Patents

Literature

88results about How to "Node structure is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

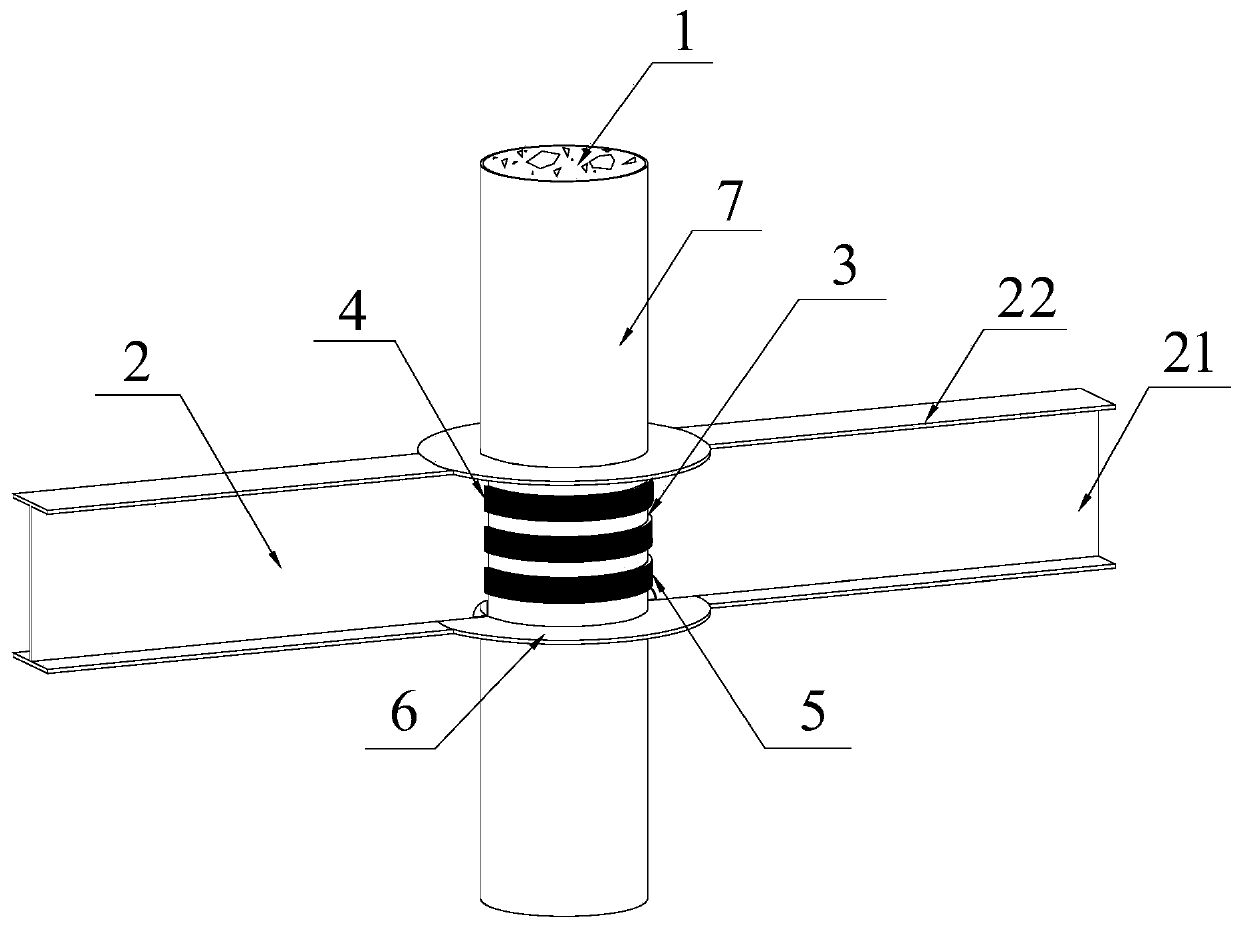

Circular steel tube concrete column and beam node connecting structure

InactiveCN101769011AFirmly connectedNode structure is simpleBuilding constructionsConcrete beamsEngineering

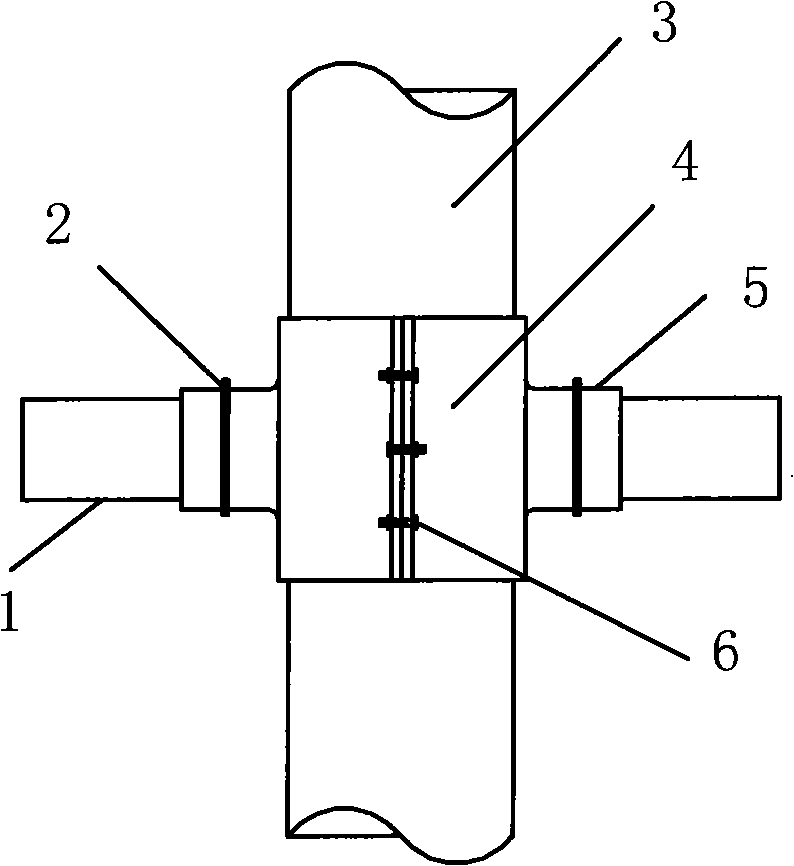

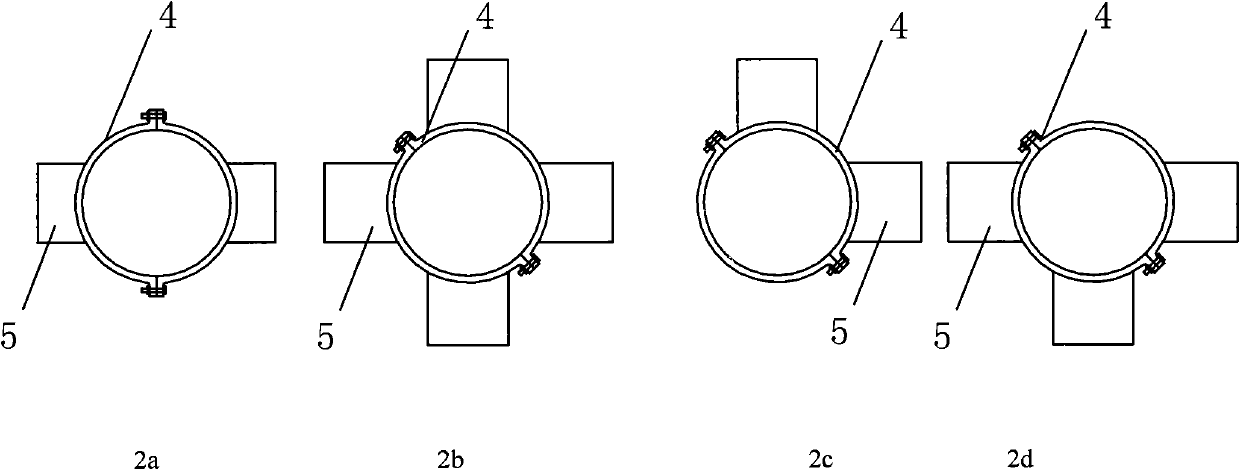

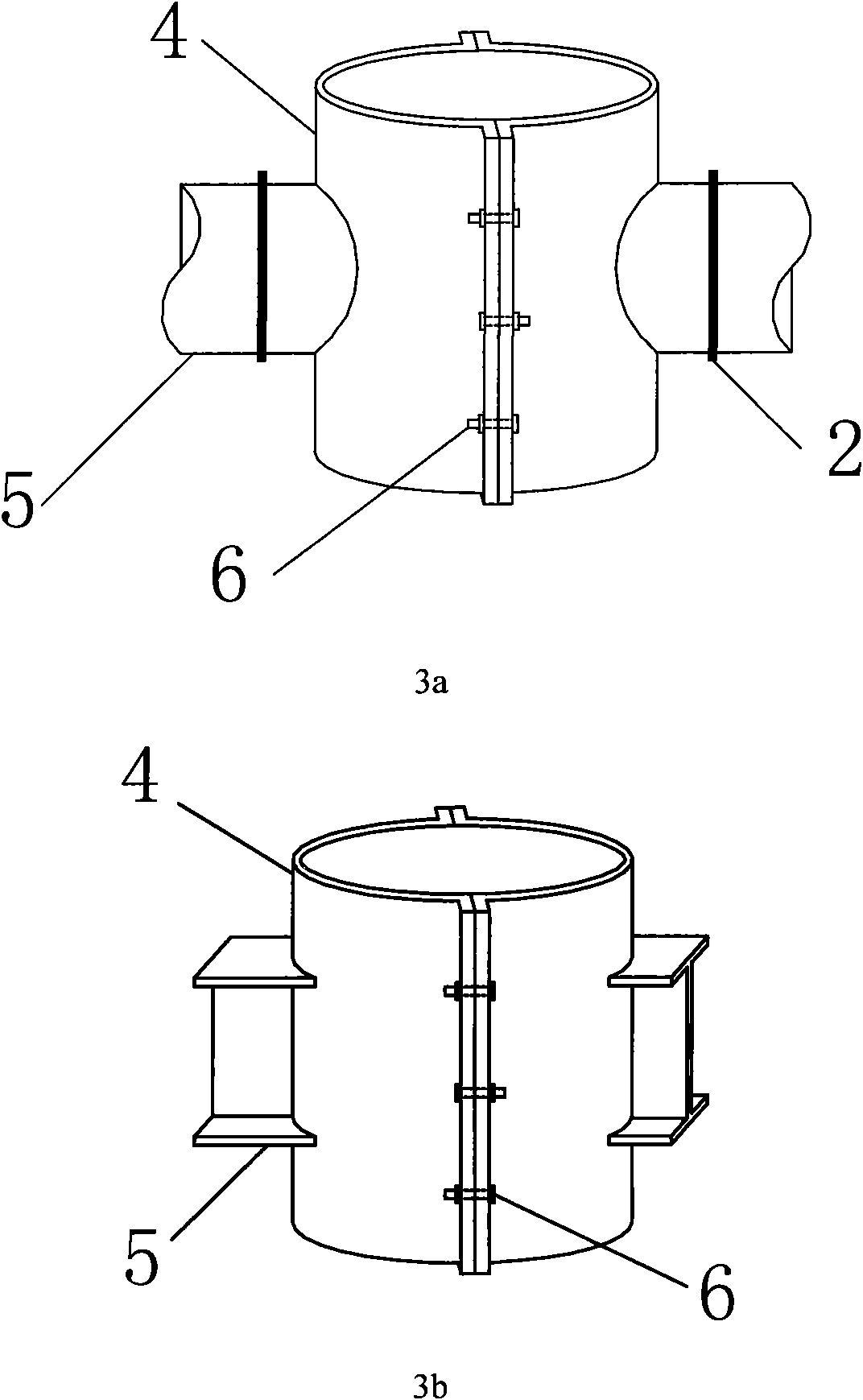

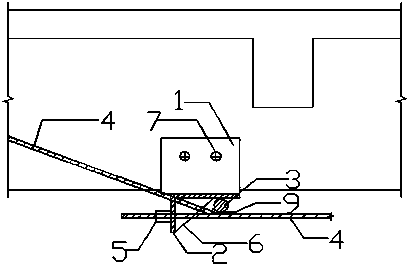

The invention discloses a circular steel tube concrete column and beam node connecting structure, which is characterized in that: the connecting structure comprises a node fastener, a bolt, a circular steel tube concrete column and a beam; the node fastener is composed of two sections of fastening rings and a joint, and the joint is in sleeve type and horizontally H-shaped type, the circular steel tube concrete column penetrates in the fastening rings and is fastened by the bolt, and the beam is connected by the joint on the fastener; the field installation is convenient without welding and the construction is rapid; the fastener is composed of two sections and is connected by the bolt after being fixed, and the circular steel tube concrete column is fixed by tightening force of the fastener; the circular steel tube concrete column is inserted in the sleeve type joint and is fixedly connected with the sleeve type joint by the bolt, and a concrete beam steel bar and a steel girder are welded with the horizontally H-shaped type joint; besides welding of the concrete beam steel bar and the horizontally H-shaped type joint, in the whole process, welding and complex distributed steel do not need, the construction is simple and rapid.

Owner:HOHAI UNIV

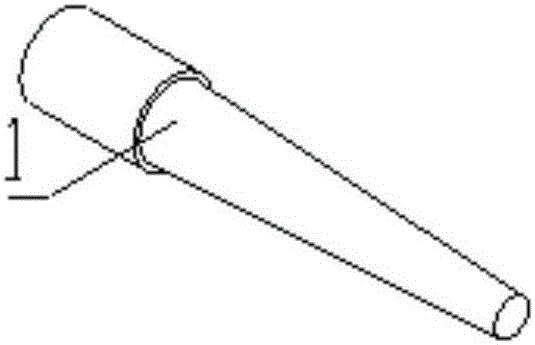

External pre-stressed tendon reinforcing steering block for building structure

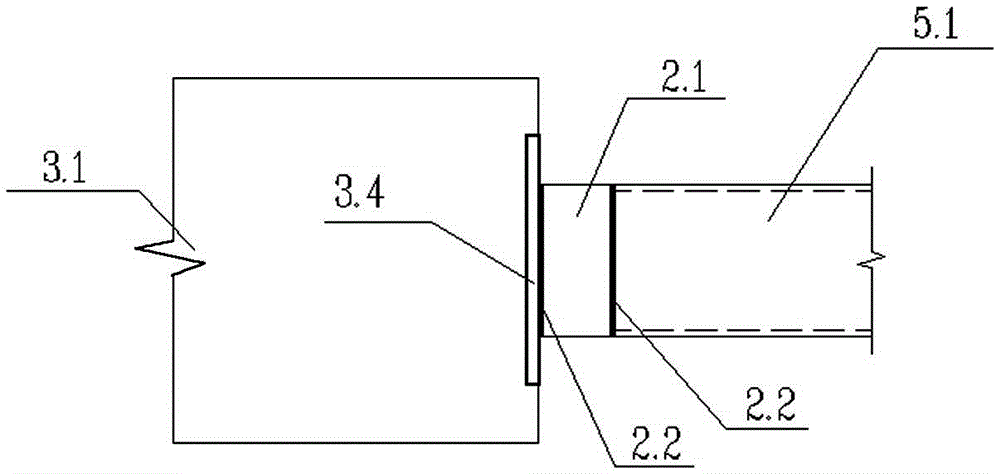

ActiveCN103388408ANode structure is simpleEasy to disassemble and maintainBuilding repairsPre stressArchitectural engineering

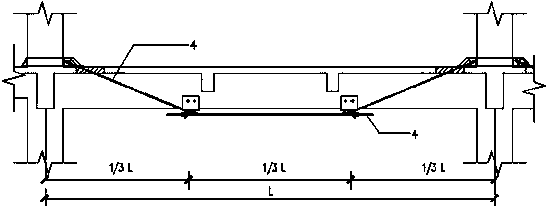

The invention discloses an external pre-stressed tendon reinforcing steering block for a building structure. The external pre-stressed tendon reinforcing steering block comprises a U-shaped steel plate, an external tendon tension L-shaped steel plate and steering solid round steel, wherein the U-shaped steel plate consists of two side plates and a bottom plate; the external tendon tension L-shaped steel plate is formed by welding a horizontal top plate and a vertical plate; the horizontal top plate is welded together with the bottom plate of the U-shaped steel plate; an oval preformed hole is formed in the vertical plate; an external pre-stressed steel strand positioning steel plate is additionally welded beside a hole; the steel plate is also an L-shaped steel plate reinforcing rib; the steering solid round steel is a steering device for an external pre-stressed steel strand; limiting baffle plates are welded at the two ends of the steering solid round steel; an arc-shaped steering base plate is arranged at a steering point under the steering solid round steel; and the steering block is a tension anchoring end as well as a steering block. The external pre-stressed tendon reinforcing steering block has the advantages of simple structure, convenience in constructing and easiness in detaching; the tension end of the pre-stressed tension is combined with the steering block, so that space is saved; and the external pre-stressed tendon reinforcing steering block is particularly suitable for external prestress reinforcing engineering of a building structure beam body with four and less external pre-stressed reinforcing steel strands.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

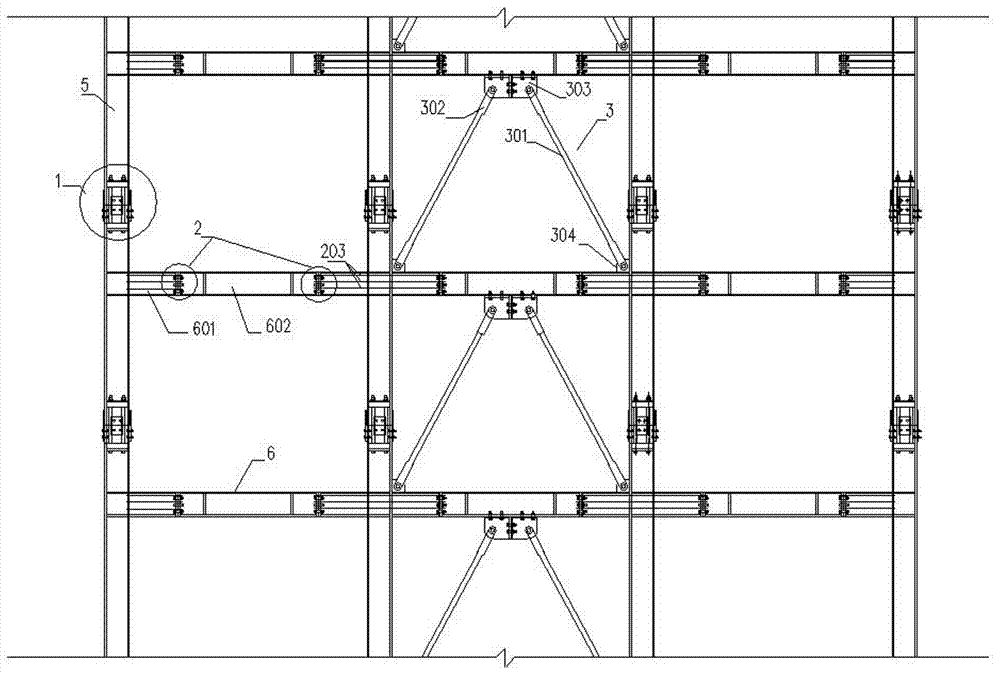

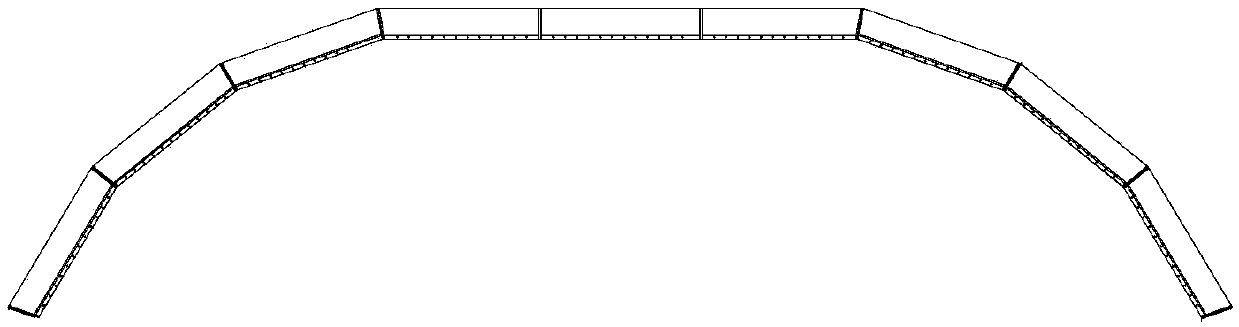

Dragline curtain wall support system with steel truss at top and construction method thereof

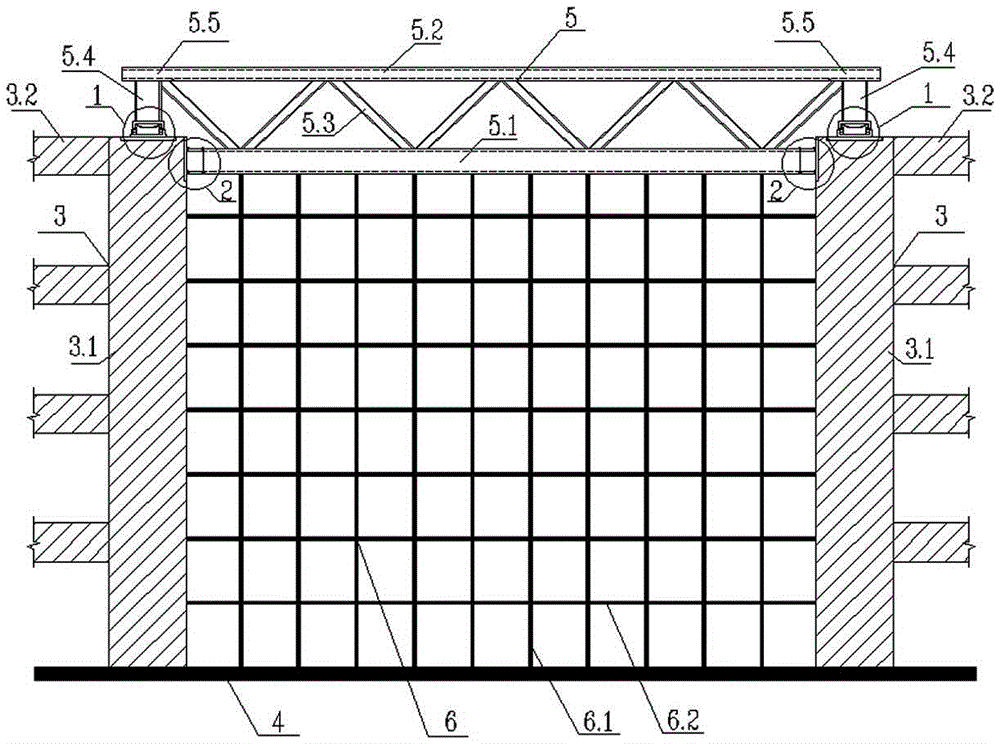

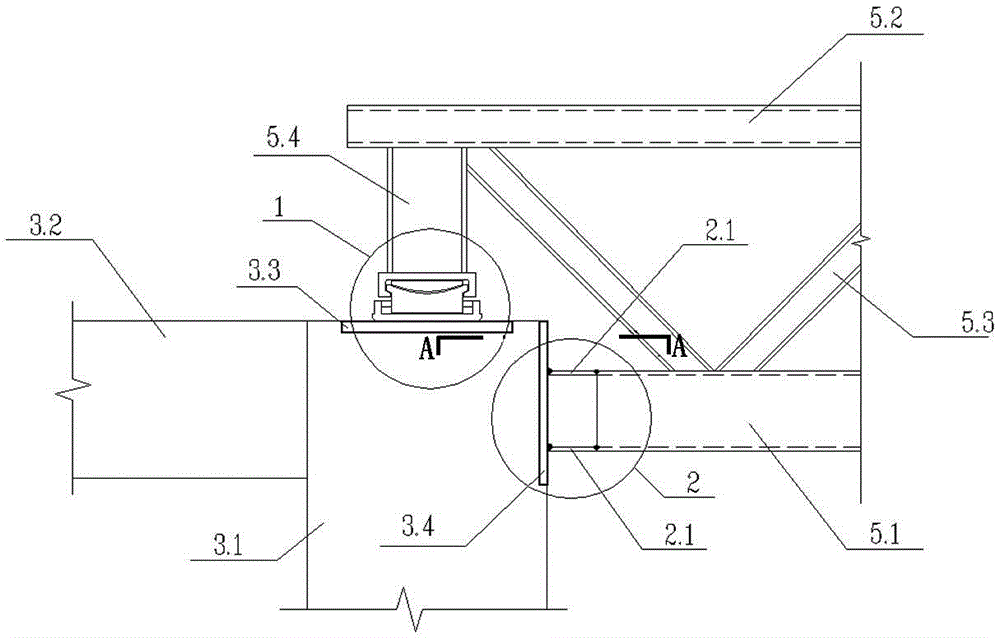

ActiveCN105332452ASolve processing problemsImprove structural strengthWallsBuilding material handlingSupporting systemPre stress

The invention provides a dragline curtain wall support system with a steel truss at the top and a construction method thereof. The dragline curtain wall support system comprises main building structures at two sides, a support structure at the lower part, the steel truss at the top and a curtain wall steel cable at the middle, wherein the main building structures provide left and right fixed points of the steel cable, and the steel truss and the support structure at the lower part provide upper and lower fixed points of the curtain wall steel cable; a two-direction fixed mode of horizontal connection and vertical connection is adopted at the two ends of the steel truss and between the main building structures; and the horizontal connection is realized through a horizontal bearing support, and the vertical connection is realized through a vertical bearing support. The dragline curtain wall support system is simple in structure and convenient in construction; by virtue of the two-direction support fixed mode, the structure strength is increased, the node structure is simplified, and the structure safety is greatly increased; The horizontal bearing support is installed after vertical steel cable prestress tension to enable the steel truss to freely rotate under the action of the vertical force, so that the secondary stress of buildings at two sides is reduced; and by transferring force by a horizontal steel plate, the bearing force is large, the stress is reliable, and micro-vertical deformation of the steel truss can also be applicable.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

