Patents

Literature

269results about How to "High degree of assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

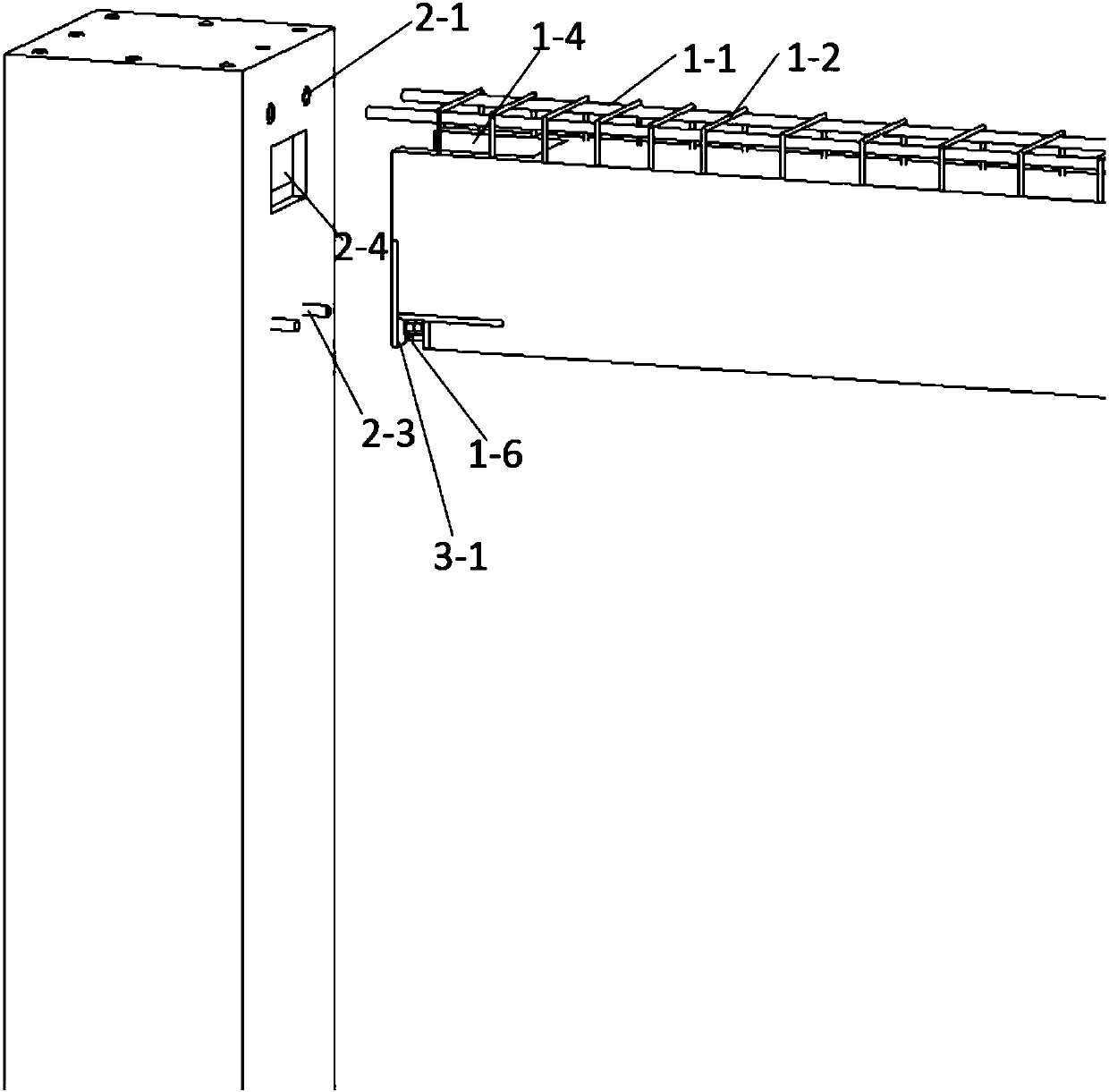

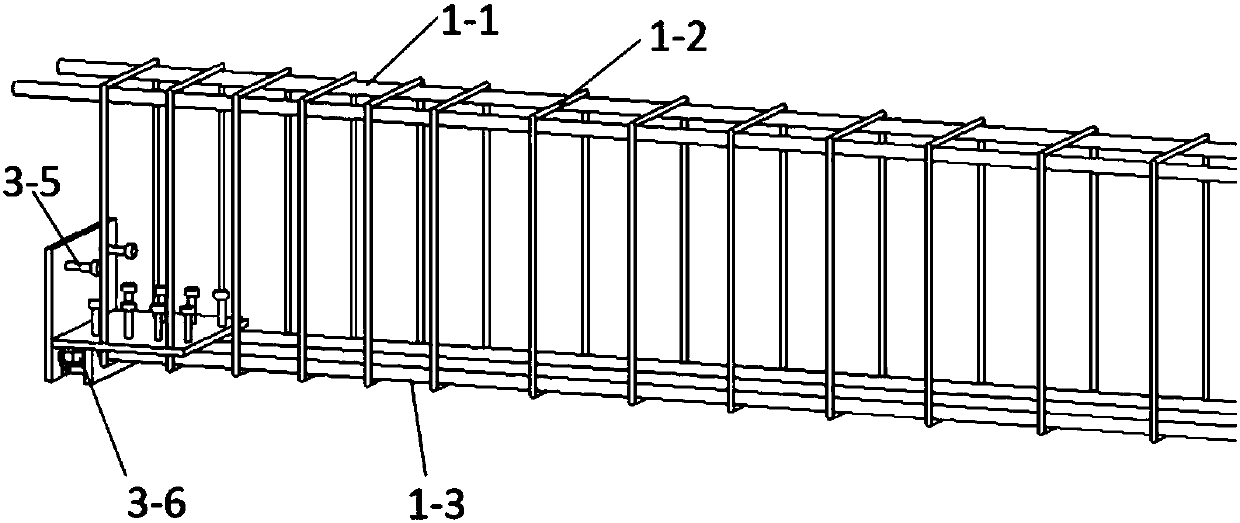

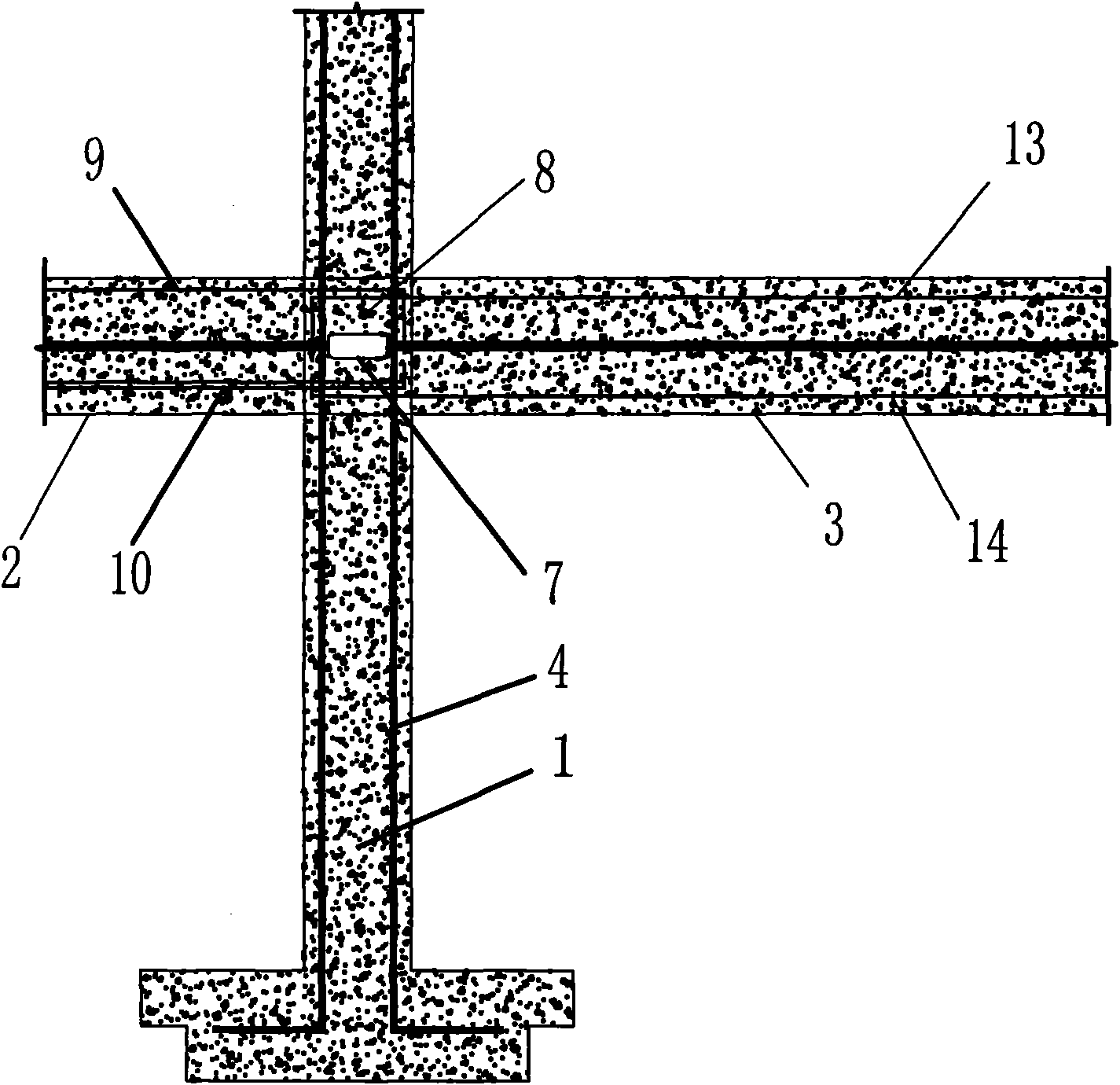

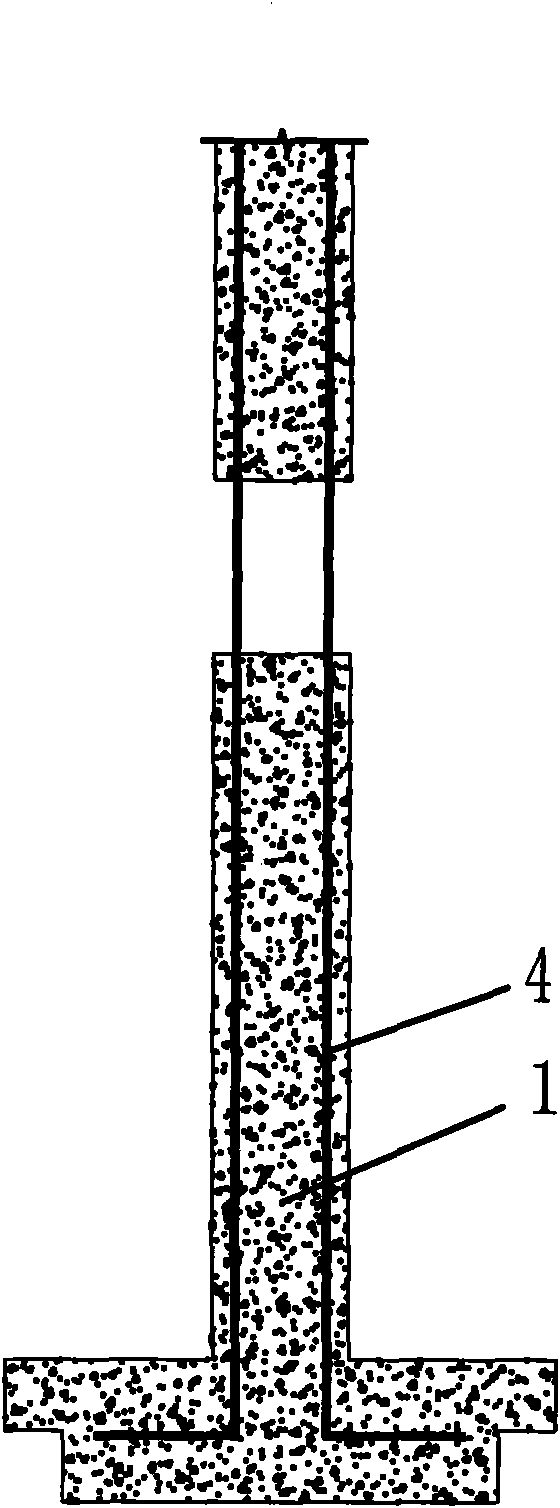

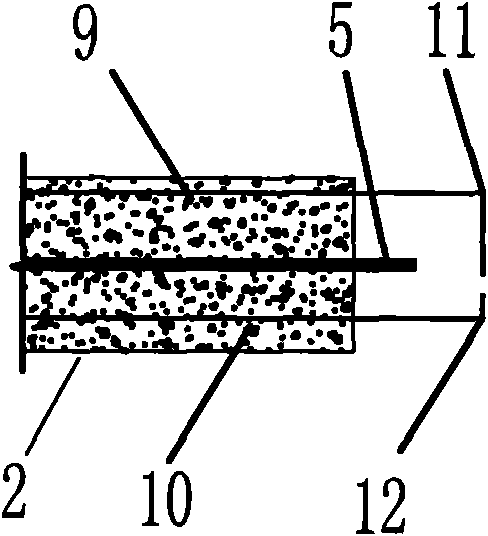

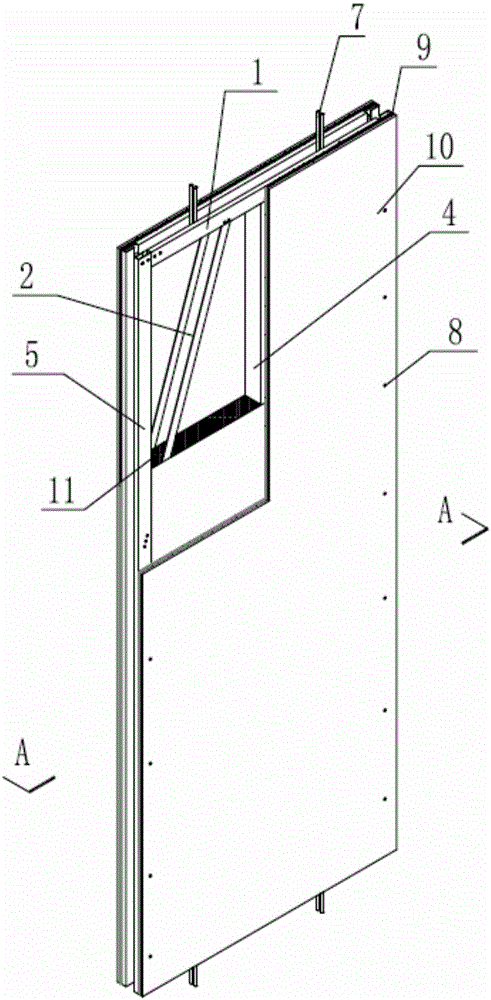

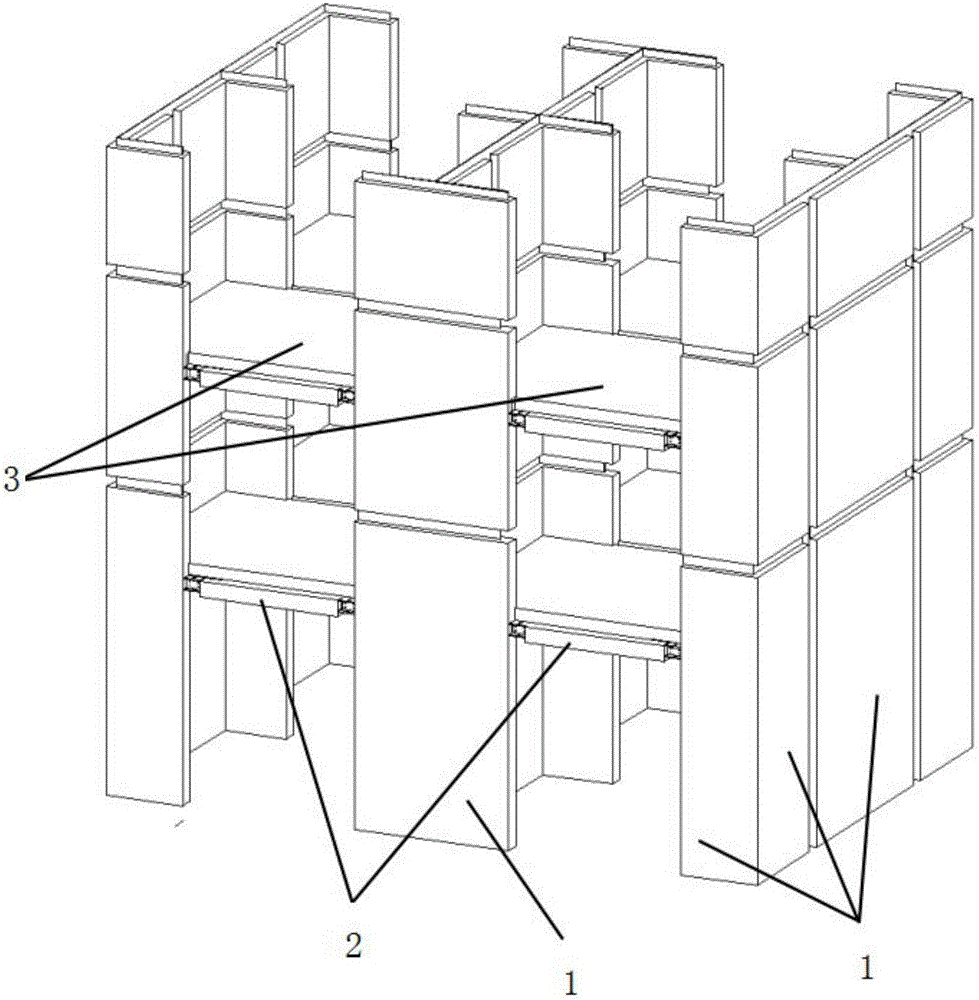

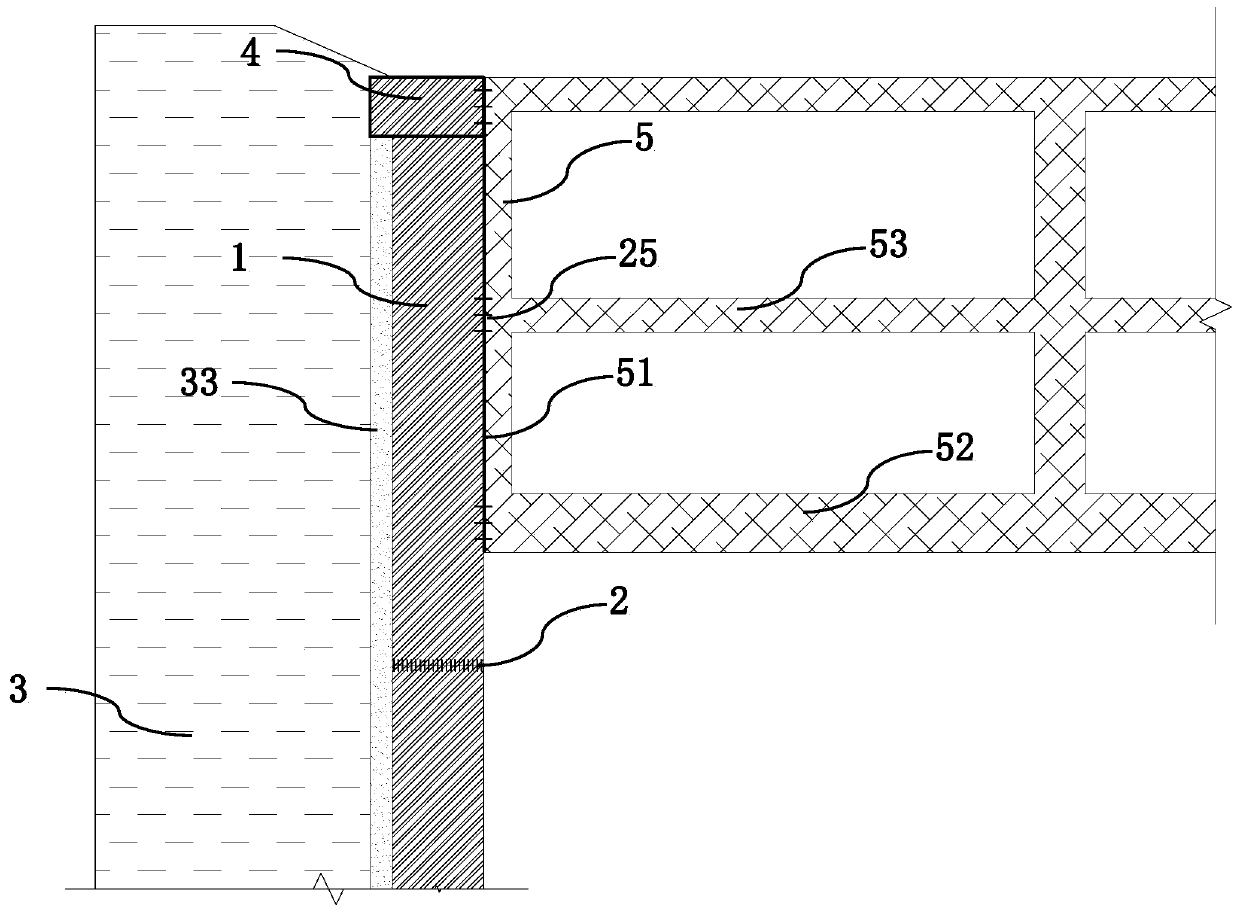

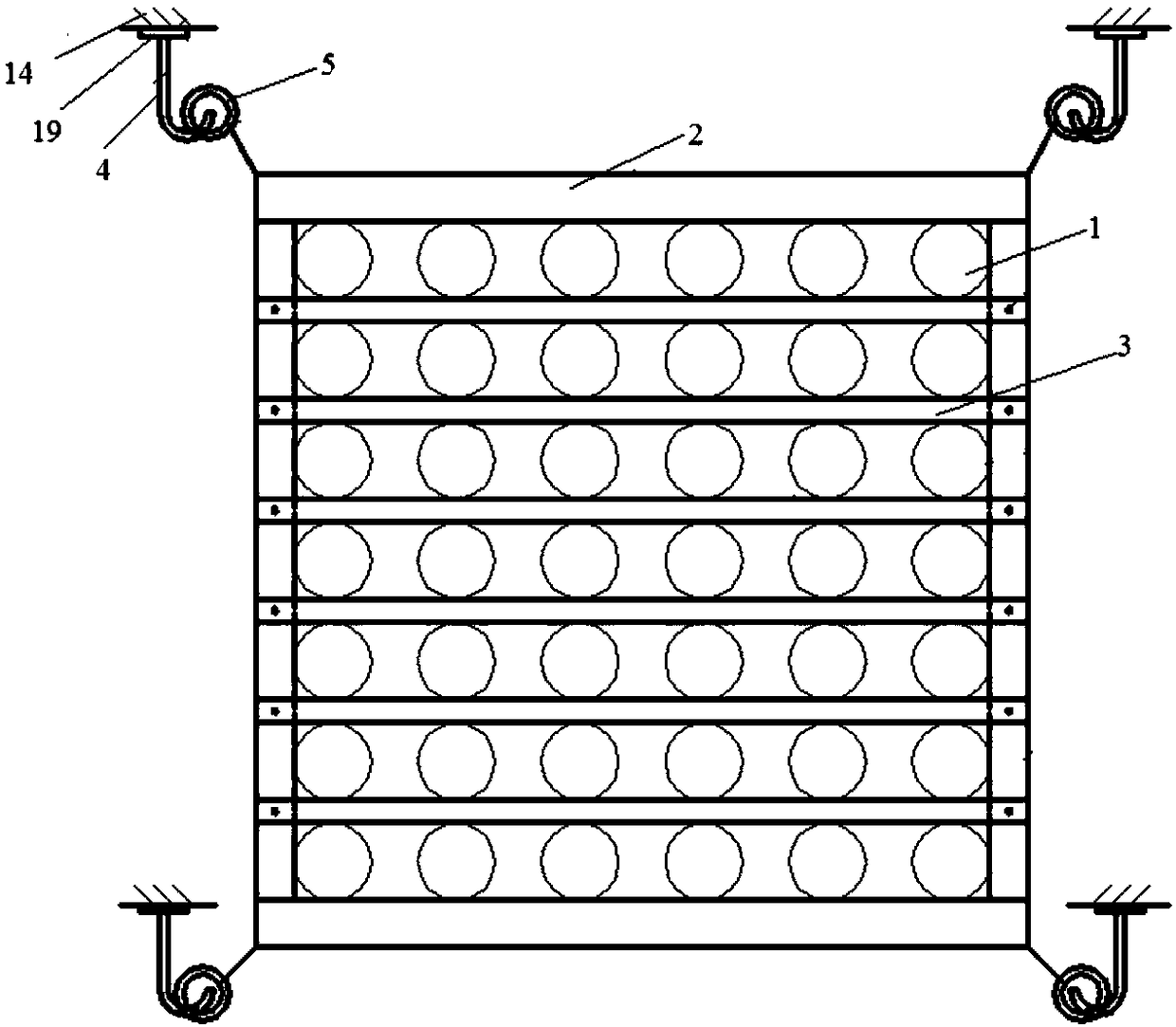

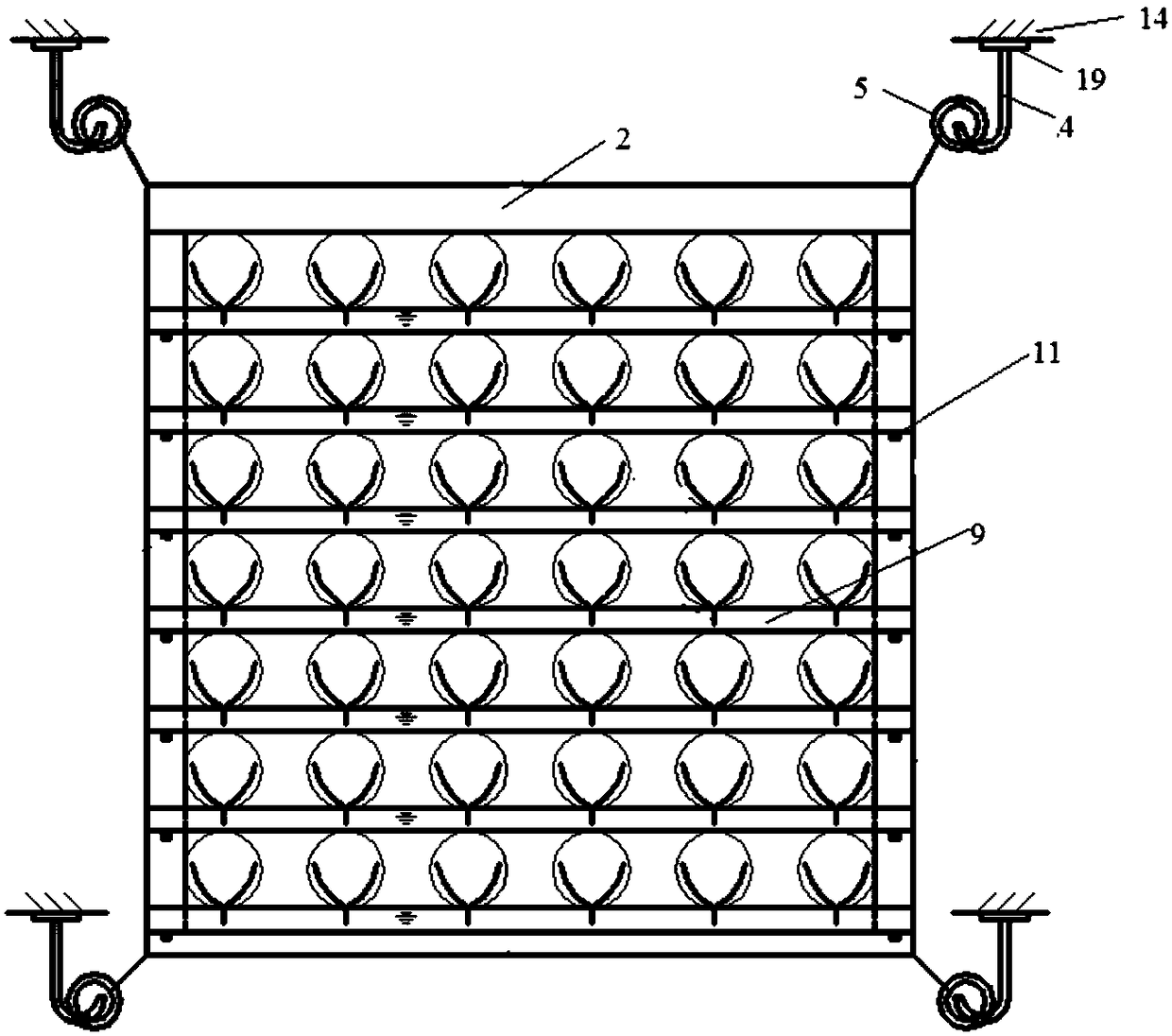

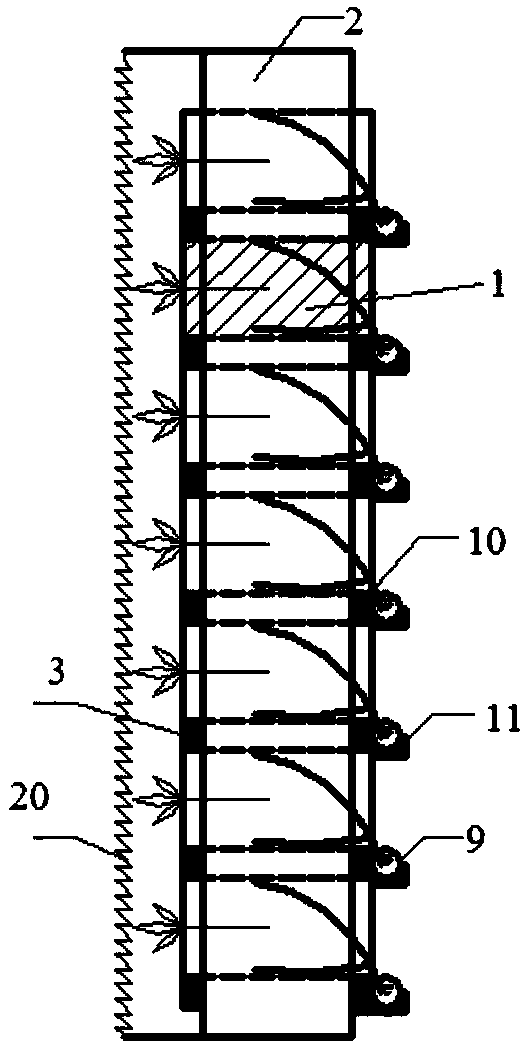

Splitting and assembling structure and assembling connecting method of assembled type concrete frame-shear wall

ActiveCN102900168ASplit location is reasonableEasy to manufactureWallsBuilding material handlingSteel barEngineering

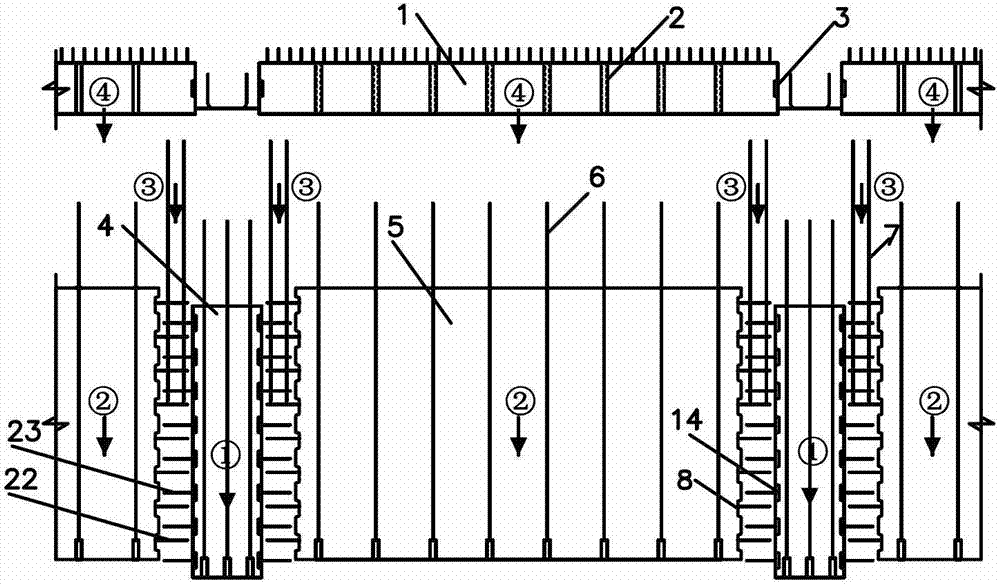

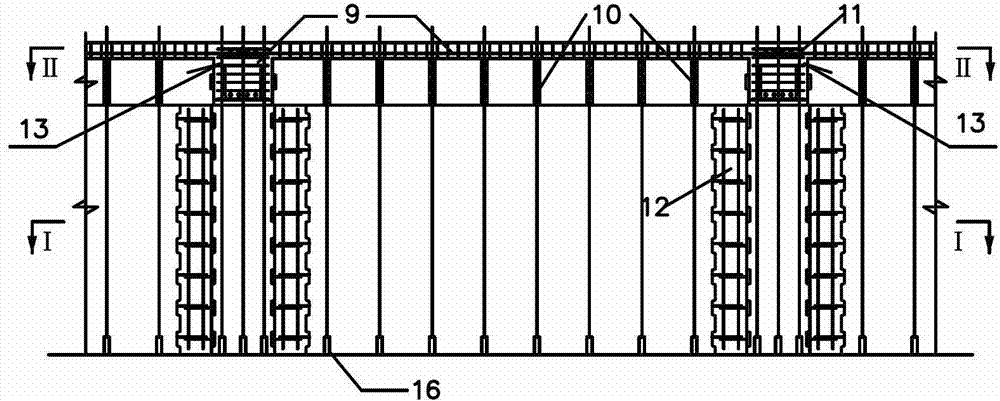

