T-shaped through clapboard-type multi-chamber concrete filled steel tube combination column and steel beam joint and assembly method thereof

A technology of steel pipe concrete and multi-chamber, which is applied in the direction of construction and building construction, can solve the problems of high manufacturing cost and complex structure of multi-chamber steel pipe concrete composite column-beam-column joints, and reduce environmental pollution and welding The effect of workload and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

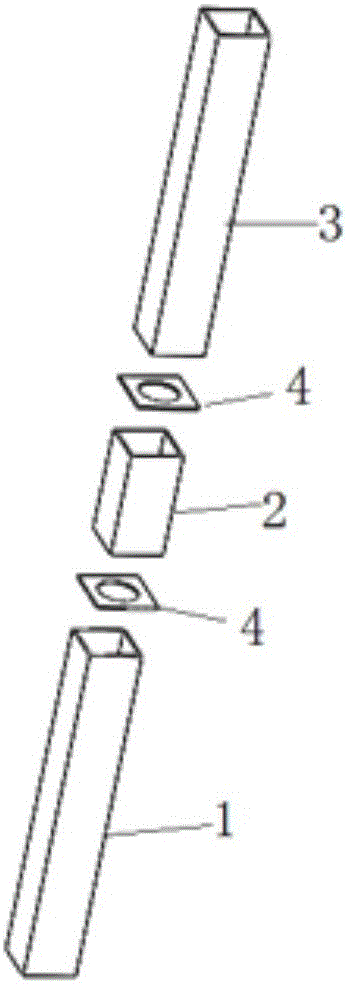

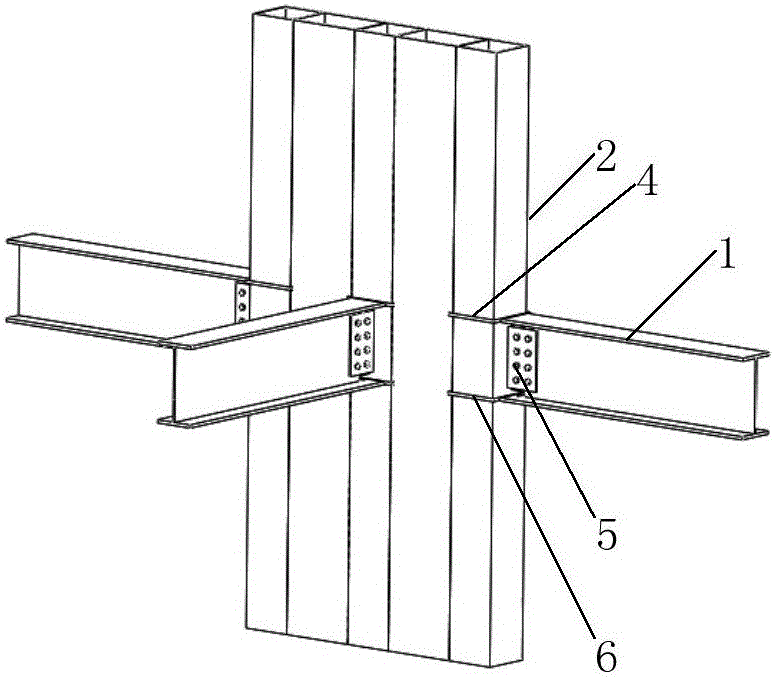

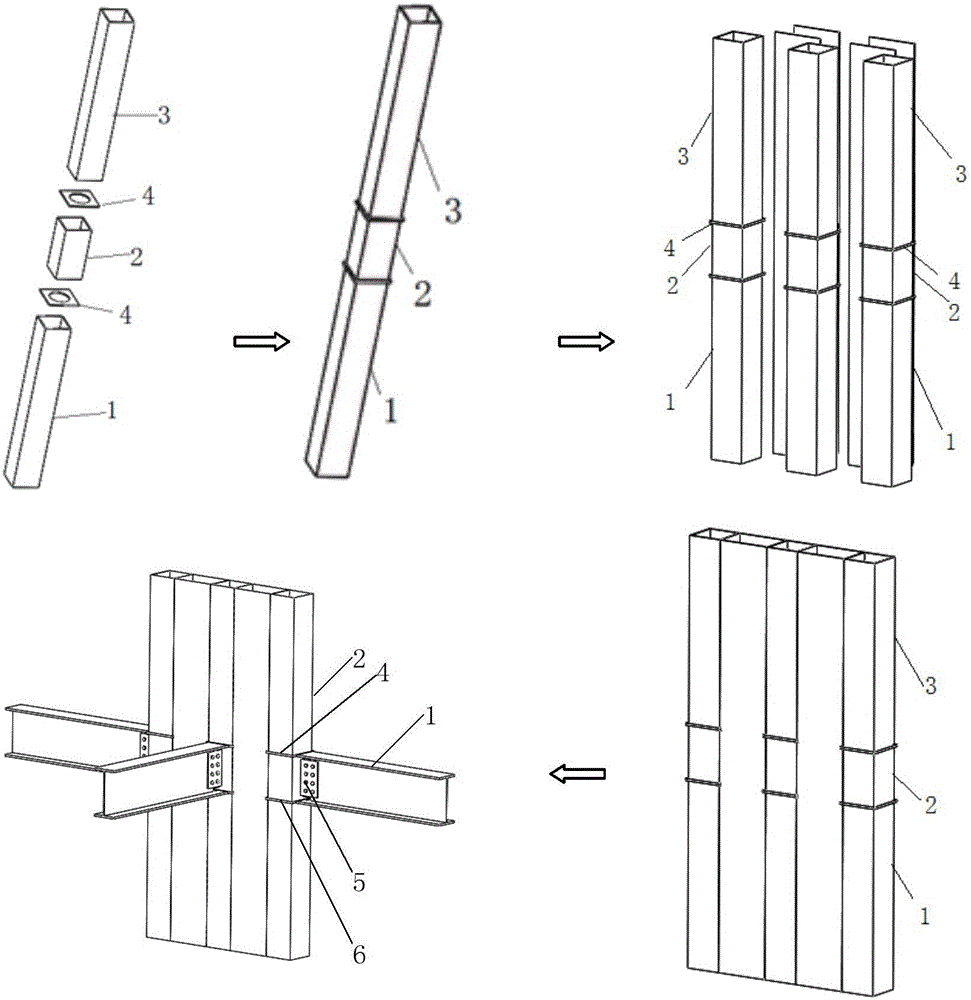

[0041] refer to Figure 1 to Figure 5 , the present invention comprises multi-chamber concrete-filled steel pipe composite columns, three concealed columns arranged at intervals in the multi-chamber steel-filled concrete composite columns, parallel webs are arranged between adjacent two concealed columns, and each concealed column is provided with The first through partition 4 and the second through partition 6 are provided with through holes. Both the first penetrating partition 4 and the second penetrating partition 6 are set horizontally and protrude from hidden columns. The first penetrating partition 4 is connected to the upper flange of the I-shaped steel beam 1, and the second penetrating partition 6 is connected to the I-shaped beam. The lower flange of steel beam 1 is connected. The web of the I-beam 1 is connected to the multi-chamber concrete filled steel pipe composite column 2 through a connecting plate 5 . The dark pillars comprise the first section of dark pil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com