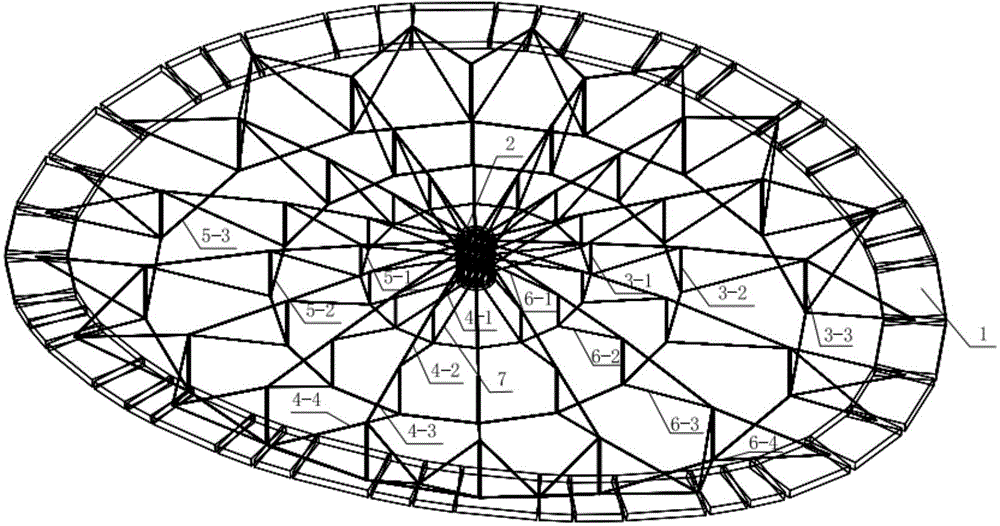

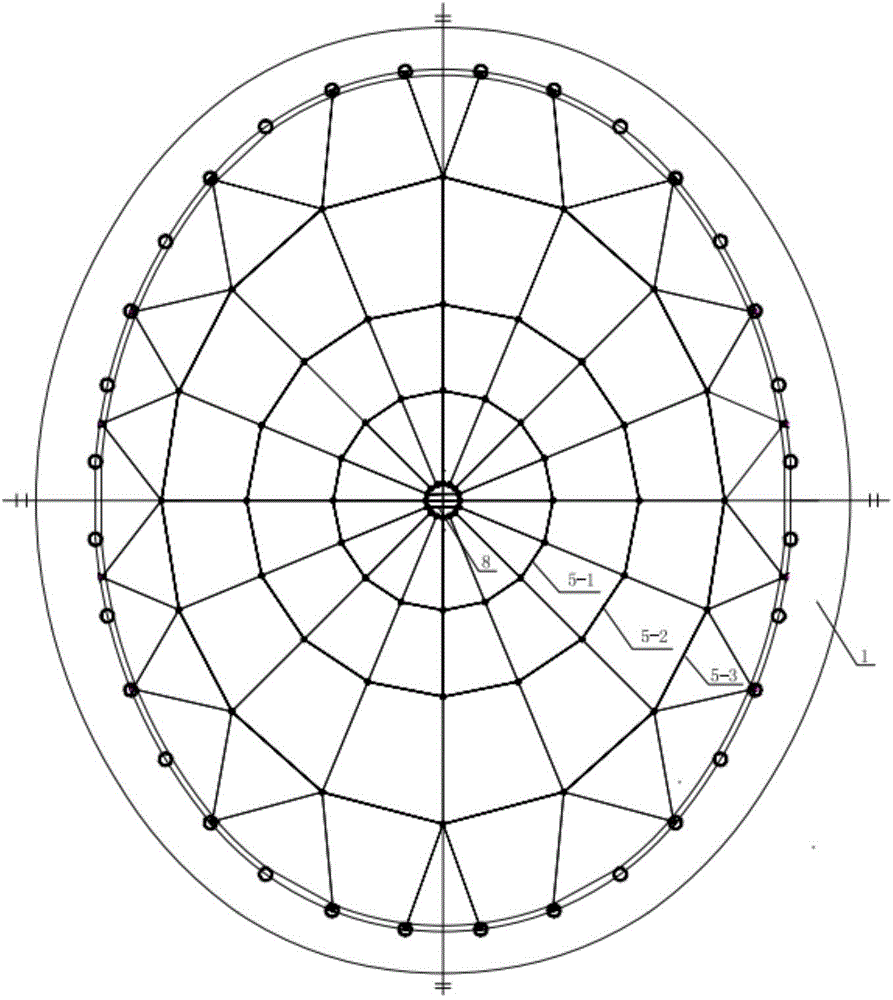

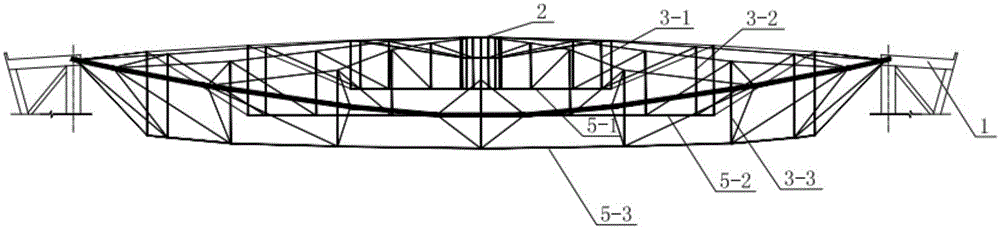

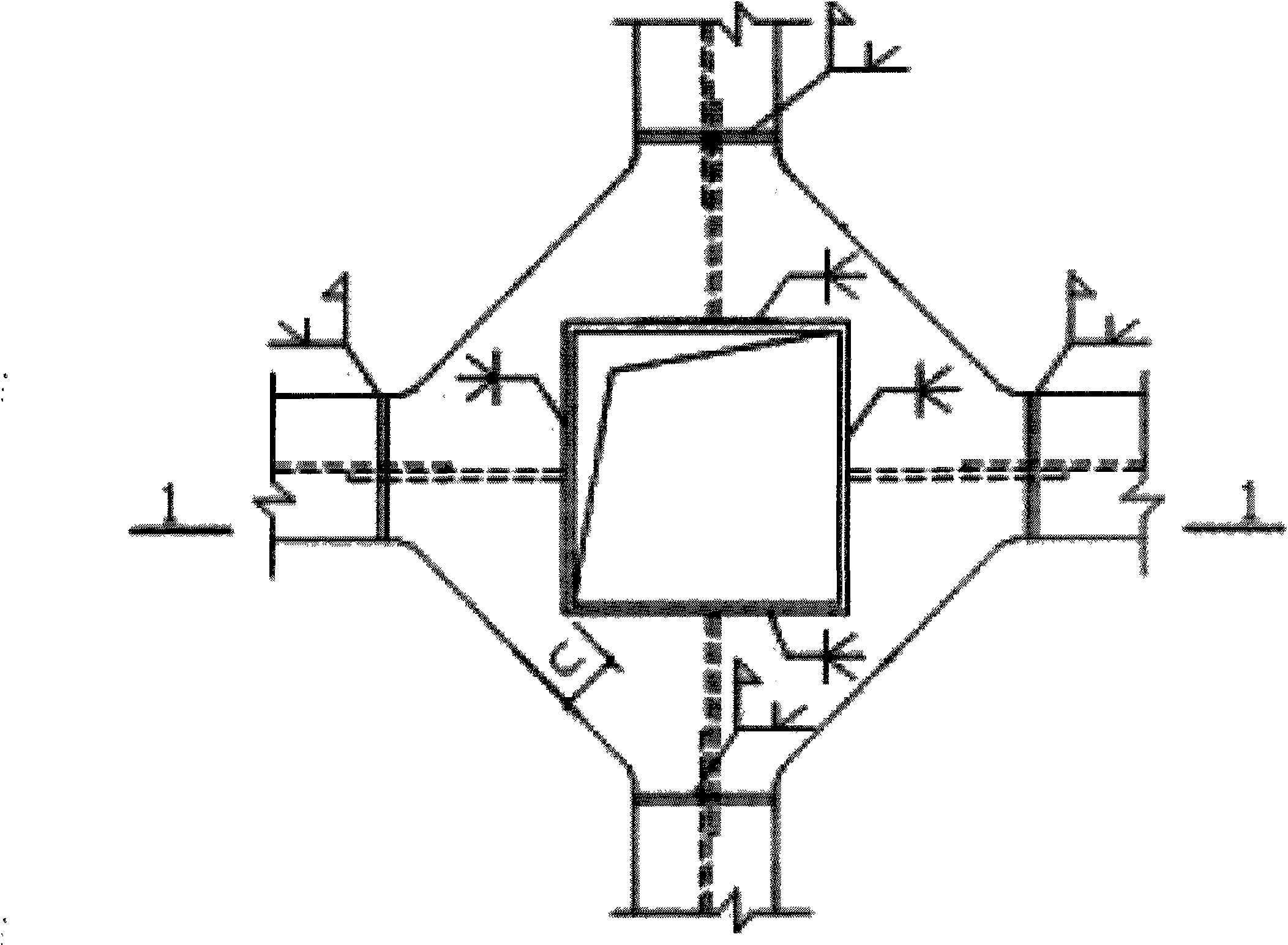

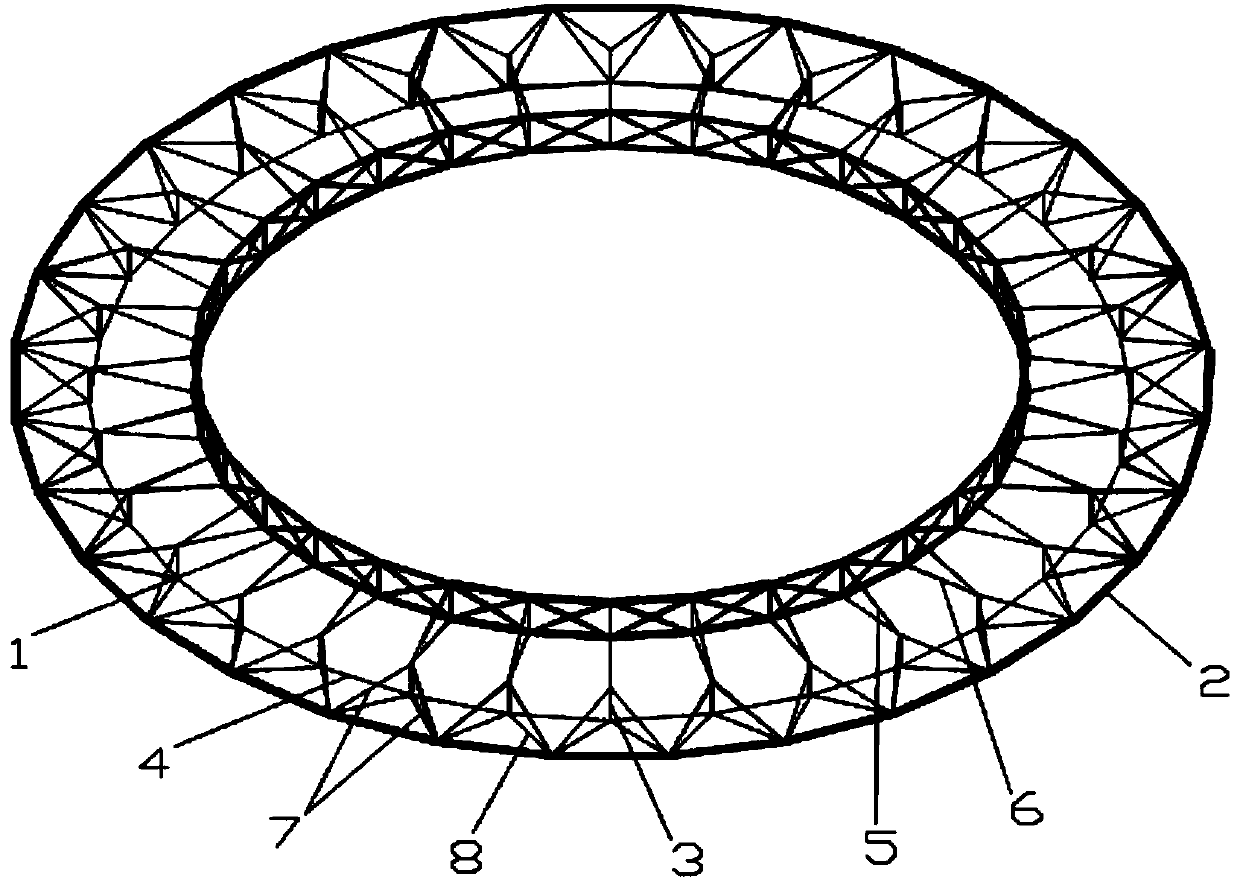

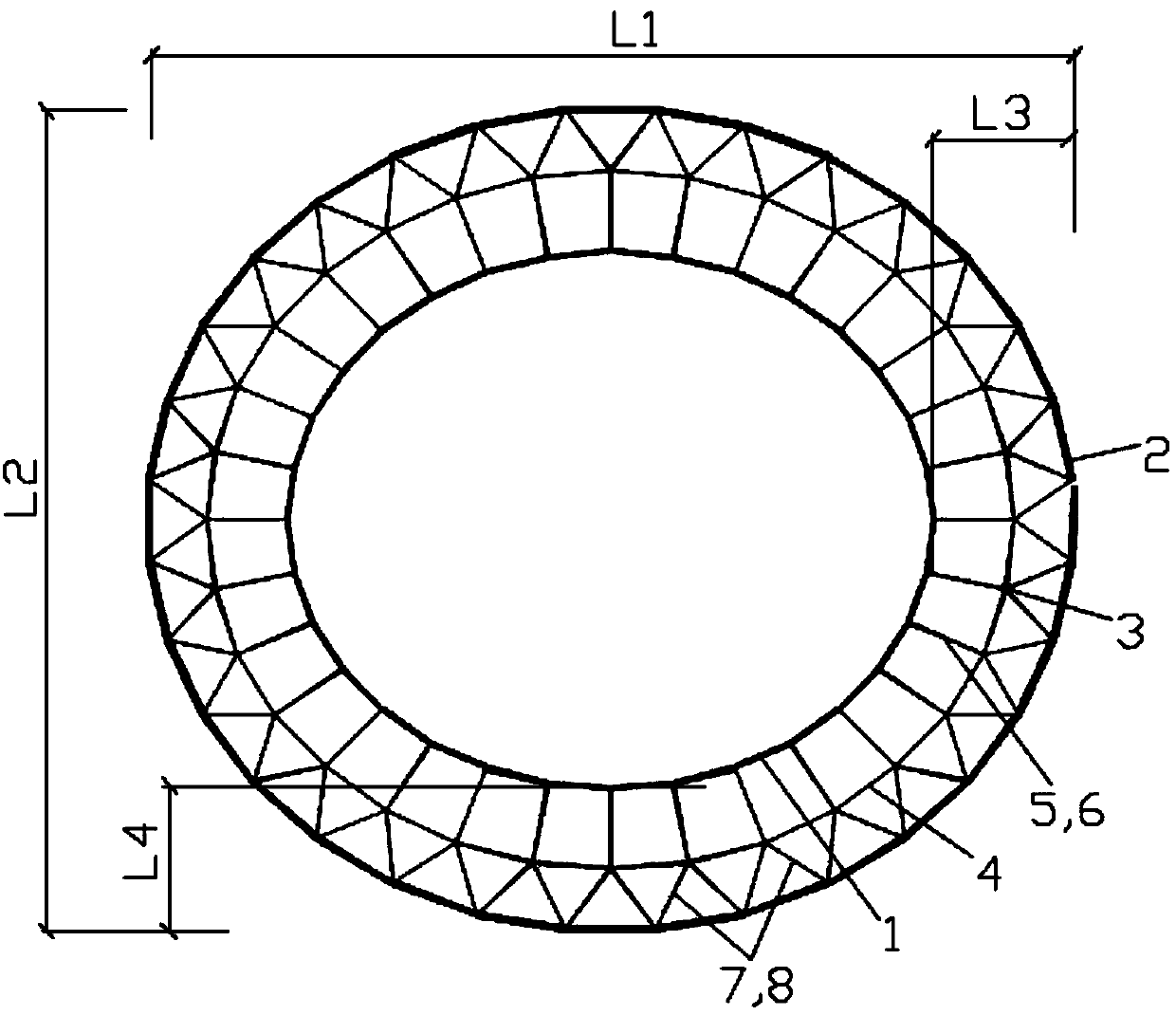

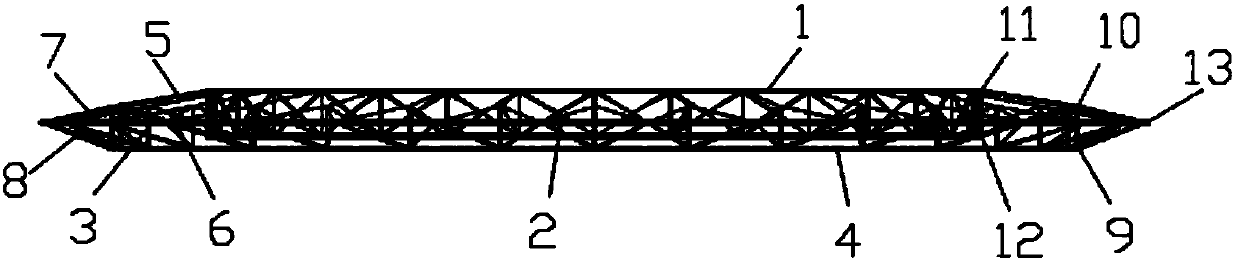

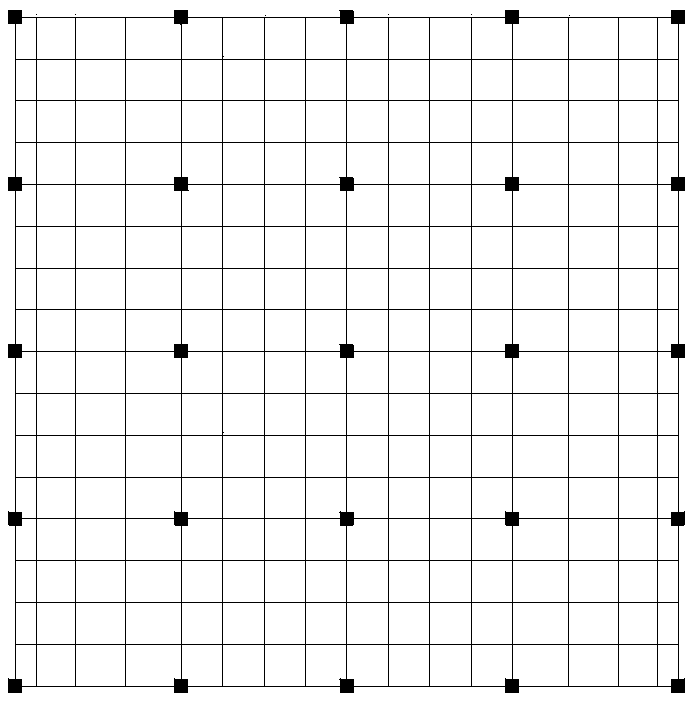

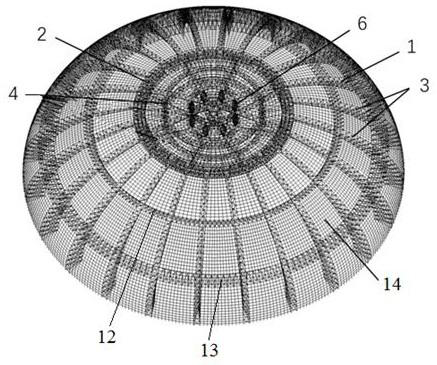

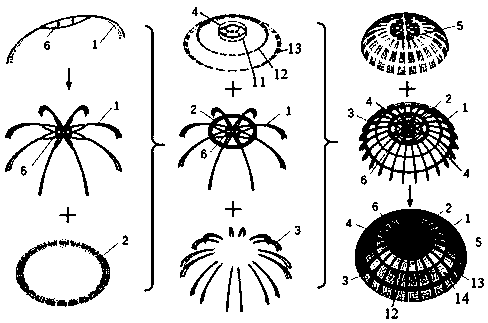

Combined-type cable dome structure for elliptic plane with unequal-height boundary

The invention discloses a combined-type cable dome structure for an elliptic plane with an unequal-height boundary. The combined-type cable dome structure comprises an outer-ring beam arranged on unequal-height capitals of a lower structure. The outer-ring beam adopts a space-curve form which changes along with the elevation of capitals of the lower structure. The horizontal projection of the outer-ring beam is ellipse. An inner-ring beam is arranged above the middle portion of the outer-ring beam. Inhaul cables and ridge cables are arranged on the outermost ring of the outer-ring beam and the inner-ring beam through a levy-type structure, and inhaul cables and ridge cables are arranged within the outermost ring through a Geiger-type structure. A connecting beam for a balancing cable is arranged on the inner-ring beam additionally, and the balancing cable is arranged between the inner-ring beam and the outer-ring beam additionally. The combined-type cable dome structure can be applied to a structural engineering of which unequal-height horizontal projection of the boundary is an ellipse plane, the structure is forced uniformly, and the stability is strong; node structure is simple, the manufacturing cost is low, and construction is convenient; laying requirements of rigid roofing material can be met.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