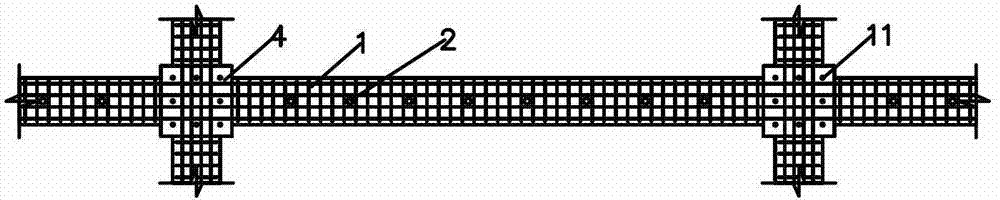

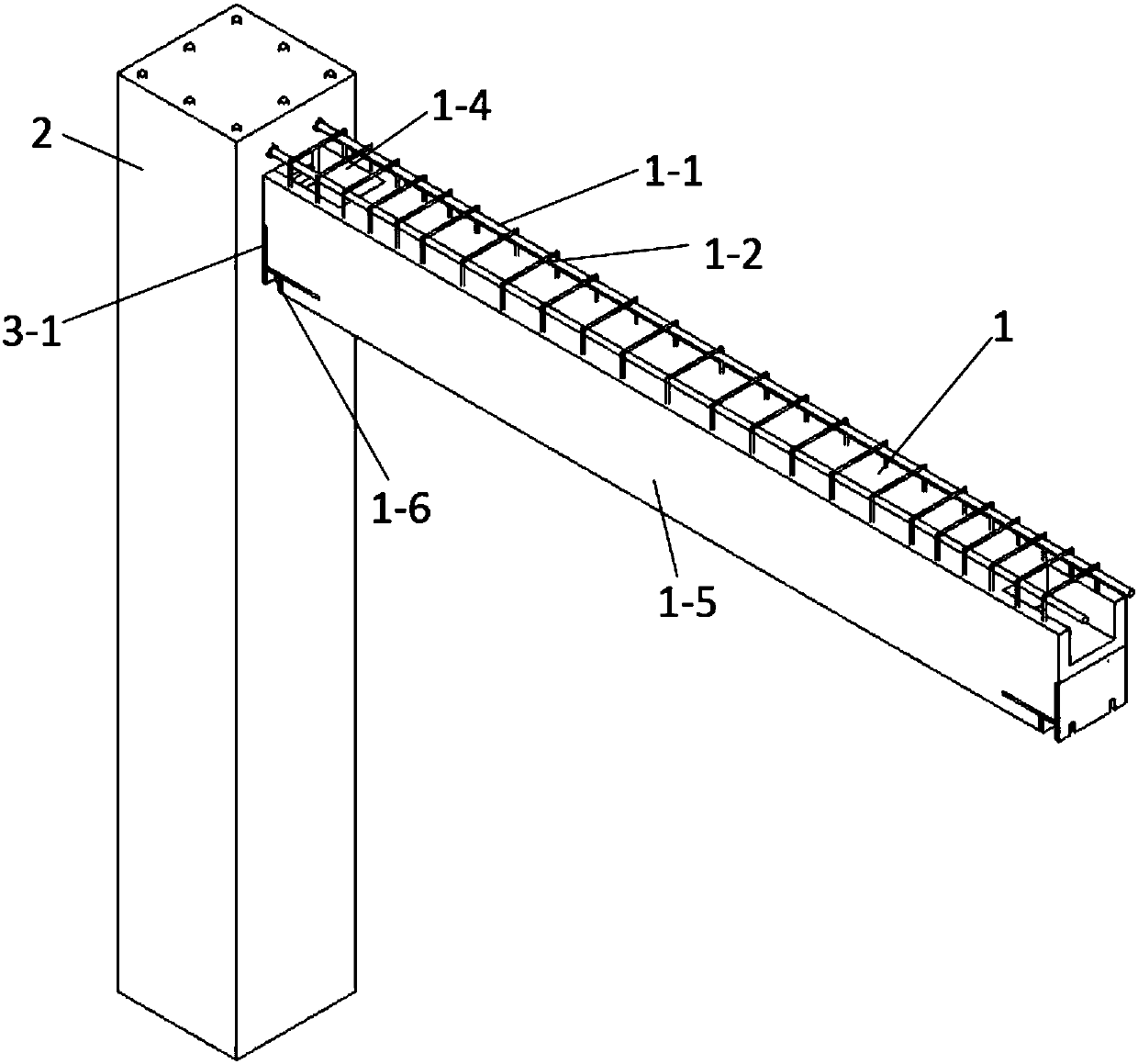

The invention relates to the field of concrete structures, in particular to a splitting and assembling structure and an assembling connecting method of an assembled type concrete frame-shear wall. The splitting and assembling structure comprises prefabricated pillars, prefabricated beams, prefabricated shear walls and cast-in-situ joints, wherein sleeves are embedded at the lower ends of the prefabricated pillars, mutually embedded with protruding reinforcing steel bar sections which extend from the upper ends of lower layer pillars and are integrally connected with the lower layer pillars by filling mortar; longitudinal prefabricated beam reinforcing steel bars extend into a joint core area to be anchored or connected with side beam ribs in a mechanical manner; a cast-in-situ zone is arranged between the prefabricated pillars and the prefabricated shear walls so as to carry out the connection of the embedded ribs of the pillars and the walls; and the embedded reinforcing steel bar sleeves at the lower ends of the prefabricated shear walls are mutually embedded with protruding reinforcing steel bar sections which extend upwards from the walls at the lower layer and are integrally connected with the walls at the lower layer by filling the mortar. The through connection of the vertical reinforcing steel bars of the share walls at the upper and lower layers is realized by filling the mortar into the through holes and the sleeves at the upper ends of the prefabricated shear walls and the prefabricated beams, so that the key problem that the vertical reinforcing steel bars of the share walls are hard to be continuous because of the isolation of the prefabricated beams is solved.

