Ground fracture region shield tunnel based on back pouring enlarged head type and construction method thereof

A technology of shield tunneling and shield tunnel segments, which is applied to shield tunneling in ground fissure areas and its construction field, and can solve problems such as poor geological conditions, unfavorable engineering quality control, unfavorable engineering risk control of mining tunnels, and environmental protection. , to achieve the effect of ensuring effective contact, facilitating processing and manufacturing, improving project quality and risk control level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in combination with specific embodiments.

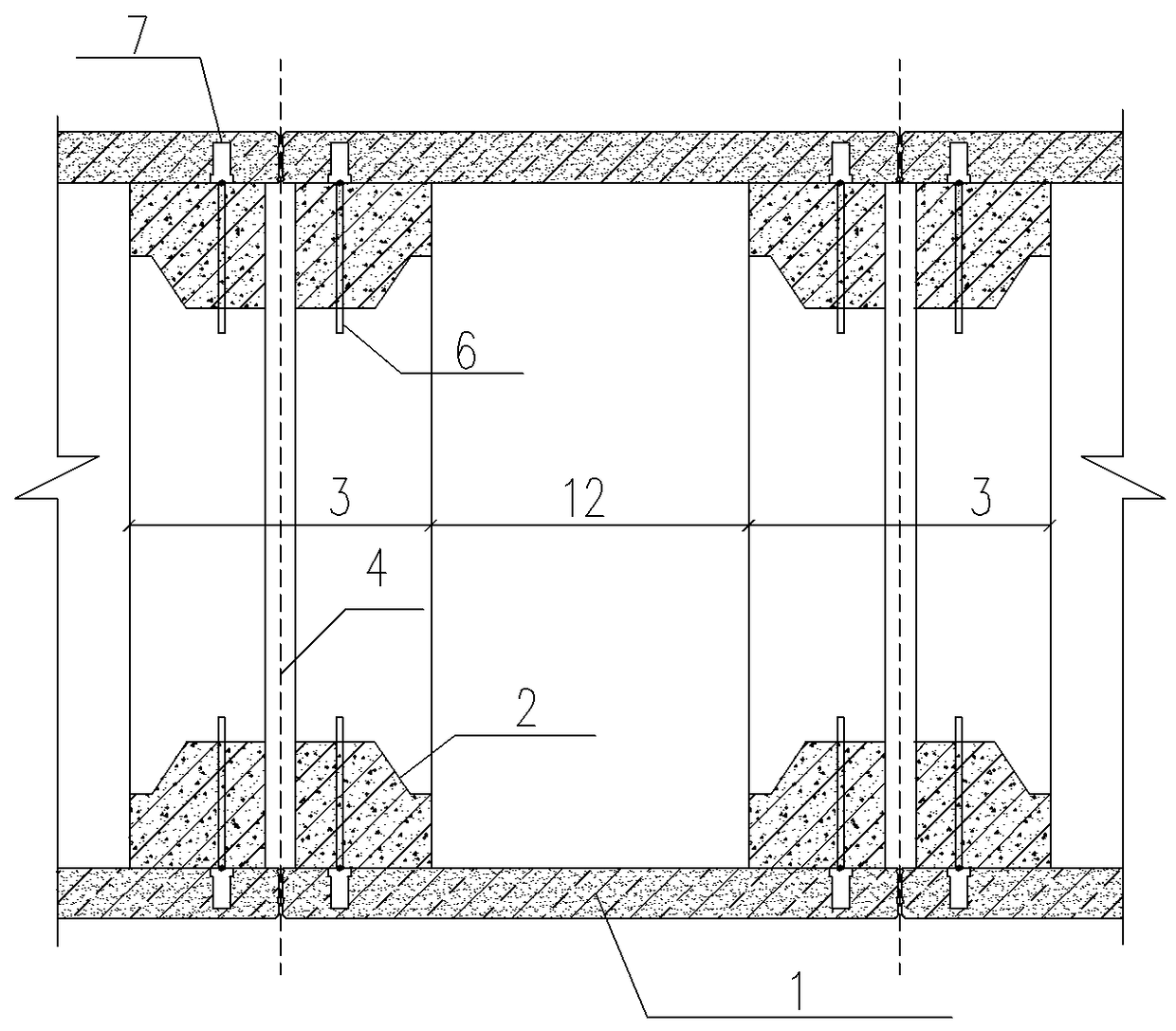

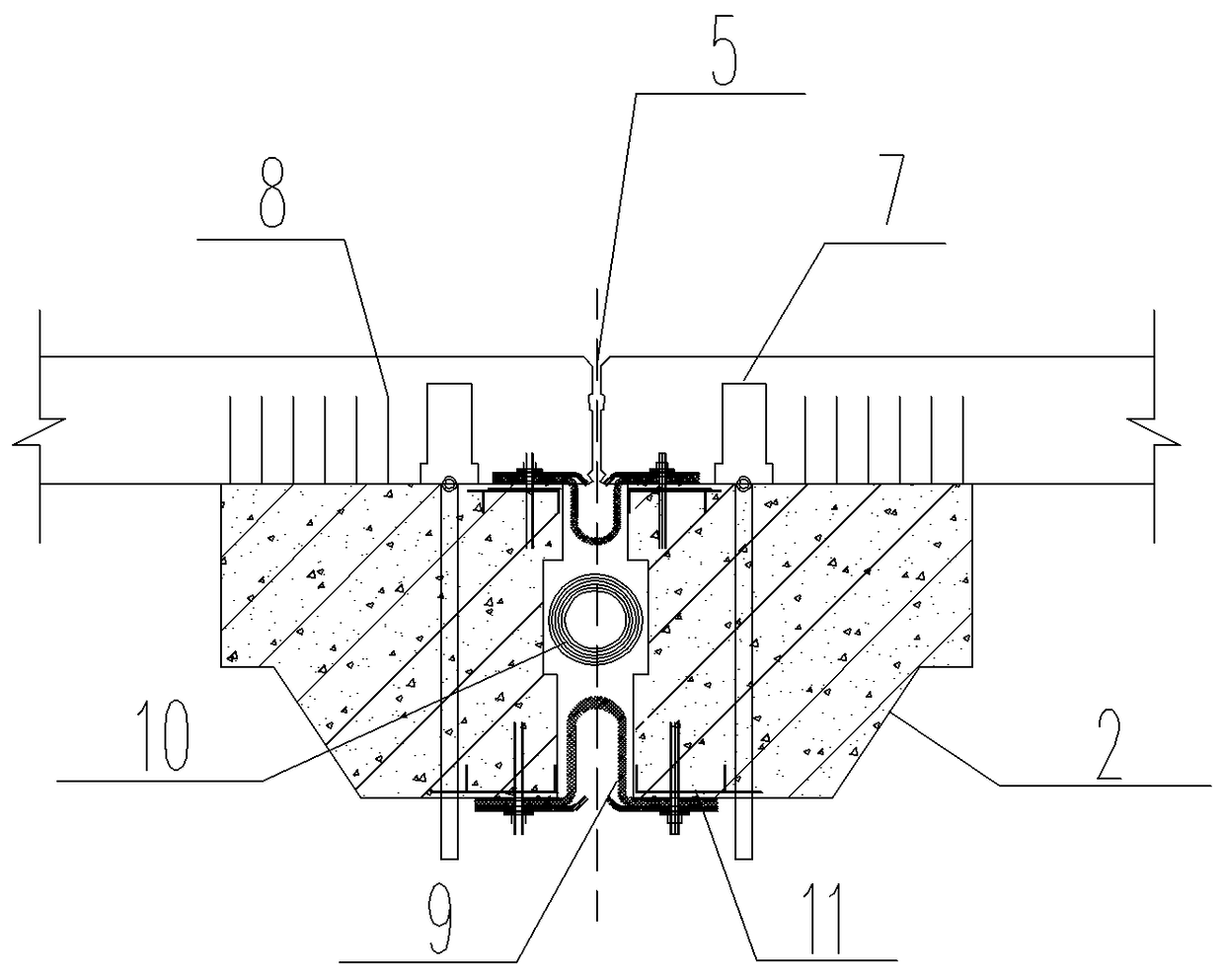

[0028] The invention relates to a ground fissure area shield tunnel based on post-casting expansion head type, which includes a tunnel lining structure composed of shield tunnel segment lining 1, which is an assembled lining structure, and each ring segment is assembled by several segments The annular seam and the longitudinal seam of the segment are connected by bolts. The two sides of shield tunnel segment annular seam 5 are provided with post-casting type inwardly convex expanding head 2, and the junction of both sides of segment annular seam 5 with inwardly convex expanding head 2 forms a special deformation seam 4, and the special deformation seam 4 and the segment The circular seam 5 is strictly aligned. The inner convex expansion head 2 is formed by integral continuous pouring of steel bars and waterproof concrete. The height needs to meet the longitudinal force r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com