control system. An inlet side of the repairing and maintaining region is connected with an injection molding machine at a previous station, and an outlet side of the repairing and maintaining region is connected with an inlet side of the conveying region; an inlet side of the storage location region is connected with an outlet side of the conveyingregion, and an outlet side of the storage location region is connected with an inlet side of the guiding and fetching region; an outlet side of the guiding and fetching region is connected with an inlet side of a coating production line at a next station. Each of the conveying region and the guiding and fetching region comprises at least one lift type AGV (automatic guide vehicle). The storage location region comprises a plurality of storage locations, and the storage locations are parallelly arrayed. The vehicle bumper repairing, maintaining, carrying and storing system has the advantages that flexible manufacturing production takt and requirements can be met by the multiple lift type AGV and the storage locations, the bumper type switching frequencies can be increased, labor environmentscan be improved, the labor intensity of workers can be relieved, the error rates of the workers can be lowered, labor loss in carrying procedures can be prevented, and bumpers can be efficiently intelligently managed.

Owner:HEBEI UNIV OF TECH

Automobile coat and hat rack and manufacturing method thereof

InactiveCN102642503AIncrease stiffnessSmall amount of deformationLaminationLamination apparatusConvex structureBearing capacity

The invention discloses an automobile coat and hat rack, which comprises a coat and hat rack plate, wherein the coat and hat rack plate is in a double-layer structure; a plurality of hollow cavities which are arranged at intervals are formed between the upper surface and the lower surface of the coat and hat rack plate; a plurality of bumps which are formed bulging from the lower surface of the coat and hat rack plate to the upper surface are arranged in the coat and hat rack plate; the tops of the bumps are connected with the upper surface into a whole; and the hollow cavities are spaced by the bumps. The coat and hat rack formed by using the technical scheme is in a double-layer hollow concave convex structure, so that the rigidity of the coat and hat rack is improved, and the load stressed by the coat and hat rack is dispersed to each concave convex structure; and thus, the deformation produced during bearing of the entire coat and hat rack is greatly improved, the degree of damage of the material body caused by fatigue is reduced, the bearing capacity of the coat and hat rack is greatly improved, a bracket is not required to be arranged below the coat and hat rack for supporting, and the requirements of large-bearing-capacity and long-span (large-space) decoration in a high-end vehicle can also be met.

Owner:芜湖尚唯汽车饰件有限公司

Light foamed soil applied to backfill of tunnel entrance and exit and production method thereof

InactiveCN105036635AHigh strengthImprove solubilitySolid waste managementCeramicwareFiberFoaming agent

The invention provides light foamed soil applied to backfill of a tunnel entrance and exit and a production method of the light foamed soil, and relates to a building material and a production method of the building material. The light foamed soil applied to the backfill of the tunnel entrance and exit is prepared from the following raw materials of cement, silica fume, kieselguhr, coal ash, water, a water reducing agent, an early strength agent, an accelerating agent, aluminite powder, sodium gluconate, plant fiber, a foaming agent and a micro foaming agent. The light foamed soil provided by the invention is light in weight and high in strength, the whole performance is good, not only can the bearing capacity of a soil body in a soft soil area be met, but also the bearing capacity of an exchange filling foundation on upper load can be met, the load of a special subgrade is reduced, and the subgrade settlement is reduced.

Owner:河南华泰新材科技股份有限公司

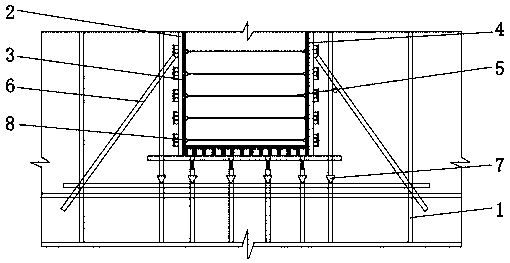

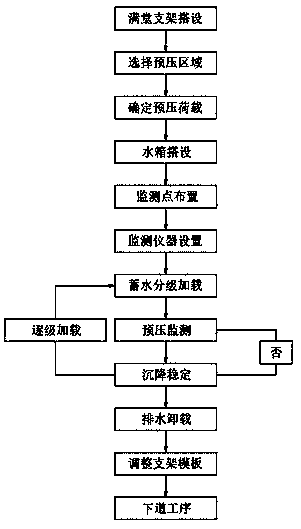

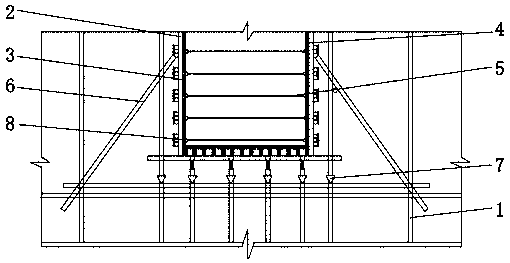

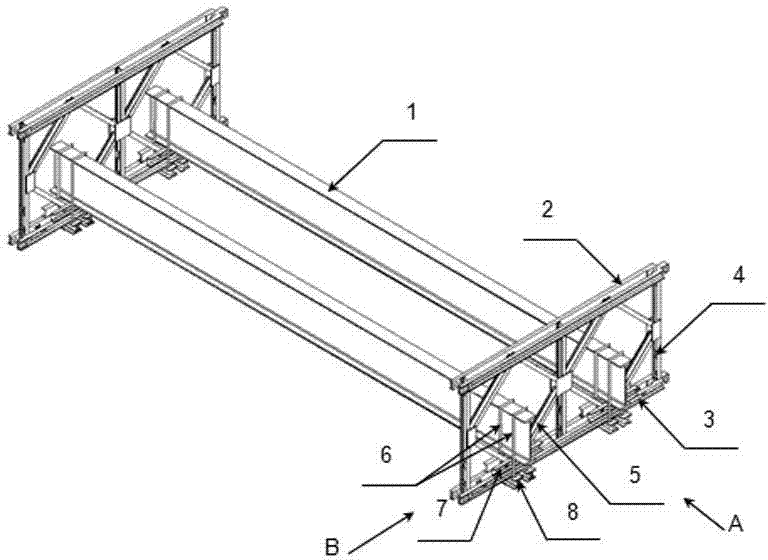

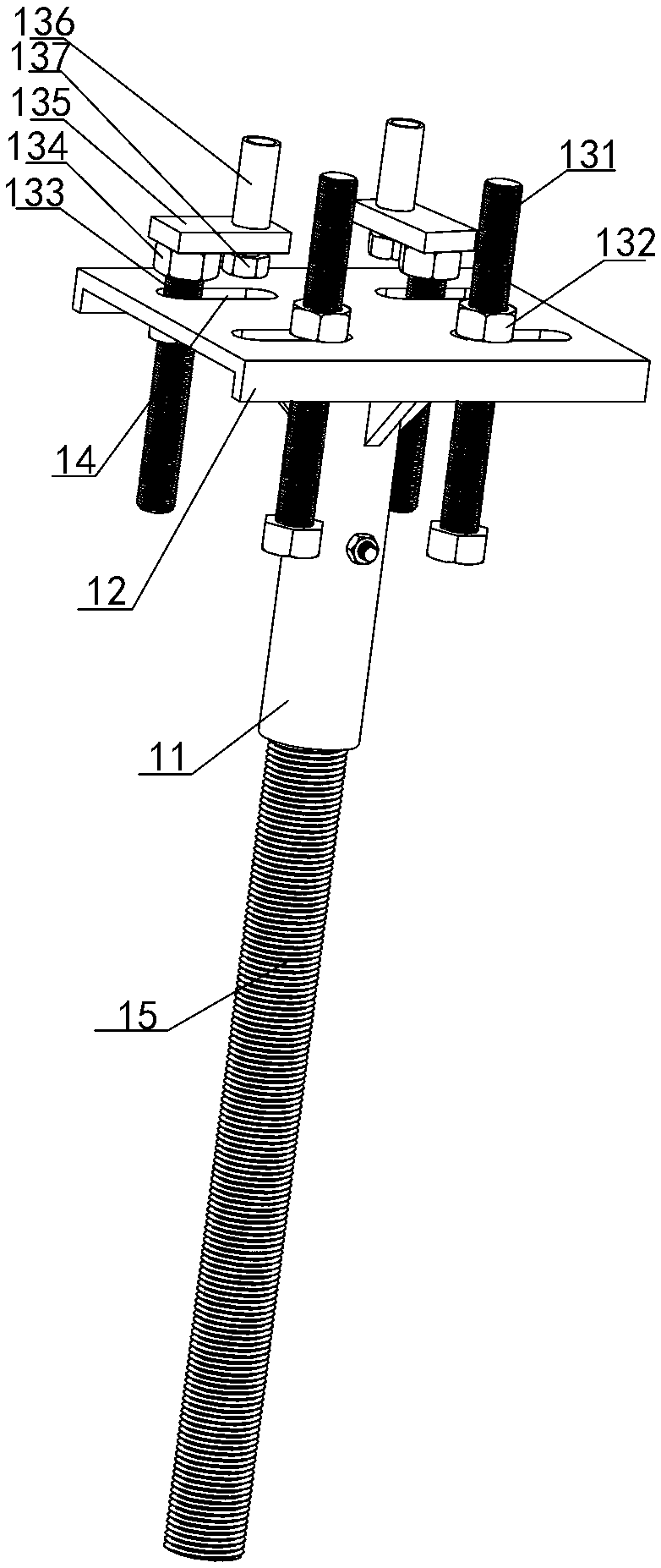

Preloading water tank and technology of huge open-frame girder steel tube full support

PendingCN110043029ASolve highSolve the problem of long and narrow pre-pressing surfaceMaterial strength using tensile/compressive forcesForms/shuttering/falseworksWater storageReinforced concrete

The invention relates to the technical field of building construction, and discloses a water tank preloading technology of a huge open-frame girder steel tube full support. The water tank preloading technology includes the following operation processes of full support erection, preloading area selection, preloading load determination, water tank erection, monitoring point arrangement, monitoring instrument setting, water storage gradation loading, preloading monitoring, settlement stabilization, drainage and unloading, support template adjustment and next procedure executing. By using simple equipment which is always available at the site and self-configuring a water tank, the flexibility, simpleness and convenience are achieved, the working efficiency is high, and compared with a traditional preloading method, the construction period can be shortened by 1 / 3 or above; and the processing cost is low, operation is easy and convenient, the cost is saved, compared with adopting a precast reinforced concrete block preloading method, the investment can be saved by 70-80%, compared with sandbag stacking preloading, the investment is saved by 30-40%, and compared with site reinforced material preloading, the investment can be saved by 20-30%, and the preloading method has the advantages of less construction equipment, high construction efficiency, local material using, easy manufacturing, environment-friendly construction, reasonable actual stress state in the simulated pouring process, and the like.