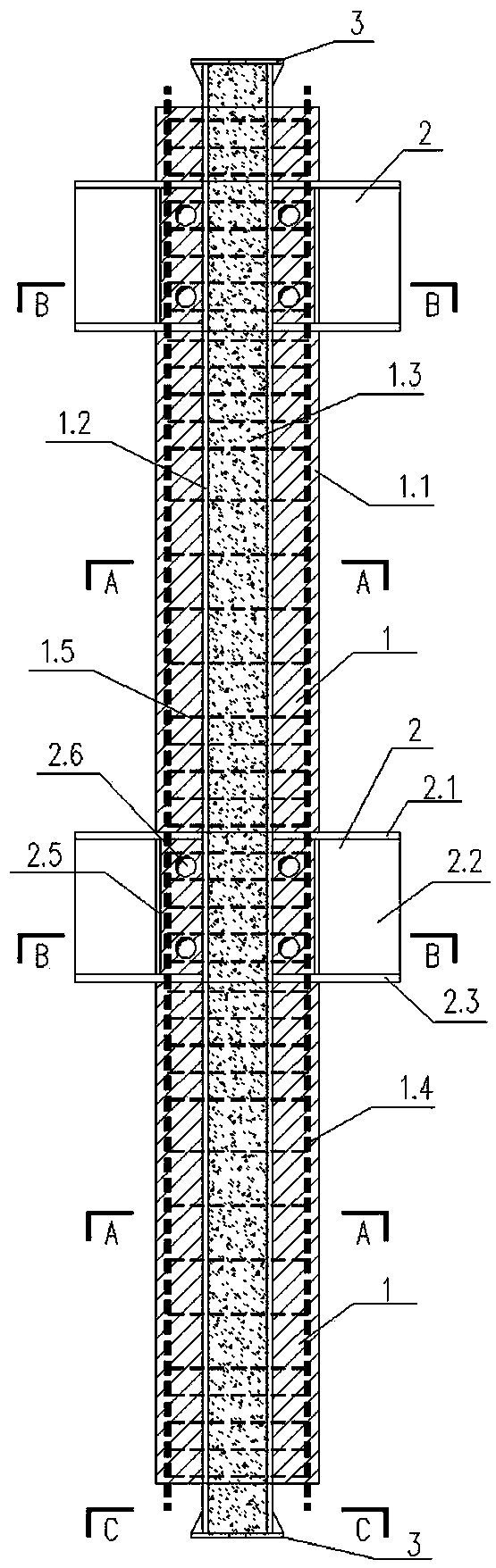

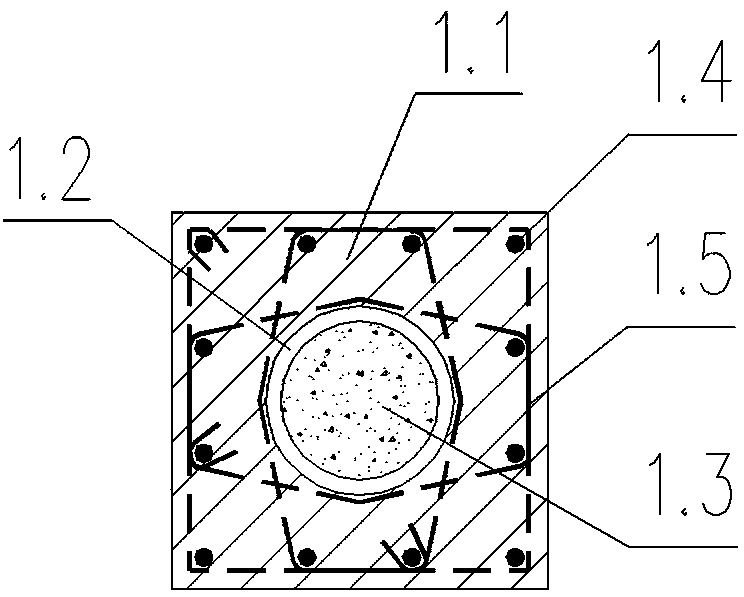

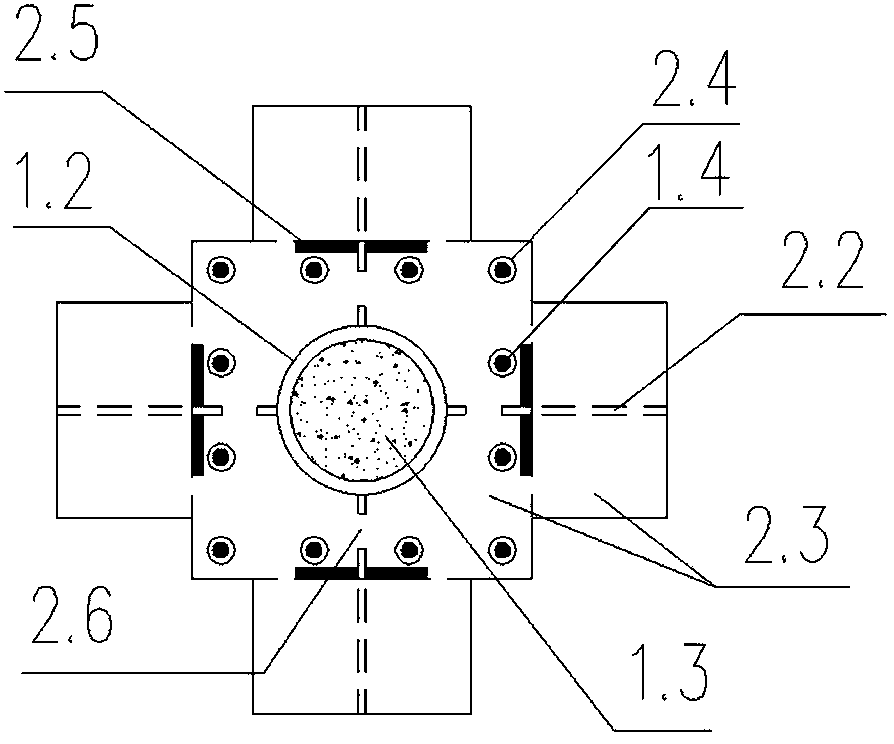

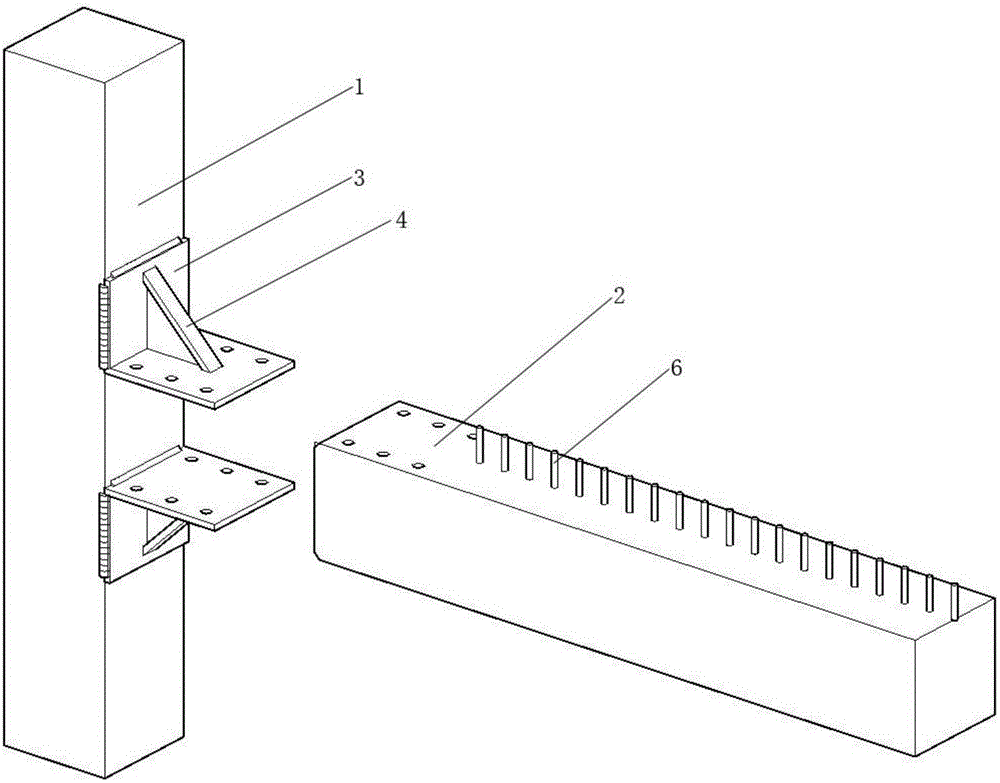

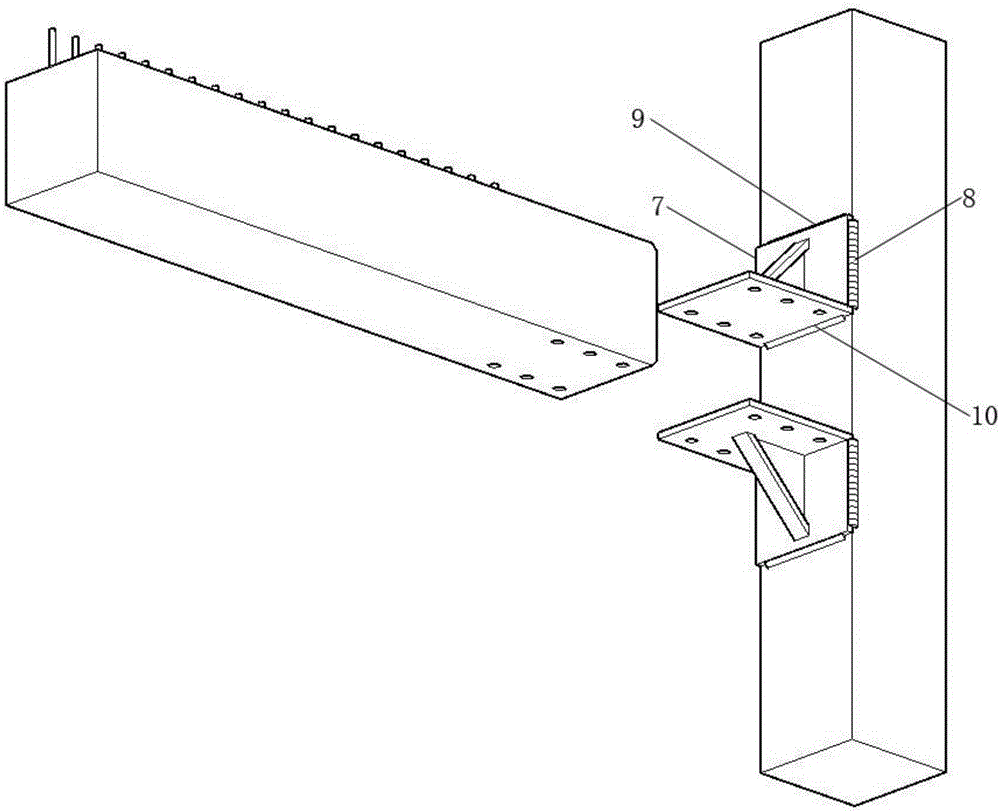

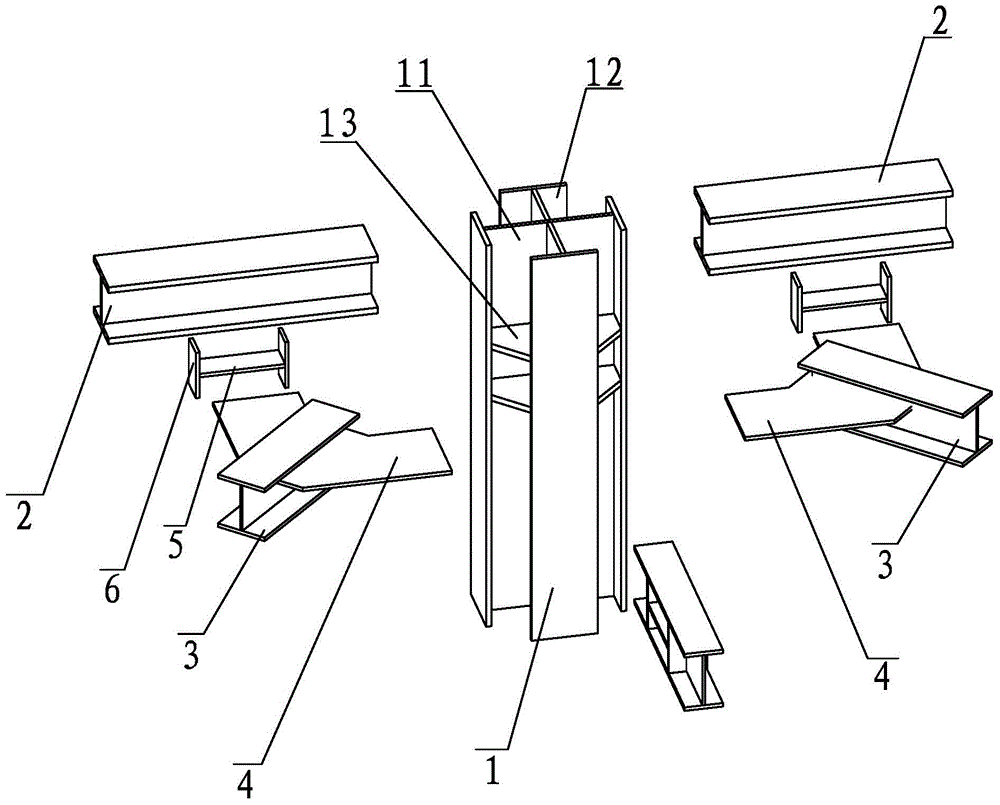

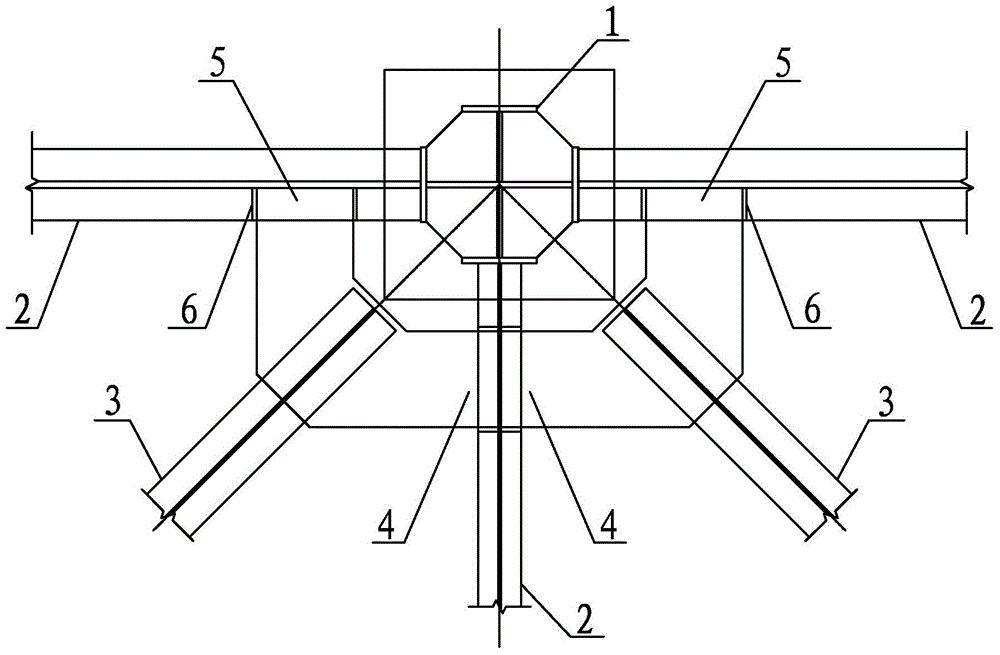

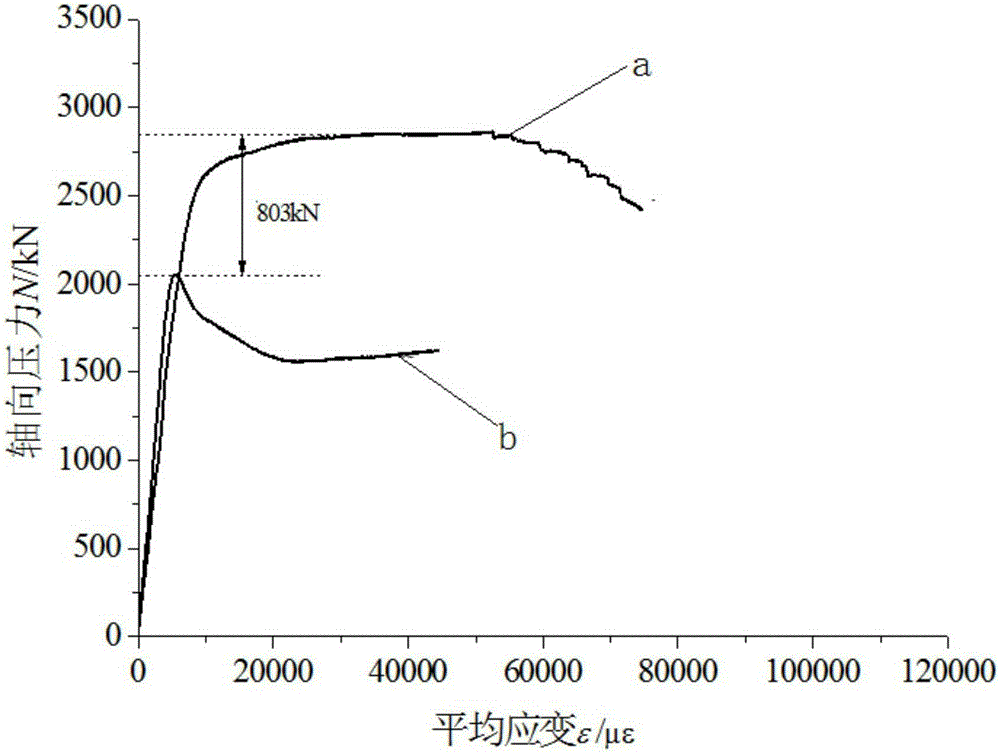

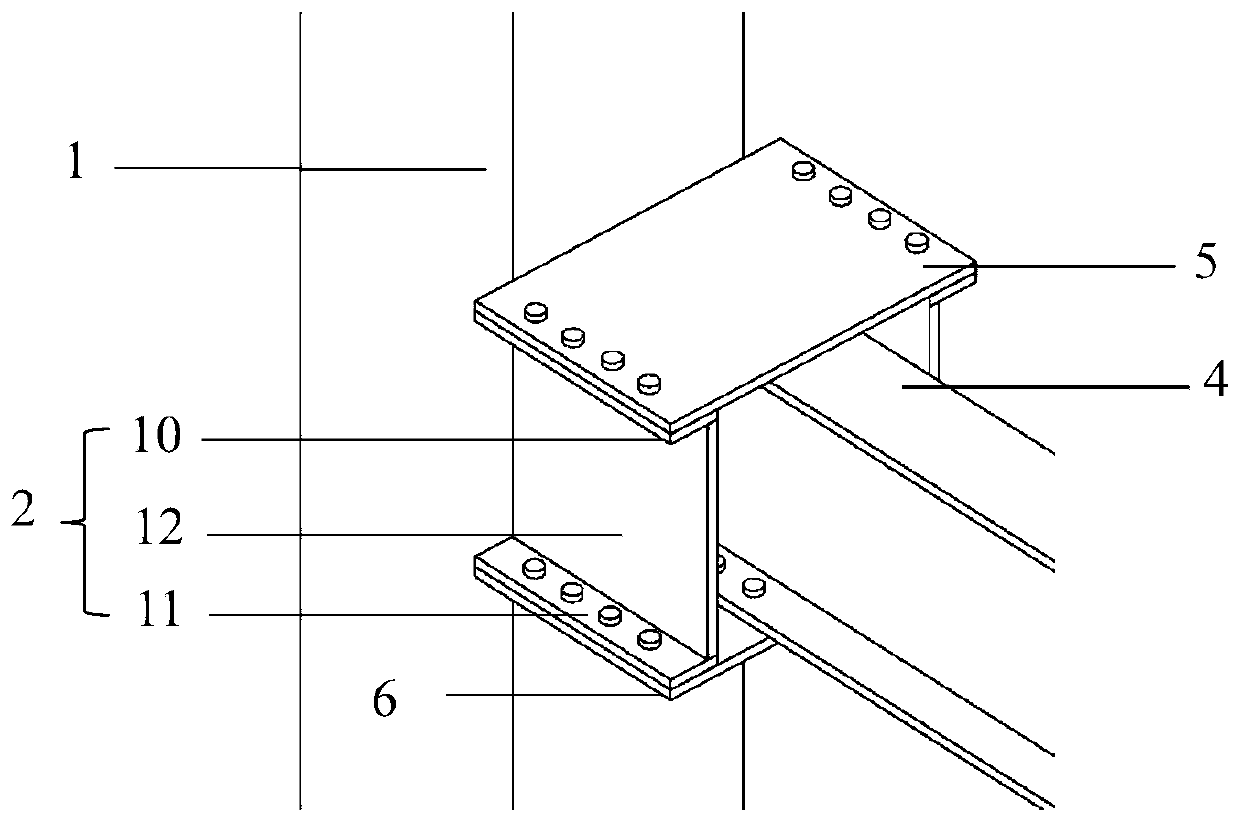

Fabricated frame strip steel bracket long column and construction method thereof

ActiveCN103556781AEasy to processEasy to installStrutsPillarsReinforced concrete columnEarthquake resistance

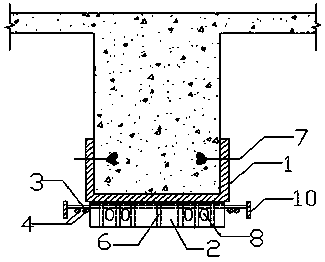

The invention discloses a fabricated frame strip steel bracket long column and a construction method of the fabricated frame strip steel bracket long column. The column body is a composite column consisting of three parts, namely steel pipe outer reinforced concrete, a steel pipe and steel pipe inner concrete; the steel pipe and the steel pipe inner concrete penetrate through the whole long column; the steel pipe inner concrete is subjected to primary prefabrication to form a steel pipe concrete column; concrete at a steel pipe outer joint or total concrete is poured in advance at the second time; a steel bracket is welded with the steel pipe. The long column has the advantages that 1, a multi-layer frame column is manufactured into a long column, the manufacture is simple, and the installation is convenient; 2, the column body is a composite column, the compression bearing capacity and shear capacity of the column are 2-4 times that of a reinforced concrete column with the same section, and the bearing capacity and anti-seismic property of the frame column are obviously improved; 3, the steel bracket is arranged and can be connected with a steel beam or a cast-in-place reinforcedconcrete beam, and the connection is convenient and reliable; and 4, high-strength concrete in the steel pipe is prefabricated in a factory, and the construction cost of the column is greatly reducedcompared with that of a conventional composite column. Therefore, the long column is suitable for various multi-story and high-rise prefabricated buildings and is wide in market prospects.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Fabricated recoverable-function steel frame-supporting system connected by prestressed joints

InactiveCN107386435APrevent bucklingGuaranteed continuityBuilding constructionsSupporting systemFloor slab

A fabricated recoverable-function steel frame-supporting system connected by prestressed joints is provided. The fabricated recoverable-function steel frame-supporting system connected by the prestressed joints comprises fabricated joints I, fabricated joints II, supporting structures and floor slabs, the fabricated joints I are fabricated prestressed column-column splicing joints and located in inflection points of columns, and the fabricated joints I comprise prestressed pull rod supporting plates, stiffening plates, half-welded lug plates, web splicing plates and prestressed pull rods; the fabricated joints II are fabricated prestressed beam-beam splicing joints and comprise cantilever beam section flange plates, middle beam section flange plates and rear-tensioning prestressed cables; the supporting structures are arranged between every two vertically adjacent steel beams in pairs, and each pair of the supporting structures comprises supporting rods, supporting rod sleeves, lower end connection pieces and upper end connecting pieces; and the floor slabs comprise three types of prefabricated concrete floor slabs, namely the I-type plate, the II-type plate and the III-type plate. According to the fabricated recoverable-function steel frame-supporting system connected by the prestressed joints, novel prestressed steel beam and steel column splicing joints are adopted, the fabricating efficiency of the structure of the fabricated recoverable-function steel frame-supporting system is improved, rapid construction is achieved, and rapid restoration and rapid rebuilding can be achieved after an earthquake.

