Automobile coat and hat rack and manufacturing method thereof

A coat rack and automobile technology, applied in the field of automobile interior decoration, can solve the problems of material body damage, difficult to use requirements, weak bearing capacity, etc., and achieve the effects of reducing damage, improving bearing capacity, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

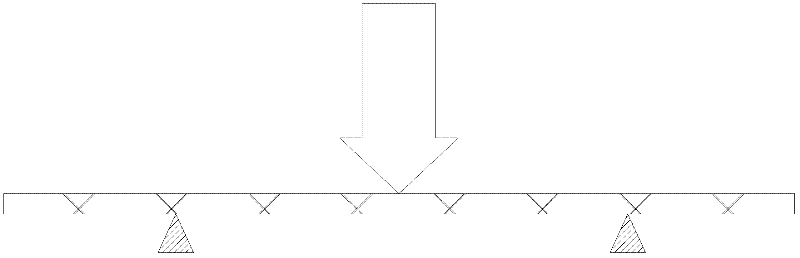

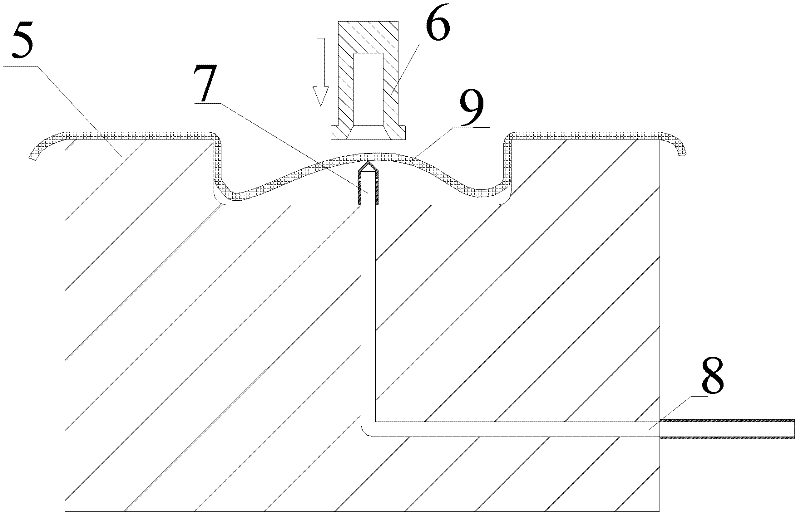

[0026] The invention relates to an automobile coat rack, which comprises a coat rack plate and a decorative fabric spread on the surface of the coat rack plate. The material of the coat rack plate is wood powder board or fiberboard, and the material of the decorative fabric is PET or composite PET. Such as Figure 10 As shown, because the coat rack in the prior art has a single-layer structure, its bearing capacity is weak, and if there is no support in the middle, it will sag and deform, resulting in fatigue damage to the coat rack. Therefore, in order to enhance the bearing capacity of the coat rack, the automobile coat rack of the present invention has been greatly improved, as shown below.

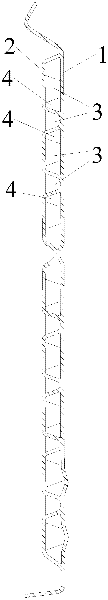

[0027] Such as figure 1 As shown, the coat rack plate has a double-layer structure, and there are a plurality of hollow cavities 4 arranged at intervals between the upper and lower surfaces 1, 2 of the coat rack plate. There are a plurality of protrusions 3 raised from the lower surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com