Owner:贵州建工集团第二建筑工程有限责任公司

Prefabricated steel highway bridge

InactiveCN102518035ASatisfy the carrying capacityImprove bearing capacityTruss-type bridgeBridge structural detailsSupport planeEngineering

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

A method of adopting greening structured soil as a rainwater accumulator

ActiveCN104120642AInhibit sheddingImprove permeabilityGeneral water supply conservationPaving gutters/kerbsPorosityDry weight

The invention relates to a method of adopting greening structured soil as a rainwater accumulator. The method includes steps of: weighing stone and soil according to a dry weight ratio of 4-5:1, uniformly mixing four raw materials comprising the stone, the soil, polyacrylamide (PAM) and gypsum, and adopting the obtained greening structured soil for a greening site of a hard road surface. By the method, the porosity under a maximum 100% compaction condition can be higher than 20%, the permeability is larger than 360 mm / h, and other physicochemical properties can meet the Greening Planting Soil CJ / T340-2011 standard in the national town construction industry. The greening structured soil has high rainwater penetration capability, and can be widely used for side pavements, business streets, public plazas, open-parking grounds, and other urban greening sites. The greening structured soil enhances the rainwater in-situ penetration property of hard greening road surfaces, relieves urban inland inundation and soil erosion, and plays a role of the rainwater accumulator. The greening structured soil provides good growing space, water and nutrients for root growth of plants and improves the greening quality of urban hard road surfaces.

Owner:SHANGHAI ACADEMY OF LANDSCAPE ARCHITECTURE SCI & PLANNING

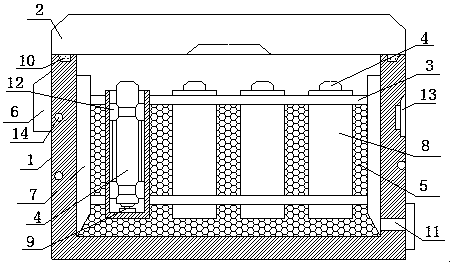

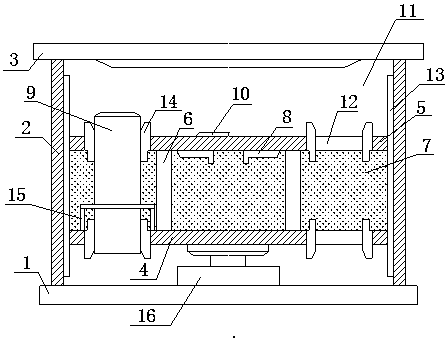

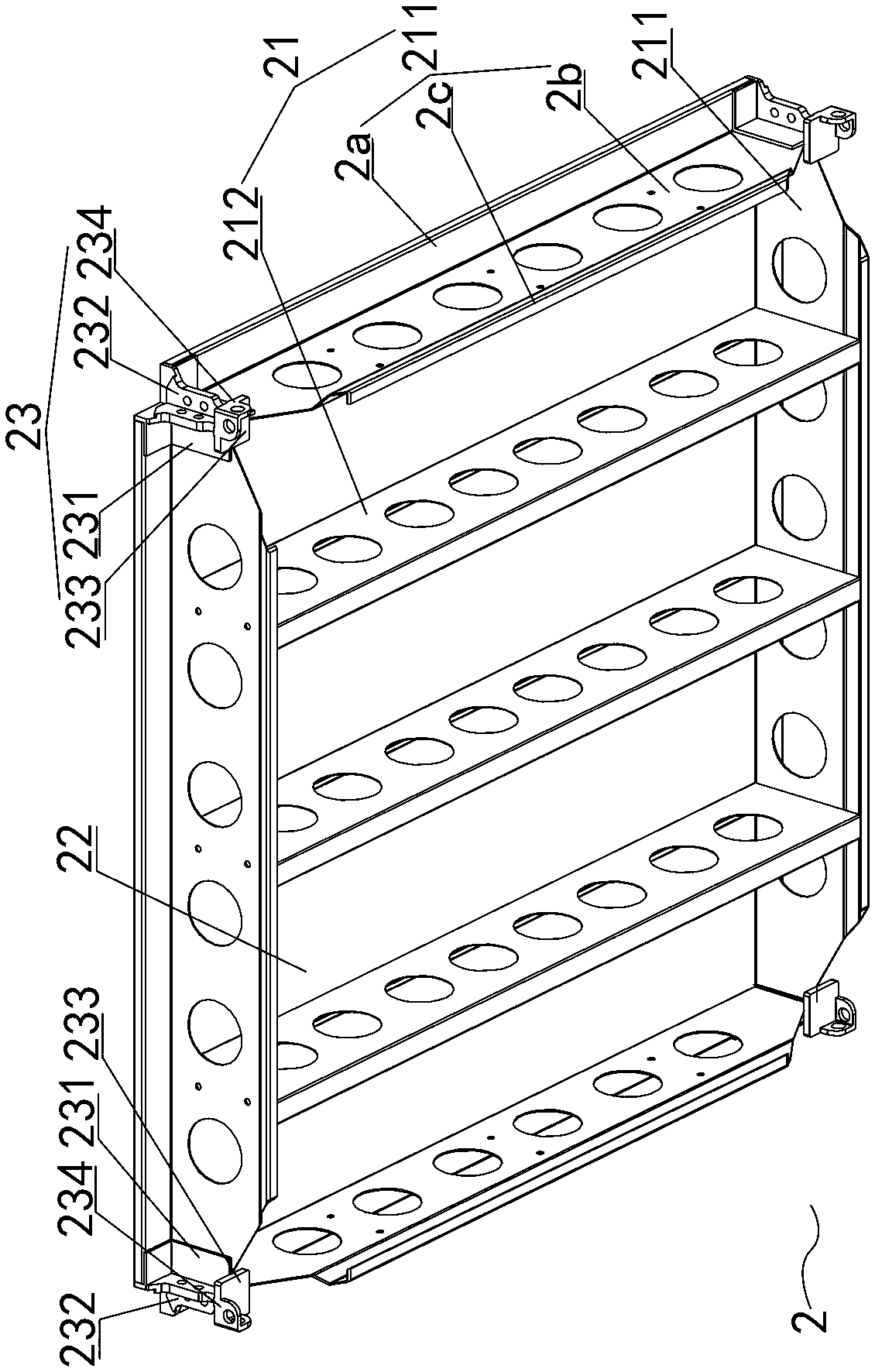

Tumor gene detection reagent storage box

InactiveCN108438446ASatisfy the carrying capacitySatisfy the protectionShock-sensitive articlesInternal fittingsAbnormal tissue growthEngineering

The invention relates to a tumor gene detection reagent storage box. The tumor gene detection reagent storage box comprises a bearing box body, a box cover, a positioning frame, reagent bottles, an elastic lining layer and a control circuit, wherein the bearing box body and the box cover are connected with each other and form a closed cavity structure, and the positioning frame is connected with the side wall of the bearing box body in a sliding mode through a sliding rail; a plurality of bearing cavities are uniformly distributed in the positioning frame, a lifting driving mechanism is arranged in each bearing cavity, and the bearing cavities are connected with the reagent bottles through the lifting driving mechanisms; and the elastic lining layer is embedded in the positioning frame andcorrespondingly abuts against the outer surface of each bearing cavity and the inner side surface of the bearing box body, and the control circuit is embedded in the outer surface of the bearing boxbody and is electrically connected with the lifting driving mechanisms in the bearing cavities correspondingly. According to the tumor gene detection reagent storage box, on one hand, good bearing capability and good safety protection capability are achieved, and the requirements for bearing, protection and transferring operation of tumor gene samples and reagents can be effectively met; and on the other hand, the reliability and convenience of storing and taking operation of the tumor gene samples and the reagents can be effectively improved.

Owner:CHENGDU ZHIA TECH CO LTD

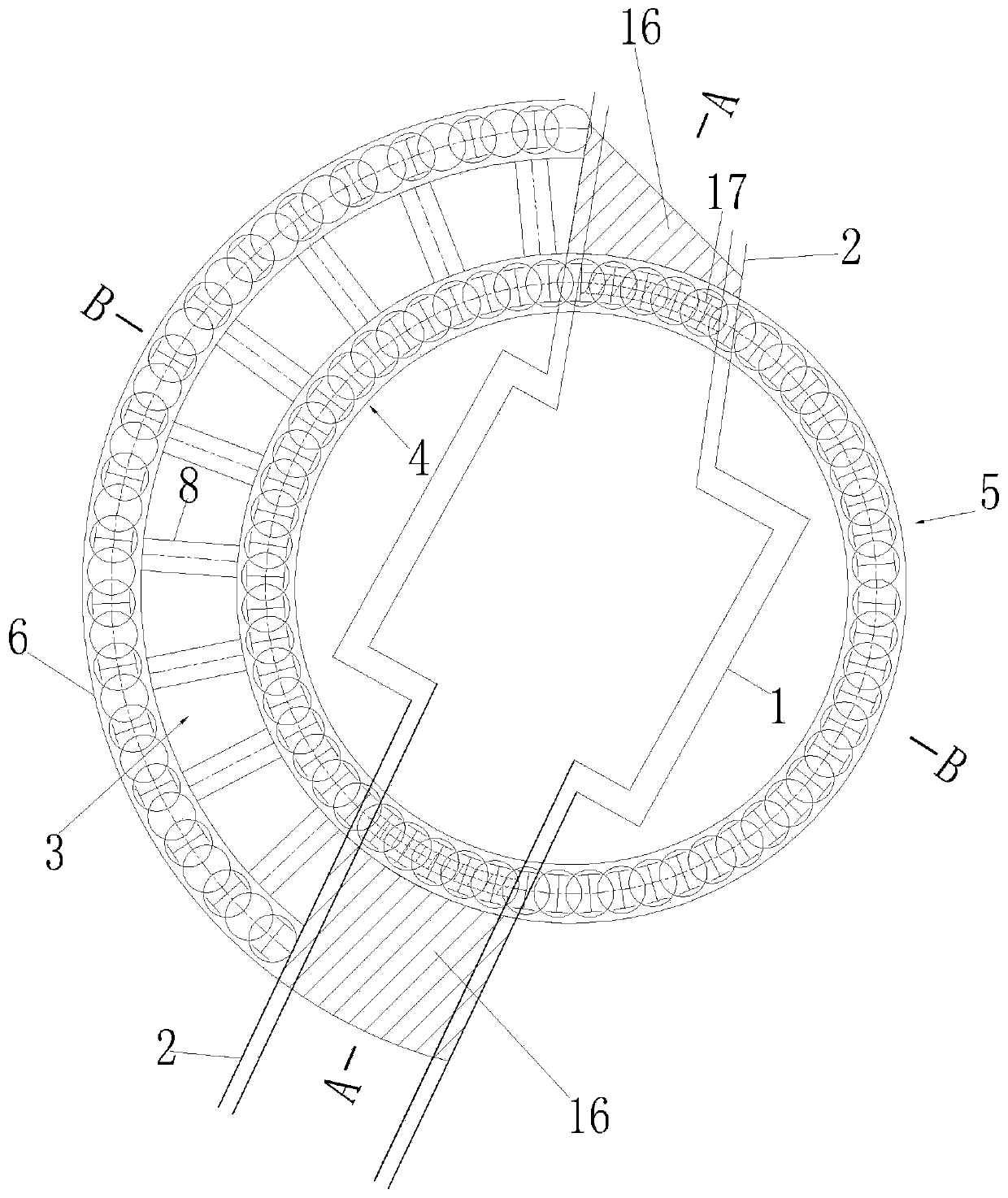

Guiding device for supporting construction of foundation pit in narrow zone and construction method