Owner:HENAN UNIV OF SCI & TECH

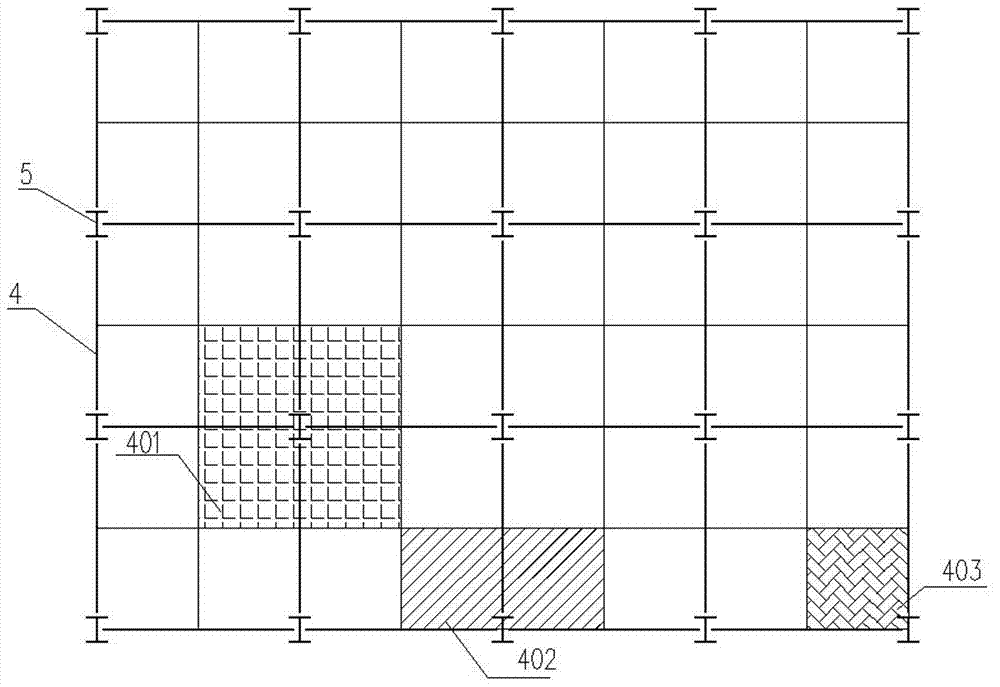

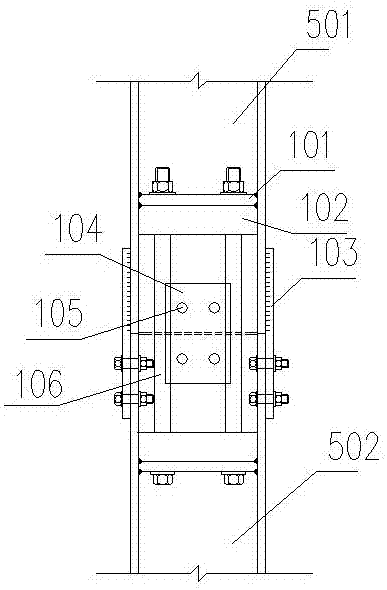

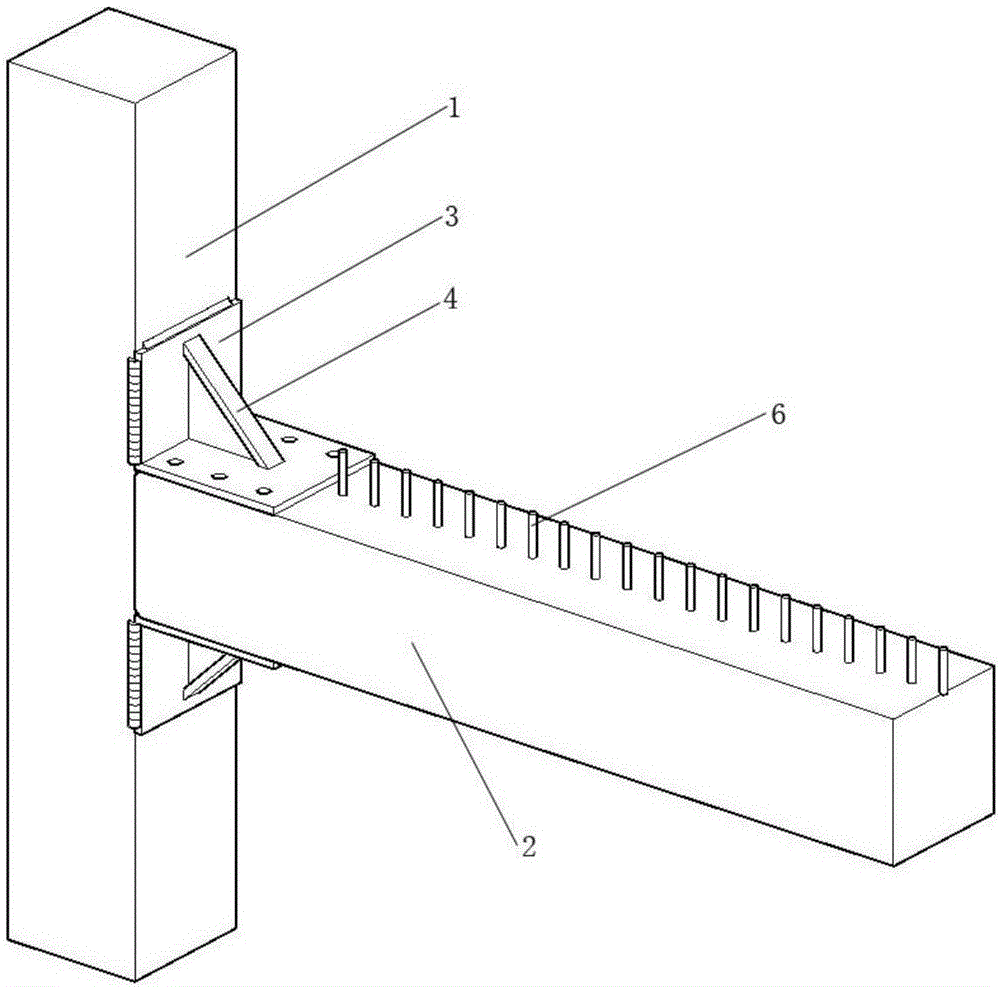

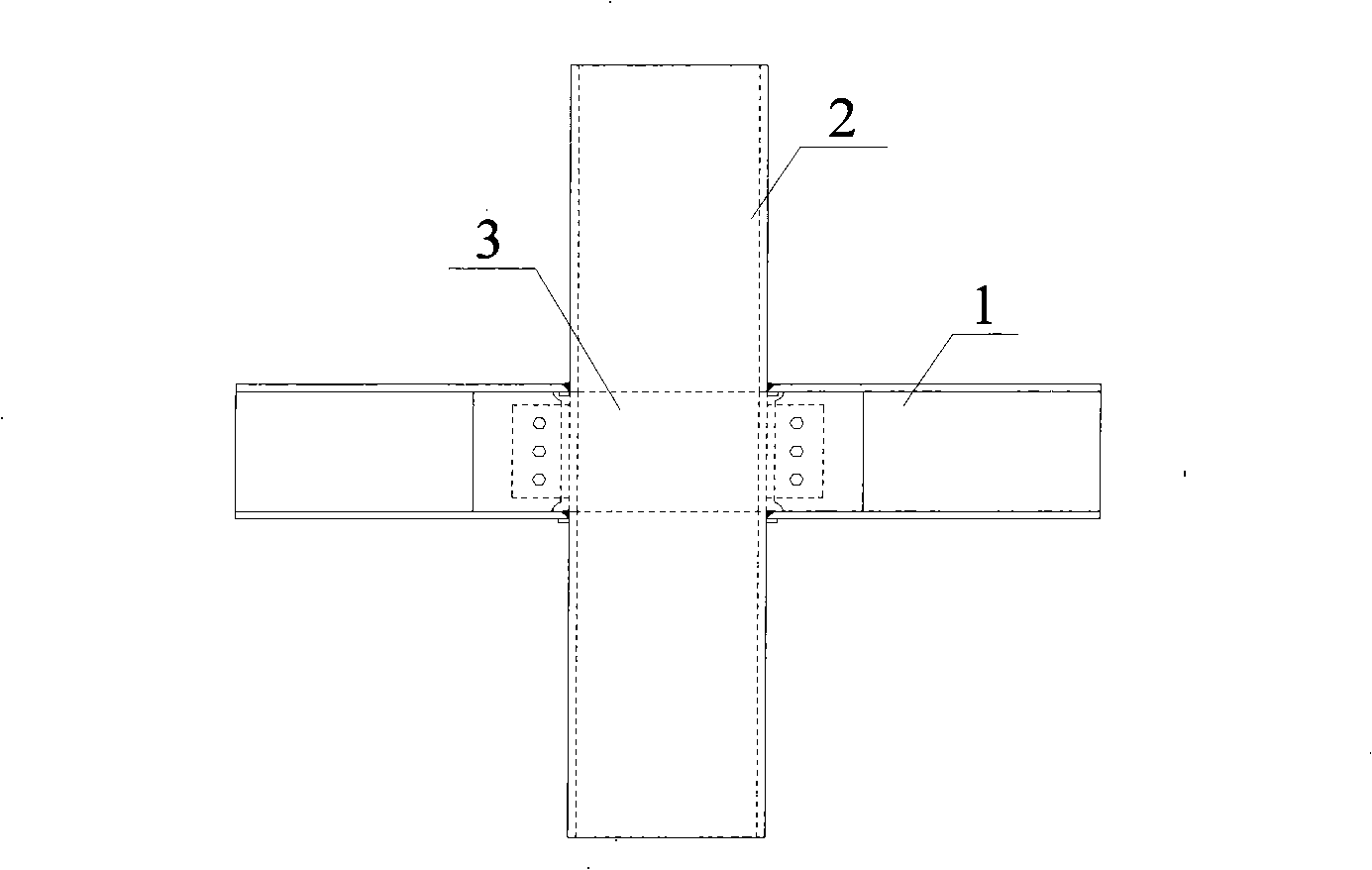

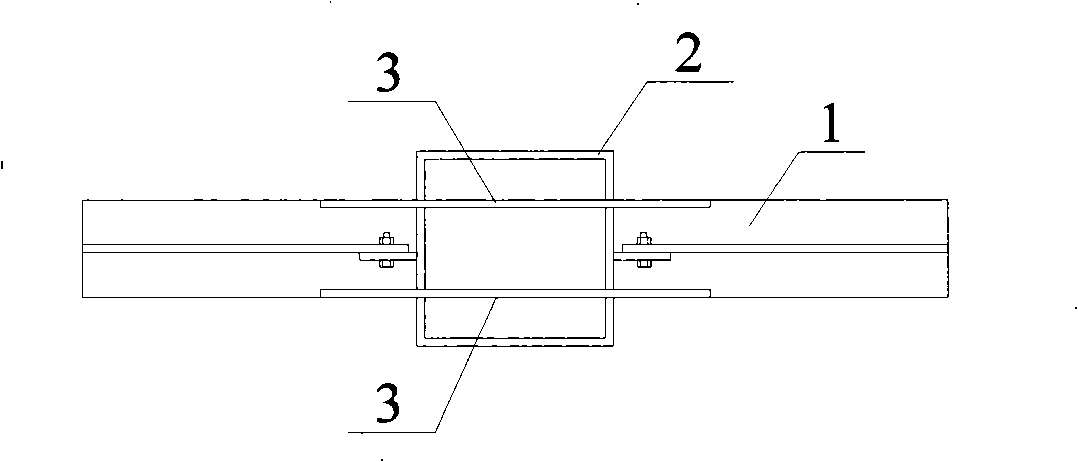

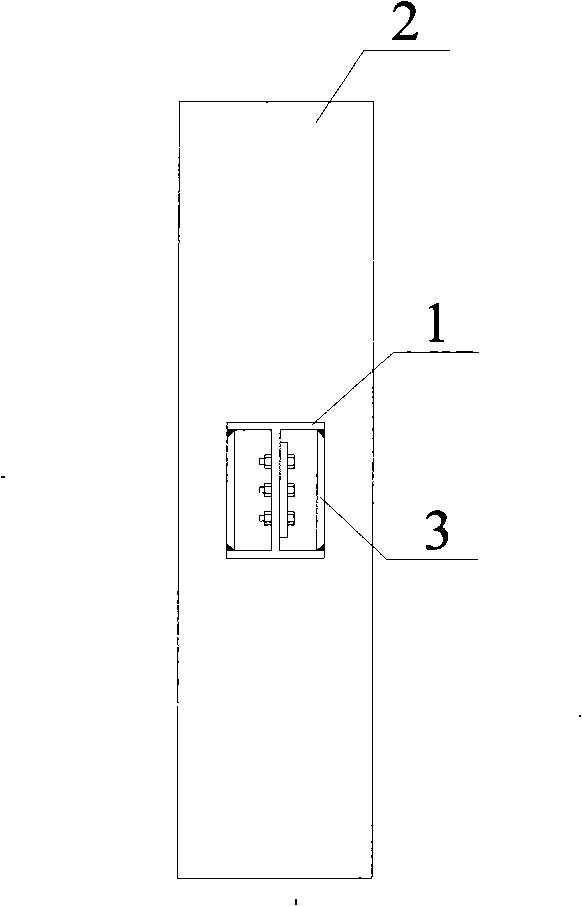

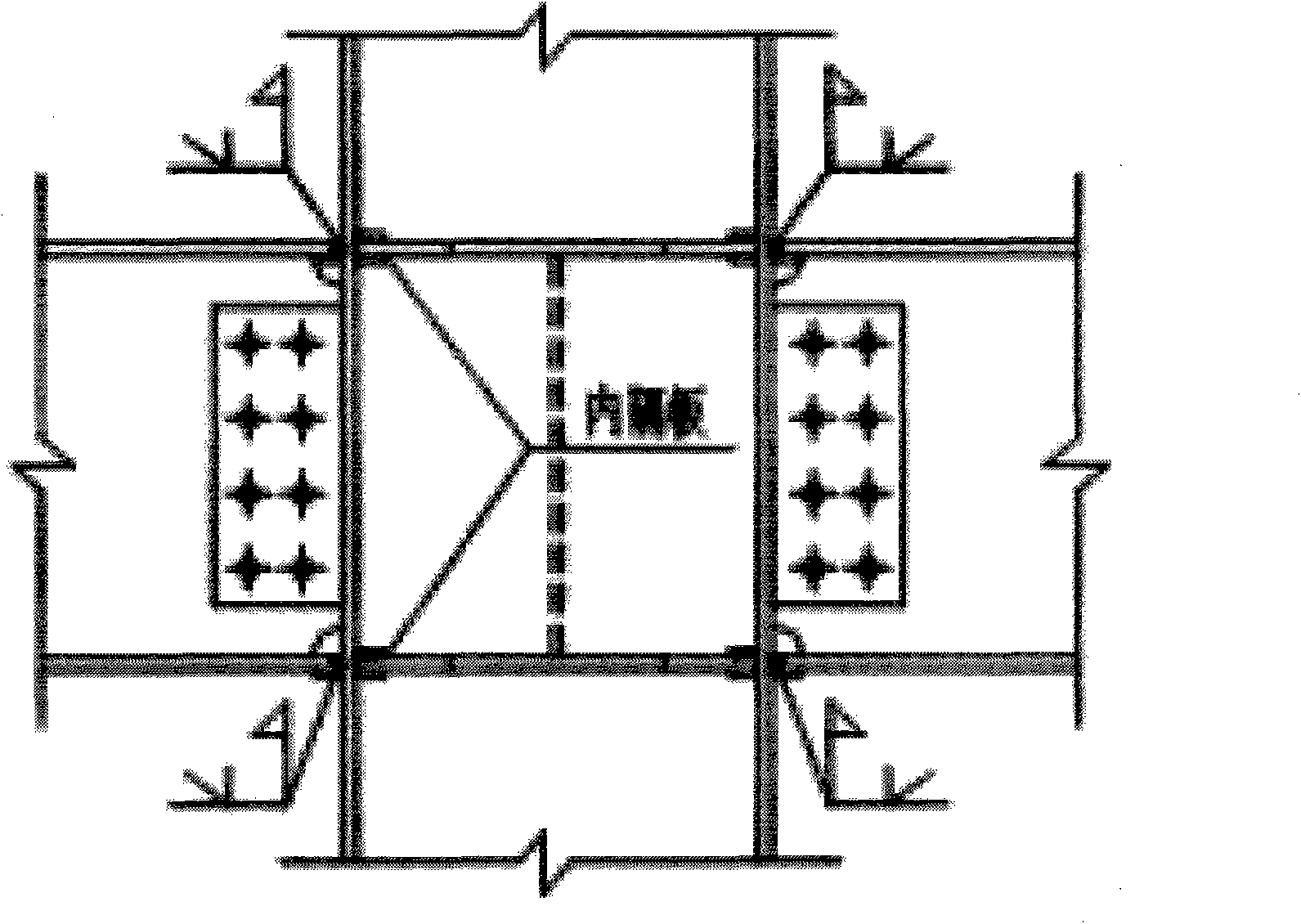

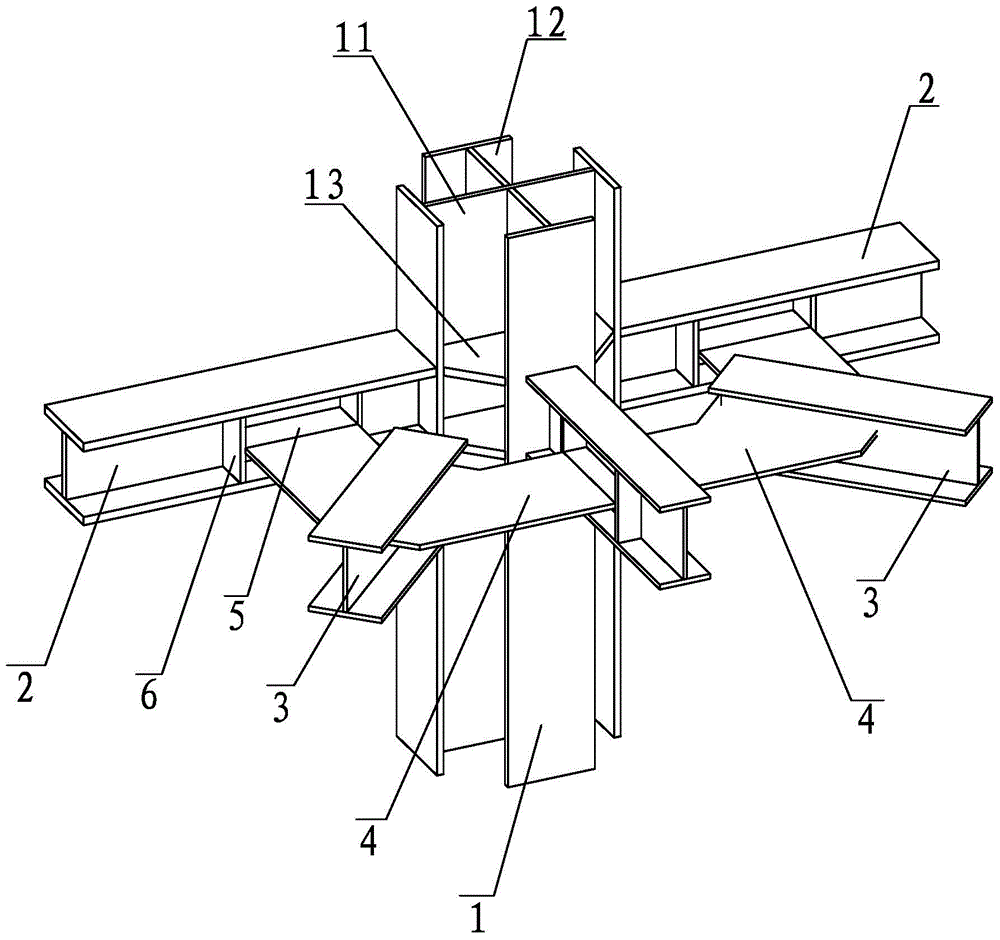

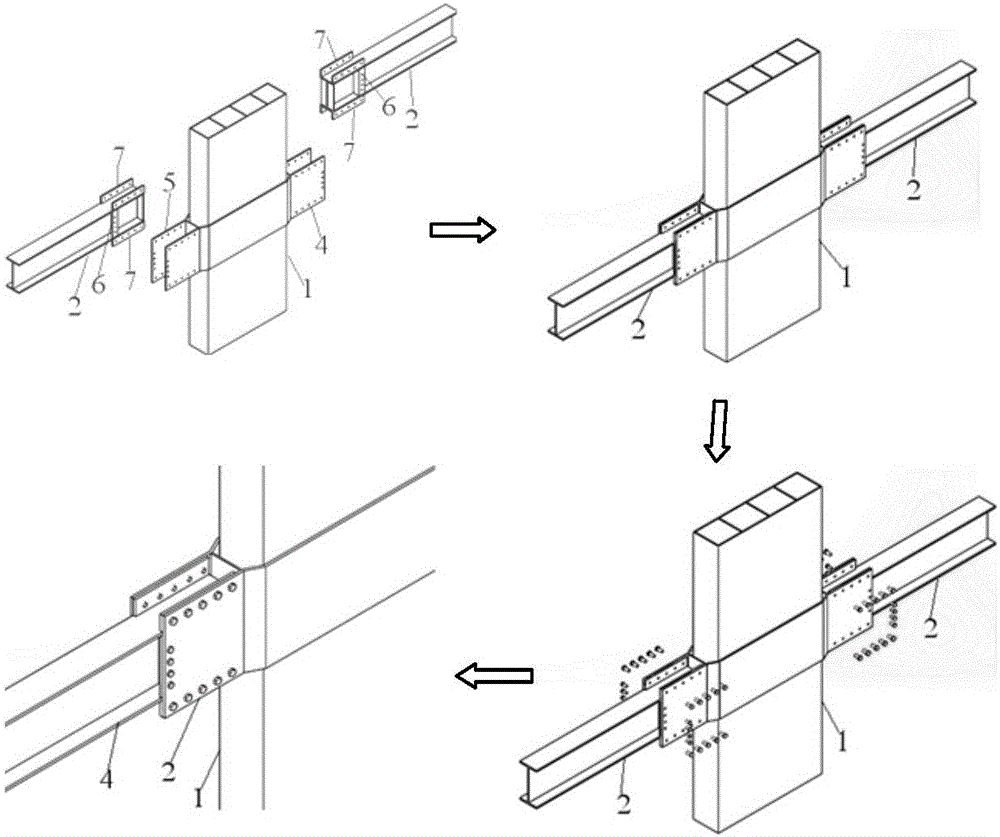

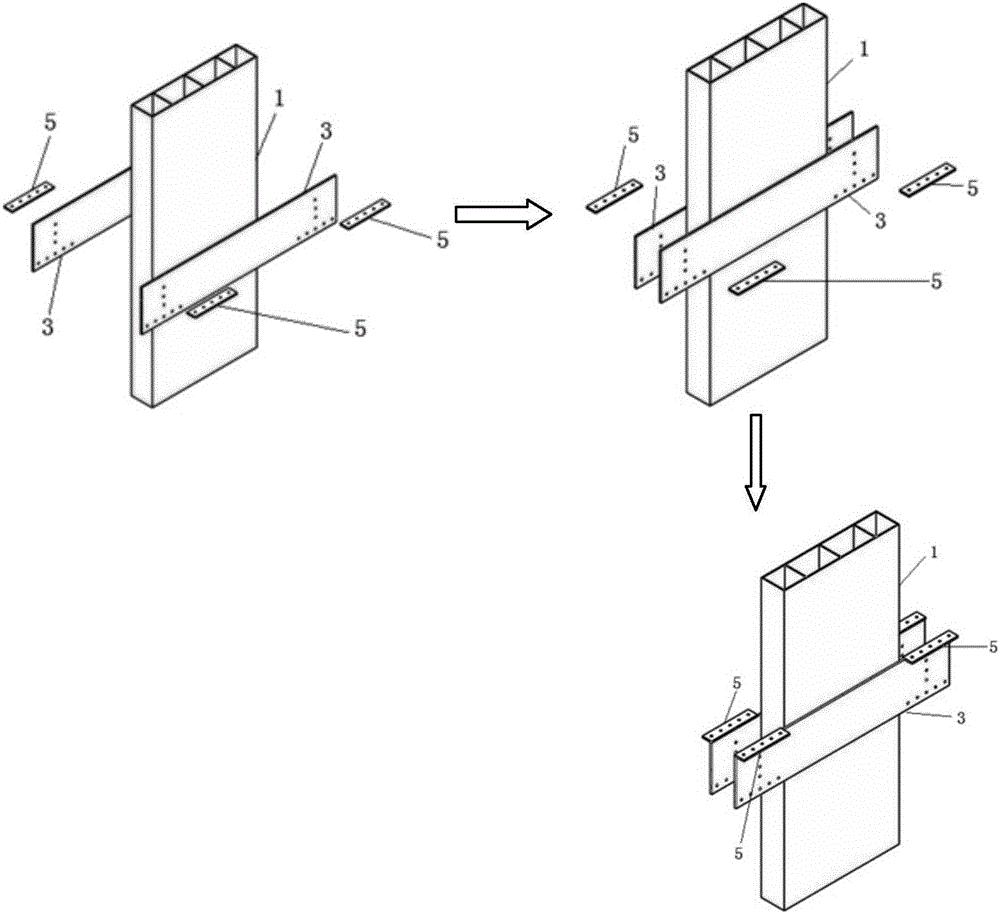

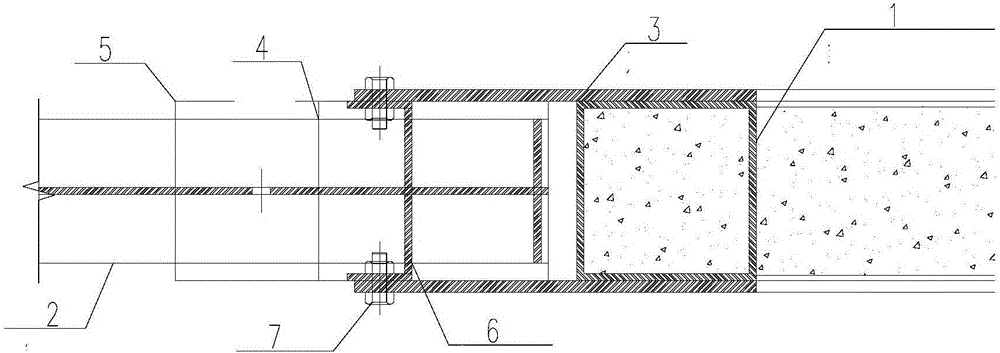

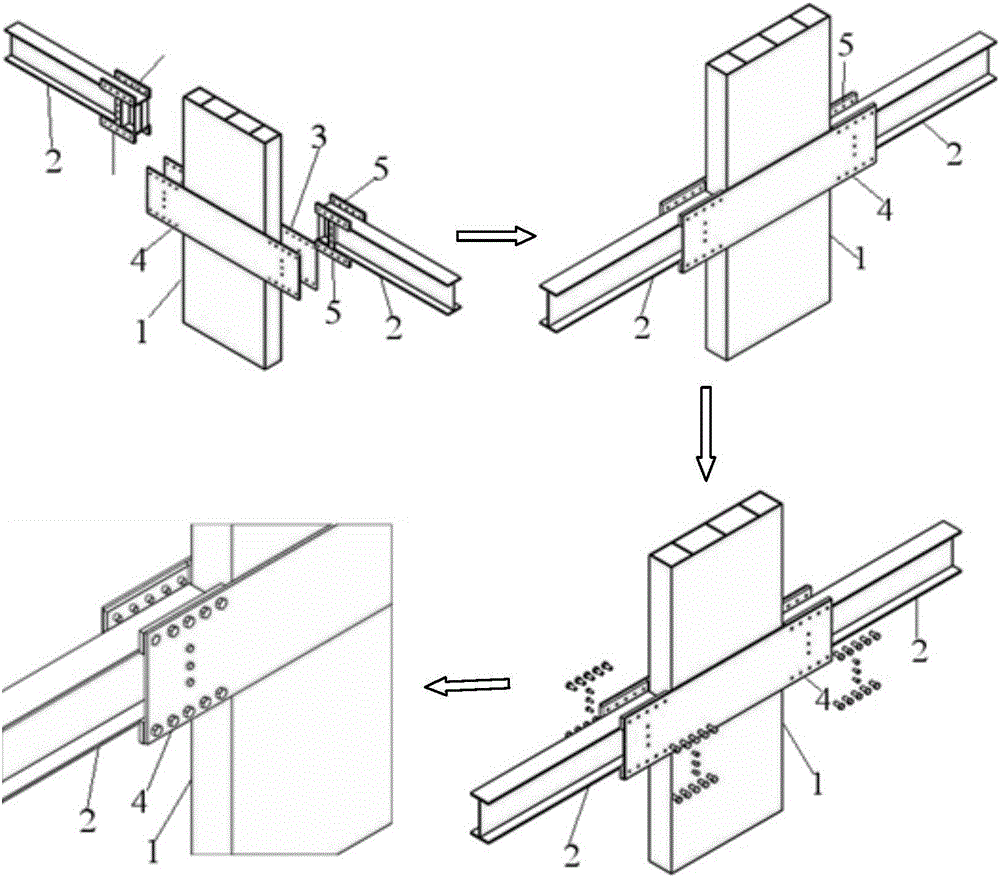

Connection node construction of concrete-filled square steel tube column and rectangular section steel beam

InactiveCN106703184ANode structure is simpleFlexible layoutBuilding constructionsLocal failureArchitectural engineering

The invention discloses a connection node construction of a concrete-filled square steel tube column and a rectangular section steel beam. The connection node construction is formed by the concrete-filled square steel tube column, the rectangular section steel beam, a right-angle connecting plate, a T-shaped triangle rib plate, a high-strength bolt, and a toggle pin on the top face of the steel beam. The connection node construction is simple, and the stress is clear. The amount of the steel for the connection node construction is less, and the connection node construction is only installed at one side of the column provided with the beam, so the composite cost is lower. The design of the beam column connection node is the ductile failure mode that the beam end is damaged by the tension, the obvious symptom and the duration time are existent before the damage, and the whole structure cannot be collapsed by the local failure. The connection of the steel beam and the concrete-filled steel tube column is firm, the integrality is good, the node rigidity is large, the assembly is simple and the construction period is short. New building rubbishes are not generated, and the requirements of housing industrialization and environmental protection are satisfied. The connection node construction is a novel node connection mode suitable for the connection of the current lower-layer and multi-layer light steel frame housing construction beam columns.

Owner:BEIJING UNIV OF TECH

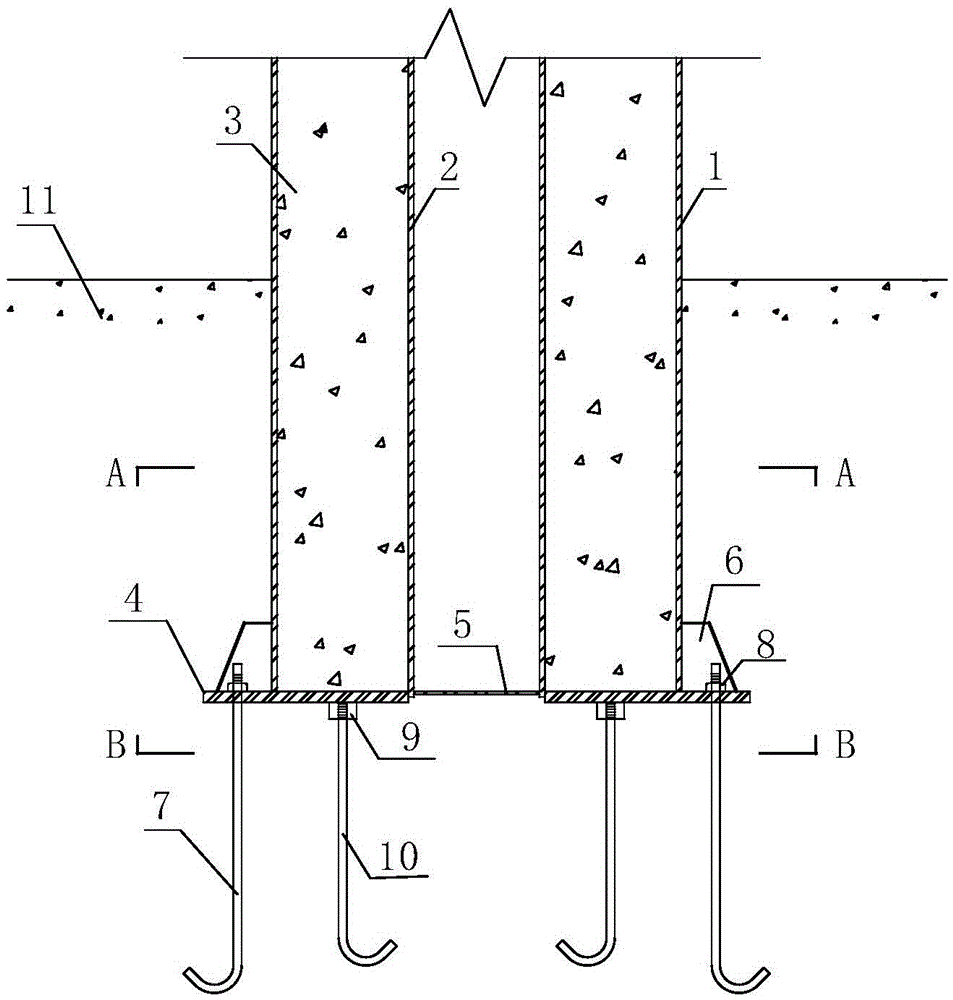

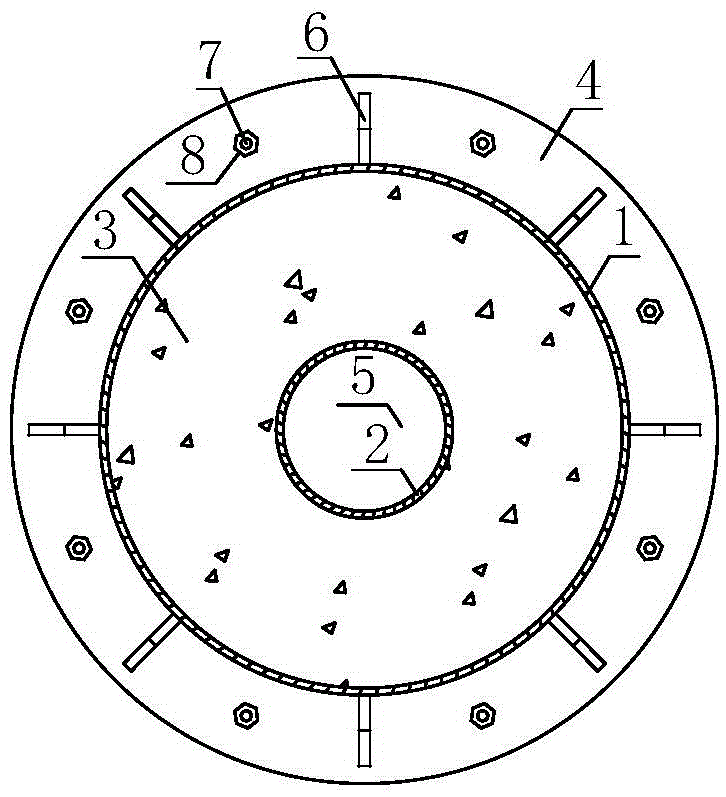

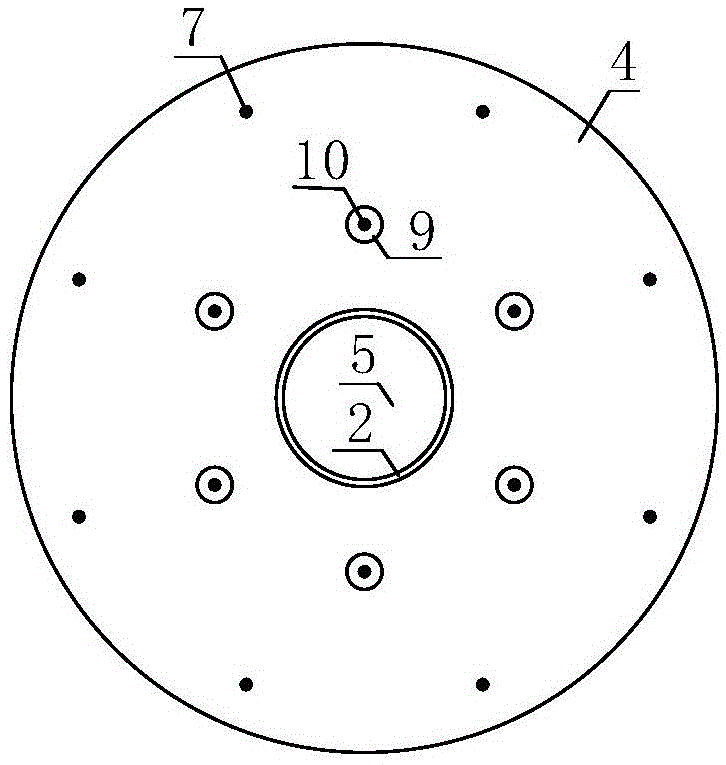

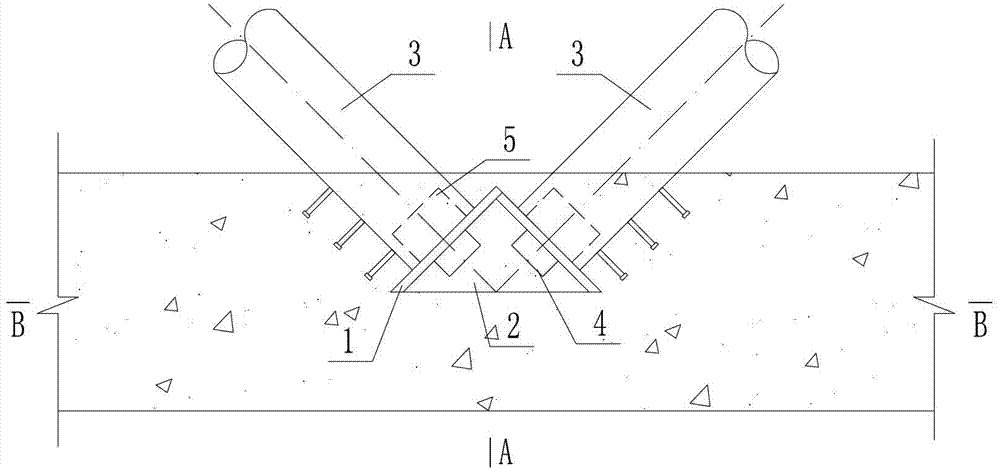

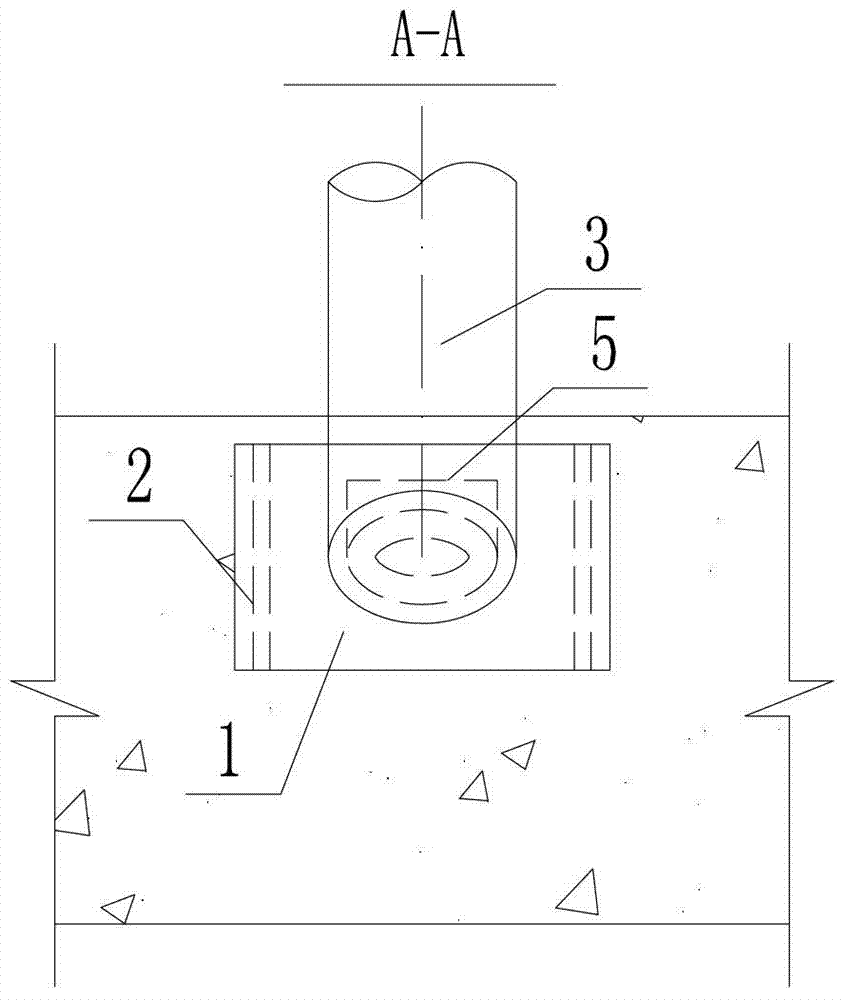

Hollow interlayer steel tube concrete column base joint

ActiveCN105569183AAvoid stress concentrationIncreased shear and pull-out capacityStrutsPillarsSteel tubeBending moment

The invention discloses a hollow interlayer steel tube concrete column base joint, and relates to the technical field of building and bridge engineering. Concrete is filled between an outer steel tube and an inner steel tube, so that a hollow interlayer concrete column is formed; the hollow interlayer concrete column is inserted into a foundation platform; the bottoms of the steel tubes are connected with a base board; rib plates are connected with the outer steel tube and the base board and are distributed on the periphery of the outer steel tube; a close plate is connected with the inner wall of the bottom of the inner steel tube; outer foundation bolts penetrate through an extend-out punching position of the base board and are distributed among the rib plates; the bottoms of the outer foundation bolts are bent outward; bottoms of inner outer foundation bolts are bent inward. The hollow interlayer steel tube concrete column base joint has the advantages that the foundation bolts are arranged inside and outside a column base, force at the upper part of a structure can be uniformly transferred to a foundation, and the phenomenon of stress concentration is avoided; the center of the base board is hollowed, so that a space for welding of the base board and the inner steel tube is formed; axial force transferred from the upper part of a column is directly transferred to the foundation through the base board, and a bending moment is transferred to the foundation platform through the base board and the foundation bolts; the combined action of the inner foundation bolts and the outer foundation bolts has good pulling resistance effect and shearing resistance effect.

