Prefabricated steel highway bridge

A prefabricated, highway technology, applied in the direction of bridges, truss bridges, bridge parts, etc., can solve the problems of small design bearing capacity, small installation space, narrow use range, etc., to reduce erection costs, increase width, and vehicle traffic capacity. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

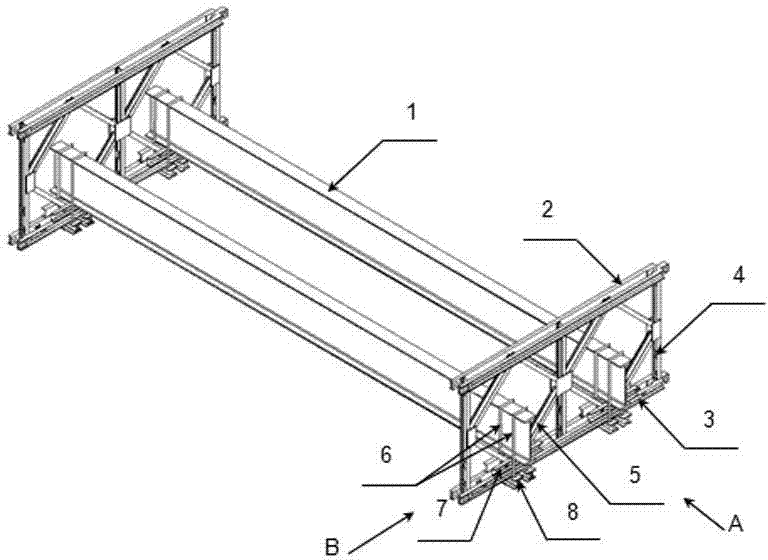

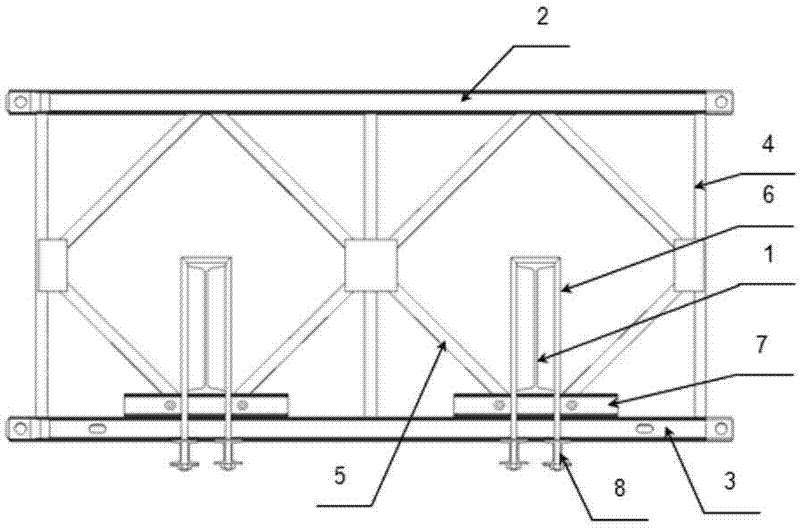

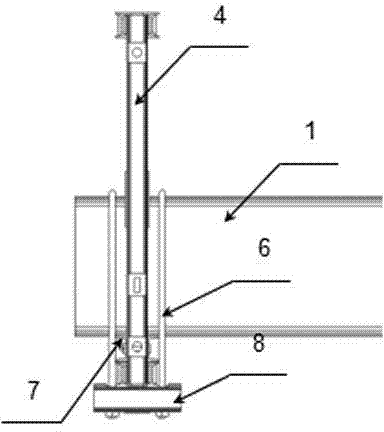

[0013] Such as figure 1 , 2 , 3, the assembled highway steel bridge of the present invention comprises a steel truss and a large crossbeam 1 erected between the steel trusses, the steel truss includes an upper chord 2, a lower chord 3 and an interval between the upper chord 2 and the lower chord The vertical rods 4 between the rods 3, the rectangular frame composed of two adjacent vertical rods 4 and the upper chord 2 and the lower chord 3 are composed of four oblique rods 5 respectively fixed at the center of the upper and lower chords and vertical rods. Diamond-shaped support frame, a pair of channel steel 7 with opposite openings is arranged on the lower chord 3 at the bottom of the diamond-shaped support frame. A support plane is formed between the root slanting bars 5, and the large beam 1 is horizontally placed on the support plane; two U-shaped bolts 6 with downward openings arranged on both sides of the lower chord 3 connect the large beam 1, the channel steel 7 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com