PendingCN110700280APlay the role of water stopResistance to deformationExcavationsBulkheads/pilesReinforced concreteArchitectural engineering

The invention provides a guiding device for supporting construction of a foundation pit in a narrow zone and a construction method. The structure is as the follows that an original box culvert is cutinto two sections of a front section and a rear section by an intercepting well; an inner circle and an outer circle of high-pressure jet grouting piles are constructed at the periphery of an intercepting well foundation pit; H-shaped steels are interpolated in modes of closely inserting and inserting one by one with one interval; the outer circle of high-pressure jet grouting pile is arc-shaped,and the positions, the right above the front section and the rear section of the original box culvert, of two ends of the outer circle of high-pressure jet grouting pile are connected with the inner circle of high-pressure jet grouting pile through full reinforcement of the high-pressure jet grouting pile; a reinforced concrete inner support is arranged between the inner circle and the outer circle of high-pressure jet grouting piles, and a guide groove foundation pit is excavated between piles; and the front and rear sections of the original box culvert are respectively provided with holes inthe side wall and the holes communicate with the guide grooves; and the front section and the rear section of the original box culvert respectively use the positions corresponding to the right lowerparts of the H-shaped steels inserted into the inner circle of high-pressure jet grouting pile as a plugging part, a temporary plugging wall is formed between the underwater concrete and the intercepting well, and bidirectional steel bars are configured in the wall. The device meets the requirement of foundation pit supporting and simultaneously has construction diversion capability.

Owner:ANHUI SHUIAN CONSTR GRP CO LTD

Determination method of angle steel length of angle steel reinforced cracking box type steel column

ActiveCN106250627ASatisfy the carrying capacityReduce welding residual stressGeometric CADBuilding repairsResidual deformationWelding residual stress

The invention relates to a determination method of angle steel length of an angle steel reinforced cracking box type steel column. The determination method comprises the following steps: taking the angle steel length as a parameter and setting one group of test pieces; carrying out non-linear buckling analysis on a component by utilizing finite element software ABAQUS; drawing a changing curve of a buckling ultimate load of a reinforced steel column along with the angle steel length; determining the angle steel length through a critical point of the curve; annularly buckling a cracking box type steel column on a column foot and a column top through groove type pieces, and reinforcing a middle part of the cracking box type steel column by adopting a manner of welding equal angle steel along four corners of the steel column. In a box type steel column reinforcing process, the bearing capacity of the box type steel column is easily insufficient when the angle steel is too short, concentration of welding stress is easy to cause when the angle steel is too long, and welding residual deformation becomes large; aiming at overcoming the disadvantages, the invention provides the determination method of the angle steel length, so that welding residual stress and residual deformation can be reduced and the bearing capacity of the reinforced box type steel column is satisfied; furthermore, the construction is convenient and the economical efficiency is relatively good.

Owner:青岛青建理工建筑工业化研究院有限公司

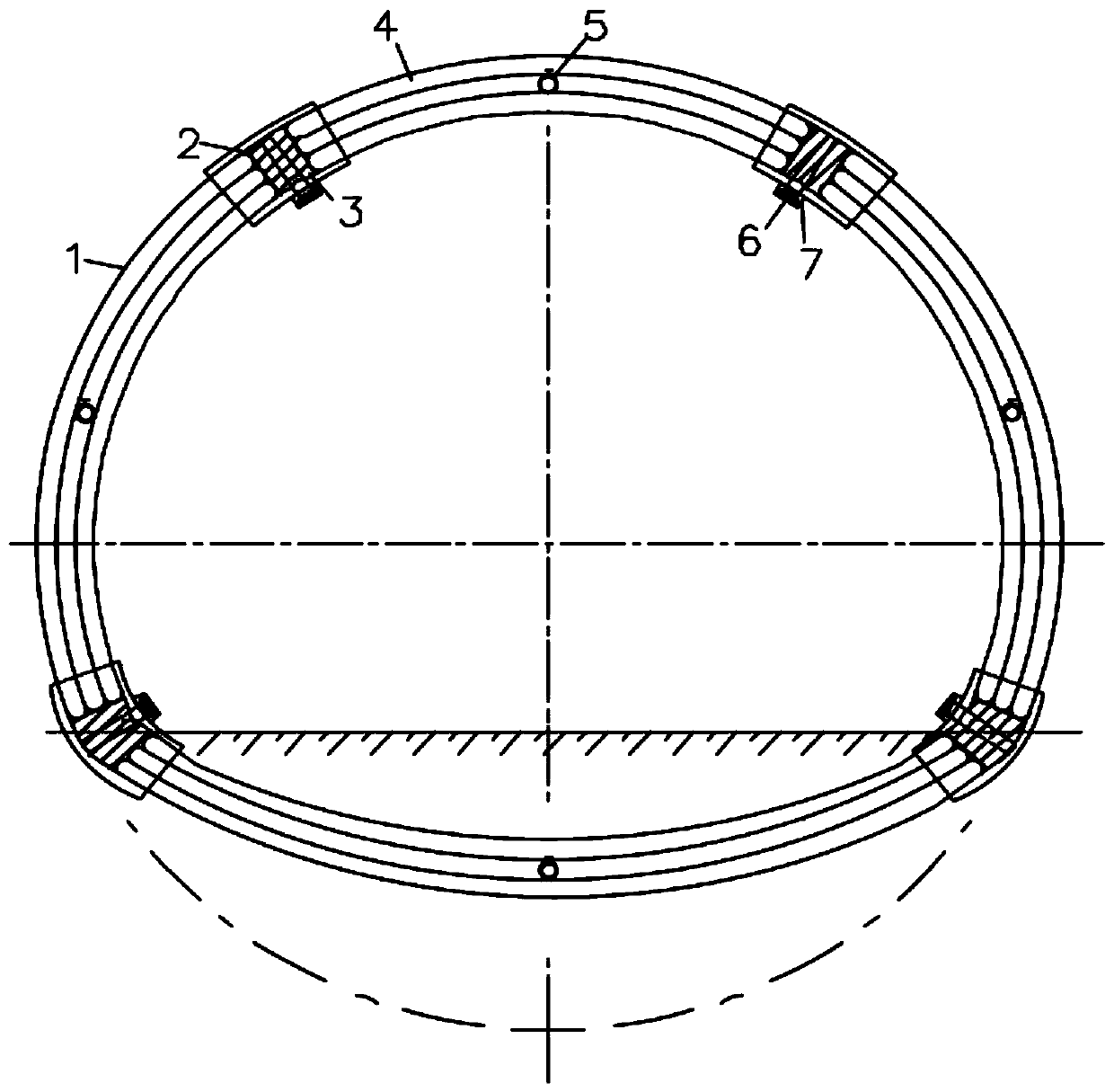

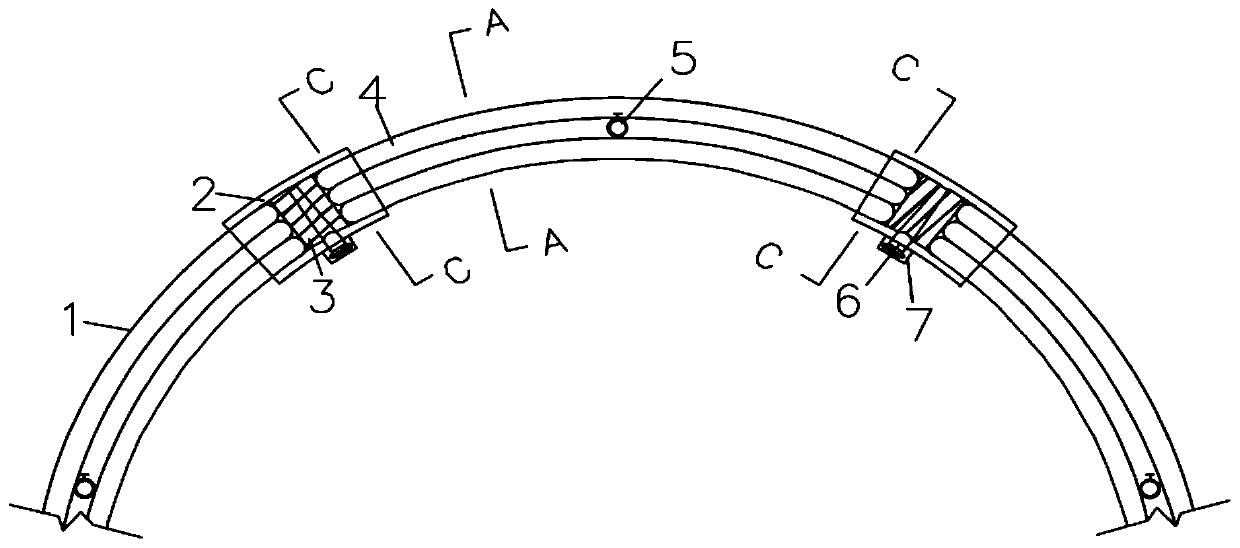

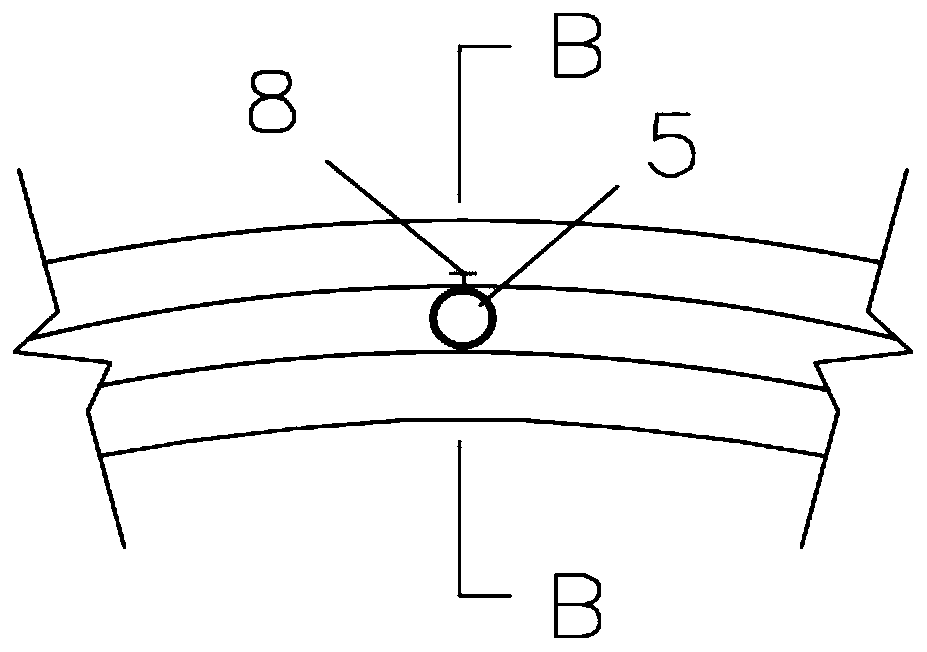

Water bag filling pipe type combined arch frame and construction process thereof

ActiveCN110700863AWith micro-expansionImprove tensile toughnessUnderground chambersTunnel liningFiberWhole body