Owner:BEIJING UNIV OF TECH

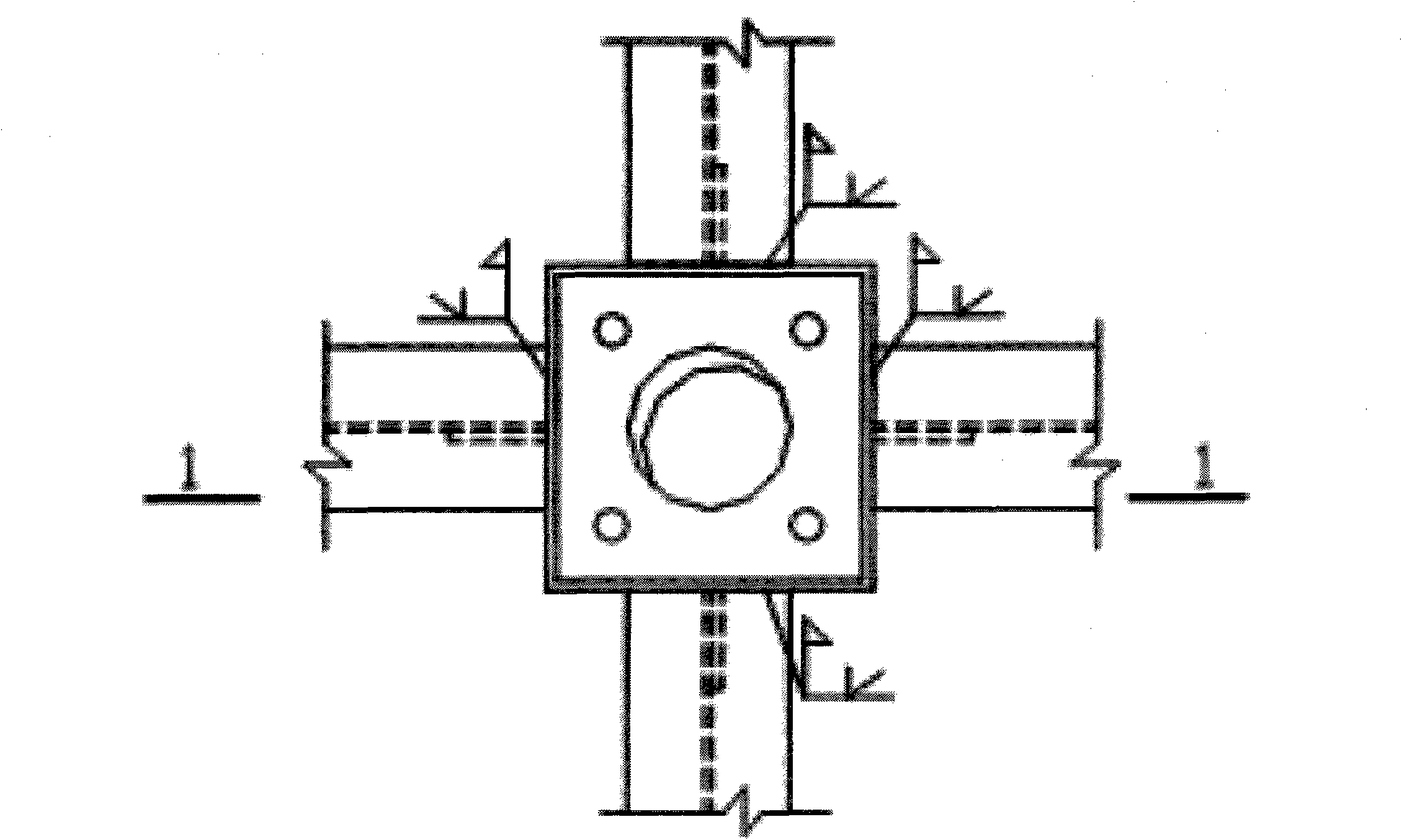

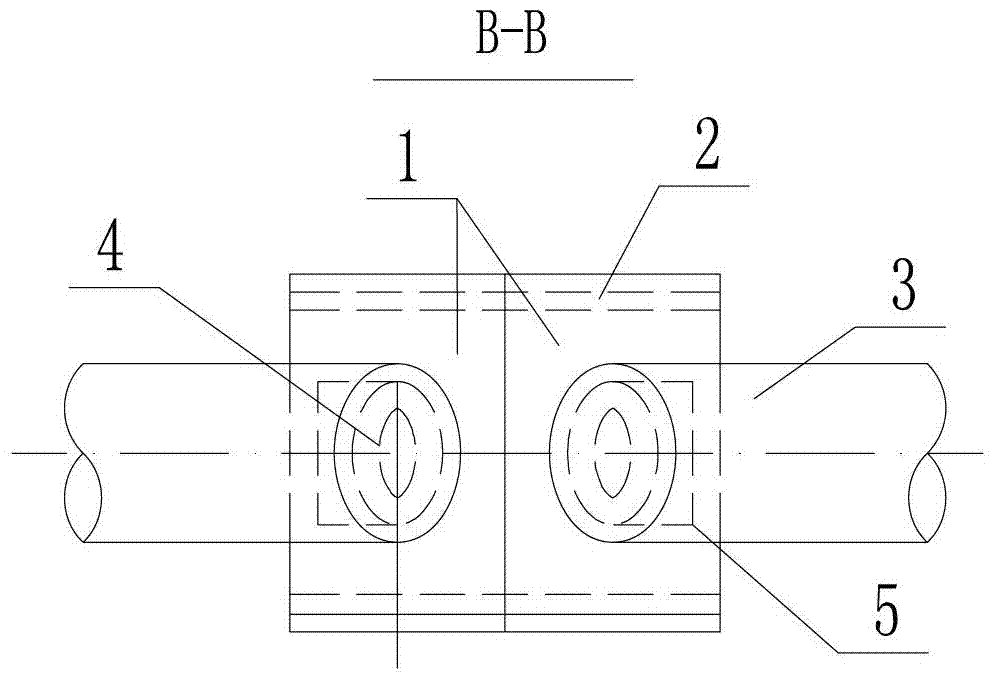

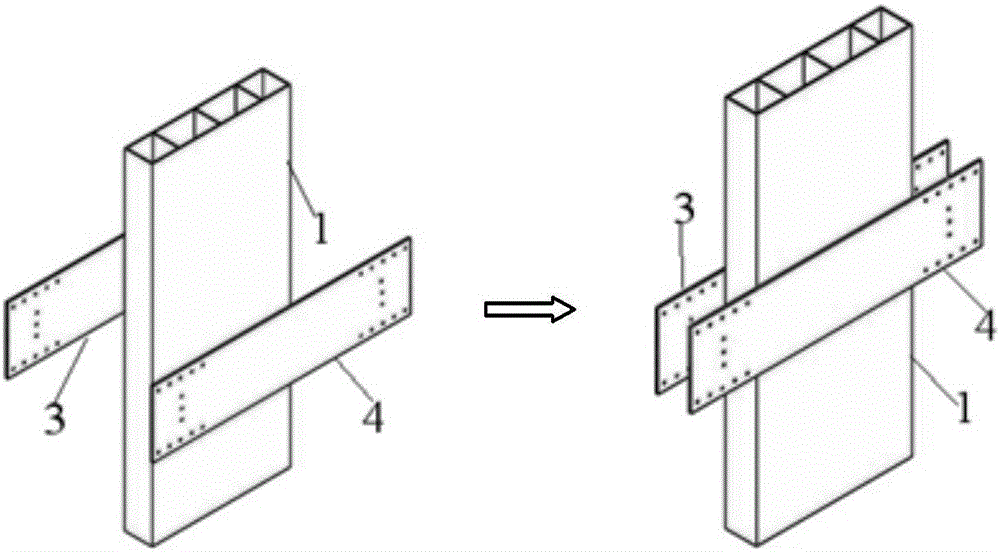

Run-through steel plate type square steel tube concrete column and axle i-beam node

InactiveCN101265724ASimple structure and processingSimple processing and structureBuilding constructionsSteel platesSteel tube

The invention relates to a square tube concrete column and an I-shaped steel beam joint of threading steel plate type in the technology field of construction engineering, and comprises the square tube concrete column, the I-shaped steel beam joint and the threading steel plate. The threading steel plate threads through the wallboard of the square tube concrete column wall plate. The threading steel plate is arranged in a vertical placement manner in the square tube concrete column, in parallel to and with the same height of the web plate of the I-shaped steel beam. A part of the threading steel plate edge protruding from the square tube concrete column is parallel and level with the I-shaped steel beam flange. The invention enhances the total bearing capacity of shearing resistance and bending resistance, and guarantees the joint work of the square tube concrete column and the I-shaped steel beam joint.

Owner:SHANGHAI JIAO TONG UNIV

Rectangular pipe column and H-shaped steel beam vertical externally-connected rigidly-connected joint

InactiveCN101949173AThe force is clear and reasonableIncrease stiffnessBuilding constructionsArchitectural engineeringShock resistance

The invention discloses a rectangular pipe column and H-shaped steel beam vertical externally-connected rigidly-connected joint aiming to solve the problems of complex manufacturing process, long construction period, and the like in the prior art. The rectangular pipe column and H-shaped steel beam vertical externally-connected rigidly-connected joint comprises a rectangular pipe column and an H-shaped steel beam, wherein a corbel box-shaped corbel connecting member is arranged between the rectangular pipe column and the H-shaped steel beam; the box-shaped corbel connecting member comprises an upper end plate, a lower end plate and a vertical plate, wherein the vertical plate is arranged between the upper end plate and the lower end plate, one sides of the upper end plate and the lower end plate are arranged on the side surface of the rectangular pipe column, and one sides opposite to the sides and the vertical plate are respectively connected with a top flange, a bottom flange and a ventral shield of the H-shaped steel beam. The invention has the advantages of completing the internal force transmission of the joint by the arrangement of the box-shaped corbel connecting piece, preventing the stress of a welding line from centralizing, enhancing the shock resistance and the bending resistance of the joint, realizing batch production, enhancing processing efficiency, simplifyingthe process, enhancing welding quality, reducing construction difficulty and being convenient for transportation and building space arrangement, solving the problem of difficult welding of a partition board in the rectangular pipe column, achieving the combination of industrialized flow line production and field fast assembly and splicing and shortening the building construction period.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

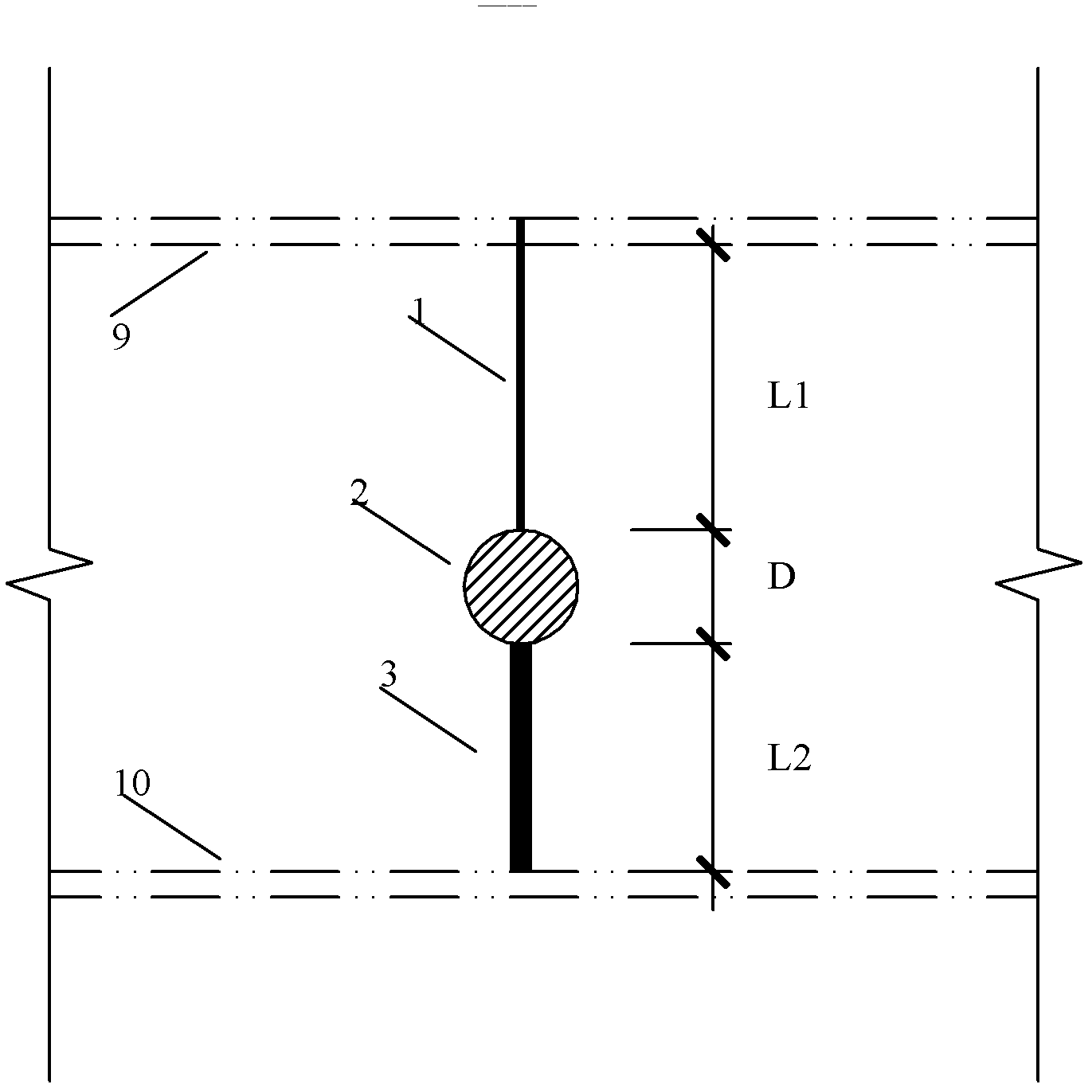

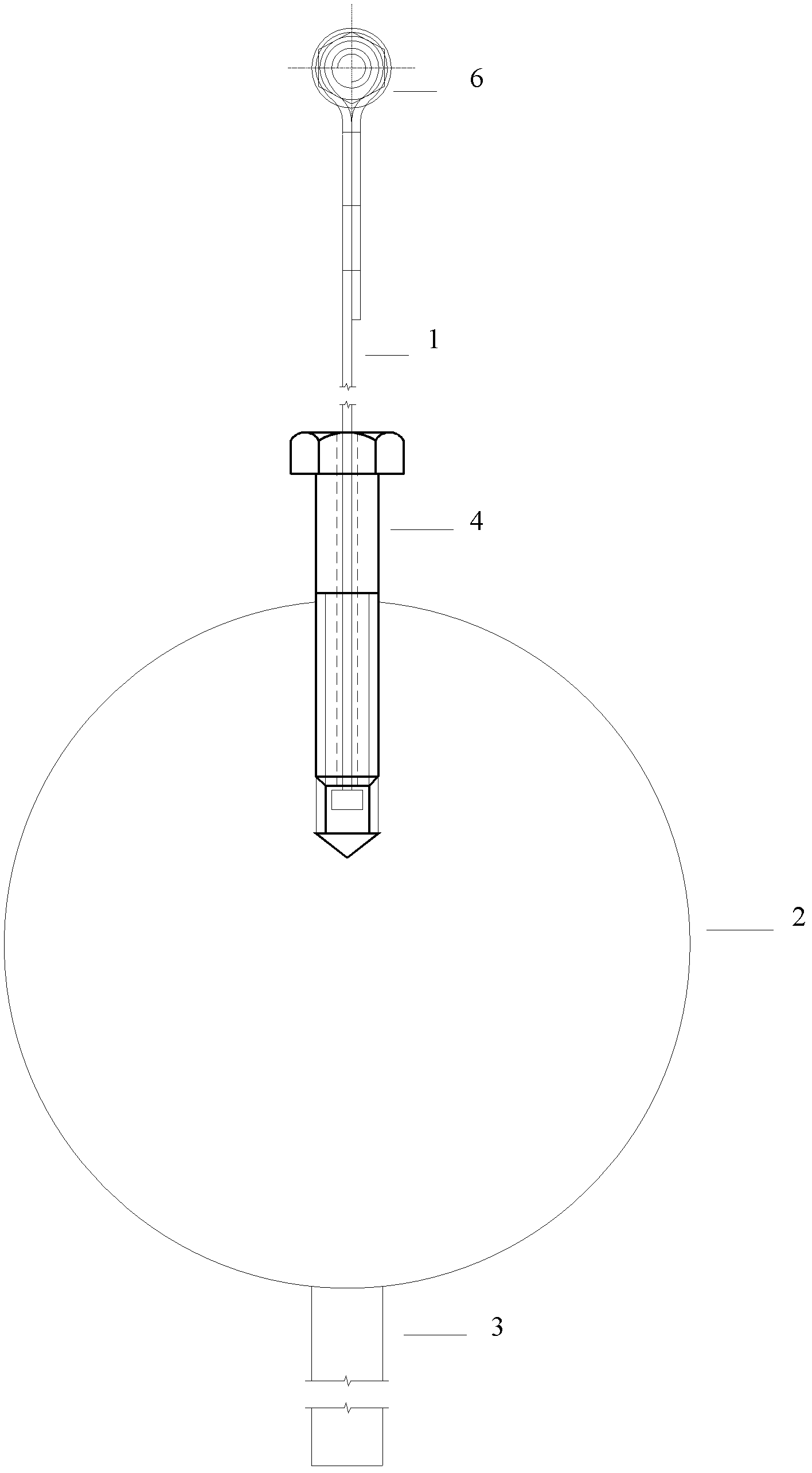

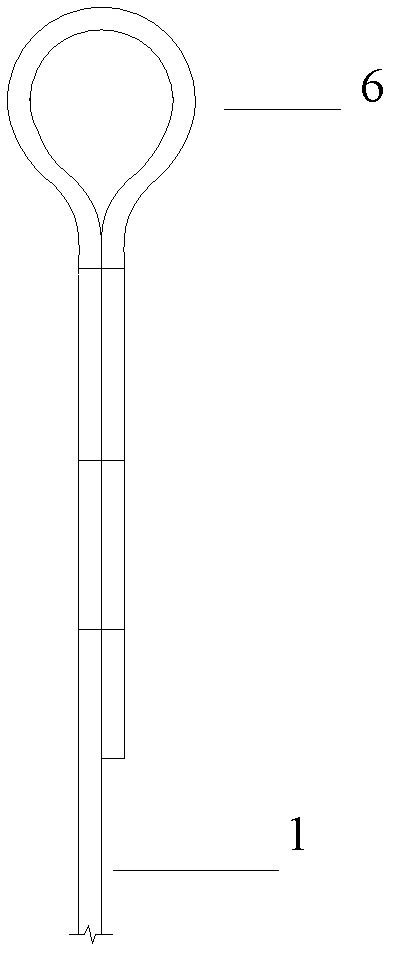

Vibration absorber for cycloid type wind driven generator tower

InactiveCN102444684AImprove shock absorptionEasy to cycle adjustmentFinal product manufactureMachines/enginesWind drivenSnubber

The invention discloses a vibration absorber for a cycloid type wind driven generator tower. The vibration absorber comprises a mass block and a steel wire rope, wherein a rubber rod is connected on the mass block; a connector is sleeved on the steel wire rope; one end of the steel wire rope is connected with a steel wire rope expansion head, and the other end of the steel wire rope is provided with a connecting installation hole; and the connector and the mass block are in a threaded connection. The damper absorbs the structure vibration energy by the swinging of the mass block, and simultaneously dissipates the energy through the axial deformation of a connected rubber spring. The movement direction of a mass cycloid is reverse to that of the structure for the action of dynamically damping; one end of the rubber spring is fixed on the mass block, and the deformation is controlled by the mass block to provide a force which is always reverse to the movement direction of the mass block, and the axial deformation of the rubber spring will have the function of consuming energy. The vibration absorber is simple to design and manufacture, convenient to install and change, has stable hysteretic characteristic, relatively low manufacture cost, and is applied to the structure for remarkably absorbing vibration.

Owner:江苏宇杰钢机有限公司 +1

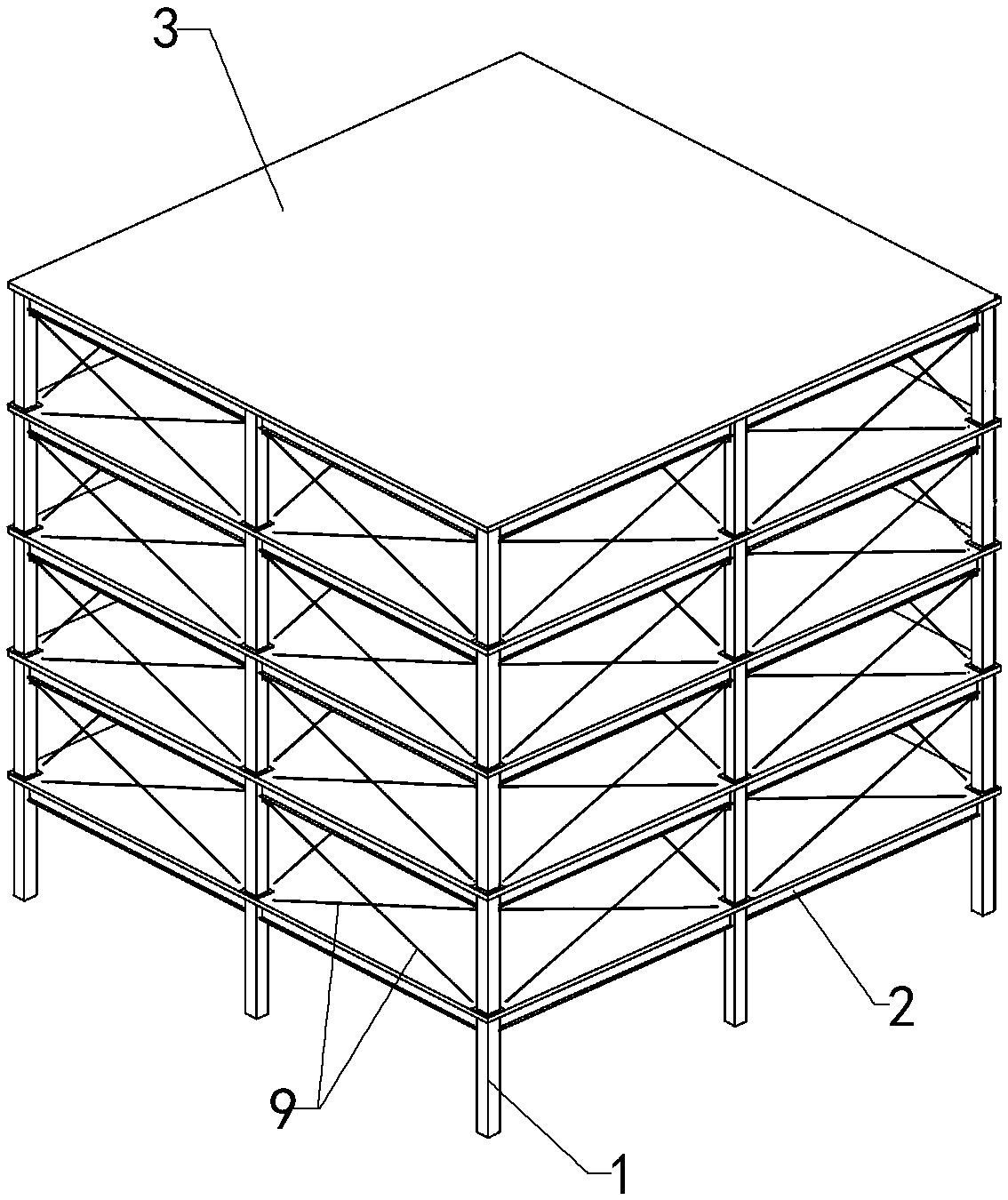

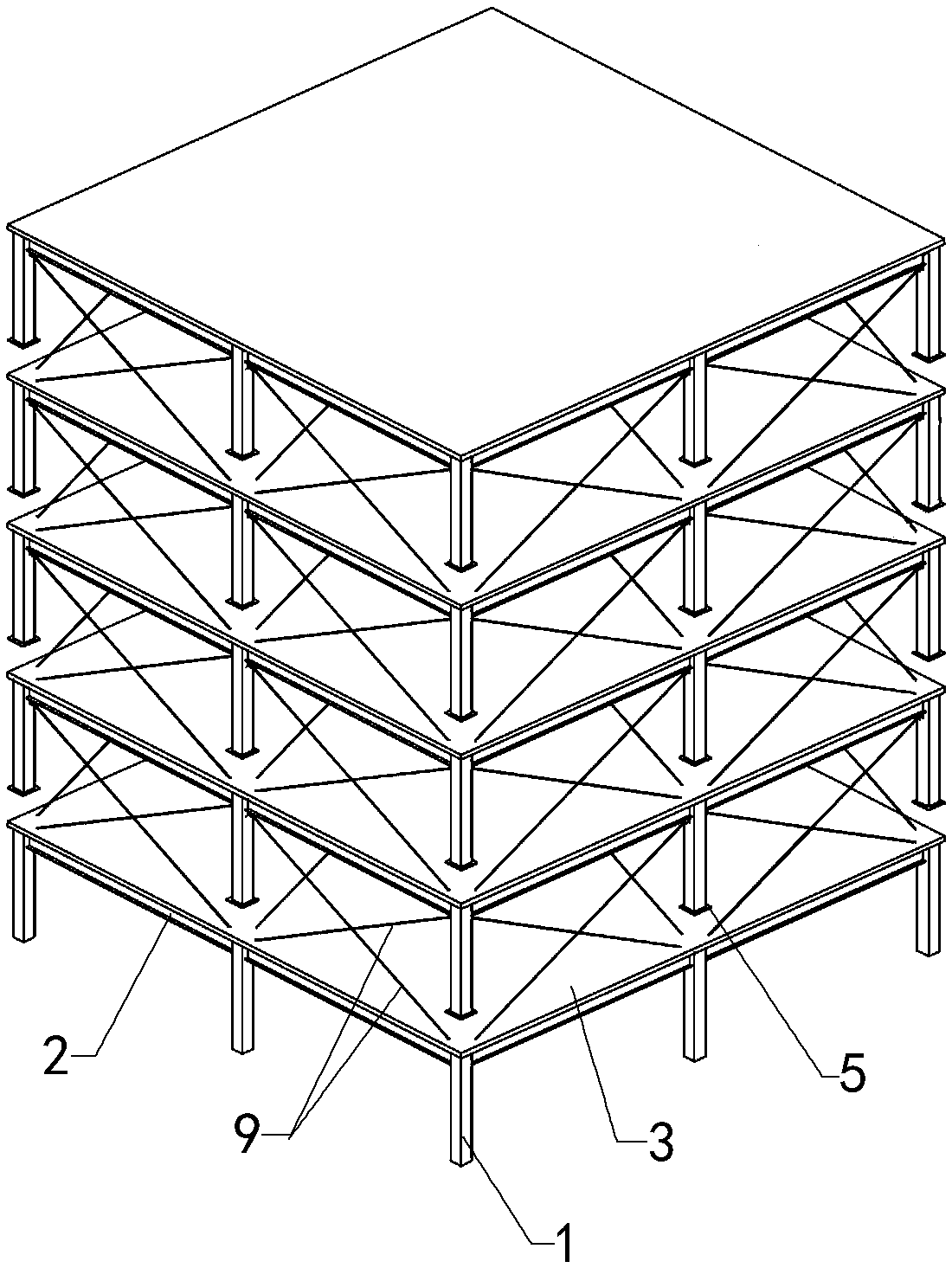

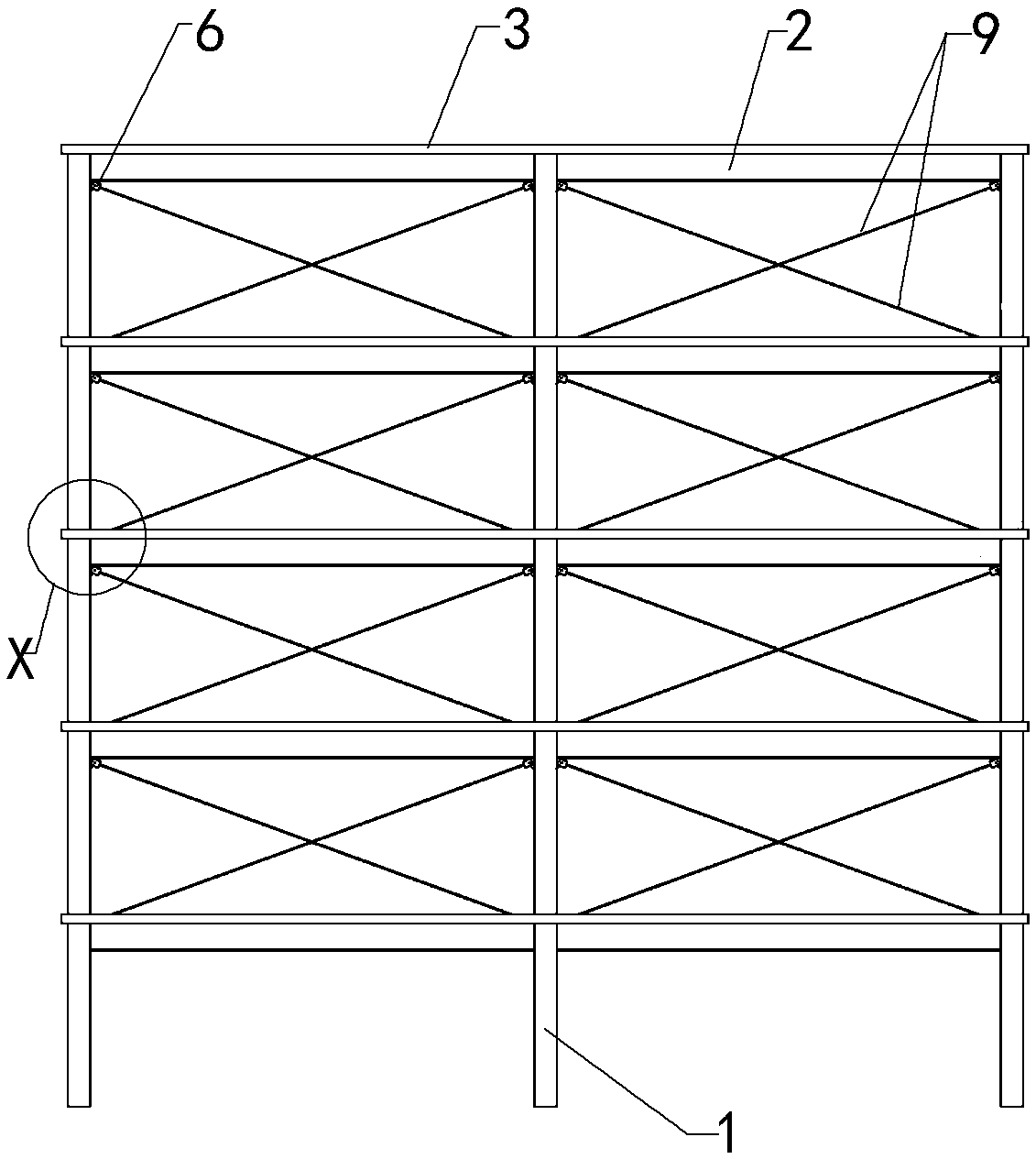

Prestressed support friction damping assembled steel structure system and design method thereof