Owner:SHENYANG JIANZHU UNIVERSITY

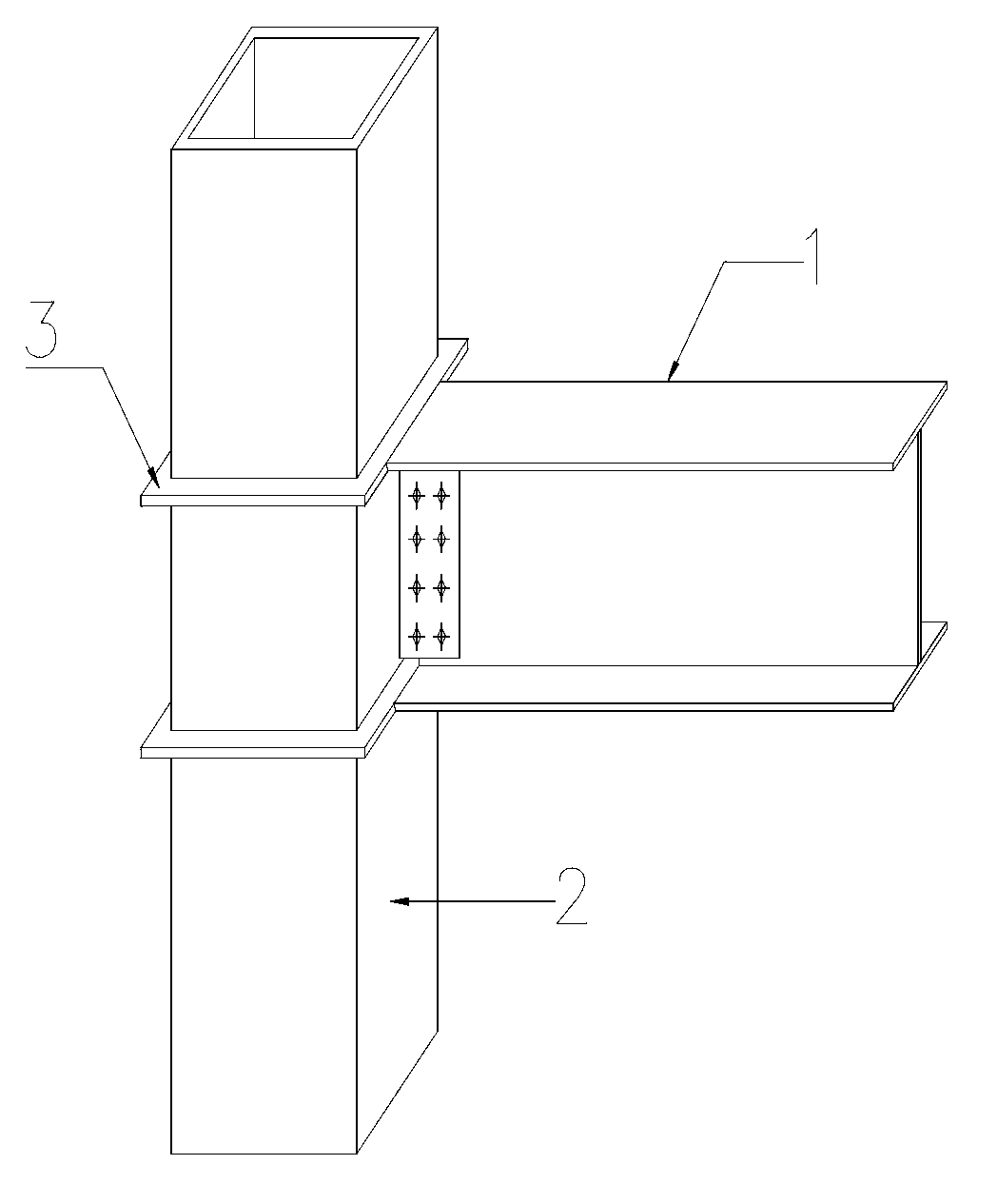

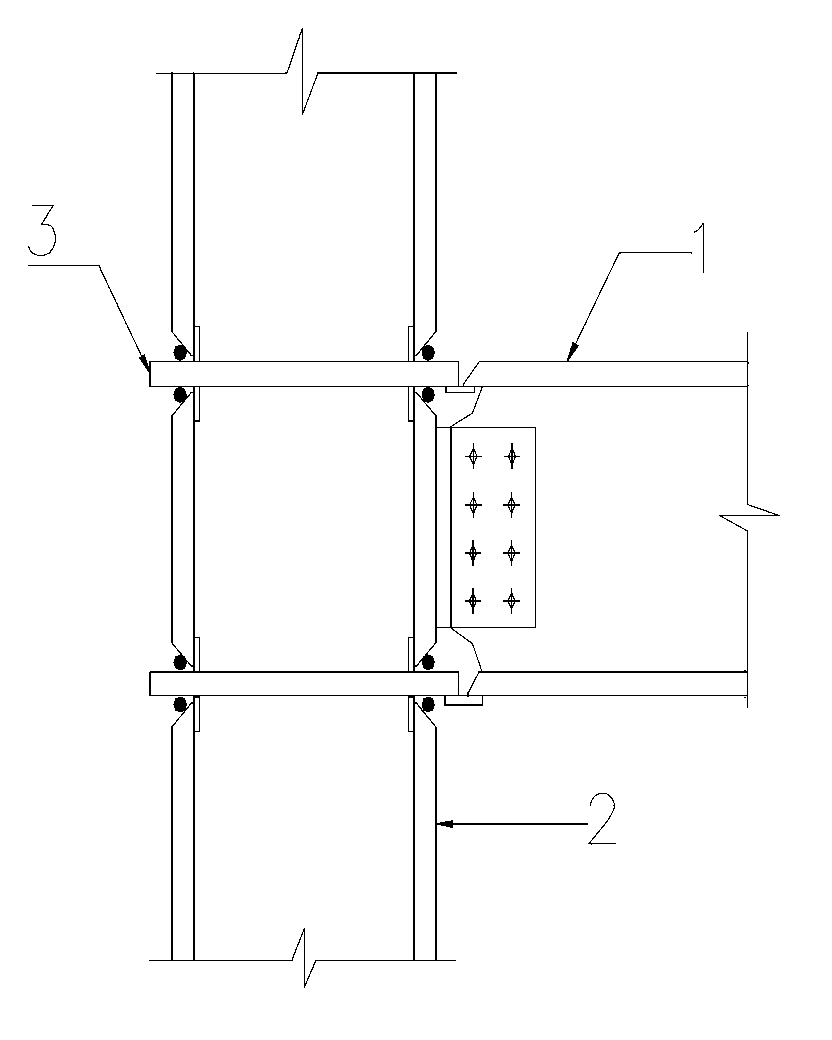

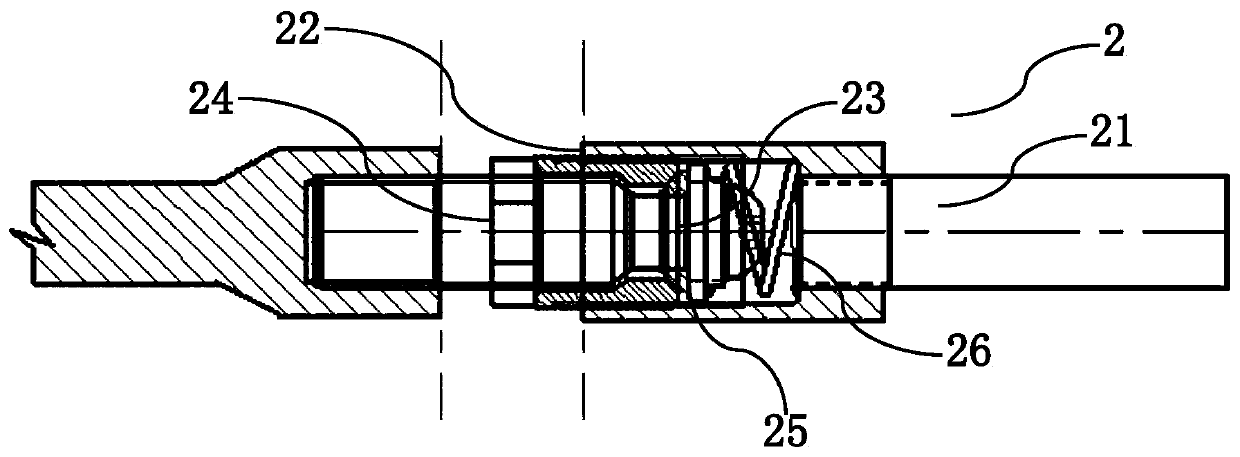

Prefabricated concrete frame beam-column joint construction method

The invention discloses a prefabricated concrete frame beam-column joint construction method, and relates to connection of a prefabricated column and a superposed beam. High-strength bolt bars and threaded sleeves are pre-buried in the column side of the prefabricated column, and a column side key groove is pre-formed; a beam end key groove is pre-formed in the beam end of a prefabricated beam, and a connection plate is pre-buried; the construction method adopts the following steps that (1), mounting of the prefabricated column is completed; (2) the prefabricated beam is mounted from top to bottom, so that the high-strength bolt rods penetrate through bolt connection holes; (3), upper longitudinal ribs of the superposed beam are mounted, firstly connection of the upper longitudinal ribs ofthe superposed beam and the threaded sleeves is completed, and then tying of the upper longitudinal ribs of the superposed beam and stirrups of the superposed beam is completed; (4) a washer and a lock nut are connected to each high-strength bolt rod to form pretightening force; and (5), templates are supported on the two sides of the prefabricated beam, concrete is poured, and a post-cast concrete anti-shear key integrated with a post-cast part of the superposed beam is formed in each of the beam end key groove and the column side key groove. The prefabricated concrete frame beam-joint construction method can achieve easy, rapid and convenient on-situ connection of the prefabricated column and the superposed beam, and connection is stable and reliable.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING

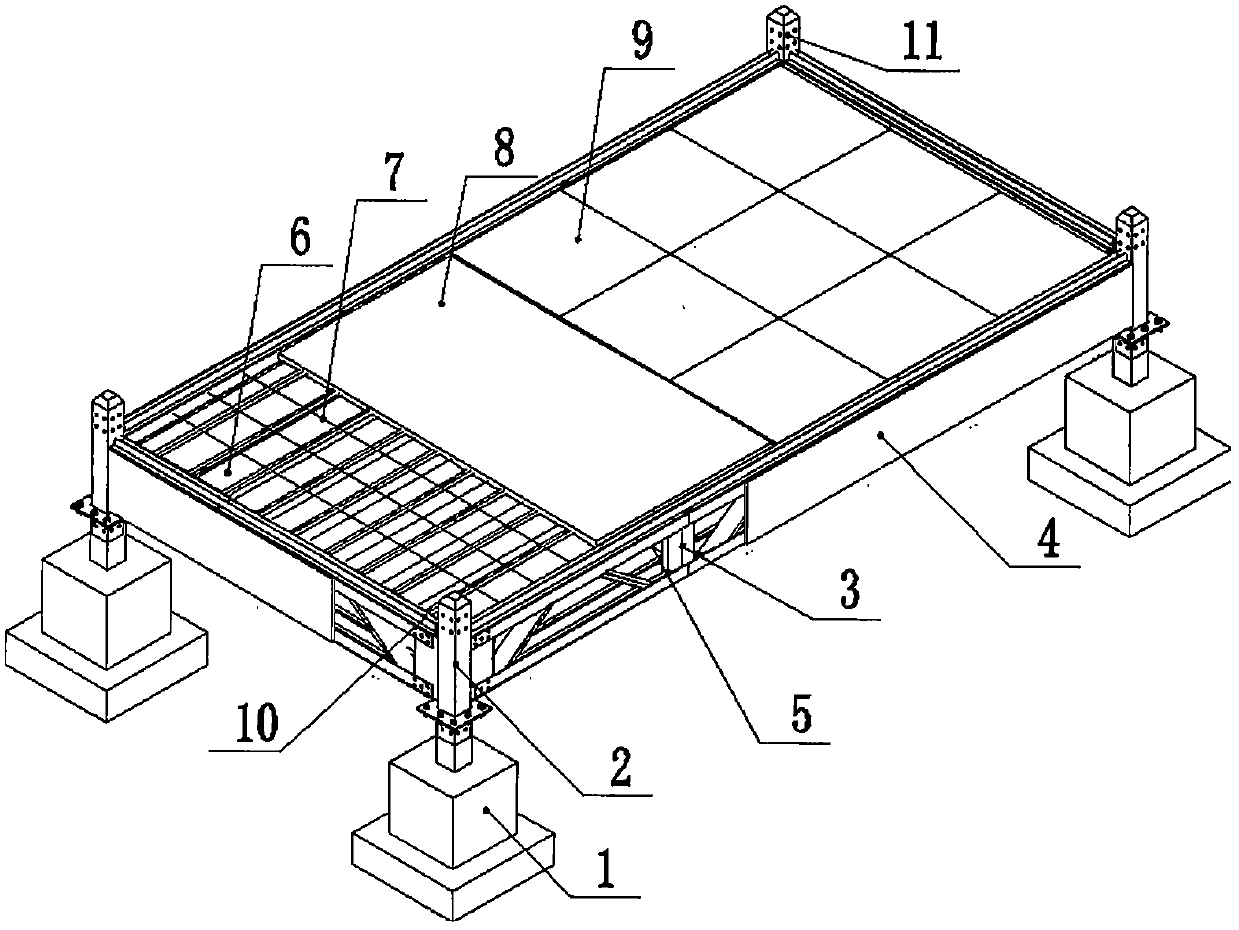

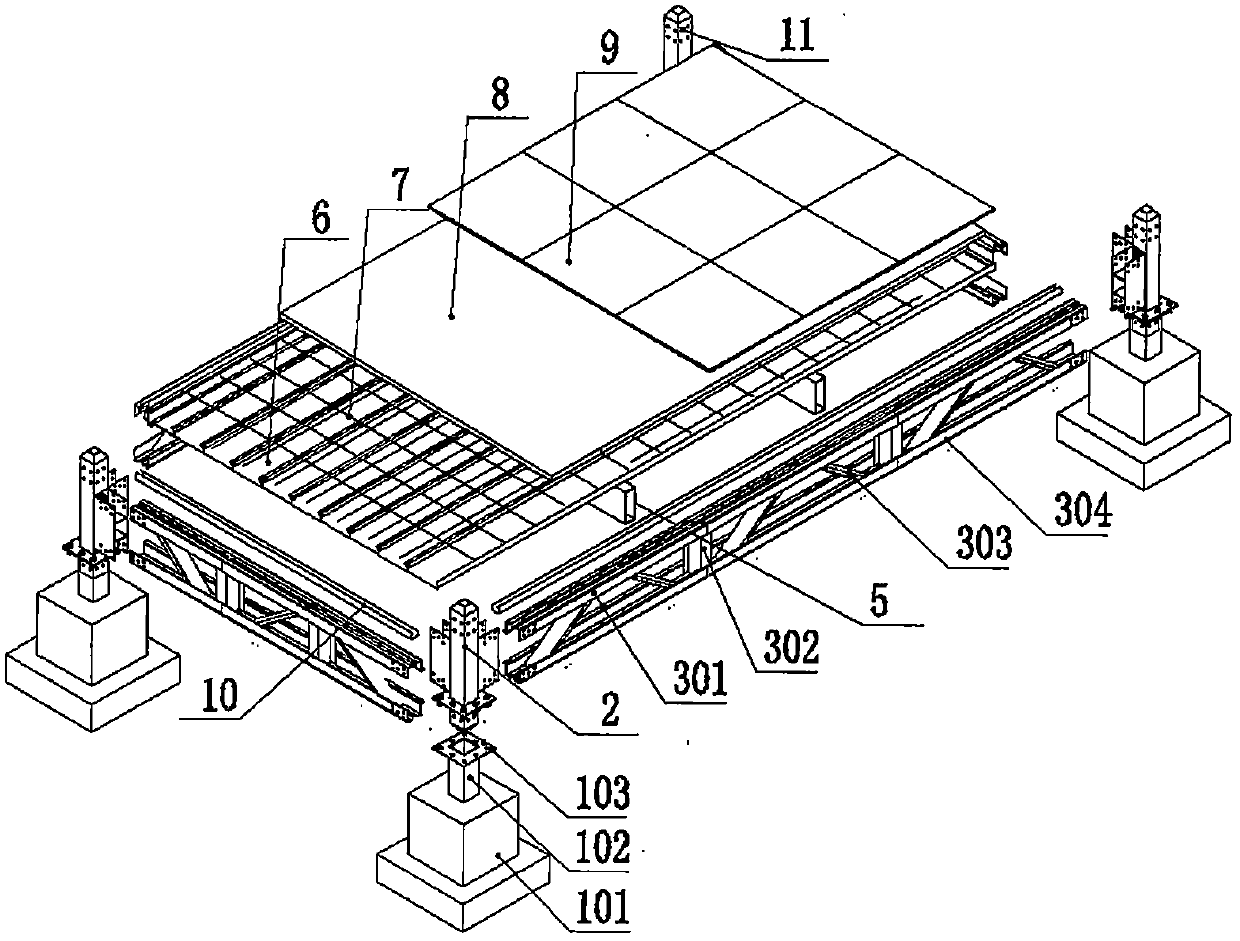

Assembly-type building bottom-layer composite floor and connection mode thereof

PendingCN107780576AImprove prefabrication rateReduce pollutionFloorsGirdersReinforced concreteMortise and tenon

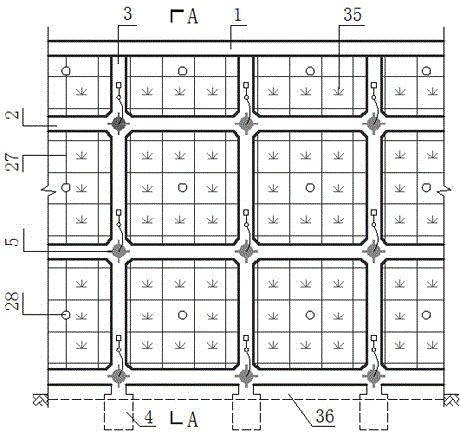

Provided are an assembly-type building bottom-layer composite floor and a connection mode thereof. Factory-fabricated reinforced concrete with embedded parts is used as independent basis, square headshort columns are factory-prefabricated connection components and connected with upper chord members and lower chord members of main beams through pulling rivets to form outer frames of floors; on thebasis of the outer frames, secondary beams, profiled steel sheets and reinforcing meshes are laid horizontally, a surface course is poured, a decorative layer is attached to the surface course, and thus a mortise and tenon joint type connection mode of the floors and basic nodes is formed by combing insertion, pulling rivet connection and flange connection. According to the assembly-type buildingbottom-layer composite floor and the connection mode, the building mode of a traditional bottom-layer floor can be changed, the assembly type can be achieved, and the defects of poor vibration performance and soundproof effect and the like of an assembly-type light steel composite floor can also be overcome; meanwhile, the assembly-type building bottom-layer composite floor also has the advantages that the floor is assembled rapidly and subjected to industrial production easily and is high in strength and high in production speed, and has large actual project significance and market values topromotion and development of assembly-type buildings.

Owner:谢志强 +1

Retard-bonded prestressed prefabricated integral frame joint system

InactiveCN101672070AImprove seismic performanceHigh degree of assemblyBuilding constructionsConcrete beamsPre stress

The invention discloses a retard-bonded prestressed prefabricated integral frame joint system. The system comprises a precast concrete column, a left precast concrete beam and a right precast concretebeam; wherein, a joint part of the precast concrete column merely consists of a main reinforcement, retard-bonded prestressed tendons are respectively laid in the left precast concrete beam and the right precast concrete beam, the right end of the retard-bonded prestressed tendons in the left precast concrete beam forms a connection part, and the left end thereof is connected with an anchorage ata tensioning end; the left end of the retard-bonded prestressed tendons in the right precast concrete beam forms a connection part, and the right end thereof is connected with the anchorage at the tensioning end; the connection part of the retard-bonded prestressed tendons in the left precast concrete beam is connected with the connection part of the retard-bonded prestressed tendons in the rightprecast concrete beam by a connector, and the precast concrete column, the left precast concrete beam and the right precast concrete beam are connected into an integral part at the joint part by castfine aggregate concrete. The system is characterized by good seismic performance, high fabrication degree and easy construction operation.