The invention discloses a water bag filling pipe type combined arch frame and a construction process thereof. The water bag filling pipe type combined arch frame comprises multiple sections of steel pipes; the multiple sections of steel pipes are connected through connecting sleeves to form an arched-shaped cross section; multiple high-performance fiber bag bodies are pasted in each section of steel pipe and are opened in advance at the position of a water injection hole and the two ends of each section of steel pipe to play a role of fixing the bag bodies; liquid is injected into the high-performance fiber bag bodies; and meanwhile, an anti-bending reinforcing steel bar is arranged on the inner arc side of the steel pipe arch frame so as to improve the bending bearing capacity of the archframe. By adopting the water bag filling pipe type combined arch frame, high-concentration fiber cement slurry is injected into gaps of the connecting sleeves, so that the whole device forms the combined arch frame; and the inner bag bodies of the water bag filling pipe type combined arch frame have the micro-expansion property, and the multiple bag bodies are mutually extruded, fill an inner cavity of each section of steel pipe and are in wet connection with the cement at a connector to form a whole body so as to fully fill the whole arch frame.

Owner:SHANDONG JIANZHU UNIV

Reagent bottle positioning inner container applied to novel gene sample bearing boxes

InactiveCN108382699ASimple structureEasy to use and flexibleDomestic cooling apparatusLighting and heating apparatusEngineeringNovel gene

The invention relates to a reagent bottle positioning inner container applied to novel gene sample bearing boxes. The reagent bottle positioning inner container comprises a bearing base, a protectionhood, an end cover, a bottom plate, an upper pressing plate, elastic telescopic rods, an elastic heat insulation cushion layer, a temperature adjusting mechanism, reagent bottles and a control circuit, wherein the bearing base, the protection hood and the end cover form a bearing cavity of a closed structure; the bottom plate, the upper pressing plate, the elastic telescopic rods, the elastic heatinsulation cushion layer, the temperature adjusting mechanism, the reagent bottles and the control circuit are embedded in the bearing cavity; the bottom plate is mounted on the bearing base; the upper pressing plate is located right above the bottom plate; the elastic telescopic rods are in mutually perpendicular connection with the bottom plate and the upper pressing plate; the control circuitis embedded in the upper surface of the upper pressing plate and is electrically connected with the temperature adjusting mechanism. On the one hand, the reagent bottle positioning inner container hashigh bearing capability and safety protection capability and is capable of effectively meeting the requirements on operations of bearing, protecting and transferring samples and reagents applied to gene detection; on the other hand, the reagent bottle positioning inner container is capable of effectively meeting the requirements on operations of storing different reagent bottles and flexibly adjusting the temperatures of the storage environments of the reagent bottles.

Owner:CHENGDU ZHIA TECH CO LTD

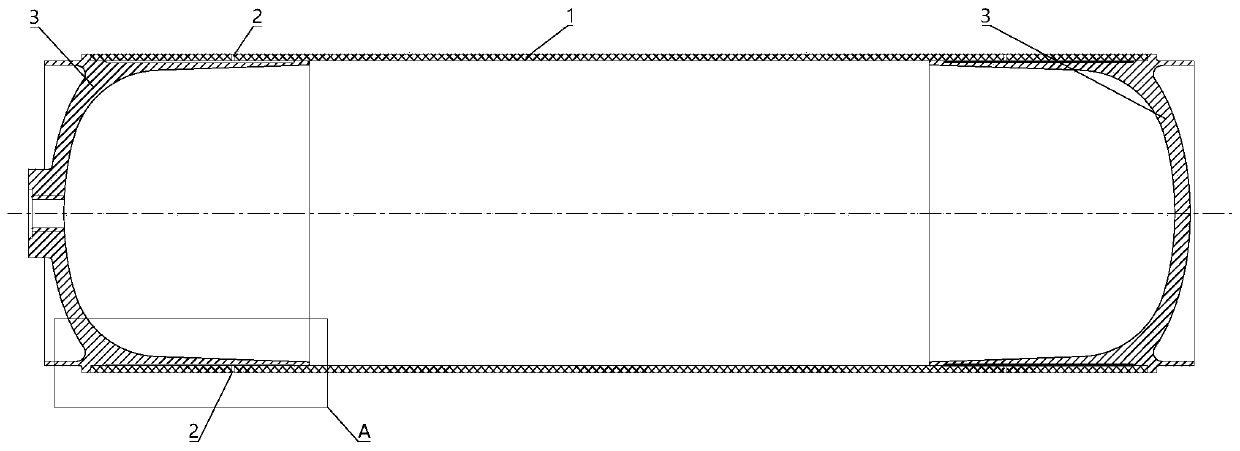

Bonding forming method for metal sealing head of large-opening composite material shell

InactiveCN110744832AMeet the intensitySatisfy the carrying capacityDomestic articlesUltimate tensile strengthMetal

The invention discloses a bonding forming method for a metal sealing head of a large-opening composite material shell. The bonding molding method effectively solves the problem of low-pressure blasting of the metal sealing head of the large-opening shell, the bonding structure is reliable, the cost is low, the metal sealing head of the large-opening composite material shell can be connected without fasteners, the redundancy mass, the production cost and the material cost of an engine is reduced, and the drug loading space and the pressure bearing capacity of the shell is increased. According to the bonding forming method, the stability of the composite shell structure under the complex working load is guaranteed, the process route is relatively simple, and the bearing requirement of the shell to strength and rigidity can be met.

Owner:湖北三江航天江北机械工程有限公司

Ground fracture region shield tunnel based on back pouring enlarged head type and construction method thereof

PendingCN109236319AEffective contactVarious processing methodsUnderground chambersTunnel liningEngineeringShield tunnelling

The invention relates to a ground fracture region shield tunnel based on a back pouring enlarged head type and a construction method thereof. The tunnel comprises a tunnel lining structure composed ofshield tunnel pipe piece linings, back pouring type inner convex enlarged heads are annularly arranged a the two sides on a shield segment circular seam, anchor holes are pre-embedded by the back pouring type inner convex enlarged heads by means of the pipe segment linings, the component overlapping mode is adopted, effective connection with the pipe segment linings is achieved, a special deformation seam is formed at the joint of the inner convex enlarged heads on the two sides of the pipe segment circular seam, the special deformation seam is strictly aligned to the pipe segment circular seam, grouting pipes are pre-embedded on an inner convex enlarged plug, the pre-embedded grouting pipes are strictly aligned to pipe segment grouting holes, a hollow type circumferential water stop is additionally arranged in the special deformation seam, and the seam waterproof capability is improved. The shield tunnel is adopted for directly penetrating through the ground crack region, the inner convex enlarged heads are poured into the shield tunnel, the requirement for stratum large deformation is met, meanwhile, the project quality and surrounding safety are improved, and tunnel construction method continuity and project risk are effectively controlled.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Steel reinforced concrete column-steel reinforced concrete inclined beam T-shaped joint

InactiveCN104294916AAvoid unfavorable mechanical performanceSatisfy the carrying capacityBuilding constructionsReinforced concrete columnStress concentration

The invention discloses a steel reinforced concrete column-steel reinforced concrete inclined beam T-shaped joint which is formed by fixedly connecting a steel reinforced concrete column with a steel reinforced concrete beam. In-beam H-shaped steel is arranged in the steel reinforced concrete beam, in-column H-shaped steel is arranged in the steel reinforced concrete column, one or more in-beam longitudinal ribs needing to penetrate flanges of the in-column steel is arranged along an upper flange and a lower flange of the in-beam H-shaped steel respectively, in-beam longitudinal ribs penetrating a joint area are arranged in the steel reinforced concrete beam, longitudinal ribs needing to penetrate the flanges of the in-beam steel and in-column longitudinal ribs penetrating a joint area are arranged in the steel reinforced concrete column, and an upper reinforcing rib and a lower reinforcing rib are arranged in the steel reinforced concrete beam at a position where the steel reinforced concrete beam is connected with the steel reinforced concrete column. The steel reinforced concrete column-steel reinforced concrete inclined beam T-shaped joint is high in rigidity, high in strength and high in ductility, and stress concentration caused by the fact that holes are formed in the steel flanges and webs can be avoided; by arranging an included angle between the beam and the column, process requirements on complex and specific structure of a main workshop of a nuclear power plant can be met, and the joint is worthy of popularization.