ActiveCN110528679ANo pollution in the processImprove construction efficiencyProtective buildings/sheltersSpecial data processing applicationsPre stressEngineering

The invention relates to the technical field of structural engineering, and discloses a prestressed support friction damping assembled steel structure system and a design method. The system is formedby stacking layered frame structures up and down, each layered frame structure includes steel columns, steel beams and floor plates, the steel columns between the upper and lower adjacent layered frame structures are disconnected at the connection positions of the floor plates on the lower layer, connection through self friction is achieved, and meanwhile, high-strength cables are connected between the adjacent layered frame structures; and the top ends of the steel columns are provided with upper flange plates so as to be fixedly connected to the steel beams, the bottom ends of the steel columns are provided with lower flange plates, the lower flange plates are in contact with the upper surfaces of the floor plates of the adjacent layered frame structure on the lower layer, the upper surfaces of the floor plates are provided with friction coating layers and limiting devices, and the limiting devices are steel plate strips arranged along the edges of the floor plates. By means of the system, the layers are connected through the high-strength cables and the mutual friction between the columns, construction is convenient and efficient to achieve, and the stress performance is good.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

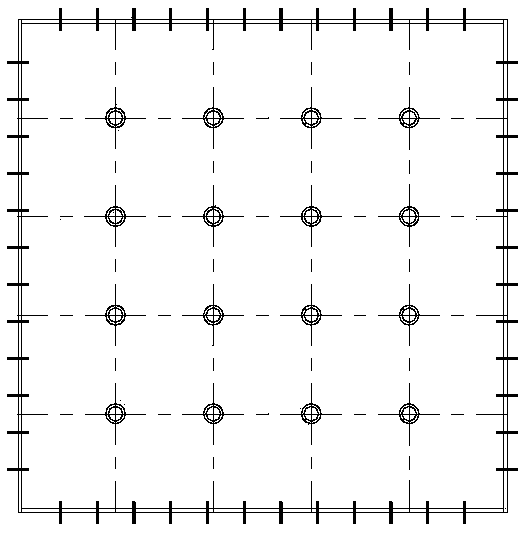

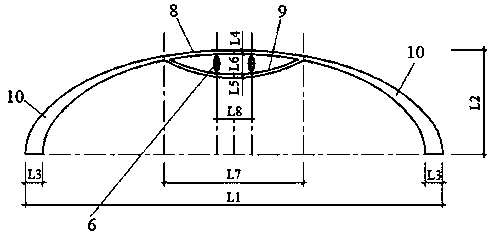

Open type super-long-span cable dome structure

The invention discloses an open type super-long-span cable dome structure. The structure is composed of an internal truss ring, an external pressure ring beam and a cable-strut system; the cable-strutsystem comprises a ring cable, supporting rods, an inner ring cable system and an outer ring cable system; the internal truss ring, the ring cable and the external pressure ring beam are coaxially arranged from inside to outside; the supporting rods are uniformly arranged in the circumferential direction and supported on the ring cable, and the supporting rods and the ring cable are crossed at the lower joints of the supporting rods. The inner ring cable system comprises inner ridge cables and inner stay cables, wherein the two ends of each inner ridge cable are connected with the internal truss ring and the corresponding supporting rod respectively, and the two ends of each inner stay cable are connected with the internal truss ring and the corresponding supporting rod respectively. Theouter ring cable system comprises outer ridge cables and outer stay cables, wherein the two ends of each outer ridge cable are connected with the corresponding supporting rod and the external pressurering beam respectively, and the two ends of each outer stay cable are connected with the corresponding supporting rod and the external pressure ring beam respectively. By means of the open type super-long-span cable dome structure, the defect that a lattice shell structure and a cantilever truss structure have many rods is overcome, and meanwhile, the problems that a cable net structure is largein supporting stress and the like are avoided, so that the structure is uniform in rigidity, and the joint construction is relatively simple. Meanwhile, a closed type cable dome is changed into the open type cable dome so that the cable dome, namely the integral tension self-balanced structure system, can be applied in a building roof structure of a stadium.

Owner:TIANJIN UNIV

Connecting joint non-orthogonal to cross column and construction method

InactiveCN105220767AReduce the number of weldsReduce welding difficultyBuilding constructionsRebarNon orthogonal

The invention belongs to the field of steel structures, and particularly relates to a connecting joint non-orthogonal to a cross column and a construction method. The connecting joint non-orthogonal to the cross column comprises the cross column and steel brackets, wherein the steel brackets are welded to a peripheral surface of the cross column in an orthogonal mode; an annular connecting plate is fixedly welded between the adjacent steel brackets; and a horizontal component is fixedly welded on the annular connecting plate. Problems that connecting plates and stiffening ribs which correspond to a non-orthogonal component in a cross column are welded difficultly, weld joints are overlapped, rebars penetrate in steel plates, field construction positioning precision is difficult to control and the like are solved, after certain modification, various stress requirements can be met, a large amount of costs can be saved, and manufacturing and mounting efficiency is improved.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

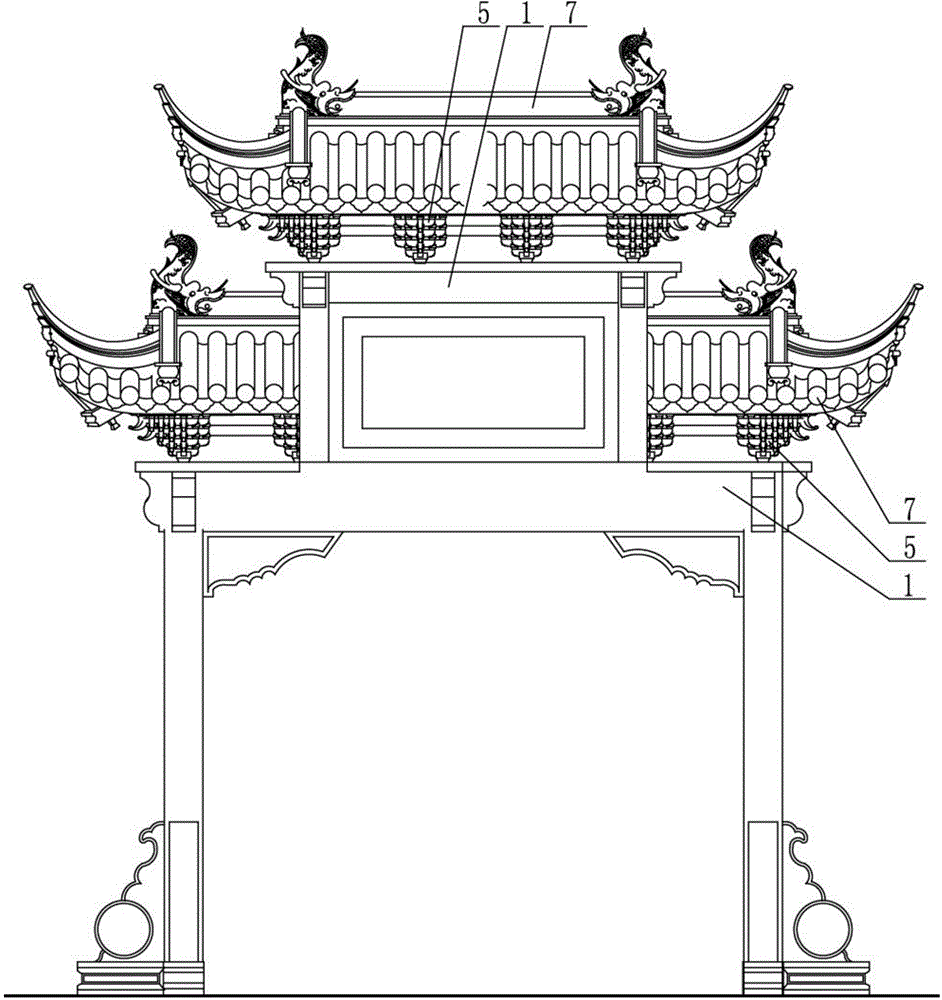

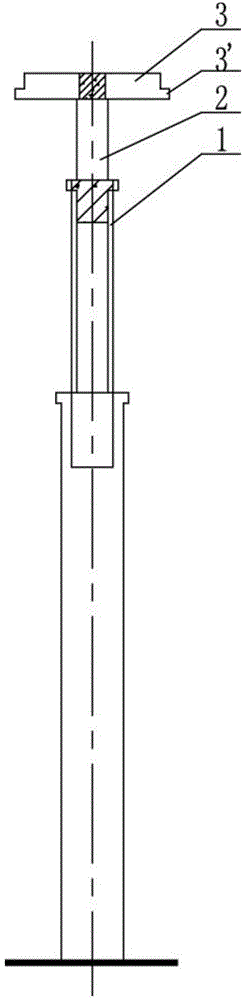

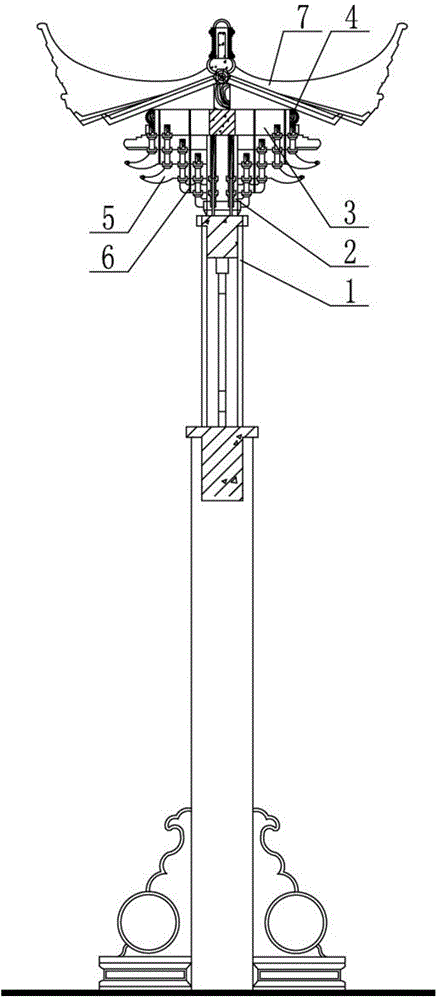

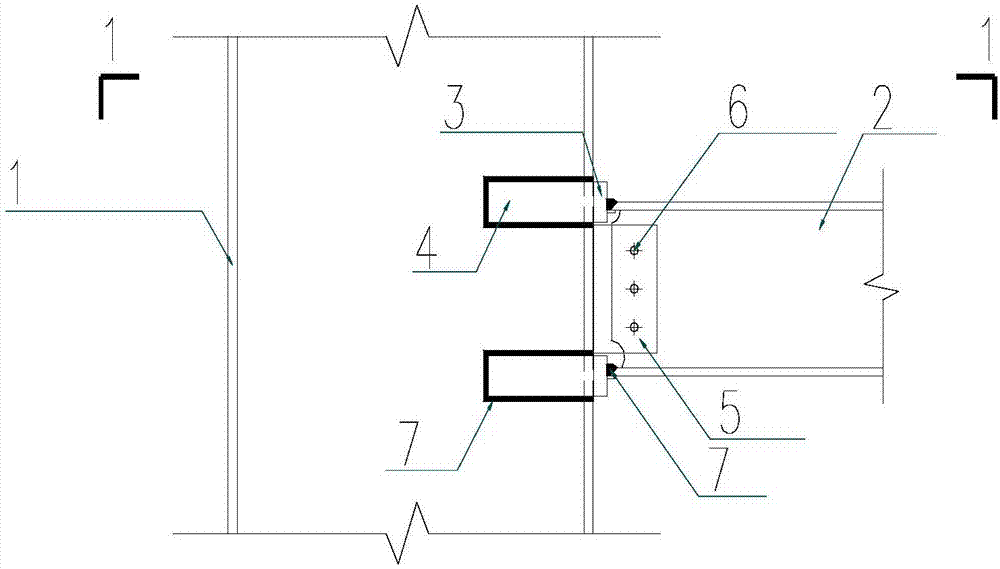

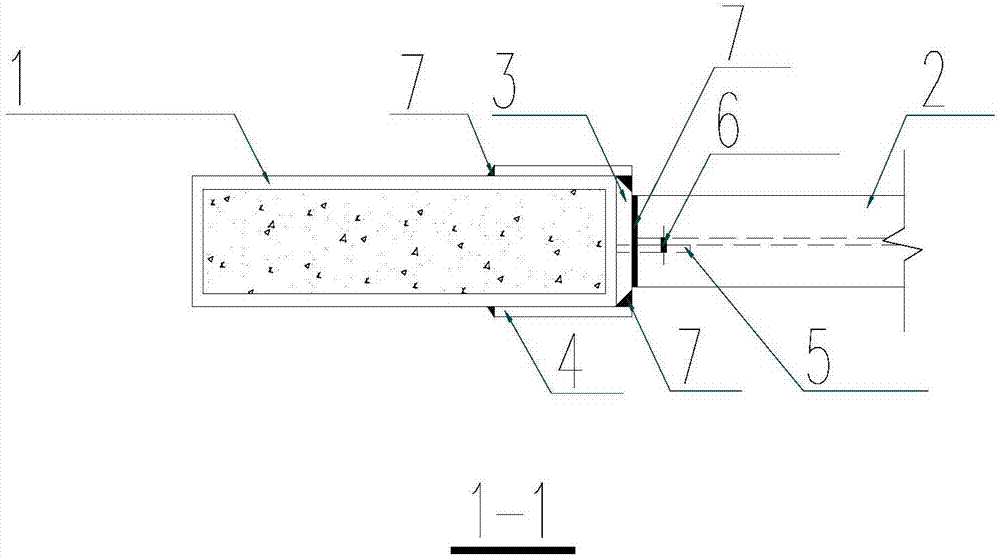

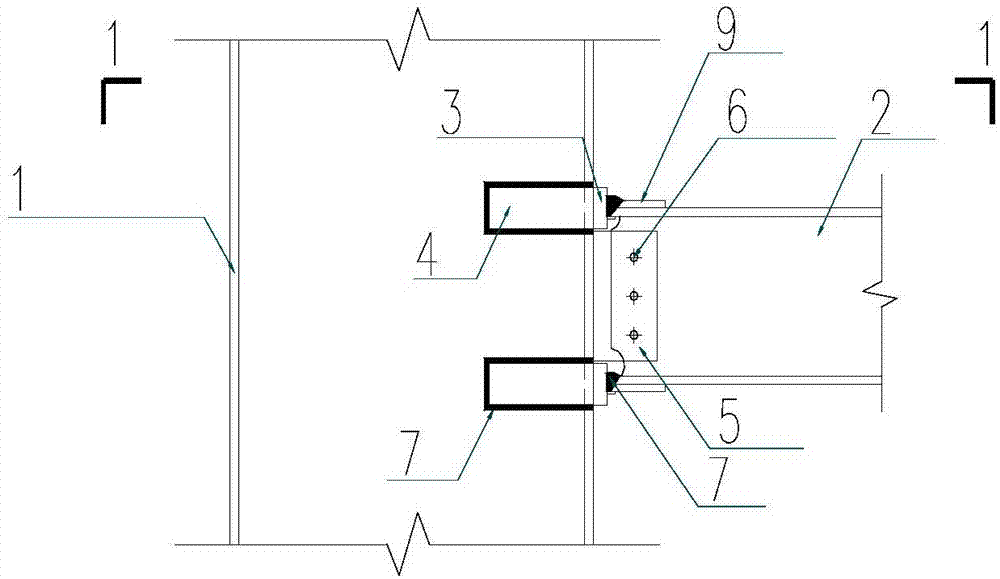

Supporting structure of archaized wood structure building roof and construction method thereof

The invention discloses a supporting structure of an archaized wood structure building roof and a construction method thereof and relates to the technical field of a building structure. The problems that in the current archaized wood structure building, a concrete material substitutes a wood structure to manufacture a system of brackets in Chinese building, the using amount of wood templates is large, the consumption of a wood material is high, and the construction cost is increased are solved. The supporting structure consists of a plurality of supporting units, wherein the supporting units consist of vertical supporting posts and cantilever beams; the cantilever beams are fixedly connected to the tops of the vertical supporting posts and are of T-shaped structures; the supporting units made of reinforced concrete are fixed to concrete cross beams; the positions of the supporting units correspond to the positions of decorative wood systems of brackets in Chinese building; the roof is fixed to the top end of the supporting structure. The construction method comprises the following steps of 1, fixing the supporting units to the concrete cross beams, wherein the positions of the supporting units correspond to the positions of decorative wood systems of brackets in Chinese building; 2, erecting the supporting unit templates, fixing the top ends of post reinforcing steel bars to pre-buried reinforcing steel bars of the cantilever beams, and connecting the other ends of the post reinforcing steel bars to main reinforcing steel bars in the concrete cross beams; 3, casting concrete to manufacture the supporting structure.

Owner:SHANGHAI LANDSCAPE ARCHITECTURE DESIGN INST

Strip-shaped reinforced joint for connection of H-shaped steel beam and short edge of wide steel pipe concrete column

ActiveCN107476446AIncrease stiffnessNode force transmission path is clearBuilding constructionsBand patternUltimate tensile strength

The invention discloses a strip-shaped reinforced joint for connection of an H-shaped steel beam and the short edge of a wide steel pipe concrete column. A flange of the H-shaped steel beam is rigidly connected to the side face of the wide steel pipe concrete column through strip-shaped reinforcing plates; a web plate of the H-shaped steel beam is rigidly connected to the side face of the wide steel pipe concrete column through combination of a connecting plate and high-strength bolts; the web plate of the H-shaped steel beam is connected with one end of the connecting plate through the high-strength bolts, and the other end of the connecting plate is welded to the side face where the short edge of the wide steel pipe concrete column is located; the end faces of the flange of the H-shaped steel beam are welded to the strip-shaped reinforcing plates; the strip-shaped reinforcing plates are closely attached and fixed to the side face where the short edge or the long edge of the wide steel pipe concrete column is located; and an inserting plate penetrating through the wide steel pipe concrete column is connected between the two strip-shaped reinforcing plates arranged on the opposite side faces of the wide steel pipe concrete column. The strip-shaped reinforced joint is easy to construct and machine and effective, machining and manufacturing difficulty is reduced, the rigidity and strength of the joint and a joint area are guaranteed, and it is guaranteed that concrete in a pipe has the good pouring quality.

Owner:HANGZHOU TONGMSK DESIGN CO LTD

Fabricated specially-shaped roof structural system and construction method thereof

PendingCN109098338AImprove construction efficiencyGuarantee the quality of the projectBuilding roofsEngineeringStructural system

The invention discloses a fabricated specially-shaped roof structural system and a construction method thereof. The fabricated specially-shaped roof structural system comprises multiple prefabricatedassembling units of independent structures, wherein the multiple prefabricated assembling units are disposed according to a predetermined order; two adjacent prefabricated assembling units are connected in a fabricated manner; each of the prefabricated assembling units comprises a polygonal-structured frame body; a first connection plate and a second connection plate are respectively arranged on apair of opened surfaces of the frame body; the first connection plate and the second connection plate are fixedly connected with the frame body respectively; a filling body is arranged among the first connection plate, the second connection plate and the frame body; the frame body comprises multiple assembling ribbed plates connected end to end; and mounting holes for connection are formed in theassembling ribbed plates. The fabricated specially-shaped roof structural system is reasonable in structural stress and high in structural rigidity; a node can be simplified; an internal force is uniformly distributed, and a spatial effect is obvious; the construction period can be shortened; the weight of the structure is reduced; materials and energy are saved, so the whole construction cost isreduced; and the fabricated specially-shaped roof structural system is high in practicability and worthy of being popularized.

Owner:洪成 +1

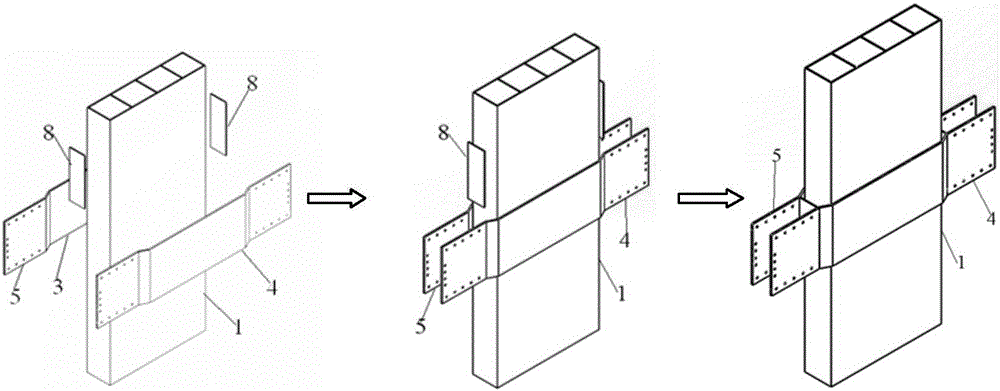

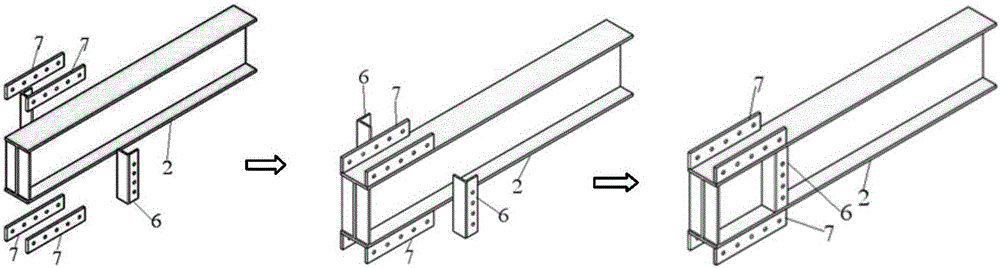

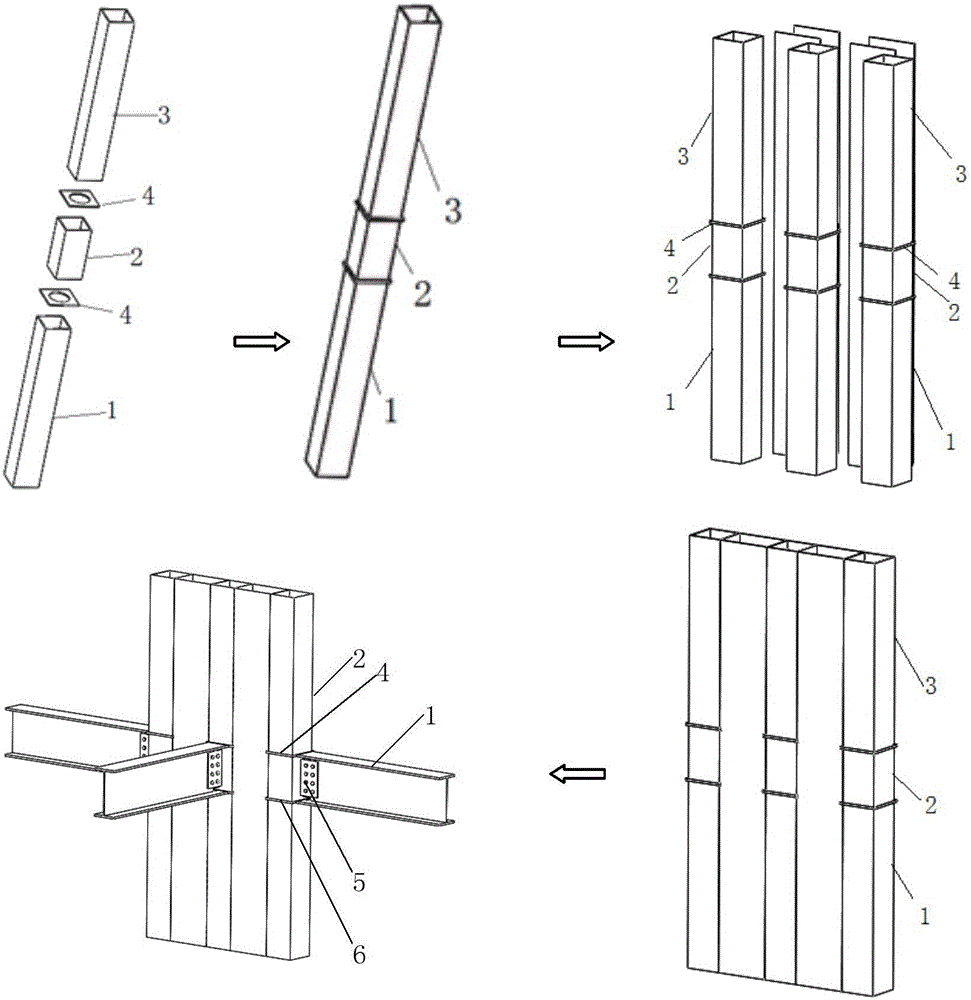

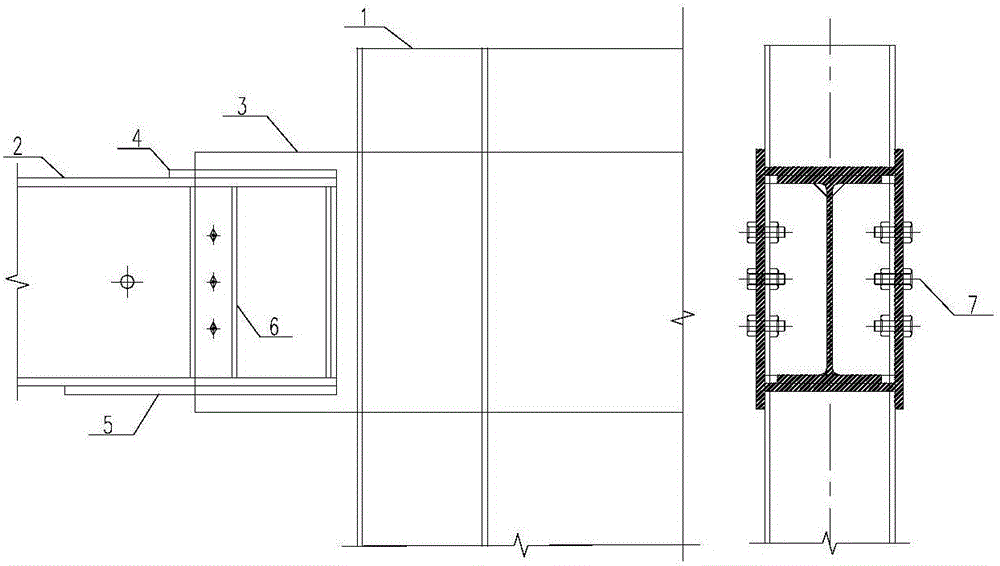

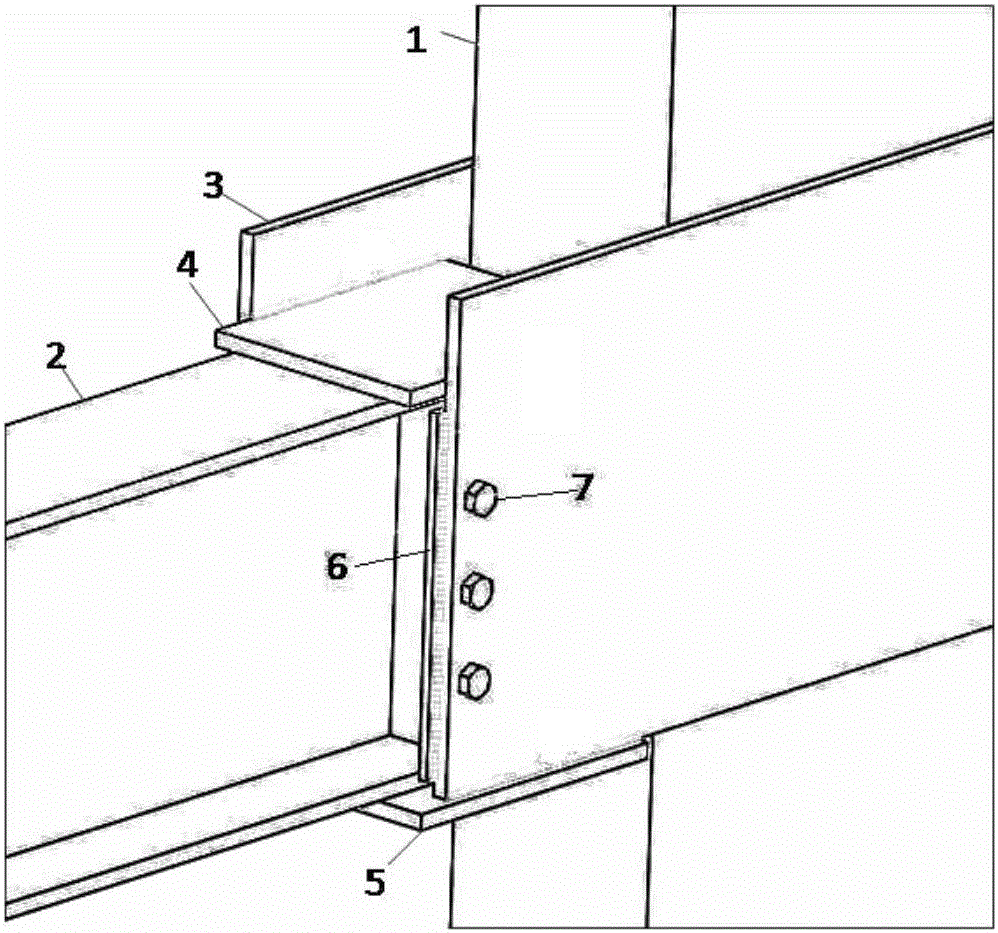

Double-side-plate screw bolt node for beam column and assembly method

ActiveCN105863056AChange the power transmission pathEliminate the defects of dependenciesBuilding constructionsStructural engineeringBeam column

