Double-side plate node using lower flange for connection and assembly method

A double-sided plate and flange technology, applied in the direction of construction and building structure, can solve the problems of large welding residual stress, complicated construction, difficult welding, etc., to meet the needs of residential functions, eliminate triaxial stress concentration, reduce Effects of Welding Workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following 的实施例。 Example.

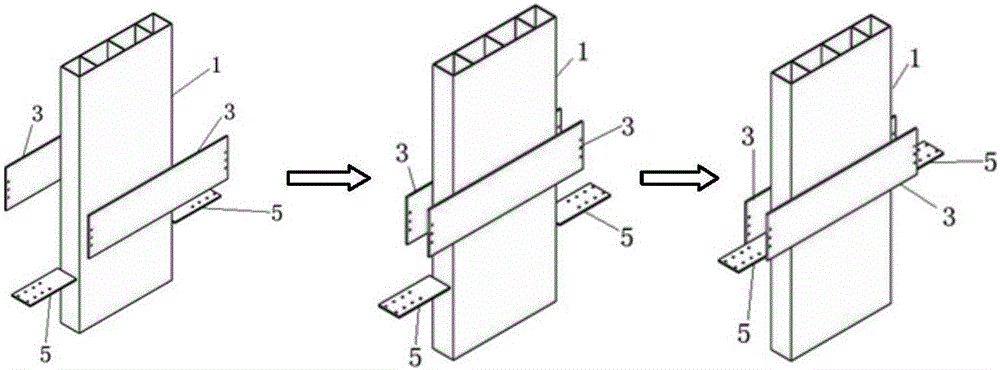

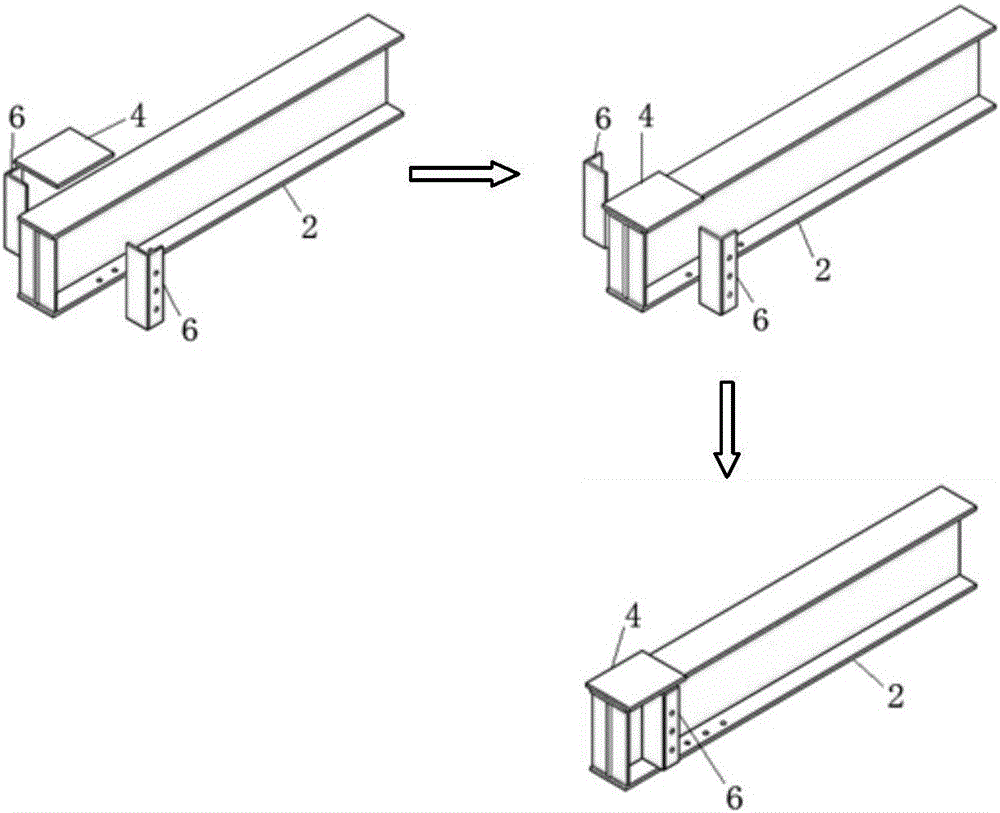

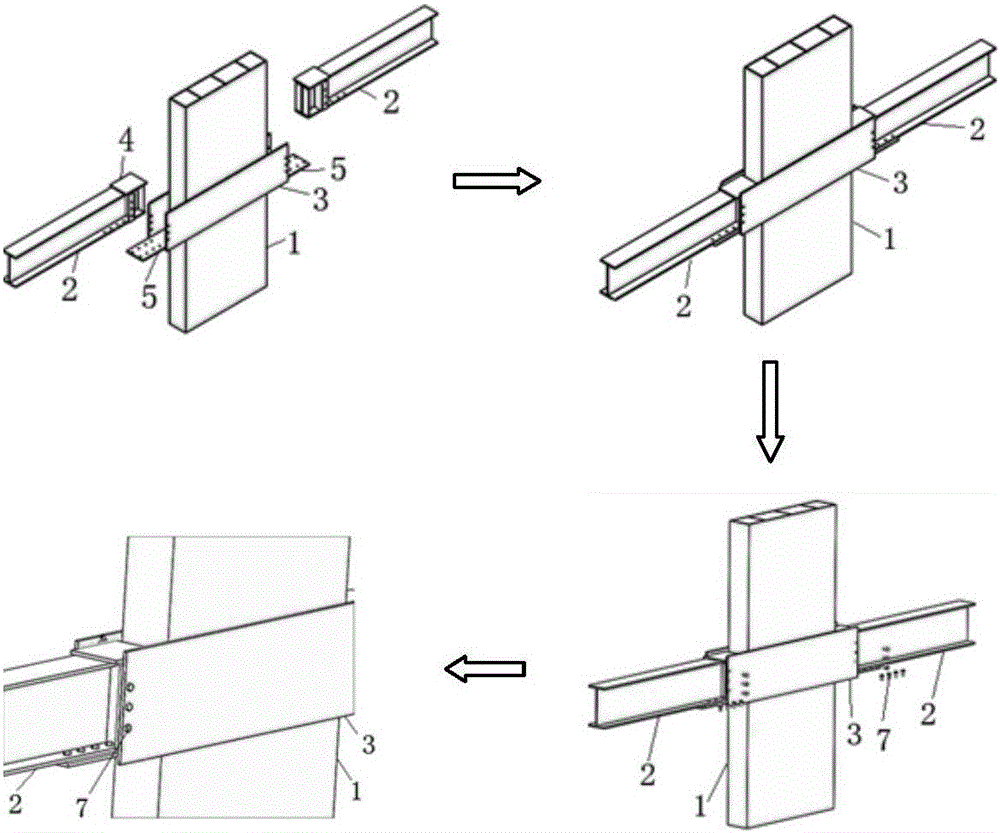

[0035] See image 3 , The present invention includes steel plates 3 arranged on both sides of the multi-cavity concrete-filled steel tube column, that is, two steel plates are arranged on both sides of the multi-cavity concrete-filled steel tube column, the bottoms of the two steel plates 3 are connected by the side bottom plate 5, and one end of the side bottom plate 5 It is in contact with the multi-cavity concrete-filled steel tube composite column; the upper cover plate 4 and the side bottom plate 5 are both connected to the steel plate 3 through fillet welds, and the steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com