Owner:STATE NUCLEAR ELECTRIC POWER PLANNING DESIGN & RES INST CO LTD +1

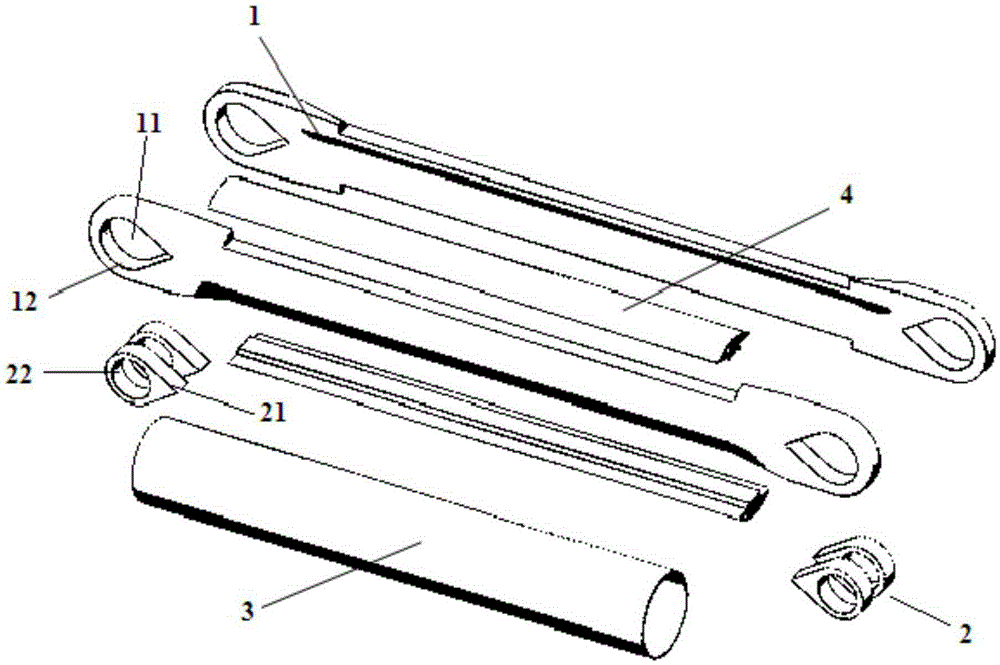

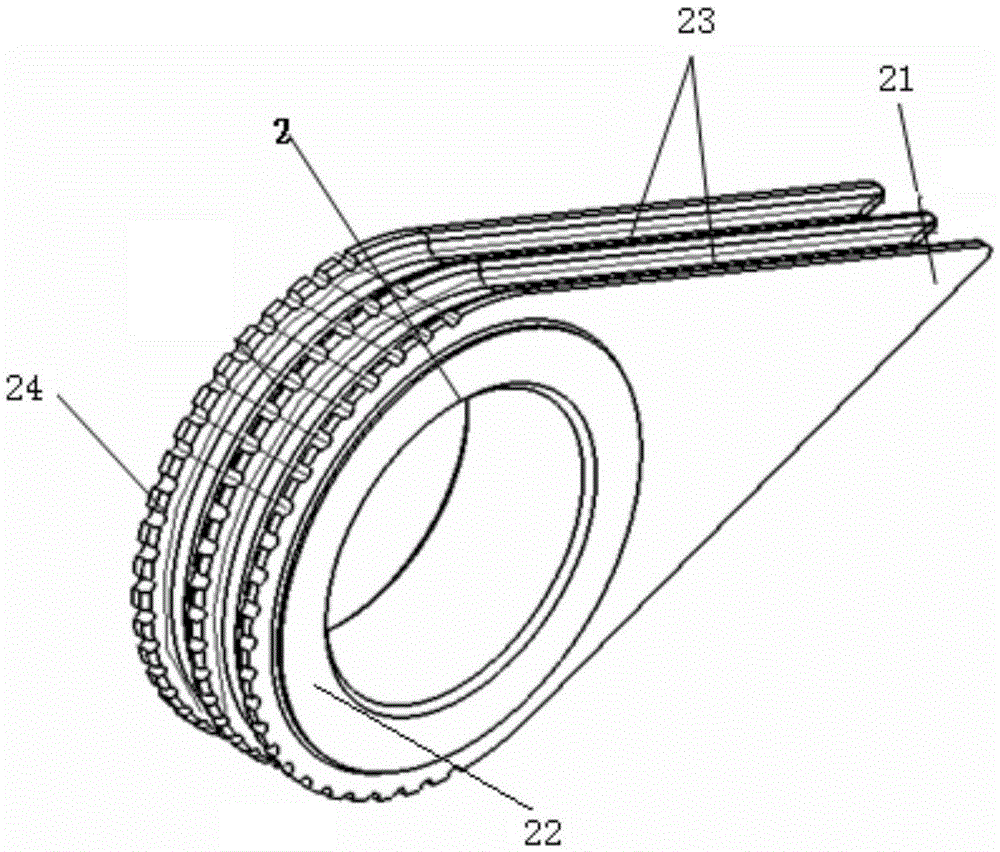

Light aviation bearing rod piece and producing method thereof

InactiveCN105299432AHigh longitudinal tensile strengthLow transverse shear stressElongated constructional elementsAviationTransverse groove

The invention relates to a light aviation bearing rod piece. The light aviation bearing rod piece comprises two bearing members, two inner liners, a metal shaft sleeve and a tubular covering layer, wherein the two side surfaces of each bearing member are embedded into the two opposite inner liners respectively to form a round tubular pull rod structure; the bearing members and the inner liners are covered with the tubular covering layer; lug piece parts are arranged at the two ends of the bearing members respectively; drop-shaped through holes are formed in the lug piece parts; the metal shaft sleeve is arranged in the through holes; a plurality of annular longitudinal grooves are longitudinally formed in the outer surface of the metal shaft sleeve, and a plurality of transverse grooves which are distributed at equal intervals along the circumference of a round through hole are transversely designed. Compared with the prior art, the light aviation bearing rod piece has the advantages that the producing method is simple and convenient, the bearing capacity is high, and the like.

Owner:TONGJI UNIV

A method of using greening structure soil as a rainwater accumulator

ActiveCN104120642BInhibit sheddingImprove permeabilityGeneral water supply conservationPaving gutters/kerbsPorosityDry weight

The invention relates to a method of adopting greening structured soil as a rainwater accumulator. The method includes steps of: weighing stone and soil according to a dry weight ratio of 4-5:1, uniformly mixing four raw materials comprising the stone, the soil, polyacrylamide (PAM) and gypsum, and adopting the obtained greening structured soil for a greening site of a hard road surface. By the method, the porosity under a maximum 100% compaction condition can be higher than 20%, the permeability is larger than 360 mm / h, and other physicochemical properties can meet the Greening Planting Soil CJ / T340-2011 standard in the national town construction industry. The greening structured soil has high rainwater penetration capability, and can be widely used for side pavements, business streets, public plazas, open-parking grounds, and other urban greening sites. The greening structured soil enhances the rainwater in-situ penetration property of hard greening road surfaces, relieves urban inland inundation and soil erosion, and plays a role of the rainwater accumulator. The greening structured soil provides good growing space, water and nutrients for root growth of plants and improves the greening quality of urban hard road surfaces.

Owner:SHANGHAI ACADEMY OF LANDSCAPE ARCHITECTURE SCI & PLANNING

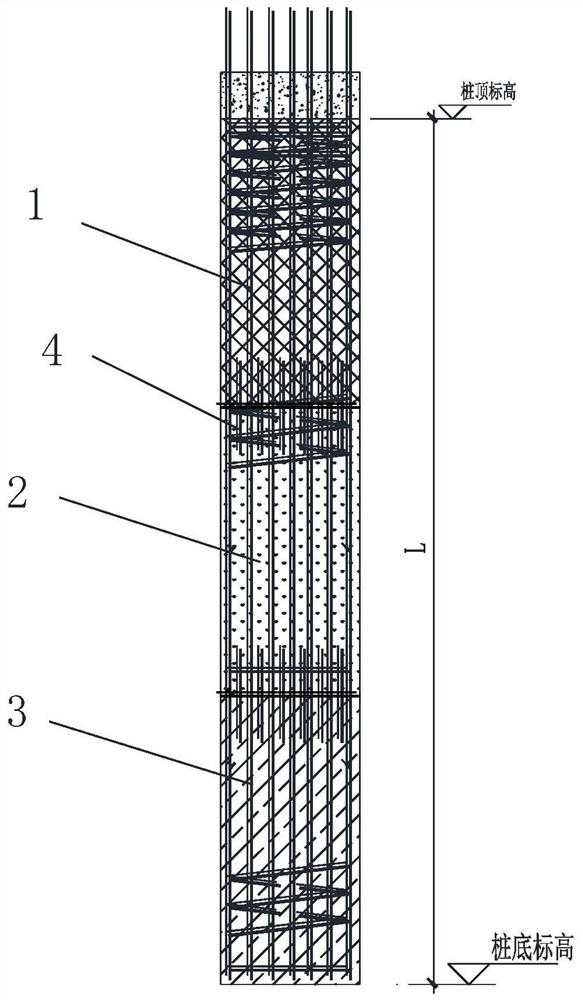

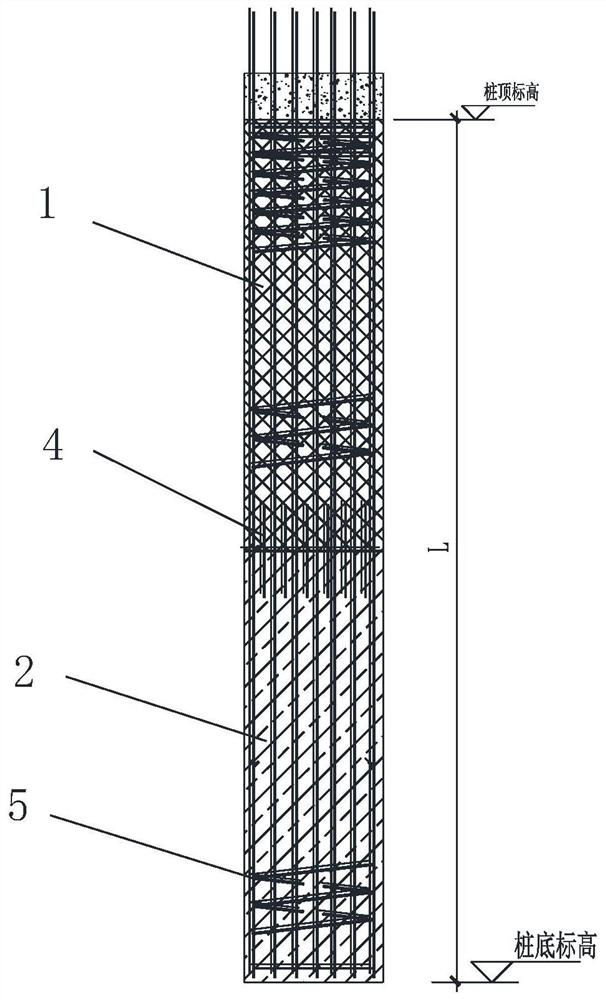

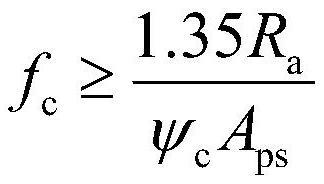

Pile body variable concrete strength grade cast-in-place pile and strength grade determining method thereof

ActiveCN112012198ALow costSatisfy the carrying capacityGeometric CADSpecial data processing applicationsBuilding designCompressive strength

The invention relates to a pile body variable concrete strength grade cast-in-place pile and a strength grade determining method thereof, and belongs to the technical field of building design and construction. A pile body of the pile body variable concrete strength grade cast-in-place pile is divided into z sections from top to bottom, z is greater than 1 and less than 4, joint bars are arranged at the joints of all the sections, and the concrete compressive strength of the tops of all the sections of the pile meets the following formula: the mechanical property of materials can be brought into full play according to the change of the internal force of the pile body, and therefore the purposes of saving energy and materials and reducing the construction cost are achieved.