Owner:CHINA JINGYE ENG +1

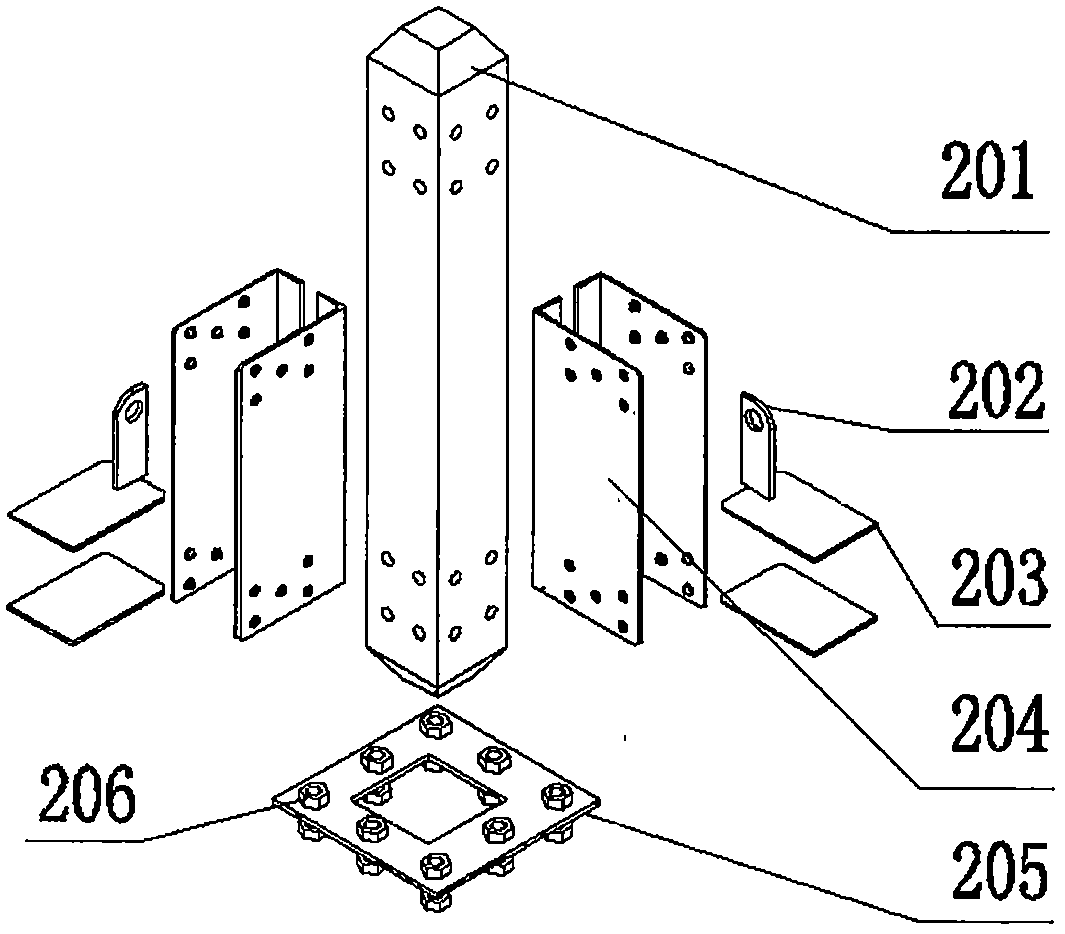

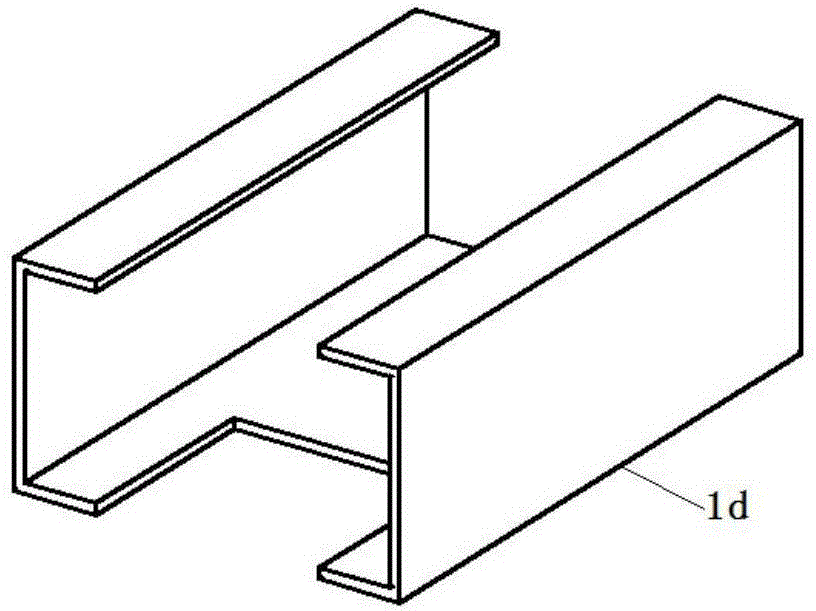

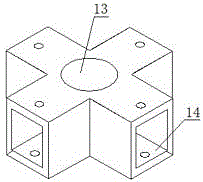

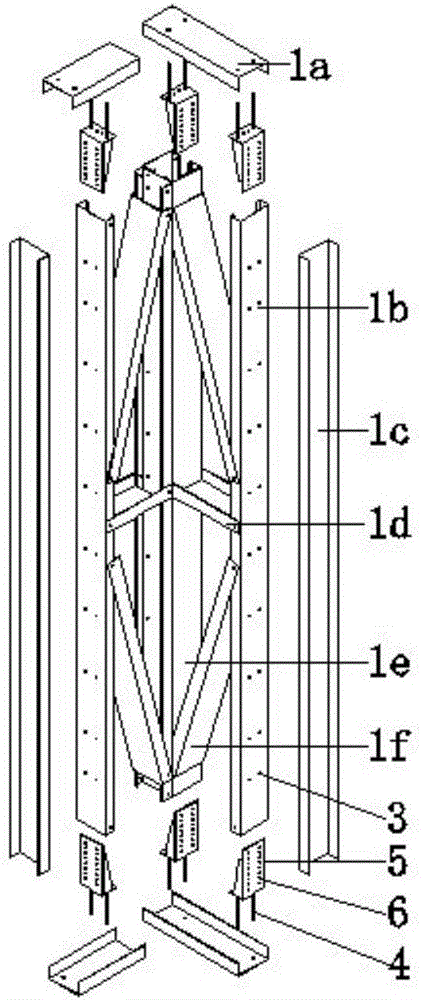

Prefabricated cold-formed thin-walled steel plate column structure tenon and mortise connection system and construction method thereof

InactiveCN107795013AImprove prefabrication rateEnsure structural safetyStrutsPillarsCold formedHouse building

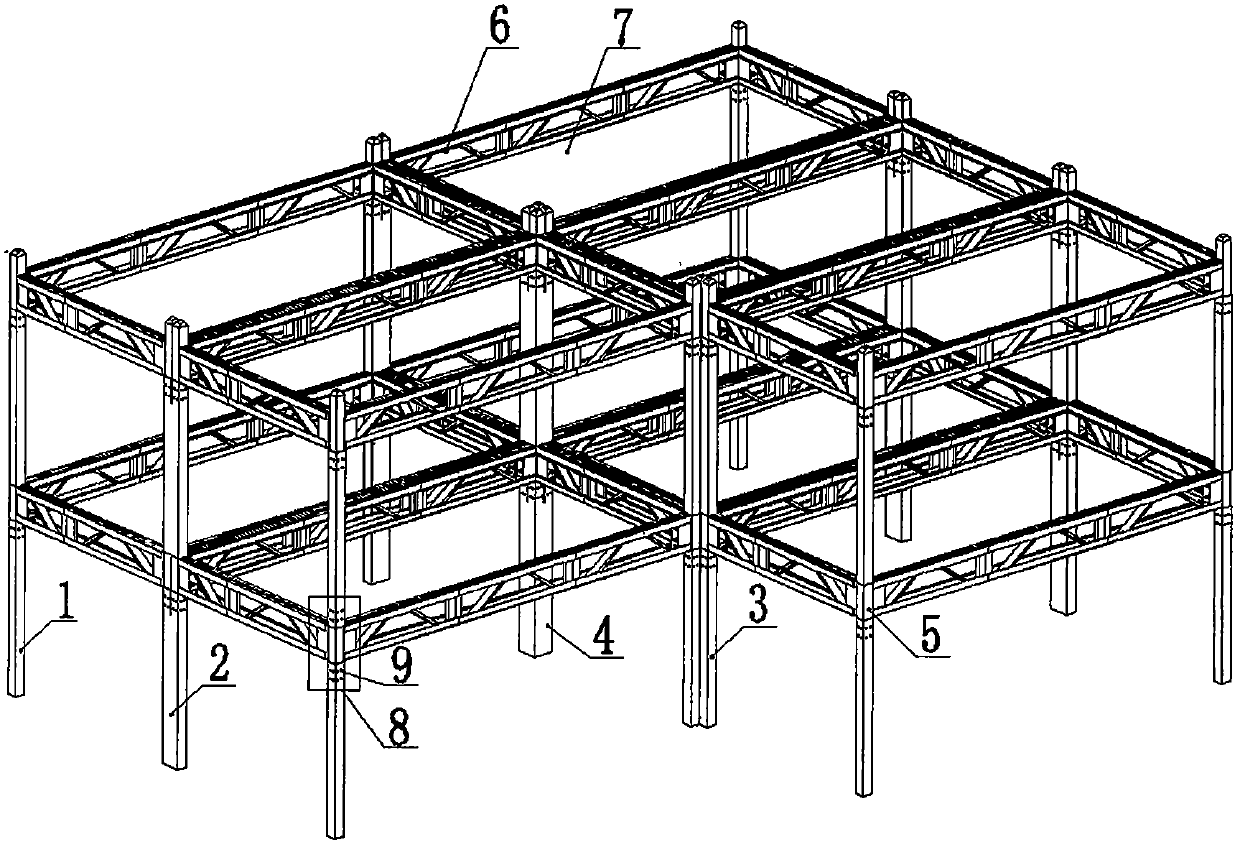

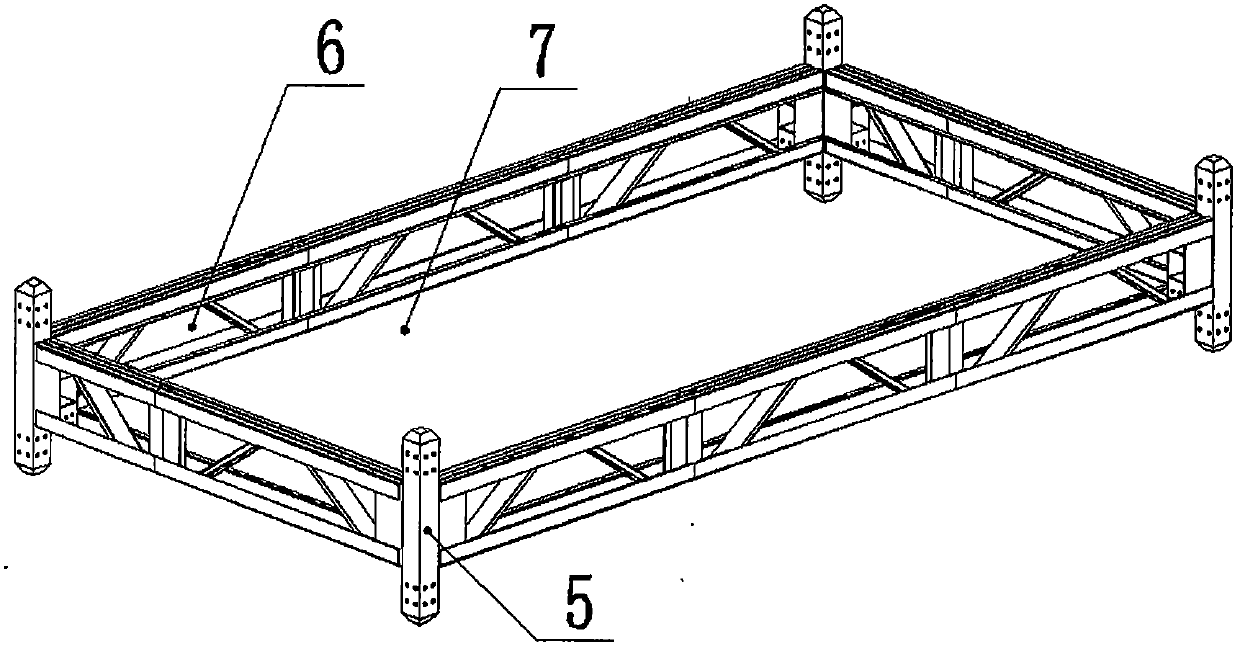

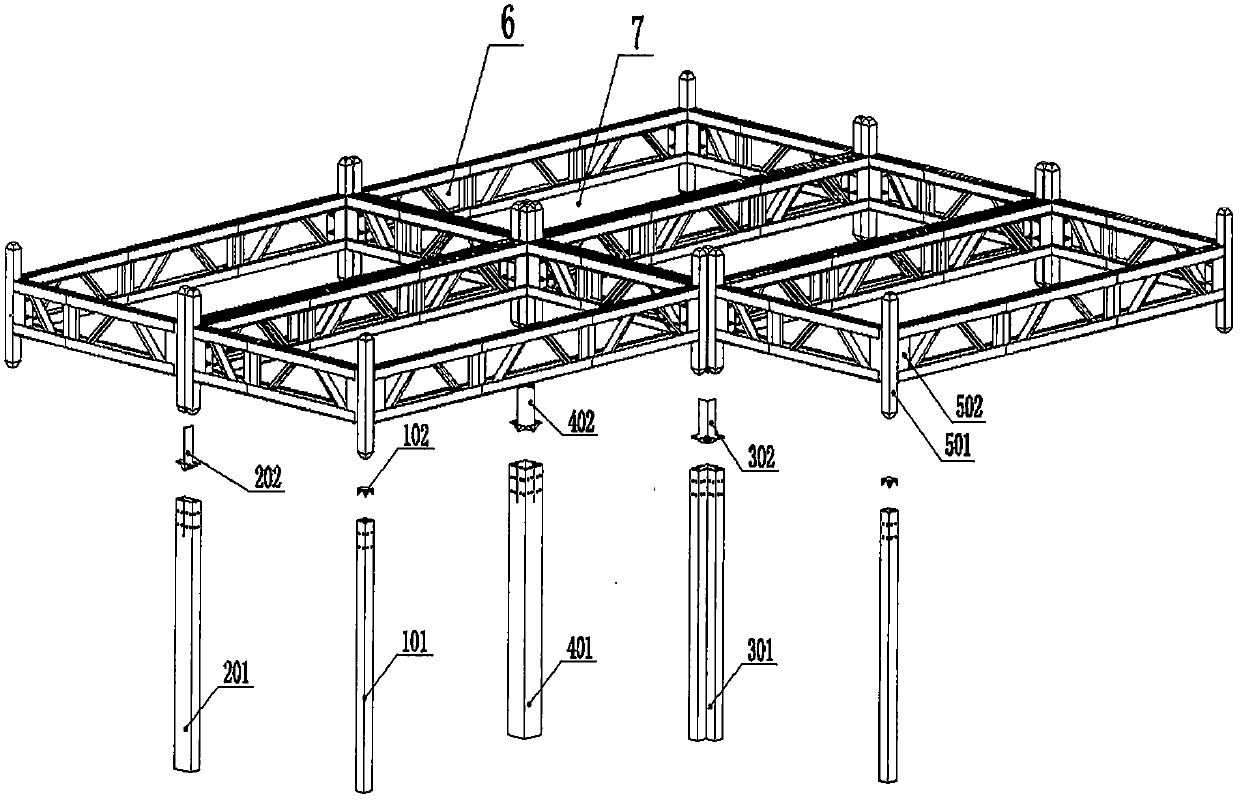

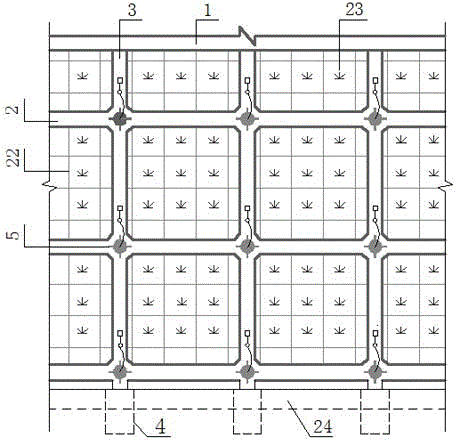

The invention relates to a prefabricated cold-formed thin-walled steel plate column structure tenon and mortise connection system and a construction method thereof, and belongs to the technical fieldof structural engineering. Single-hole columns, double-hole columns, three-hole columns and four-hole columns are support columns of the system. A floor module is the main structure of the system. Theconnection mode between the floor and the columns is the connection mode between the support columns and the main structure of the system. The single-hole columns and the double-hole columns are respectively arranged at joint connection support parts at the bottom of the floor module. The three-hole columns are arranged at corner support parts at the bottom of the floor module. The four-hole columns are located at center cross support parts at the bottom of the floor module. Through the method of optimizing the light steel plate column structure system by implanting beam-column joints in thefloor, the structure is allowed to bear the force more reasonably, the consumption of building materials and the amount of construction work at a construction site are greatly reduced, and a rapid green construction is truly realized. The whole building is sturdy and durable, thermal-insulating, lightweight, energy-saving, environmentally friendly, suitable for all kinds of housing construction and highly applicable, and will bring good economic and social benefits.