The invention relates to a double-side-plate screw bolt node for a beam column and an assembly method. The double-side-plate screw bolt node comprises a first steel plate and a second steel plate, wherein the first steel plate and the second steel plate are symmetrically welded at the two sides of a multi-cavity steel pipe concrete combination column, and have the same structure; the first steel plate comprises a first section steel plate, a second section steel plate, a third section steel plate and a fourth section steel plate; the first section steel plate and the third section steel plate are symmetrically arranged at the two sides of the second section steel plate in an inclined way; the end parts of the first section steel plate and the third section steel plate are provided with a fourth section steel plate parallel to the second section steel plate; lug plates are arranged on the upper wing edge and the lower wing edge of the steel beam, and are connected with the four section steel plates; connecting angle steel is symmetrically arranged at the two sides of a web plate of the steel beam. The node provided by the invention has the advantages that the assembling degree is high; the multi-cavity steel pipe concrete combination post, the steel plate, the steel beam, the lug plates and the connecting angle steel can be prefabricated and completed in factories; the installing and welding workload is reduced; only the positioning assembly is needed in the field installation. The form of the node is simple; the assembling degree is high; the installation is convenient and fast.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Spatial panel point structure of steel truss and web PC (poly carbonate) combined bridge and construction method of spatial panel point

ActiveCN103243636AImprove fatigue resistanceIncreased shear capacityBridge structural detailsBridge erection/assemblyStress concentrationSheet steel

The invention relates to a spatial panel point structure of a steel truss and web PC (poly carbonate) combined bridge and a construction method of the spatial panel point. An embedded plate is embedded in concrete at a panel point of the spatial panel point structure of the steel truss and web PC combined bridge and connected with two steel truss and web pipes forming a 90-degree include angle and comprises two welded-together rectangular steel plates and at least two triangular reinforced steel plates, the triangular reinforced steel plates are welded to the inner sides of the rectangular steel plates forming a 90-degree included angle, and ends of the two steel truss and web pipes are respectively welded to the outer sides of the two rectangular steel plates. By the spatial panel point structure of the steel truss and web PC combined bridge, the problem about stress concentration and single function can be sufficiently solved.

Owner:SHENZHEN BRIDGE DOCTOR DESIGN & RES INSTITUDE CO LTD +1

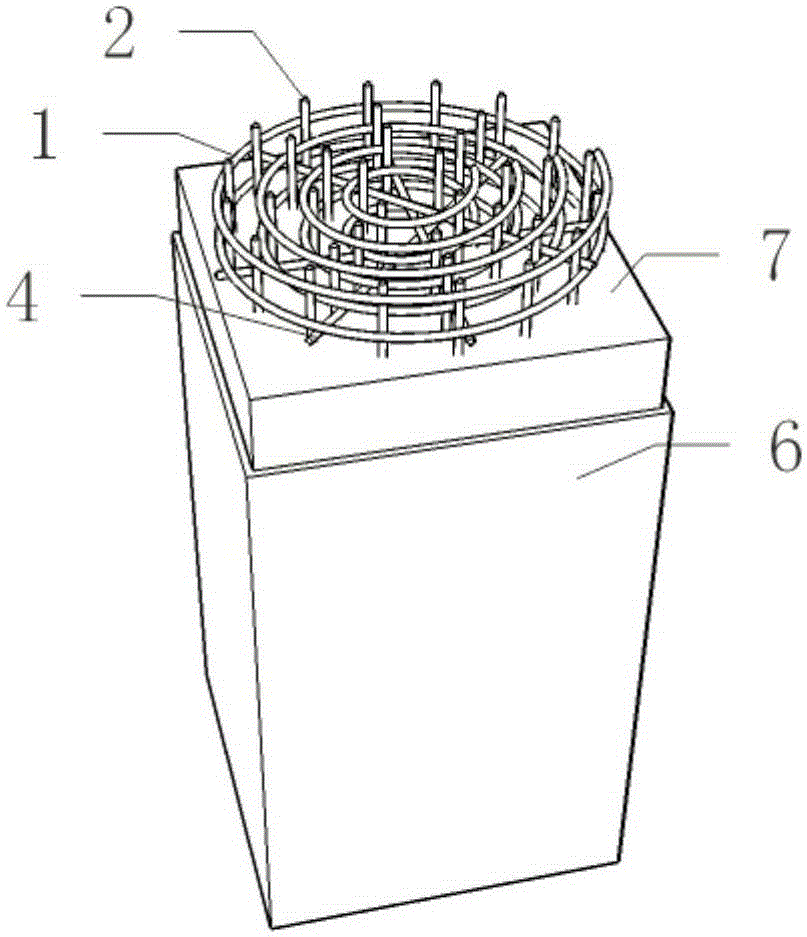

Tree ring type high-strength concrete filled square steel tube column equipped with multiple spiral stirrups

The invention discloses a tree ring type high-strength concrete filled square steel tube column equipped with multiple spiral stirrups. The tree ring type high-strength concrete filled square steel tube column comprises a square steel tube, the spiral stirrups, longitudinal bars, horizontal radiation steel bars and high-strength concrete, wherein the longitudinal bars and the spiral stirrups are bound or welded to constitute single-cylinder reinforcement cages; the single-cylinder reinforcement cages with different diameters are sleeved sequentially from large to small and are bound and welded with the horizontal radiation steel bars to constitute a reinforcement cage with a cylinder-in-cylinder structure; the reinforcement cage with the cylinder-in-cylinder structure is arranged in an inner chamber of the square steel tube, and the high-strength concrete is poured into the inner chamber of the square steel tube. The high-strength concrete filled column is simple in structure, convenient to construct, good in ductility, high in bearing force and excellent in seismic performance and is applicable to bearing columns of special structures such as super high-rise buildings, industrial heavy-duty workshops and other structures bearing heavy load.

Owner:GUANGXI UNIV

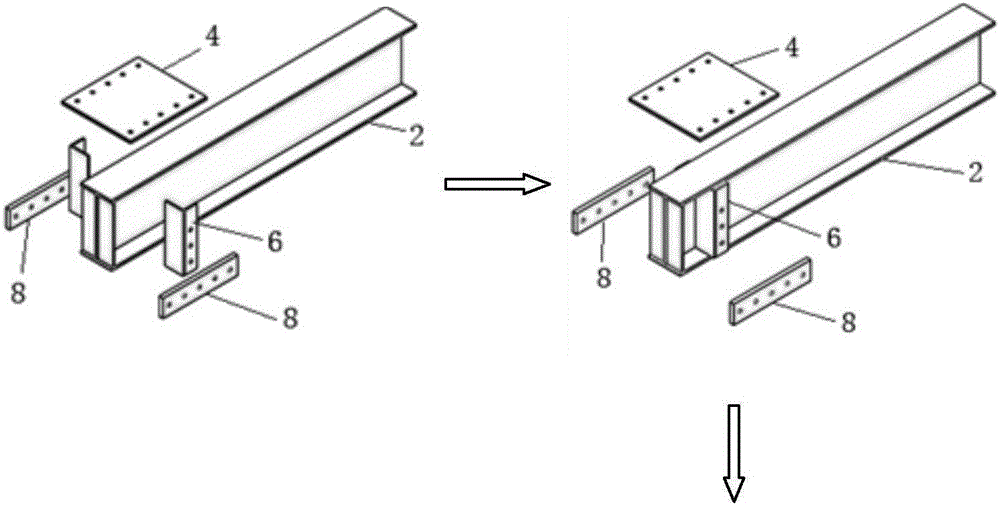

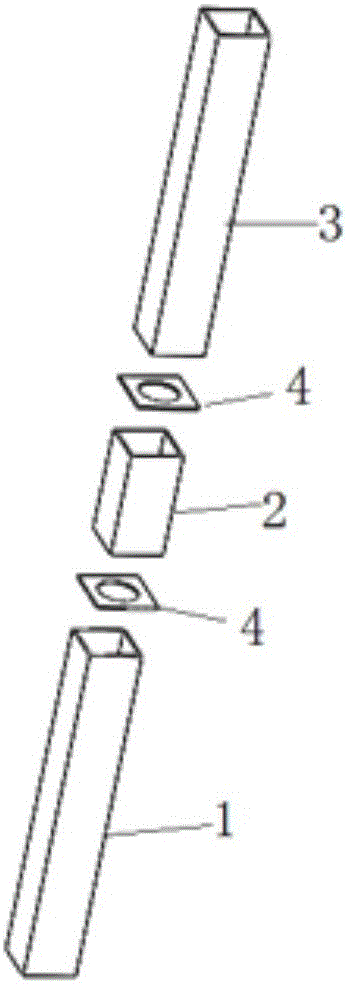

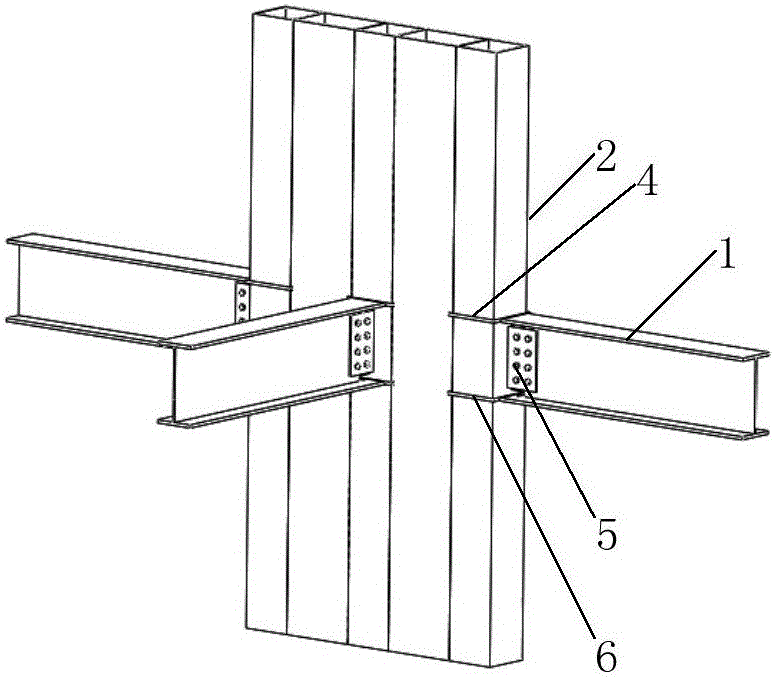

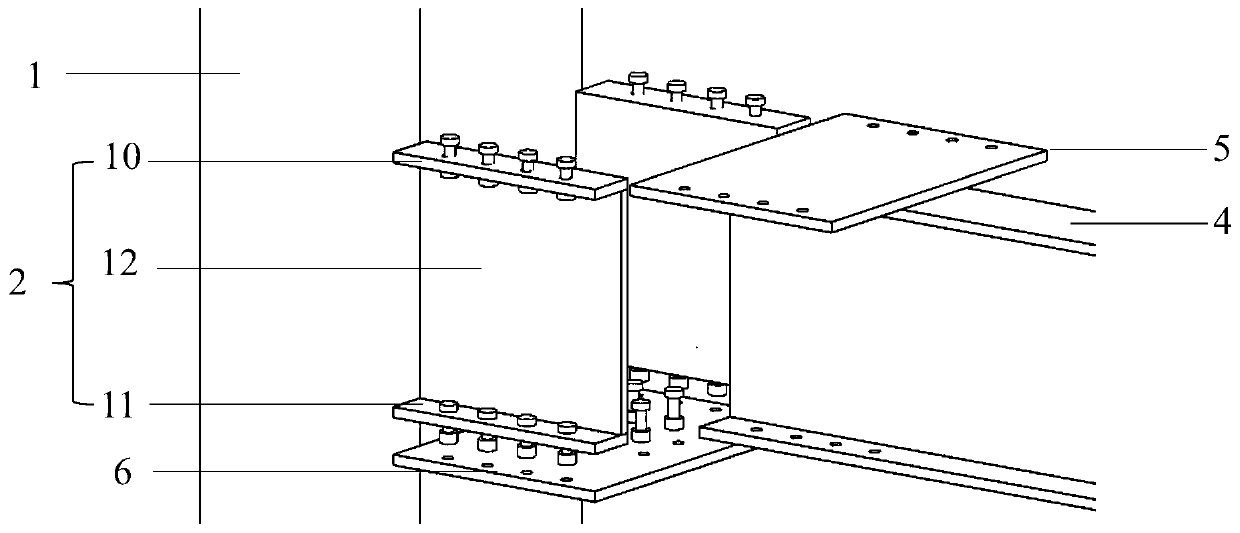

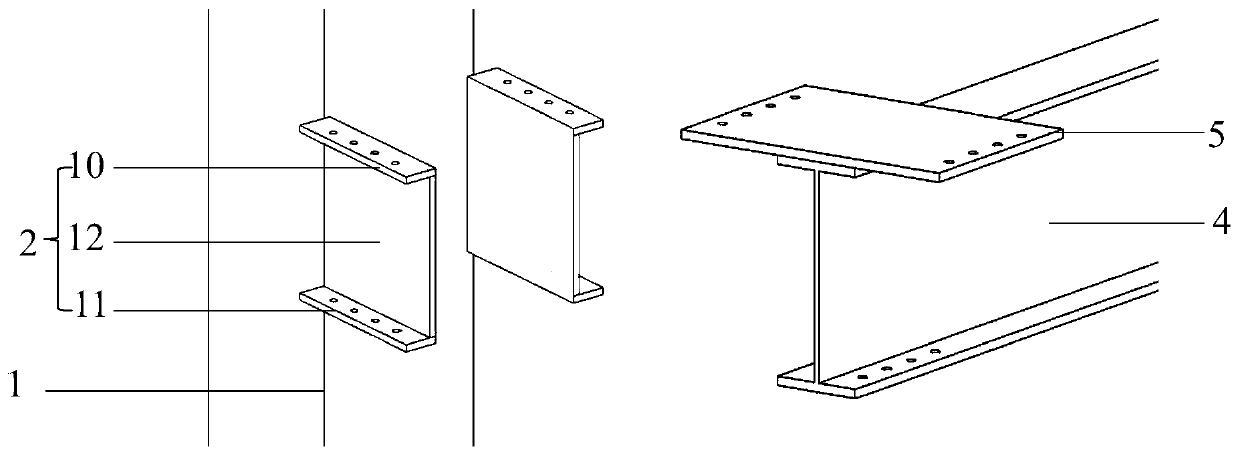

Multi-cavity concrete filled steel tube combination column and steel beam bolt joint and assembly method

ActiveCN105863081AReduce stress concentrationEliminate the defects of dependenciesBuilding constructionsSteel platesSteel tube

Owner:西安建大装配式钢结构研究院有限公司

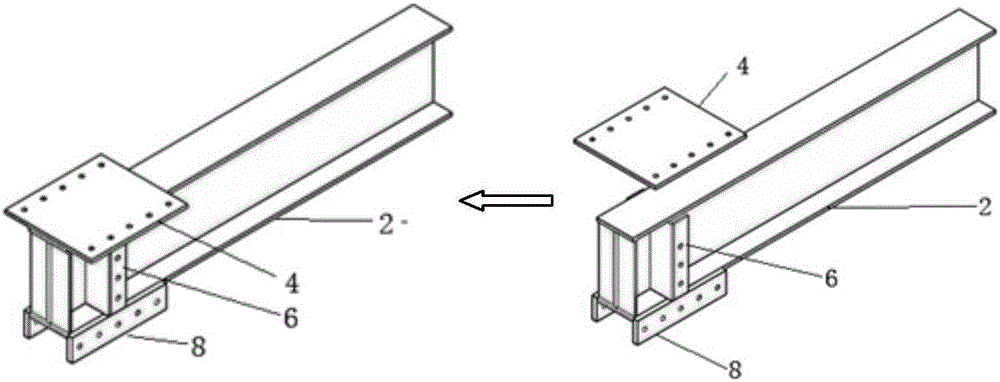

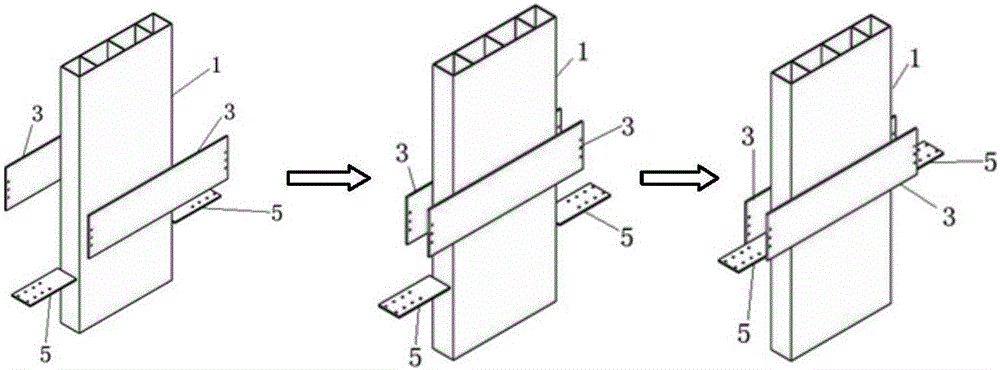

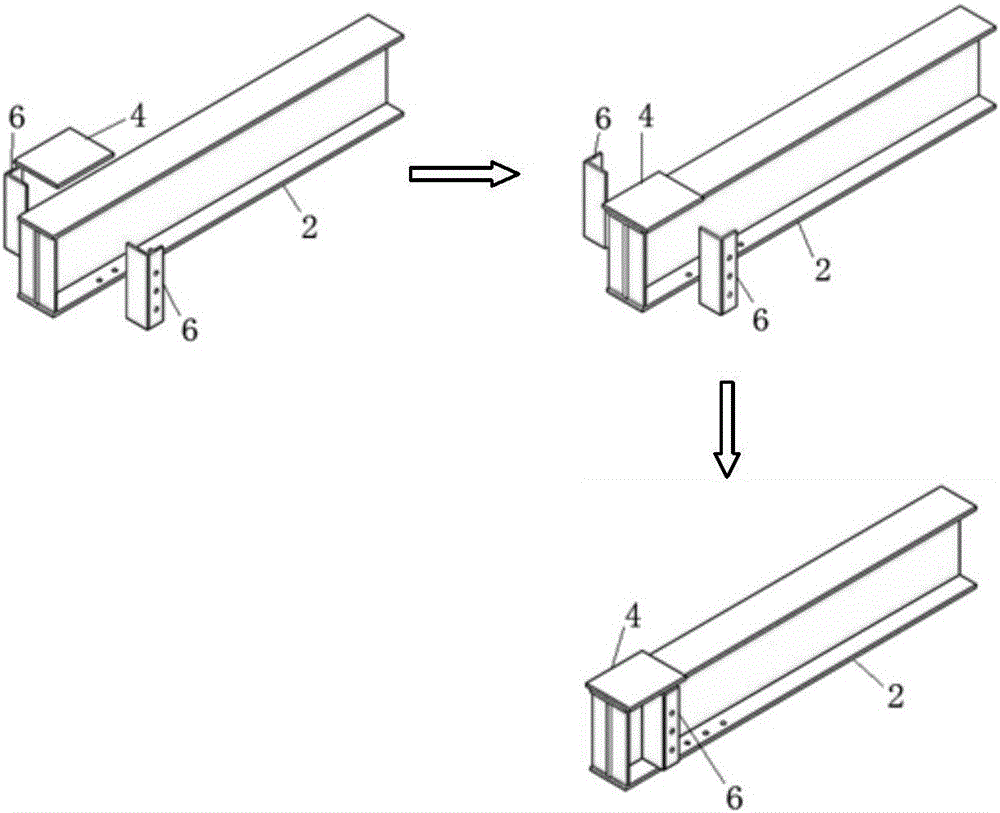

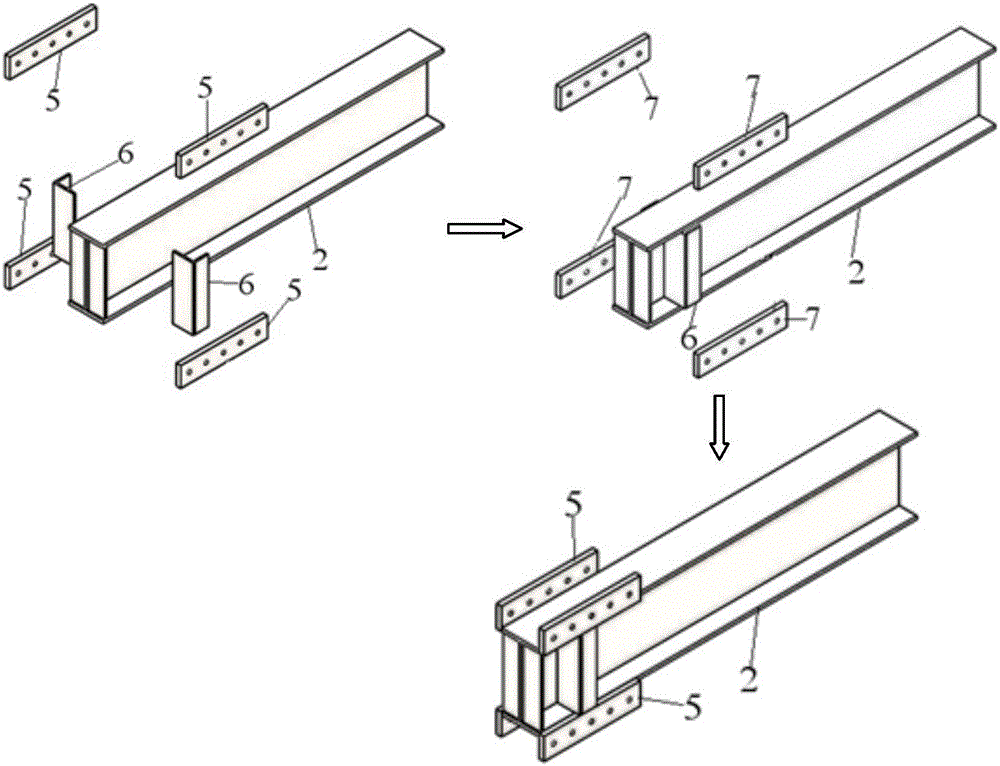

T-shaped through clapboard-type multi-chamber concrete filled steel tube combination column and steel beam joint and assembly method thereof

ActiveCN105863082AReduce decreaseGuaranteed vertical force transmissionBuilding constructionsSteel tubeMaterials science

The invention relates to a T-shaped through clapboard-type multi-chamber concrete filled steel tube combination column and steel beam joint and an assembly method thereof. The T-shaped through clapboard-type multi-chamber concrete filled steel tube combination column and steel beam joint comprises a multi-chamber concrete filled steel tube combination column and an I-steel beam, wherein the multi-chamber concrete filled steel tube combination column comprises three embedded columns which are arranged at intervals, and parallel web plates are arranged between two adjacent embedded columns; a first through clapboard and a second through clapboard are arranged on each embedded column and are horizontally arranged and extend out of the embedded column, and the first through clapboard is connected with the top flange of the I-steel beam; the second through clapboard is connected with the bottom flange of the I-steel beam. The through clapboards fully penetrate through the embedded columns, the lateral dimension of the clapboard is wider than the beam, and the beam web plates are connected with the multi-chamber concrete filled steel tube combination column through double connecting plates to achieve a design guideline of strong column and weak beam, strong joint and weak rod piece. Because the through clapboards only penetrate through the embedded columns, a column cross-section is less weakened, and the vertical transmitting force of the multi-chamber concrete filled steel tube combination column is effectively ensured.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Double-side plate node using lower flange for connection and assembly method

ActiveCN105863080AReduce stress concentrationEliminate the defects of dependenciesBuilding constructionsStress concentrationPlastic hinge

The invention relates to a double-side plate node using a lower flange for connection and an assembly method. The double-side plate node comprises steel plates, wherein the steel plates are arranged at the two sides of a multi-cavity steel pipe concrete combined column, and are connected by an edge bottom plate; an upper cover plate is arranged on an upper flange of a steel beam, through holes are formed in the bottom part of a lower flange of the steel beam, and the lower flange of the steel beam is arranged on the edge bottom plate; the upper cover plate is connected with the steel plates, and connecting angle steels are symmetrically arranged at the two sides of a web plate of the steel beam. The double-side plate node has the advantages that by separating the beam end and the column wall and using the full-height side plates, the connecting type and force transfer type of the multi-cavity steel pipe concrete combined column and the steel beam double-side plate rigid connecting node are particular; the force transfer path of the traditional node is changed by the physical isolation between the beam and column, and the three-axis stress concentration is eliminated; a plastic hinge is outwards transferred from the node to the beam, the tearing failure of traditional node column flange is avoided, and the defect of reliance of node rotating capability on the column web plate weak plate area is overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

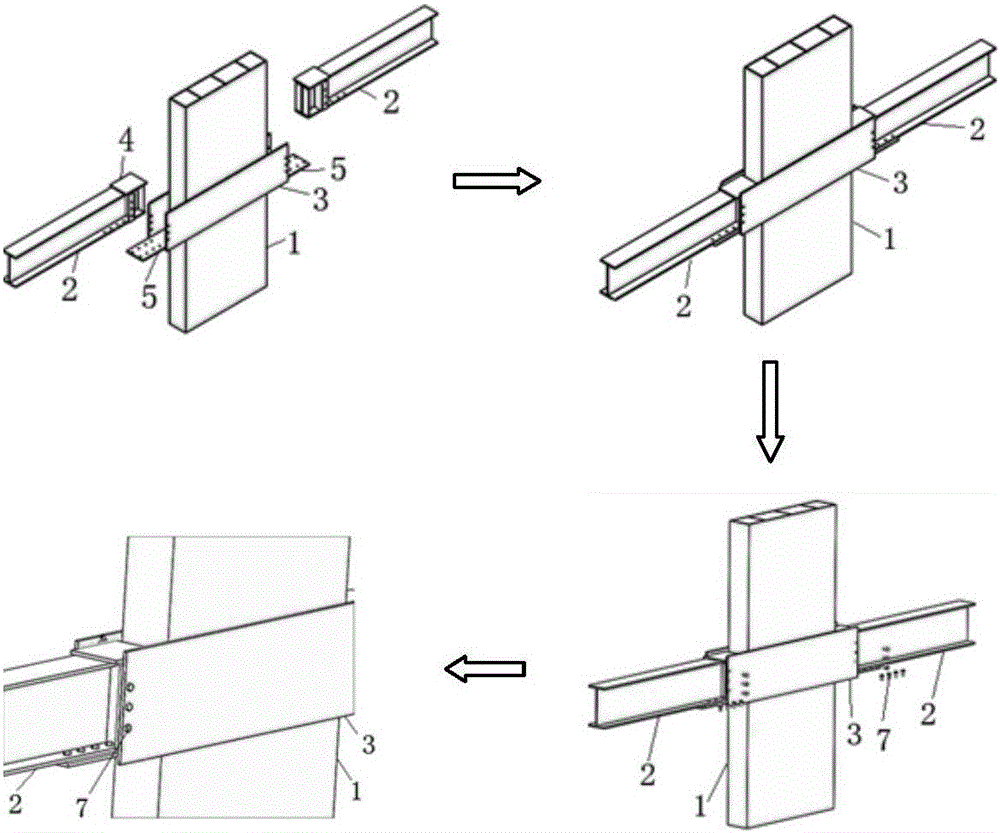

Multi-cavity steel pipe and concrete combined column and steel beam U-shaped connecting joint and assembling method