Owner:CHINA NORTHWEST ARCHITECTURE DESIGN & RES INST CO LTD

Bearing type military off-road vehicle rear wheel cover assembly and welding method thereof

ActiveCN113548115ASatisfy the carrying capacityMeet needsArc welding apparatusSuperstructure subunitsFuel tankLap joint

The invention discloses a bearing type military off-road vehicle rear wheel cover assembly and a welding method thereof. The rear wheel cover assembly comprises a rear wheel cover outer plate, a chassis suspension system mounting mechanism welded on the rear wheel cover outer plate, a chassis suspension system wheel jump limiting mechanism welded on the chassis suspension system mounting mechanism and the rear wheel cover outer plate, and an accessory mounting mechanism which is welded on the rear wheel cover outer plate and is used for accessories such as an auxiliary fuel tank, a back door pedal and a rear traction member; the rear wheel cover outer plate is formed by welding a high-strength bulletproof steel plate MAG, the front face and the back face of a weld joint are welded in a gas shielded welding mode, so that it is guaranteed that the lap joint of the steel plate is completely welded, and then the strength of the rear wheel cover outer plate is guaranteed. According to structural design and selected materials, impact of certain explosives at the bottom of the vehicle can be resisted, safety of members and goods in the vehicle can be effectively protected, the structure is novel and ingenious, the manufacturing process is reasonable, and the strength can meet the functional requirements of bearing, bulletproof and impact resistance of the military off-road vehicle.