Owner:谢志强 +1

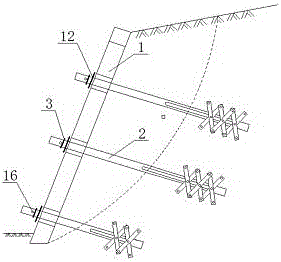

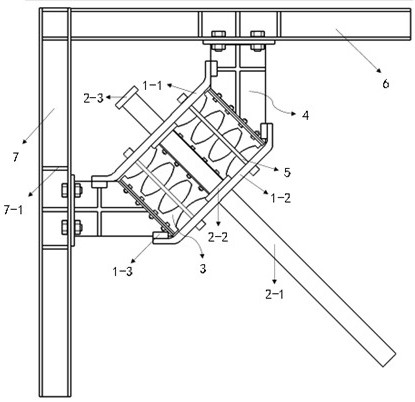

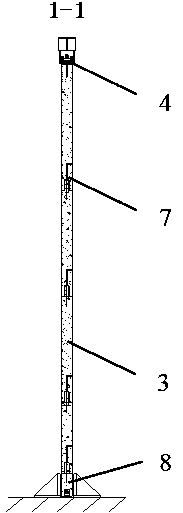

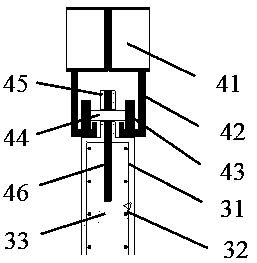

Active refrigeration and self-recovery cold region side slope support structure and construction method

ActiveCN104358265AAchieve churnAchieve harmonyExcavationsBulkheads/pilesTemperature controlSelf recovery

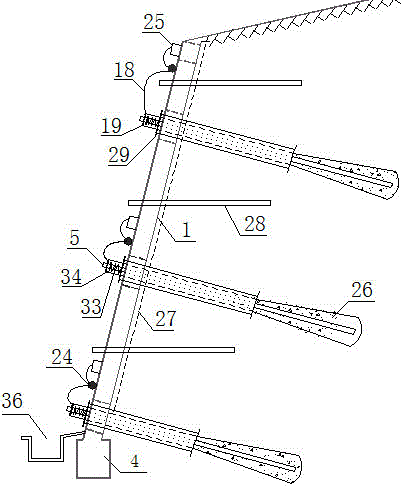

The invention discloses an active refrigeration and self-recovery cold region side slope support structure and a construction method, and belongs to the field of cold region side slope support. The structure comprises a frame, heat anchor pipes and a refrigeration device, wherein the heat anchor pipes are formed by connecting heat pipes with hollow anchor pipes through threads; the refrigeration device is formed by connecting refrigeration sheets, temperature control switches and solar panels through wires; condensation sections of the heat anchor pipes are provided with the refrigeration sheets; an anchorage device, a spring and a backing plate are arranged on each heat anchor pipe in a sleeving manner in sequence, and the heat anchor pipes is arranged in slope holes; slurry is injected into the heat anchor pipes through pressure to anchor the heat anchor pipes in a stable frozen soil layer; a geogrid and the frame are constructed on a slope; the heat anchor pipes are anchored in the frame by using the anchorage devices; a drainage ditch is formed in the toe of the slope; the refrigeration sheets, and the temperature control switches and the solar panels on the frame are connected in sequence by using the wires.

Owner:DALIAN KENVIS IND TECH CO LTD

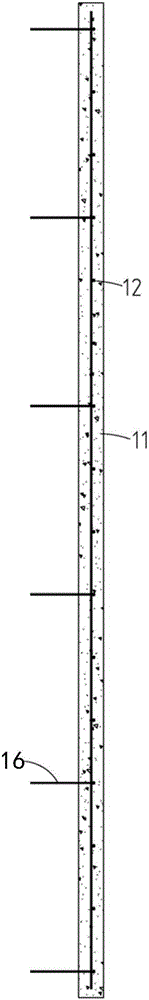

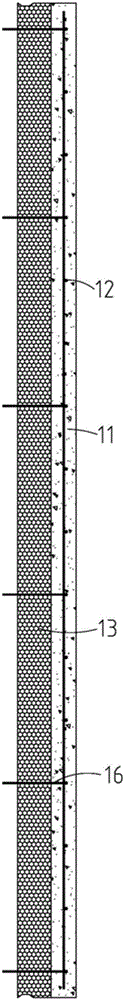

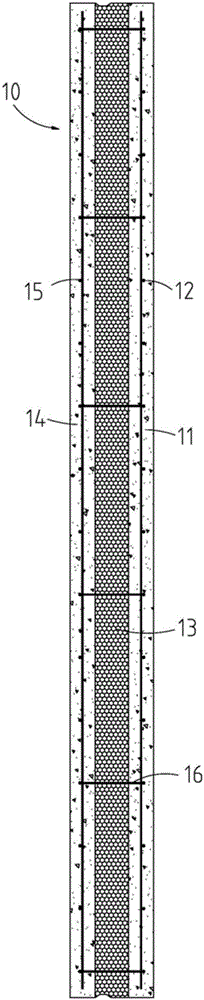

Modular assembly type composite wall and connecting mode thereof

The invention discloses a modular assembly type composite wall and a connecting mode thereof. A foamed cement core material is filled in the middle of a cold-formed thin-wall type steel framework; a self-leveling cement surface layer is bonded with the foamed cement core layer, and the self-leveling cement surface layer and the cold-formed thin-wall type steel framework are connected by a self-tapping bolt; and the cold-formed thin-wall type steel framework, the foamed cement core material and the self-leveling cement surface layer are connected to form the modular assembly type composite wall. Adjacent two modular assembly type composite walls are horizontally connected by a connector among wall modules. The modular assembly type composite wall and floor modules are vertically connected by a connector among the floor modules. The modular assembly type composite wall disclosed by the invention is a wall which is integrated with structural bearing, thermal insulation and decoration, is high in degree of integration and assembly, low in material cost, cheap in overall price and simple in configuration, and greatly saves labor cost.

Owner:BEIJING UNIV OF TECH

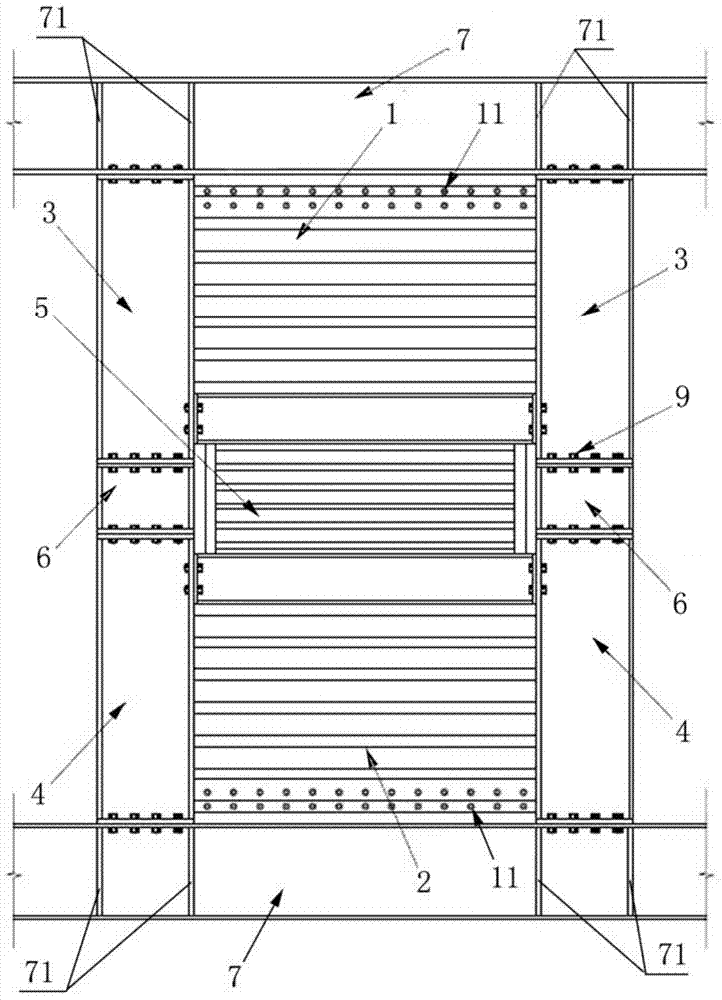

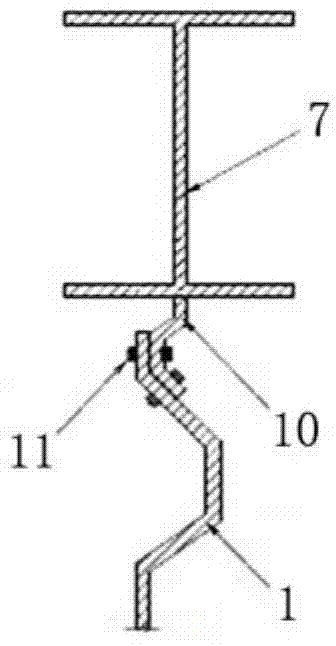

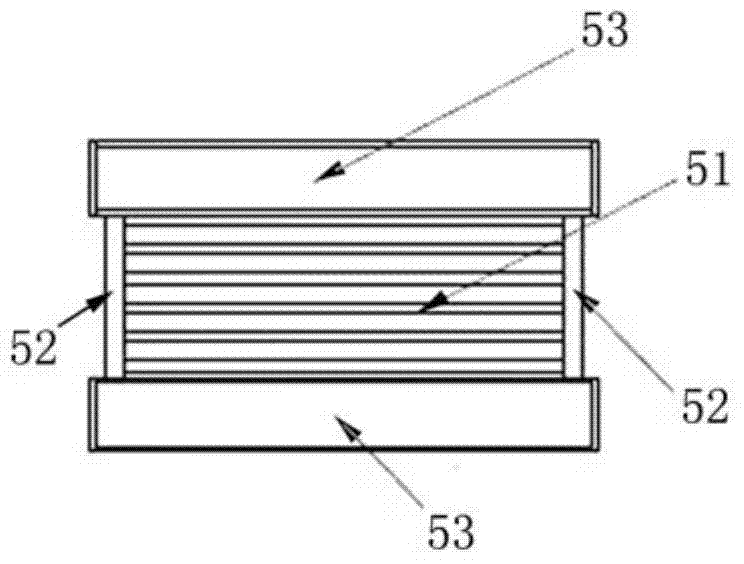

Beam through type corrugated steel plate energy consumption shear wall structure

ActiveCN104746774AIncreased shear capacityReduce building weightWallsShock proofingSheet steelShear capacity

The invention provides a beam through type corrugated steel plate energy consumption shear wall structure which comprises a first corrugated steel plate shear wall piece, a second corrugated steel plate shear wall piece, an upper edge steel column, a lower edge steel column, a corrugated steel plate energy consumption section and short steel columns on the left side and the right side of the corrugated steel plate energy consumption section. The corrugated steel plate energy consumption section and the short steel columns are located in the middle of a floor. The upper end and the lower end of the corrugated steel plate energy consumption section are connected with the first corrugated steel plate shear wall piece and the second corrugated steel plate shear wall piece respectively. The first corrugated steel plate shear wall piece and the second corrugated steel plate shear wall piece are connected with a floor beam through bolts respectively. The lower end of the upper edge steel column is connected with the upper ends of the short steel columns through bolts, and the upper end of the lower edge steel column is connected with the lower ends of the short steel columns through bolts. The upper end of the upper edge steel column and the lower end of the lower edge steel column are connected with the floor beam through bolts respectively. The first corrugated steel plate shear wall piece and the second corrugated steel plate shear wall piece are connected with the upper edge steel column and the lower edge steel column respectively. The corrugated steel plate shear wall pieces are adopted as a body of the shear wall structure, and therefore a building is small in dead weight, the material consumption is low, and the shear capacity of a wall body is improved.

