Hollow interlayer steel tube concrete column base joint

A technology for steel pipe concrete columns and concrete columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of increased construction time and cost, insufficient shear and pull-out bearing capacity, and reduced rigidity, so as to improve shear and Pull-out bearing capacity, good pull-out resistance and shear resistance, and the effect of avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

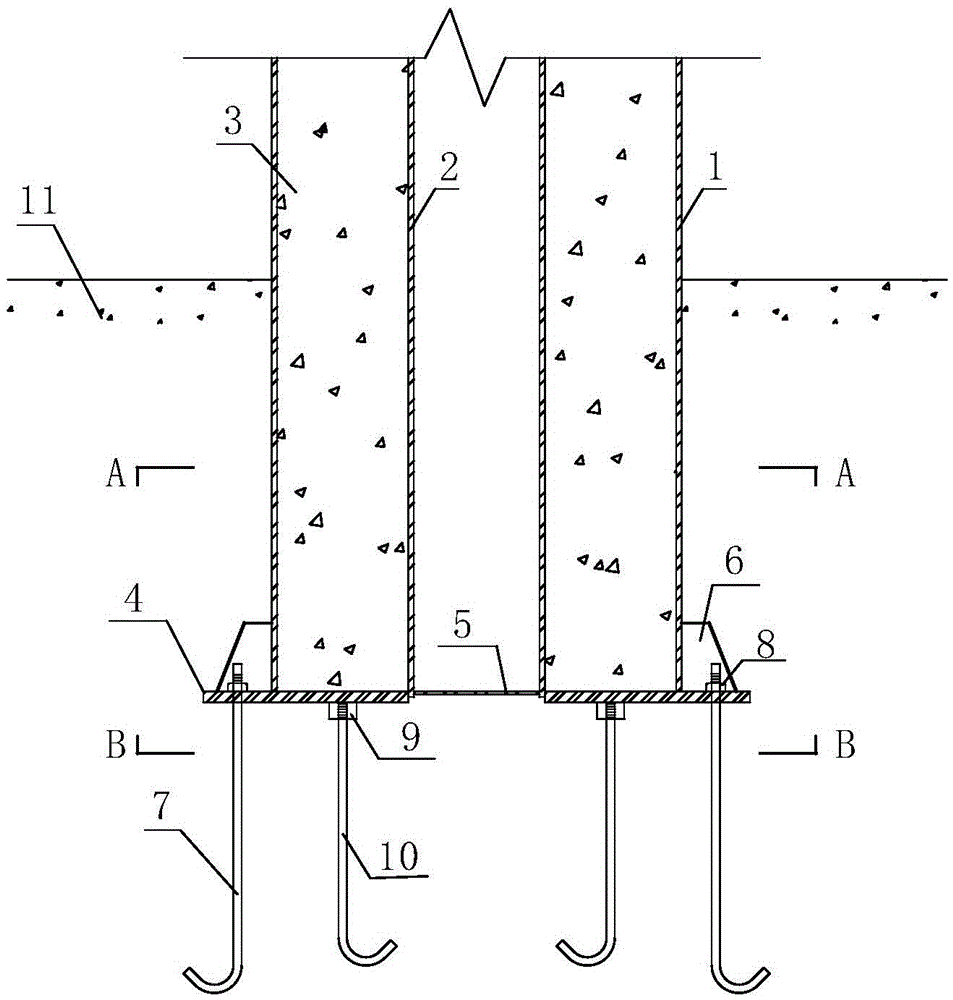

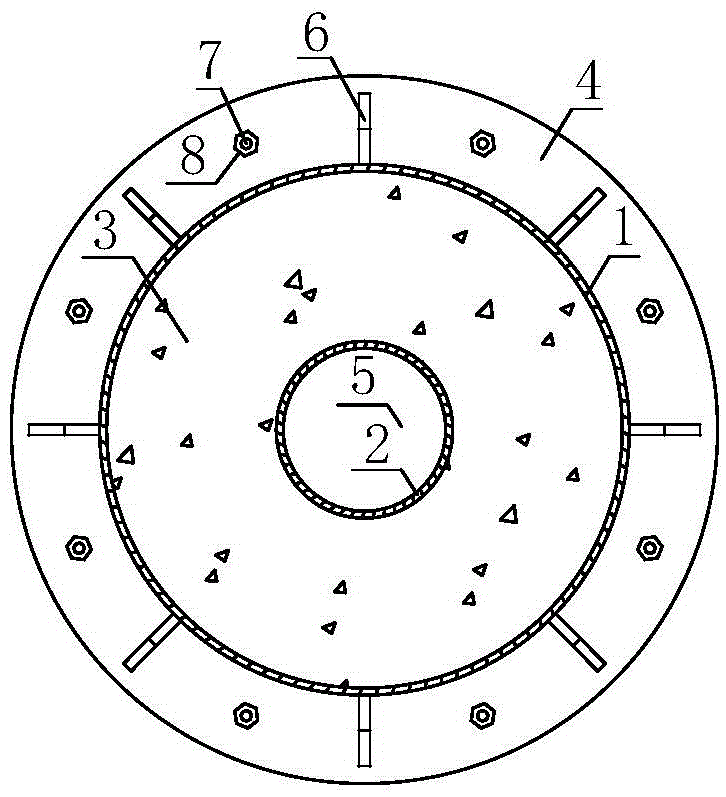

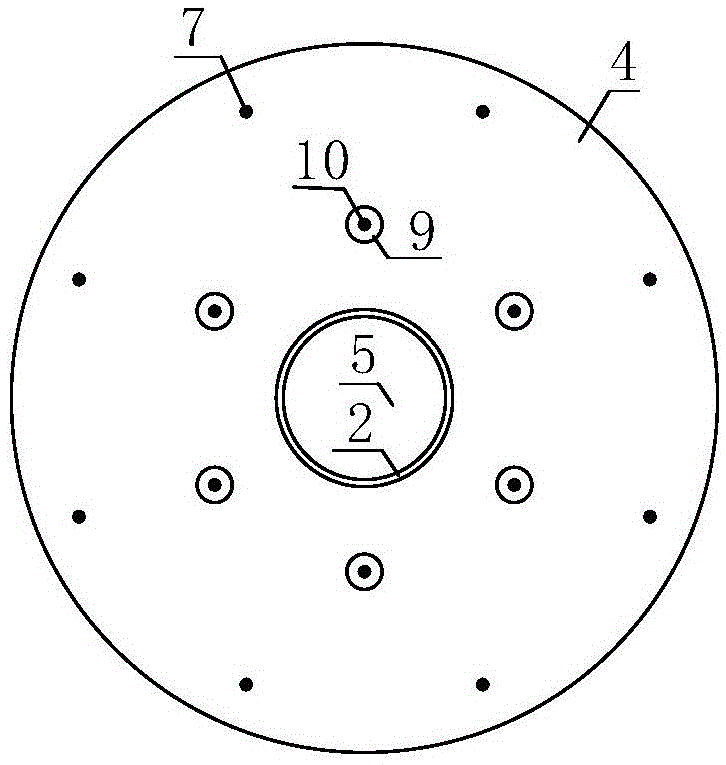

[0025] As attached figure 1 Shown: First, the foot plate 4 is processed. The center of the foot plate 4 is processed into a hollow according to the outer contour of the inner steel pipe 2, and the outside of the foot plate 4 is drilled according to the diameter of the outer anchor bolt 7, and the drilling positions are evenly arranged on the outer side of the outer steel pipe 1. At the same time, a special nut 9 is prefabricated and welded on the foot plate 4. A foot plate 4 is welded to the bottom of the outer steel pipe 1 and the inner steel pipe 2, the lower surface of the inner steel pipe 2 exceeds the upper surface of the foot plate 4 to reach between the upper surface and the lower surface of the foot plate, and the bottom inner wall of the inner steel pipe 1 is welded with a sealing plate 5. Then, concrete 3 is poured between the outer steel pipe 1 and the inner steel pipe 2. At the junction of the outer steel pipe 1 and the foot plate 4, the outer steel pipe 1 is welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com