Owner:DONGFENG OFF ROAD VEHICLE CO LTD

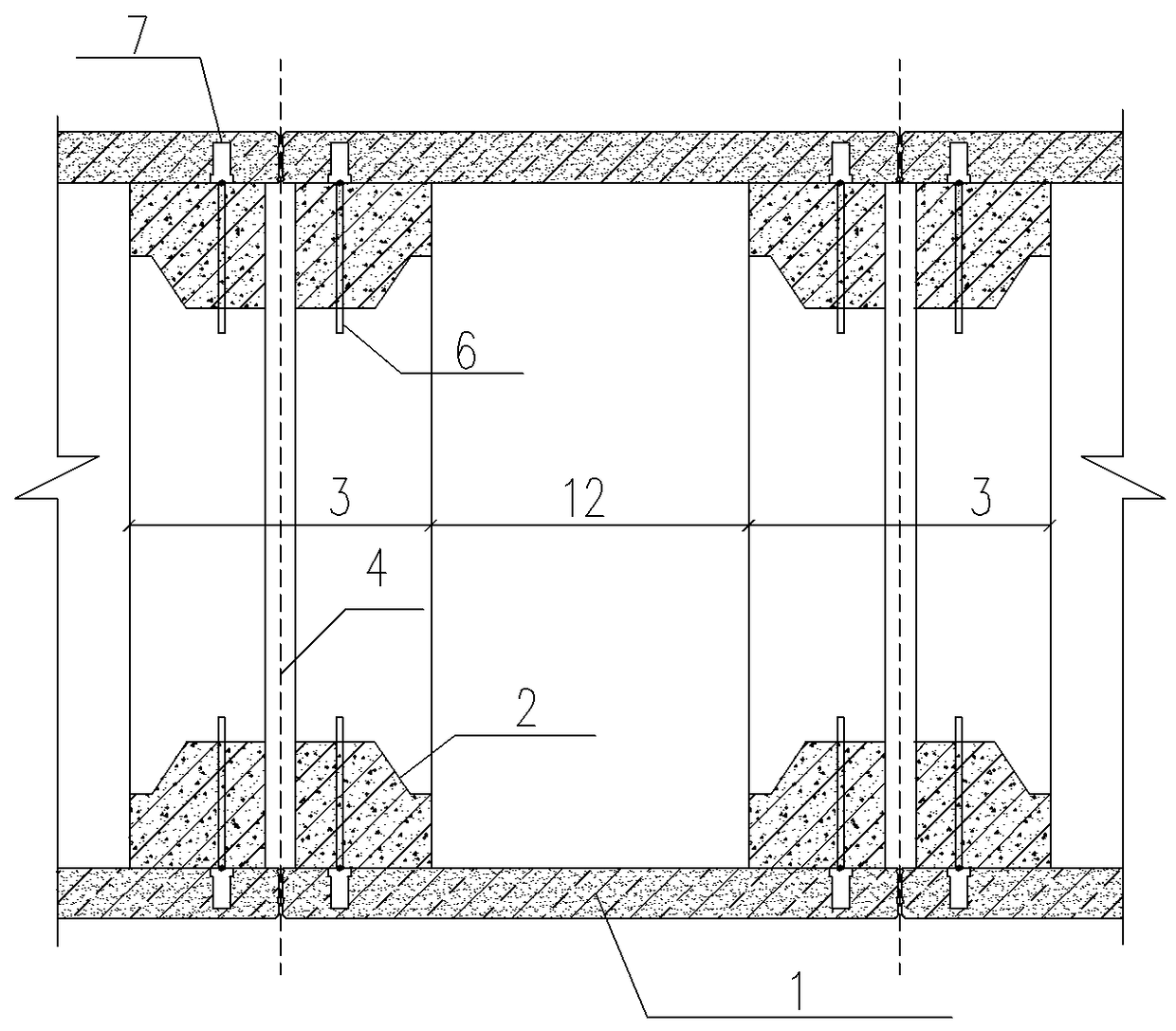

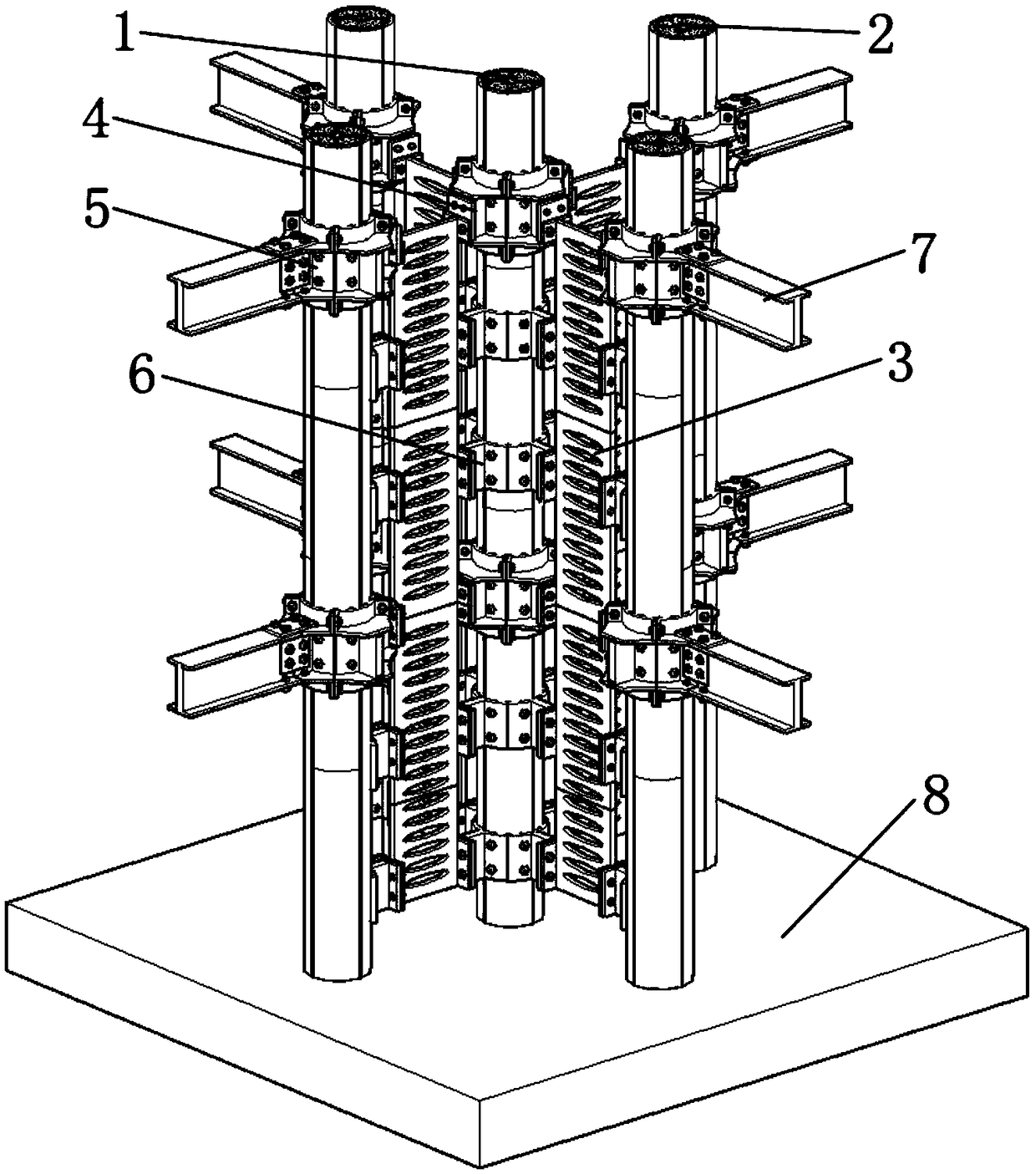

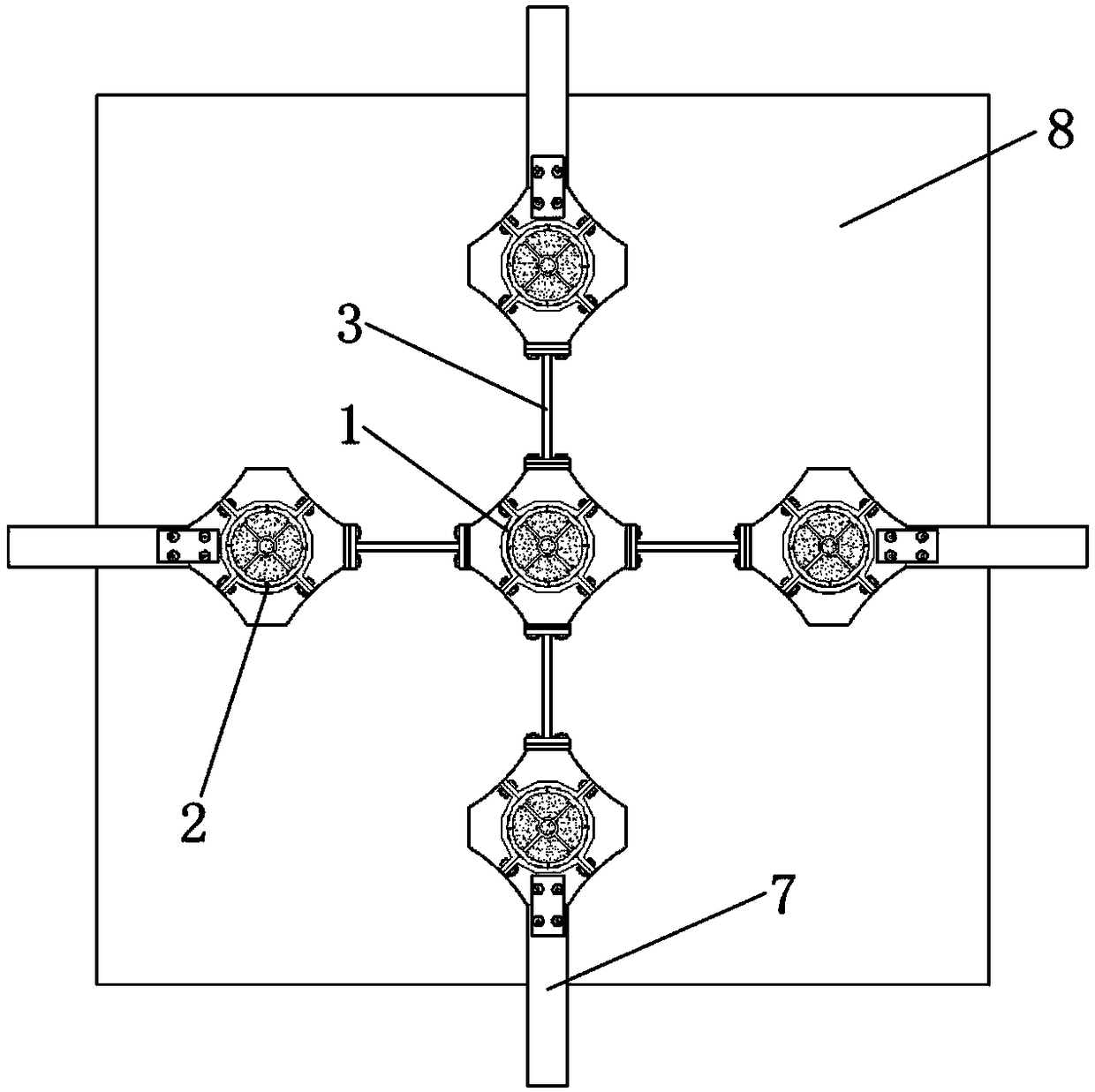

Assembling functional restorable steel skeleton concrete combined column and installation method

ActiveCN108487549ALow technical requirementsAvoid quality problemsStrutsPillarsStress concentrationEnergy consumption

The invention relates to an assembling functional restorable steel skeleton concrete combined column and an installation method, which belongs to the technical field of structural engineering. The assembling functional restorable steel skeleton concrete combined column comprises a group of steel pipe main columns, a steel pipe auxiliary column, a main and auxiliary energy consumption connecting bridge and a full-assembling connecting assembly; the full-automatic connecting assembly comprises a plurality of arc leg connecting members and a plurality of pairs of outer reinforced ring tiles, theouter reinforced ring tiles are spliced to form a circular outer reinforcing ring to tightly lock the steel tubular column; the main column and the auxiliary column are connected by utilizing the C-shaped arc leg connecting member and the full-assembling connecting assembly by virtue of the main and auxiliary column energy consumption connecting bridge to form the functional restorable steel skeleton concrete combined column; and concrete is poured into the steel tubular column. The bridge is provided with an elliptic through hole, so that the stress concentration of the bridge when in earthquake can be avoided, the absorption capability is excellent, more earthquake energy is consumed, the suffering of the main column and the auxiliary column when in earthquake can be reduced, the energyconsumption of an energy consumption component can be damaged, and the structural shock absorption performance is greatly improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

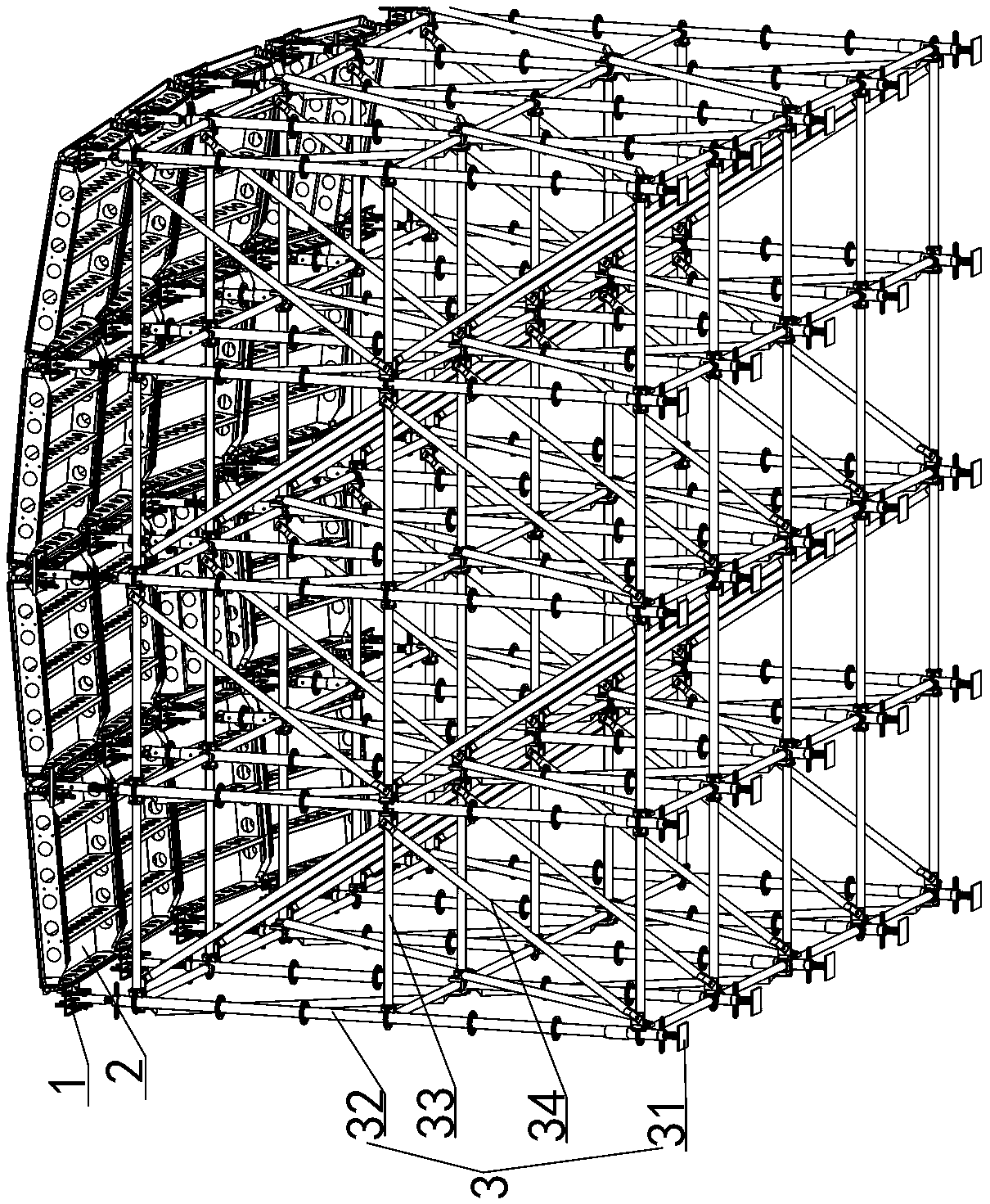

Cast-in-place gentle-gradient spatial curved roof formwork system and construction method thereof

PendingCN109372256AEasy to operateSave operating timeForms/shuttering/falseworksBuilding material handlingFalseworkKeel

The invention discloses a cast-in-place gentle-gradient spatial curved roof formwork system and a construction method thereof. The formwork system comprises a supporting structure and a panel structure; the supporting structure comprises a bottom all-round scaffold and a group of height-adjustable jacking and connecting assemblies, the number of the jacking and connecting assemblies is the same asthat of vertical rods, and the jacking and connecting assemblies are fixedly connected to the top ends of the vertical rods; and the panel structure is divided into a group of rectangular unit modules, each unit module comprises formwork keels, formwork panels and formwork connecting assemblies, the formwork connecting assemblies are fixedly connected to the four corners of each unit module, andthe formwork connecting assemblies of every four adjacent unit modules intersect at the same position and are located on the top of the same jacking and connecting assembly. The cast-in-place gentle-gradient spatial curved roof formwork system is suitable for a large-thickness curved roof of which the curvature change is irregular and the curved unit is approximately regarded as a plane and meetsthe designed curvature requirement. The construction method is high in operability, not only can meet the bearing force requirement, but also can be fitted with the curved surface curvature change, and has the very high market value.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

Arch bar construction method

InactiveCN103774852ASimplify the construction processGood arch structureBuilding material handlingSpandrelStructural engineering

Owner:SHAANXI LONGHAI ENG CONSTR

Processing method of Cr-Zr-Cu ring

ActiveCN101602166BIncrease the outer diameterSatisfy the carrying capacityOther manufacturing equipments/toolsSolution treatmentElectric machine

The invention relates to a processing method of Cr-Zr-Cu rings, in particular to a squirrel-cage type rotor which is formed by welding the Cr-Zr-Cu rings and rotor copper bars; the Cr-Zr-Cu ring is a short-circuiting ring which is arranged at two ends of the rotor of a wind driven generator and a high-speed train pulling motor, belonging to the technical field of hot processing. The processing comprises the following steps: Cr-Zr-Cu ingot blank is chosen as raw material, the processes of hot forging, solution treatment, cold forging, ageing treatment, milling processing and the like are carried out, and then detection / package is carried out, thereby obtaining finished products. The Cr-Zr-Cu ring has good electricity-conducting property and can meet the bearing capacity of a motor; the mechanical capacity is high, and the ring is wear-resistant and hot-resistant, and can work under 400 DEG C, thereby improving the reliability of the motor and prolonging the service life of the motor.

