Fabricated specially-shaped roof structural system and construction method thereof

A construction method and assembly technology, which is applied to roofs, building components, building structures, etc., can solve the problems of large proportion of bolt balls, difficulty in deformation of the whole structure, and difficulty in welding deformation, so as to achieve superior stability of components and improve Construction efficiency and the effect of simple node structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

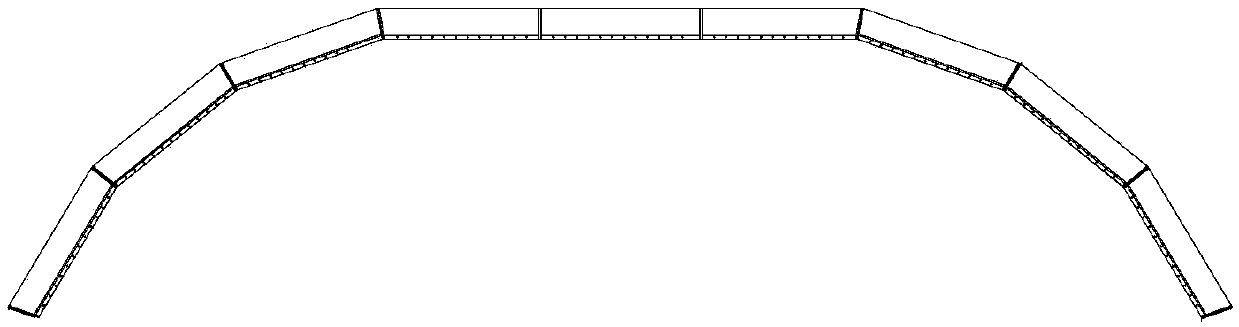

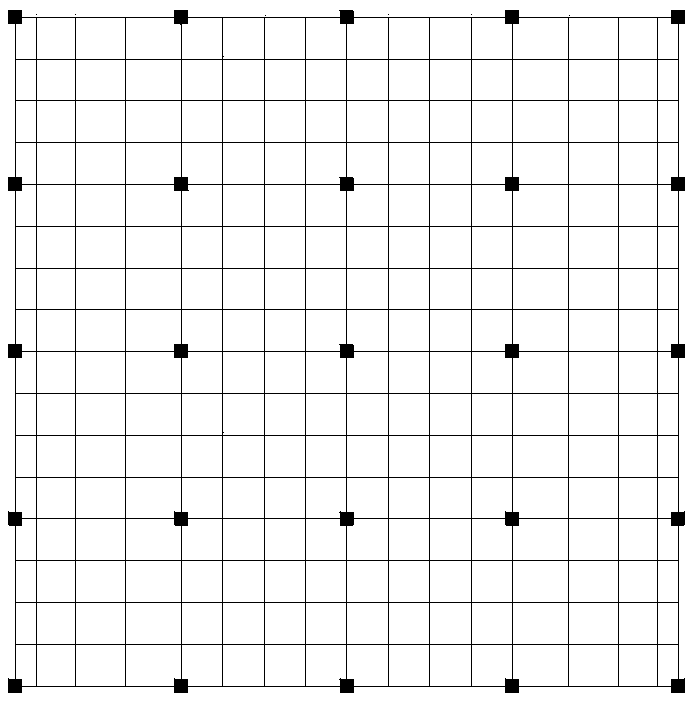

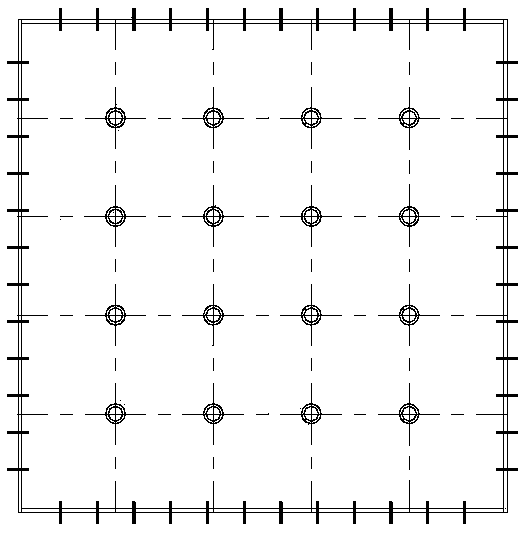

[0053] The present invention provides an assembled special-shaped roof structure system and its construction method, combined below Figure 1 to Figure 19 The structure schematic diagram of the present invention is described.

[0054] Such as figure 1 and figure 2 As shown, a prefabricated special-shaped roof structure system provided by the present invention includes a plurality of prefabricated assembly units with independent structures, and a plurality of prefabricated assembly units are arranged in a predetermined order, and two adjacent prefabricated assembly units are prefabricated to connect ; The prefabricated assembly unit includes a frame body with a polygonal structure, a pair of opening surfaces of the frame body are respectively provided with a first connecting plate and a second connecting plate, and the first connecting plate and the second connecting plate are respectively connected to the The frame body is fixedly connected, a filling body is arranged betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com