ActiveCN105821968AReduce stress concentrationEliminate the defects of dependenciesBuilding constructionsStress concentrationEngineering

The invention relates to a multi-cavity steel pipe and concrete combined column and steel beam U-shaped rigid connecting joint and an assembling method. The multi-cavity steel pipe and concrete combined column and steel beam U-shaped rigid connecting joint comprises steel plates welded to the two sides of a multi-cavity steel pipe and concrete combined column, a side bottom plate is arranged between the steel plates, an upper cover plate is arranged on the upper wing edge of the steel beam, two connecting angles are arranged at a web plate of the steel beam, and the upper cover plate, the side bottom plate and the steel plates are connected. By means of the physical isolation of the beam and the column, the force transmission path of a traditional joint is changed, three-axis stress concentration is eliminated, a plastic hinge can be moved outwards to the beam from the joint, and the defects of tearing damage of the column wing edge of the traditional joint and the dependence of the rotating capability of the joint on the weak plate area of a column web are overcome. The design and principle for a strong column and a weak beam, and a strong joint and a weak component are met. Meanwhile, the joint can be divided into two parts which can be prefabricated in factories respectively, only simple assembling is needed in field installation, and thus the joint is simple in structure and high in assembling degree.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

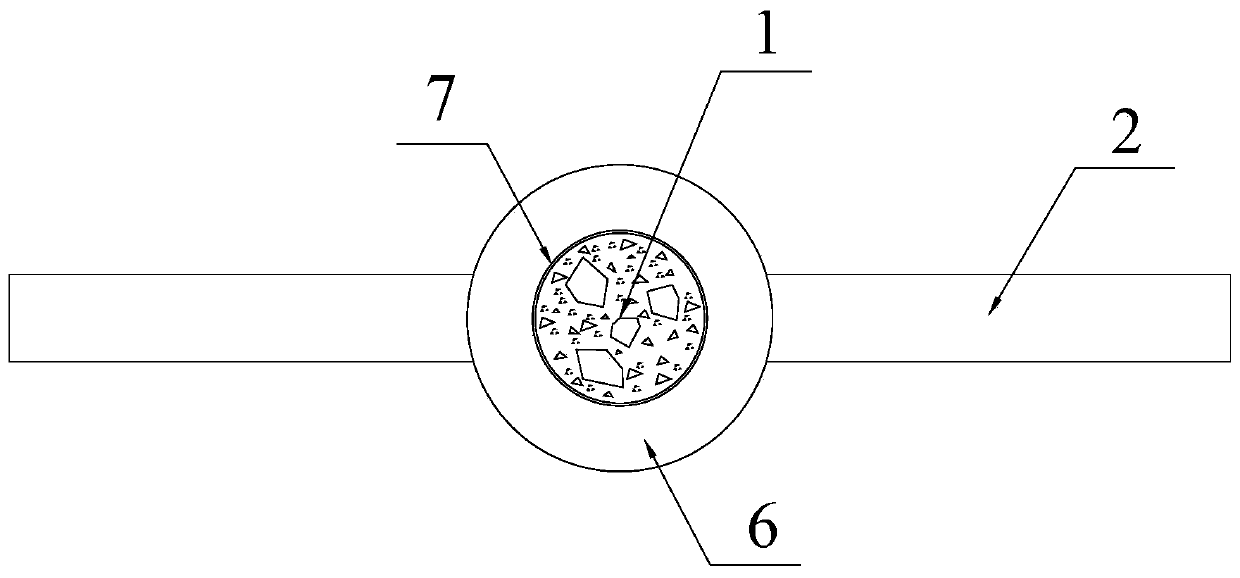

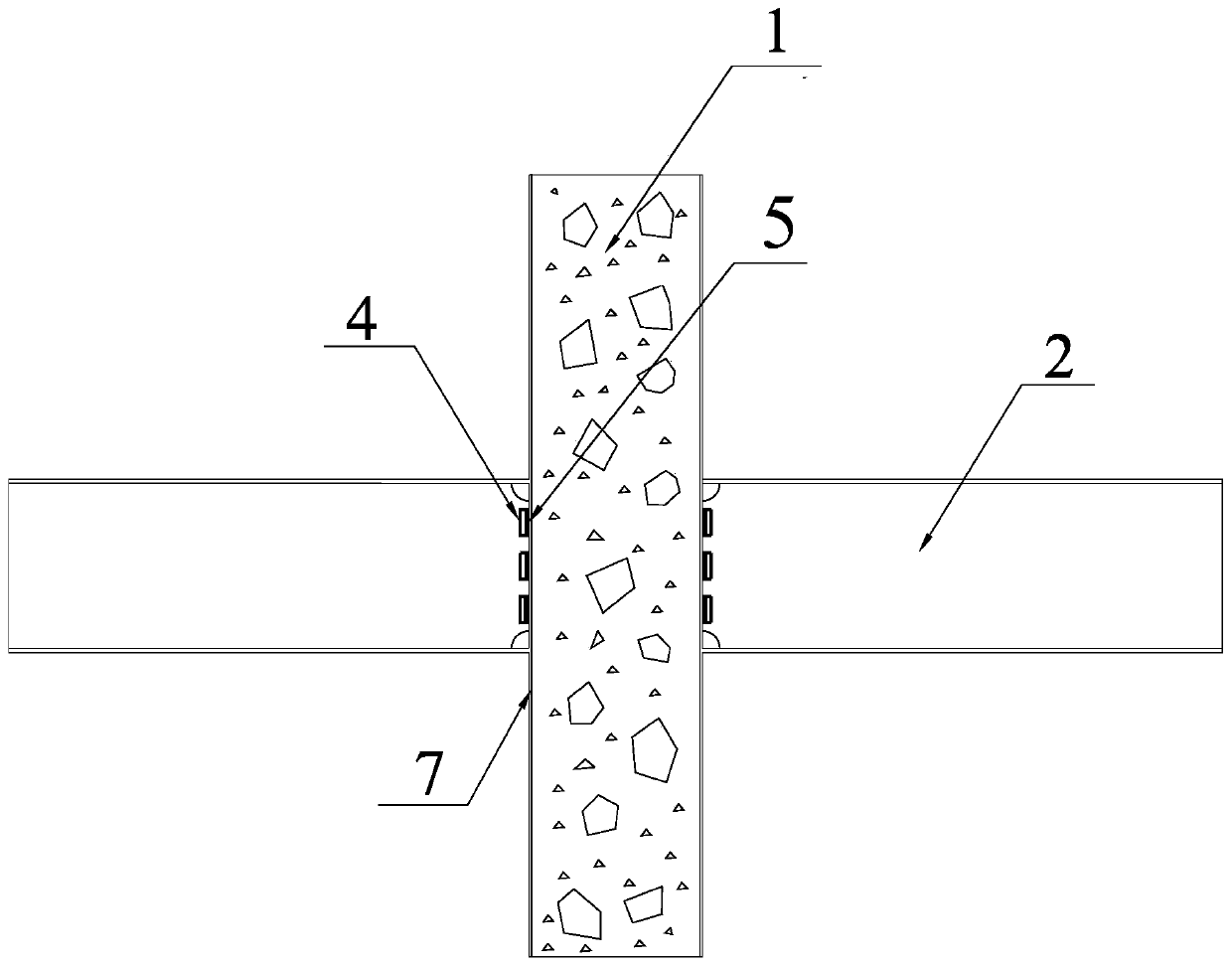

FRP hoop joint of thin-walled circular steel tube regenerated block concrete structure

PendingCN111441469AEfficient use ofEfficient recyclingBuilding constructionsMaterials scienceSteel tube

The invention discloses an FRP hoop joint of a thin-walled circular steel tube regenerated block concrete structure. The FRP hoop joint comprises a thin-walled circular steel tube regenerated block concrete column, a steel beam, two reinforcing ring plates and at least two FRP hoops, the thin-walled circular steel tube regenerated block concrete column comprises a column steel tube, the thin-walled circular steel tube regenerated block concrete column and the steel beam intersect to form a joint domain, a groove-shaped opening is formed in a web of the steel beam, each FRP hoop penetrates through the groove-shaped opening and is pasted to the column steel tube, the two reinforcing ring plates are flush with and welded to an upper flange and a lower flange of the steel beam, and the two reinforcing ring plates are welded to the column steel tube. Each FRP hoop comprises at least one layer of FRP cloth, the width of each FRP hoop is not larger than 1 / 4 of the height of the web, the totalwidth of all the FRP hoops is not larger than 1 / 2 of the height of the web, and all the FRP hoops and the two reinforcing annular plates jointly form discontinuous constraint on the joint domain. Byapplying the FRP hoops, the stress performance of the joint domain can be remarkably improved, and the phenomenon that the thin-wall steel tube in the joint domain is bent and loses efficacy too earlyis avoided.

Owner:SOUTH CHINA UNIV OF TECH

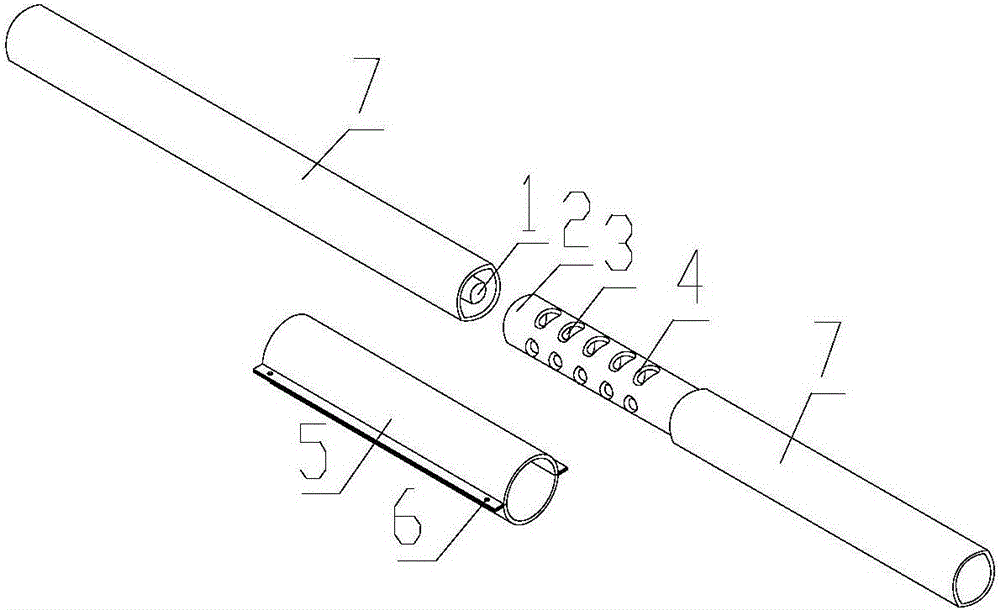

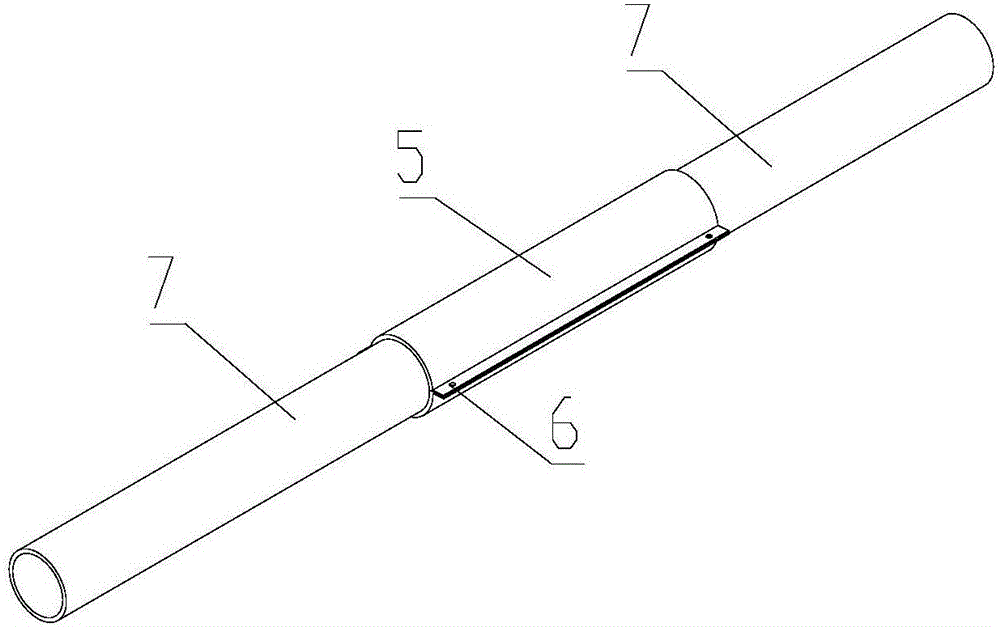

Connecting node for trusses made of composite materials

ActiveCN105756200APrevent pulling outImprove tensile propertiesBuilding constructionsAdhesiveEngineering

The invention provides a connecting node for trusses made of composite materials. The connecting node comprises a conical connector and a conical connecting barrel. The shape of an inner barrel of the conical connecting barrel is consistent with the external profile of the conical connector, through holes are formed in barrel walls of the conical connecting barrel, sealing adhesive hoses are arranged on the barrel walls of the conical connecting barrel and are filled with adhesive, the conical connector is embedded in a truss pipe made of composite materials, a large-diameter end of the conical connector is integrated with the inner wall of the truss pipe, and the conical connecting barrel is fixedly connected to the other end of another truss pipe made of composite materials. The connecting node has the advantages that various accessories of the connecting node can be prefabricated and machined in a factory in advance, accordingly, truss structures can be modularly produced and can be transported to fields in a sectioned manner, the connecting node can be quickly assembled, the construction time can be effectively saved, the work efficiency can be improved, and nodes for the trusses can be assuredly reliably connected with one another, and reasonable stress on the nodes can be guaranteed.

Owner:HARBIN ENG UNIV

Super-long-span dome structure

ActiveCN111379321AImprove mechanical performanceUniform structural stiffnessArched structuresVaulted structuresStructural rigidityLong span

The invention discloses a super-long-span dome structure. The super-long-span dome structure comprises multiple variable-cross-section midspan dual-limb cavity giant arches with a joint rotating shaft, upper limbs and lower limbs in the variable-cross-section midspan dual-limb cavity giant arches define cavity structures, two energy dissipating vibration reducing devices are symmetrically mountedin each cavity structure, the energy dissipating vibration reducing devices in the variable-cross-section midspan dual-limb cavity giant arches are located on the same circumference, branch limbs of the upper limbs and the lower limbs are fixedly connected with a first ring truss, at least two giant variable-cross-section space trusses are evenly mounted in an annular interval between the variable-cross-section midspan dual-limb cavity giant arches, the upper end of the giant variable-cross-section space trusses are fixedly connected with a first ring truss, the first ring truss is covered with a first dome surface single-layer net shell, each space is covered with a second dome surface single-layer net shell fixedly connected with the first ring truss, due to the dome structure, the stress property is greatly improved, the structure rigidity is uniform, joint configuration is relatively simple, and in the building process, large geometrically nonlinear deformation cannot be generated.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

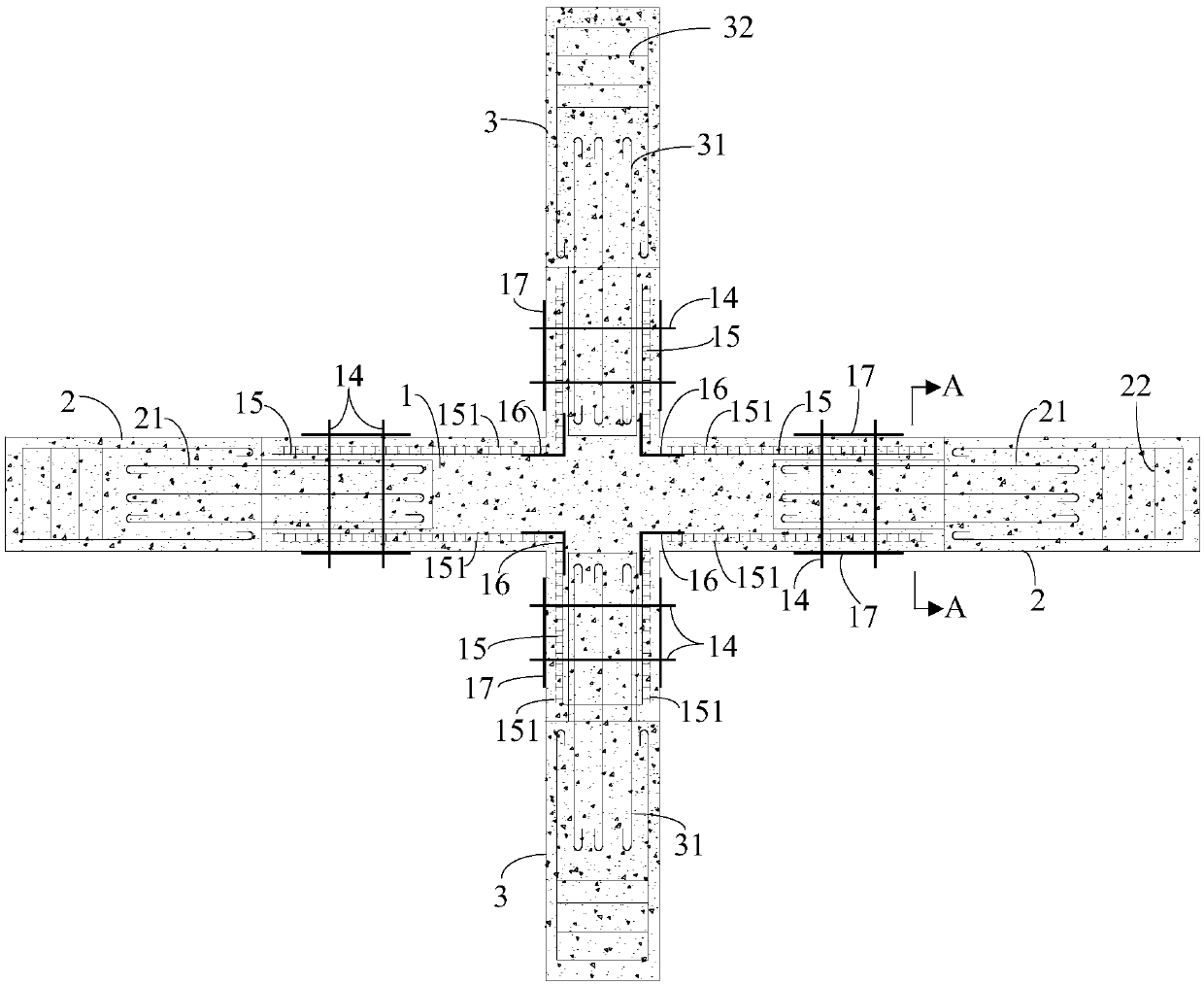

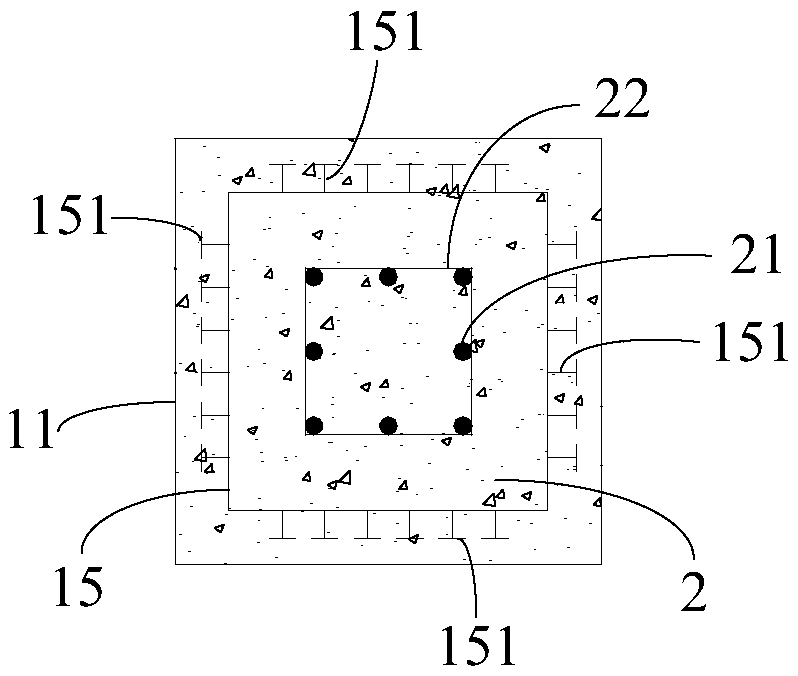

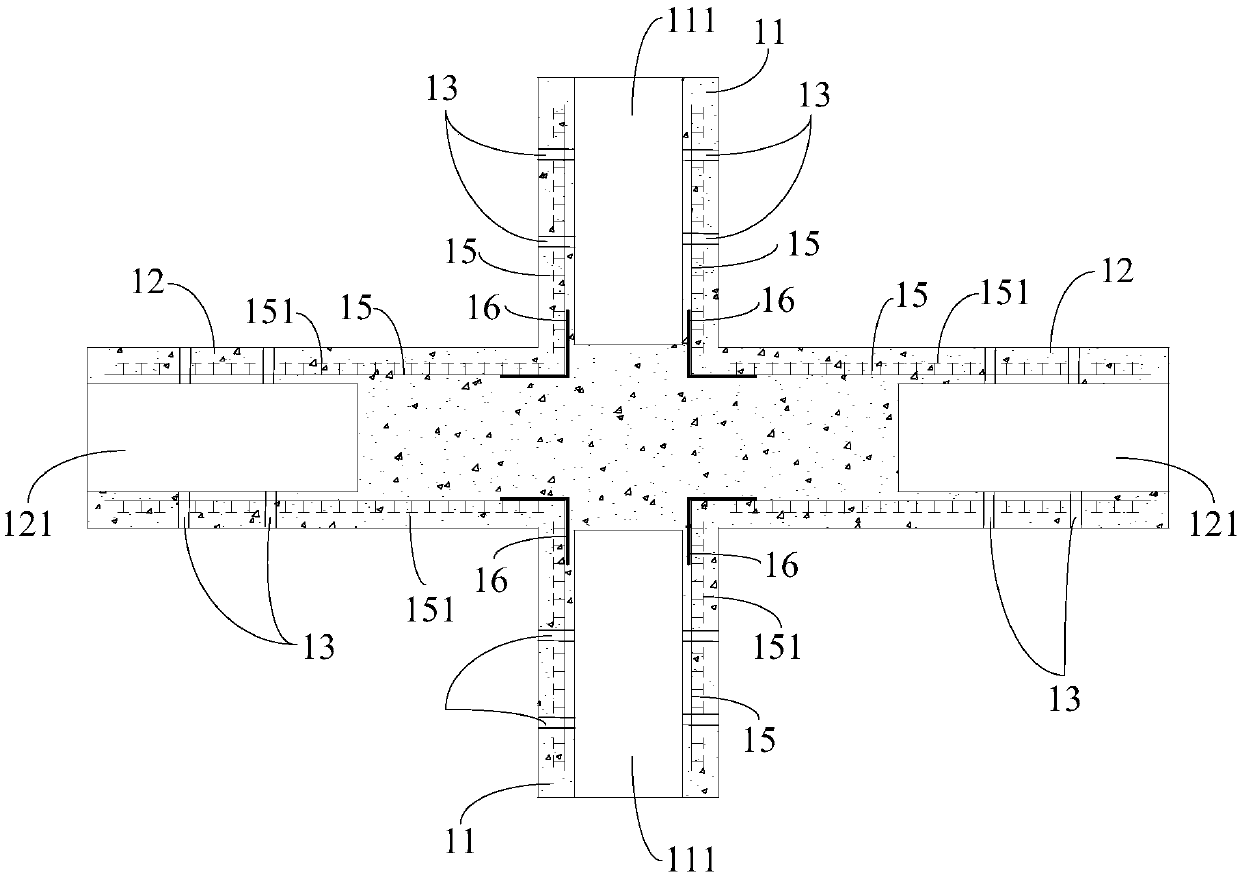

Fabricated coal gangue ceramsite concrete filled steel tube beam column joint structure and construction method thereof

ActiveCN109610637ALow costImprove structural integrityBuilding constructionsJoint componentTransverse groove

The invention discloses a fabricated coal gangue ceramsite concrete filled steel tube beam column joint structure and a construction method thereof. The structure comprises a beam column joint component, a beam component and a column component. The beam column joint component comprises a transverse supporting arm and a vertical supporting arm. A transverse groove is formed in the end of the transverse supporting arm. A vertical groove is formed in the end of the vertical supporting arm. Through holes penetrating the corresponding transverse groove and the vertical groove are formed in the armbodies of the transverse supporting arm and the vertical supporting arm. Steel pipes are separately arranged in the same directions in the transverse supporting arm and the vertical supporting arm. The steel pipes in the two directions are connected and a steel angle is connected to the connecting position. A transverse embedded inserting bar is arranged at one end of the beam component. The transverse embedded inserting bar is inserted in the transverse groove, and concrete is poured in the transverse groove. A vertical embedded inserting bar is arranged at one end of the column component. The vertical embedded inserting bar is inserted in the vertical groove. Concrete is poured in the vertical groove. The bearing capacity is high, impact resistance and shearing resistance are better, andconstruction is facilitated.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Cantilever side plate connecting assembly type joint suitable for multi-story high-rise steel structure

InactiveCN109736431AMeet the needs of assemblyImprove energy consumptionBuilding constructionsRear quarterArchitectural engineering

The invention discloses a cantilever side plate connecting assembly type joint suitable for a multi-story high-rise steel structure, including a box-type steel column, an H-shaped steel beam and a lower flange cover plate, wherein the box-shaped steel column is connected with an H-shaped steel beam through groove-shaped connecting pieces, the groove-shaped connecting pieces are welded to the wallthickness positions of the two sides of the box-shaped steel column, the two groove-shaped connecting pieces are symmetrically arranged, an upper flange cover plate is fixed to the position, close toan upper flange of the box-shaped steel column, of the H-shaped steel beam, and the upper flange cover plate is fixedly connected to the two groove-shaped connecting pieces; a lower flange cover plateis fixed to a lower flange of the H-shaped steel beam, and the lower flange cover plate and the upper flange cover plate are symmetrically arranged. And the lower flange cover plate is also fixed atthe bottoms of the groove-shaped connecting pieces. According to the joint, plastic hinges can be moved outwards, the anti-seismic requirement of strong joints and weak components is met, and the joint is quickly assembled on site only through bolt connection in the on-site assembly operation, so that the construction period is greatly shortened.

Owner:XIAN UNIV OF TECH

Double-side-plate joint in bolted connection and assembling method

ActiveCN106013466AReduce stress concentrationEliminate the defects of dependenciesBuilding constructionsWelding residual stressEngineering

The invention provides a double-side-plate joint in bolted connection and an assembling method. The double-side-plate joint comprises a first steel plate and a second steel plate which are arranged on the two sides of a multi-cavity steel pipe concrete combination column and arranged in parallel. Multiple lug plates are arranged on the two sides of an upper flange and the two sides of a lower flange of a steel beam. The lug plates are connected with the first steel plate and the second steel plate. Connecting steel angles are symmetrically arranged on the two sides of a web of the steel beam. The double-side-plate joint is high in assembling degree, the multi-cavity steel pipe concrete combination column, the steel plates, the steel beam, the lug plates and the connecting steel angles can all be prefabricated in a factory, the welding workload of installation is reduced, and only locating assembling is needed for field installation. The joint is simple in manner, high in assembling degree and convenient and quick to install. Due to the fact that traditional fusion-through welding is prevented from being adopted in field installation, the relatively large welding residual stress of steel is likely to be generated through traditional fusion-through welding, and the steel of the position of the joint is likely to be layered or prone to brittle failure. The joint is connected completely through high-strength bolts during field installation, the assembling degree is high, and joint connection is reliable.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com