FRP hoop joint of thin-walled circular steel tube regenerated block concrete structure

A technology of concrete structure and round steel pipe, which is applied in the direction of building structure, construction, etc., can solve the problems that are not conducive to the placement of waste concrete, affect structural performance and safety, and affect appearance, and achieve the effects of saving manpower, ensuring quality, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the examples and accompanying drawings, but the embodiment of the present invention is not limited thereto. Technical realization.

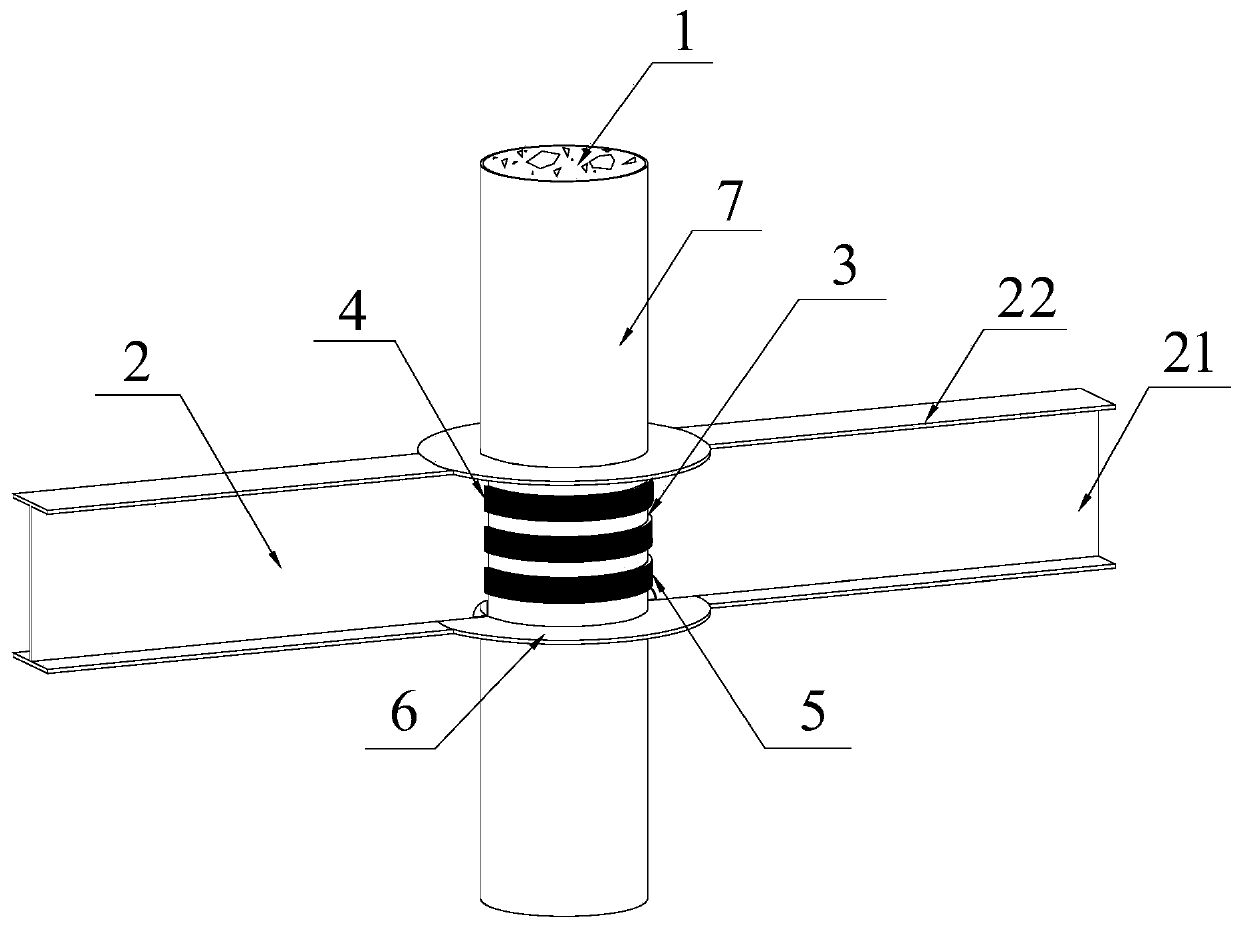

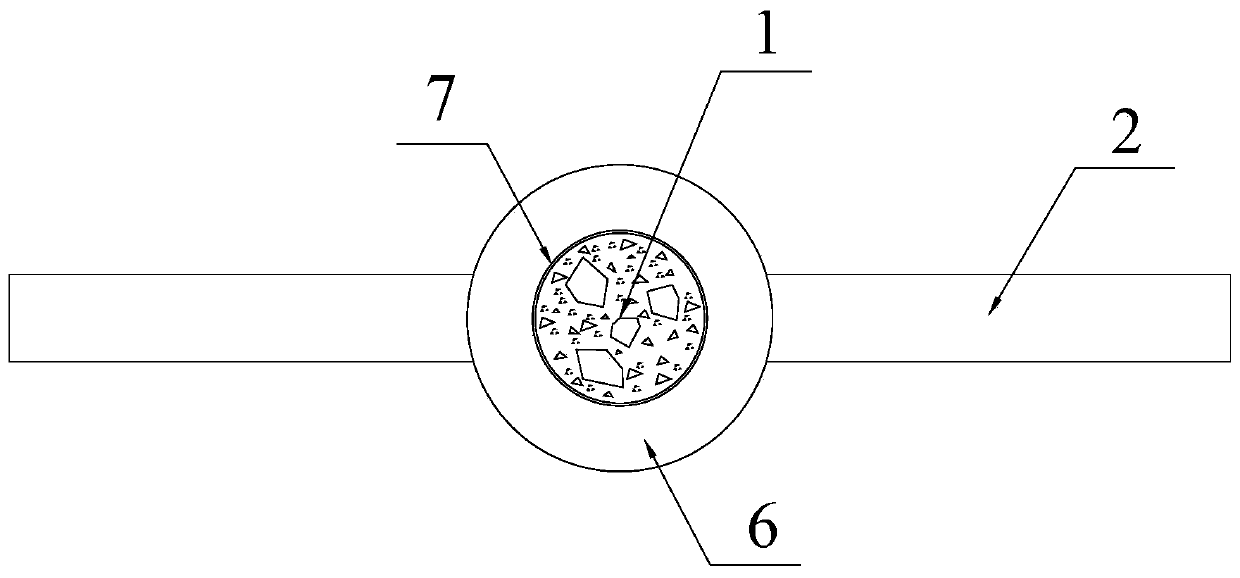

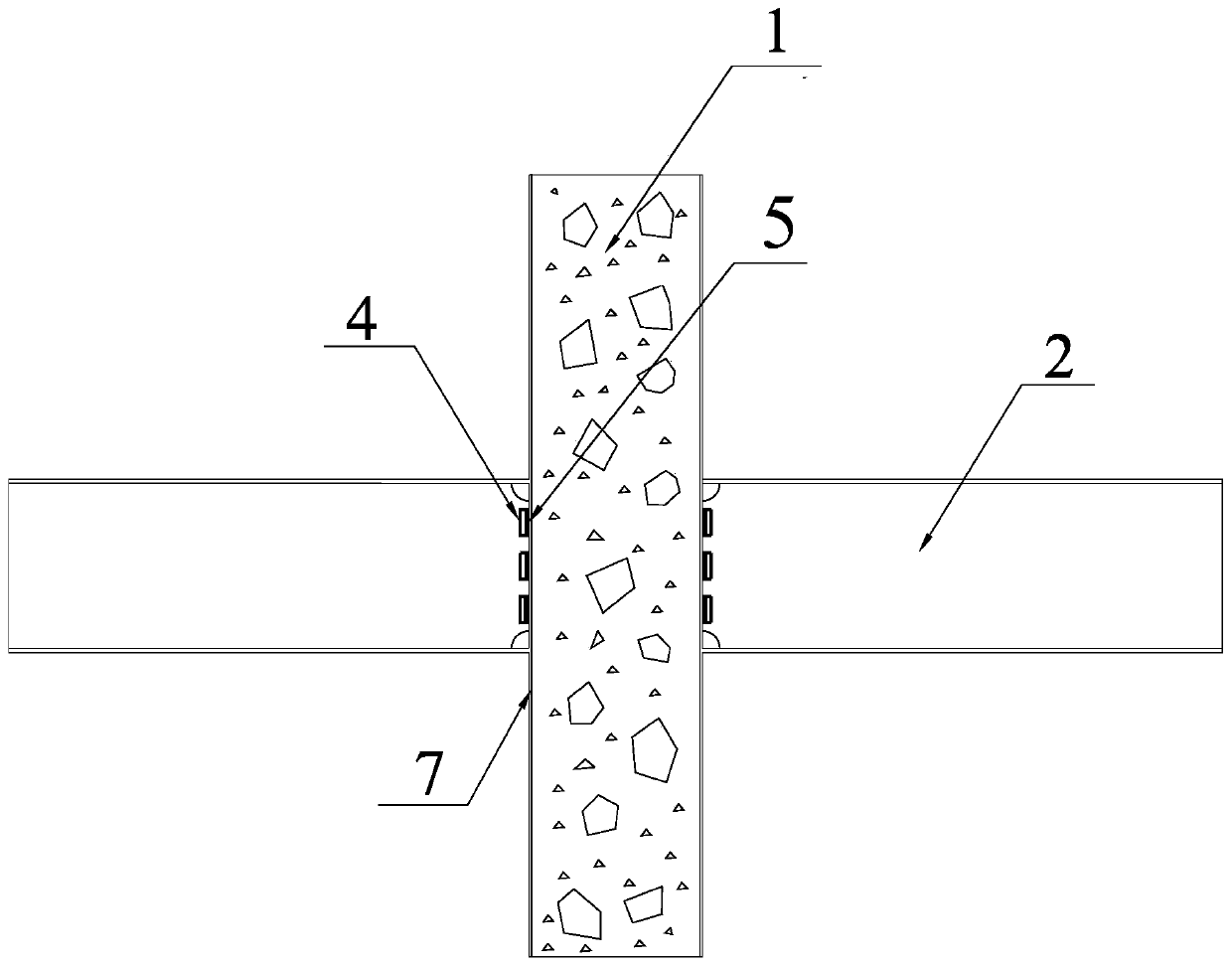

[0025] Such as Figure 1 to Figure 4 As shown, an FRP hoop node of a thin-walled circular steel tube recycled block concrete structure includes a thin-walled round steel tube recycled block concrete column 1 , a steel beam 2 , a hoop 5 and two reinforcing ring plates 6 .

[0026] Thin-walled circular steel tube recycled block concrete column 1 includes column steel tube 7 and waste concrete blocks and new concrete filled inside column steel tube 7 . The outer diameter of the column steel pipe 7 is 400mm, the wall thickness is 6mm, and the height is 1800mm.

[0027] Specifically, the gap between the waste concrete block and the column steel pipe 7 in this embodiment is filled with new concrete, the strength grade of the new concrete in the thin-walled circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com