Owner:WUXI TONGWEI ELECTRIC POWER EQUIP

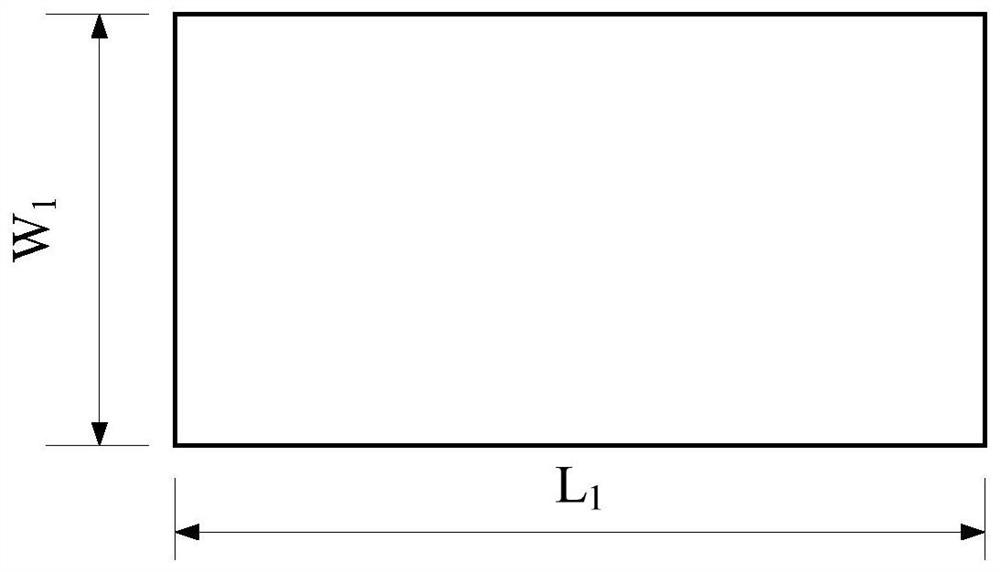

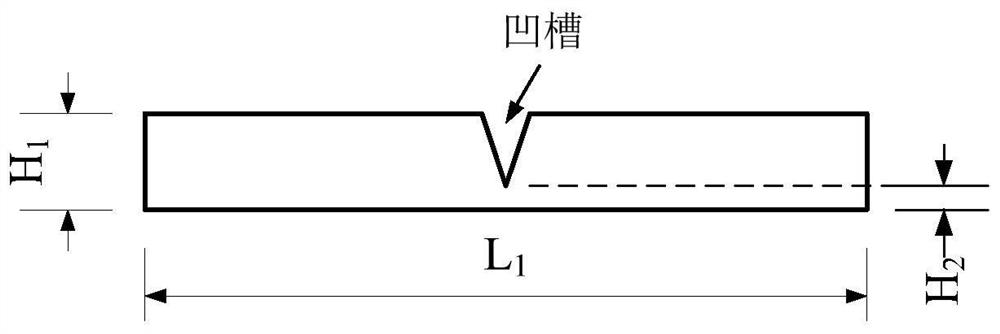

Foldable PP cellular board, preparation method thereof and trunk carpet comprising foldable PP cellular board

InactiveCN112045974AHelps to reduce weightReduce intensityVehicle componentsMechanical engineeringMaterials science

The invention provides a foldable PP cellular board, a preparation method of the foldable PP cellular board and a trunk carpet comprising the foldable PP cellular board. The foldable PP cellular boardcomprises a PP cellular board body, a groove is formed in the PP cellular board body, and the end of the groove is located on the edge of the PP cellular board body. The foldable PP cellular board isobtained by placing a PP cellular board substrate in a mold and hot-pressing the PP cellular board substrate into the shape of the foldable PP cellular board. The groove is machined in the PP cellular board through the thermal forming punching technology, so that the PP cellular board is locally weakened, then the folding function is realized, and materials are saved on the premise that the product bearing requirement is met, meanwhile, the whole part is light, and the requirements of car trunk carpet parts for the high bearing performance and folding function are met.

Owner:湖北吉兴汽车部件有限公司

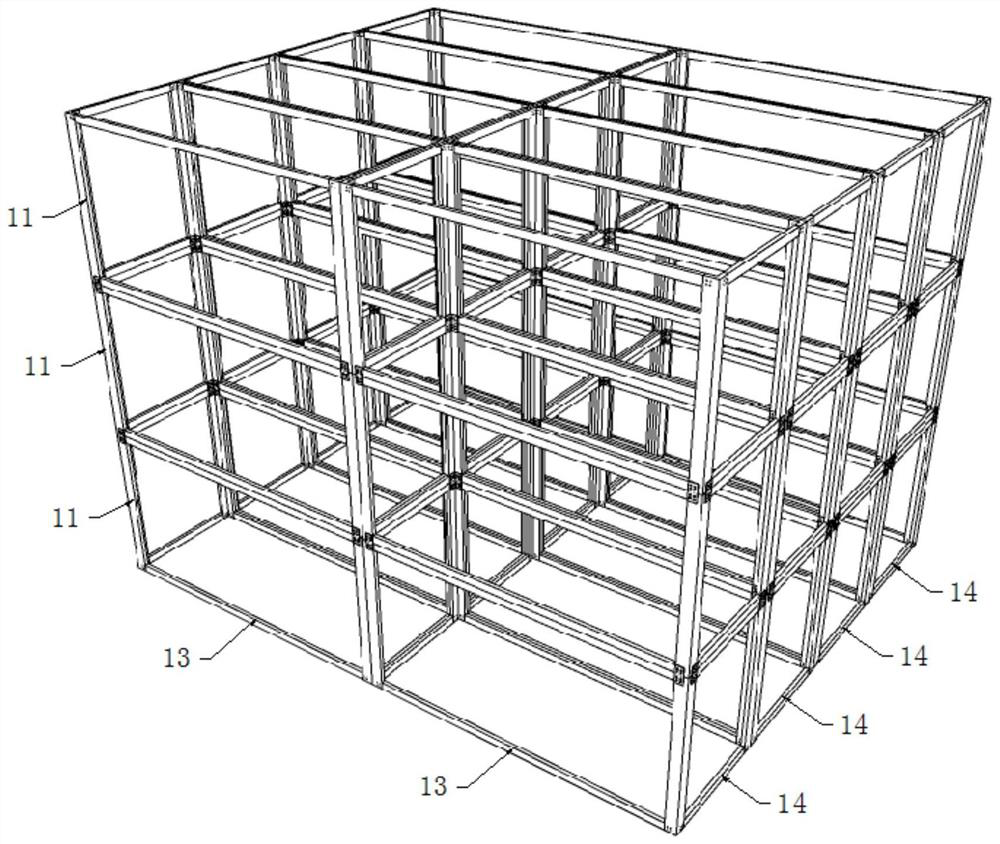

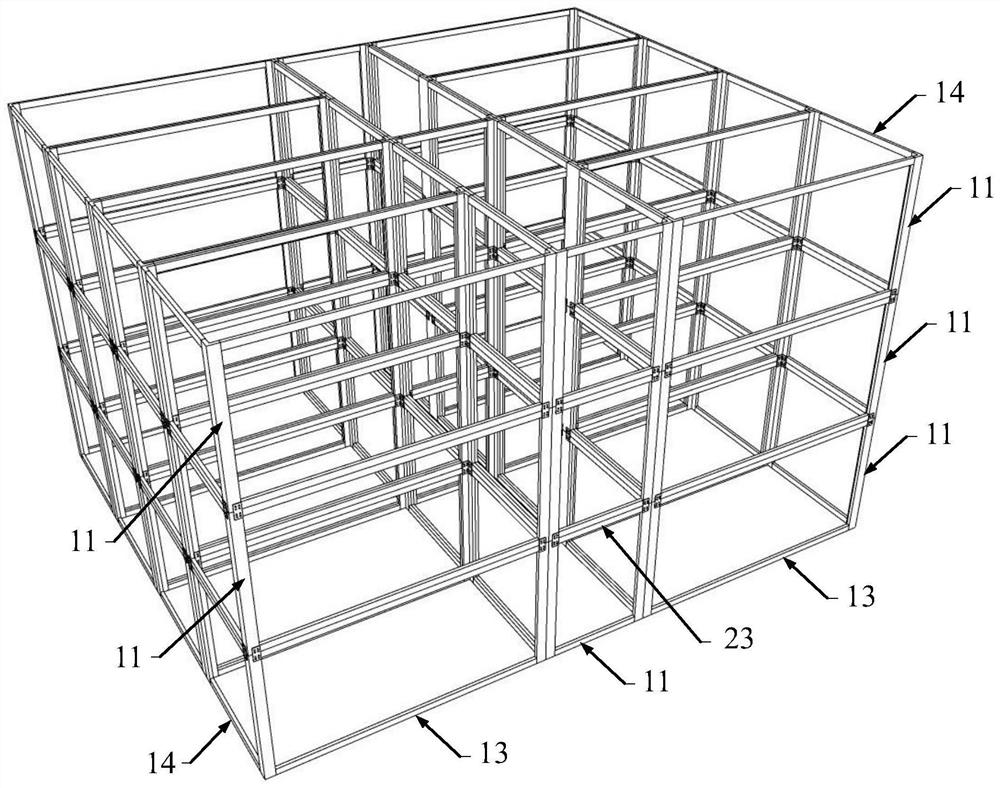

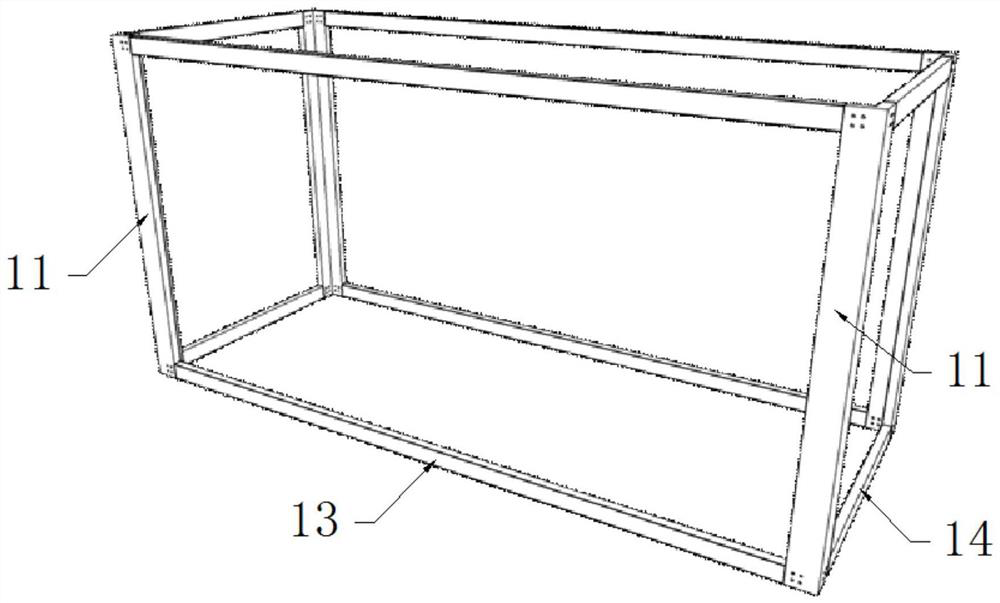

Full-modular building structure system

PendingCN112282066ANode structure is simpleEffective forceBuilding constructionsStringerJoint (building)

The invention discloses a full-modular building structure system. The construction method thereof comprises one or more standard module units, wherein each standard module unit consists of four steelpipe columns, four steel pipe cross beams and four steel pipe longitudinal beams, the section of each steel pipe column is in an L shape, all the steel pipe columns are vertically arranged, and all the steel pipe cross beams and all the steel pipe longitudinal beams are horizontally arranged. The four steel pipe columns, the four steel pipe longitudinal beams and the four steel pipe cross beams are connected to form a cuboid frame structure, and the steel pipe longitudinal beams are longer than the steel pipe cross beams. The full-modular building structure system has the beneficial effects that the connecting mode between the modules is column-column connection with direct force transmission, the node structure is simple, and the stress is effective. By changing the size of a connecting piece and the number of bolts, requirements for bearing capacity of joints at different positions of different building structures and bearing performance of multi-storey and high-rise buildings can bemet, the two module units can be freely combined and stacked, space layout is flexible, transportation and hoisting of the module units are rapid and stable, the overall performance of the structureis high, on-site splicing is efficient, and the application range is wide.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com