Owner:TONGJI UNIV

Cold region active ventilation cooling self-recovery slope anchorage structure and construction method

ActiveCN104452782AStrong convective heat transfer capacityGood cooling effectExcavationsBulkheads/pilesAgricultural engineeringSelf recovery

The invention belongs to the field of cold region slope support and discloses a cold region active ventilation cooling self-recovery slope anchorage structure and a construction method. The cold region active ventilation cooling self-recovery slope anchorage structure comprises a framework, ventilation anchor pipes and a ventilation system. The ventilation anchor pipes are formed in the mode that anchor pipes are nested in ventilation pipes coaxially through positioning rings and the ventilation pipes are coaxially sleeved with exhaust pipes. The ventilation system is composed of fans, temperature control switches and solar panels, all of which are connected through wires. Slurry is injected into the anchor pipes, passes through slurry outlet holes and is bonded with surrounding stable frozen soil; geogrids, drain pipes and the framework are constructed on the slope surface, and the ventilation anchor pipes penetrate through the framework; the front section of each ventilation anchor pipe is sleeved with a flange base plate and a spring sequentially and is fixed on the framework through an anchorage device; plants are planted in the geogrids, and a drain channel is arranged at the slope toe; the fans are installed at the front sections of the anchor pipes, the temperature control switches and the solar panels are arranged on the framework, and the fans, the temperature control switches and the solar panels are connected through the wires. The cooling effect is remarkable due to automatic air supply, the swelling reduction, shock absorption and self-recovery functions are remarkable, water is drained in time, and development of frozen soil is promoted due to the geogrid slope surface and the plants; the method is easy and convenient to implement, and construction is rapid.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

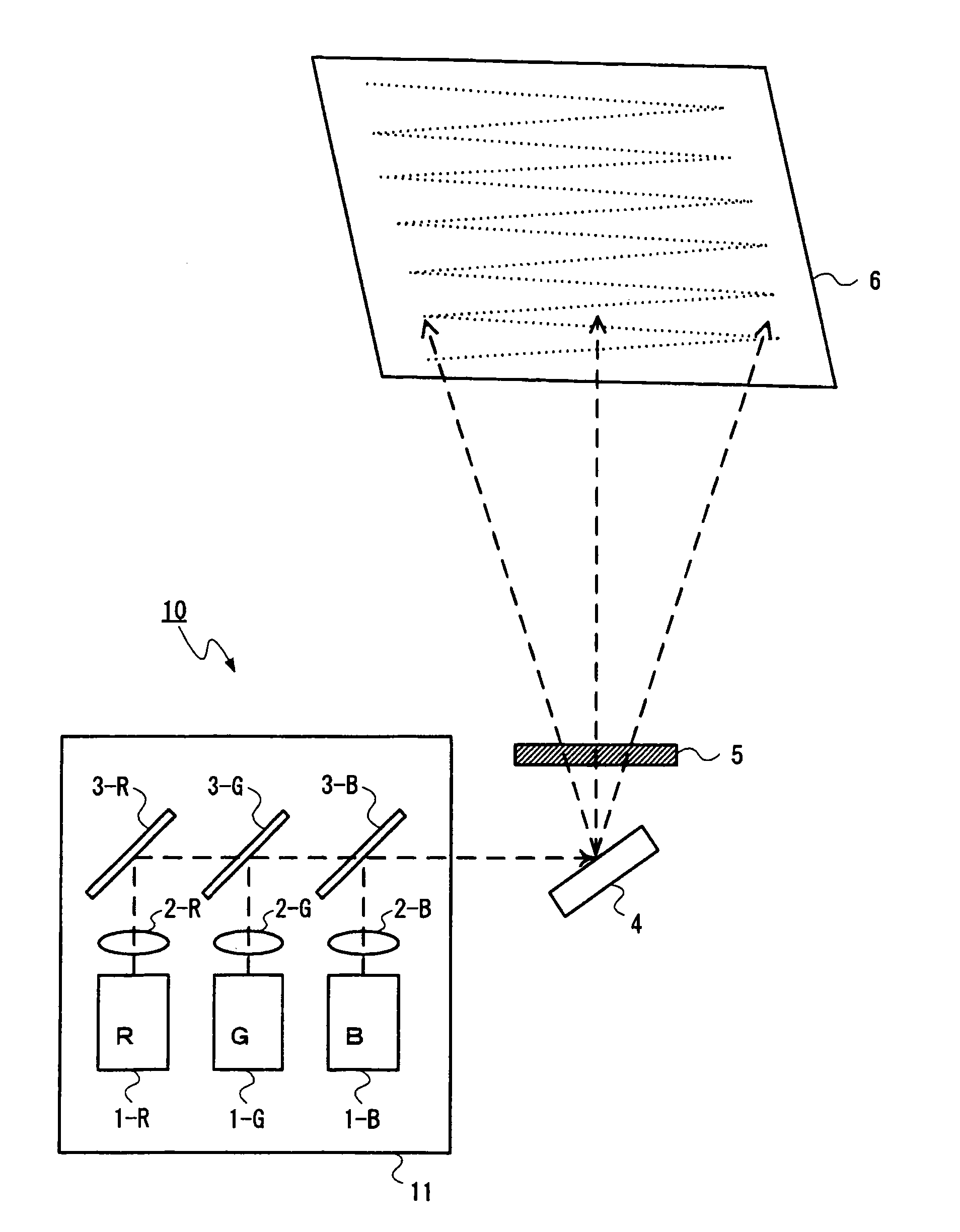

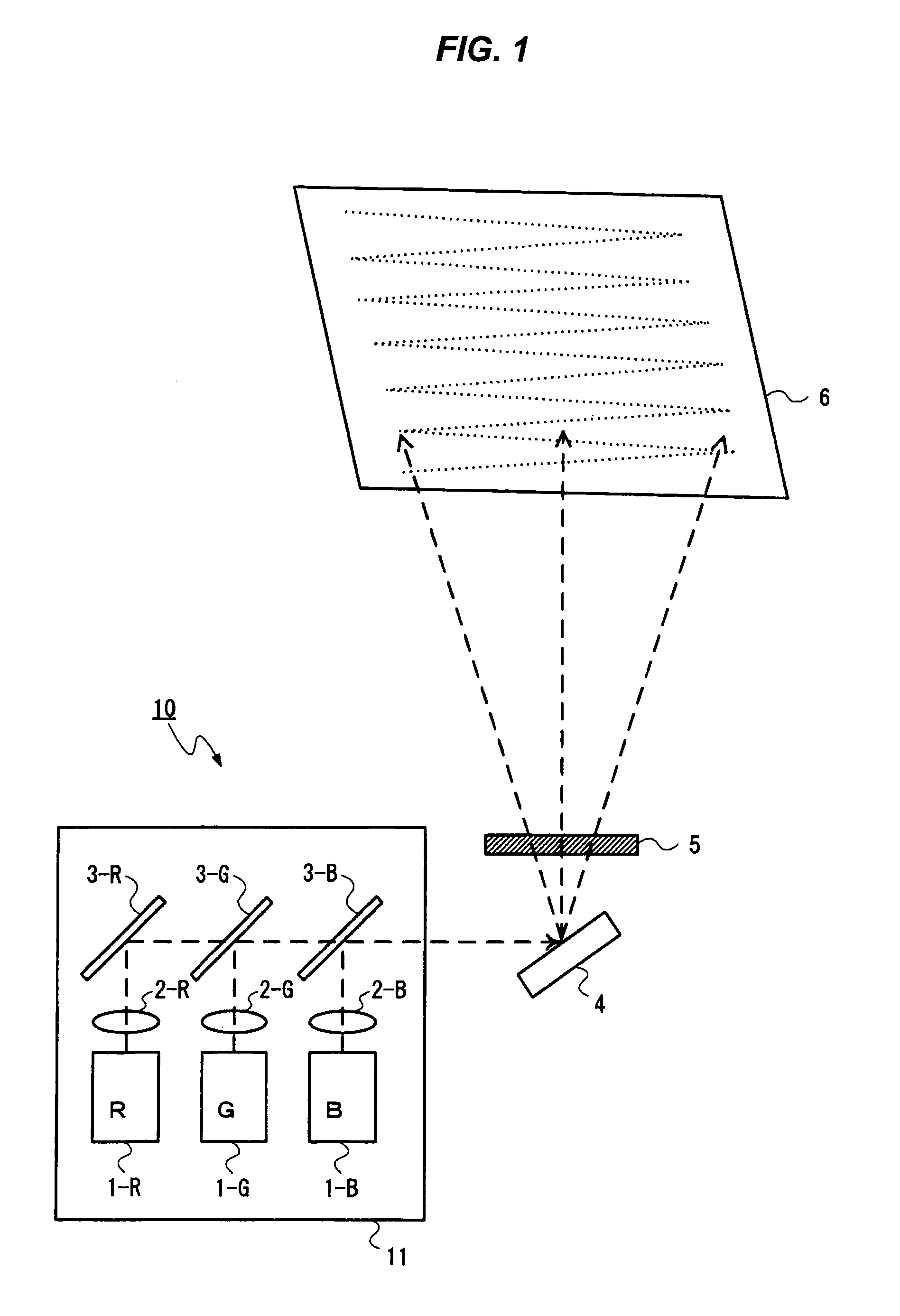

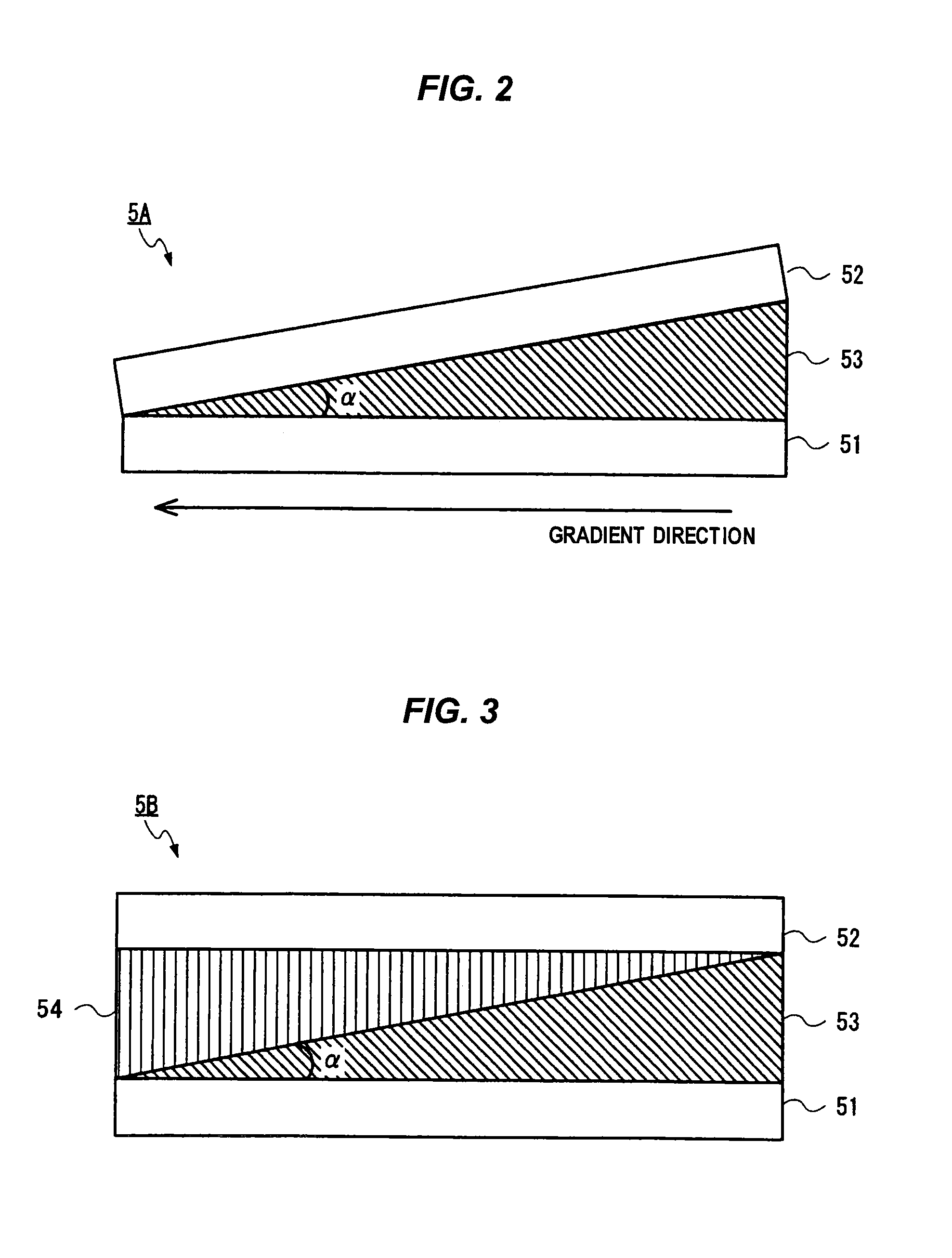

Scanning display device and speckle reduction method

A scanning display device includes: a light source section including at least one light source configured to emitting coherent light; a light scanning section including: a scan mirror configured to reflect the light originated from the light source section and scan over a screen; and a turning section configured to turn the scan mirror; a depolarizer having outgoing polarized light distribution in which a state of polarization of outgoing light consecutively changes within an element plane, wherein: the depolarizer is placed in an optical path along which the light emitted by the light source section reaches the screen; and the state of polarization of the light is changed, thereby scanning the screen with light that has a polarized light distribution, in which the state of polarization consecutively changes, in a beam diameter.

Owner:ASAHI GLASS CO LTD

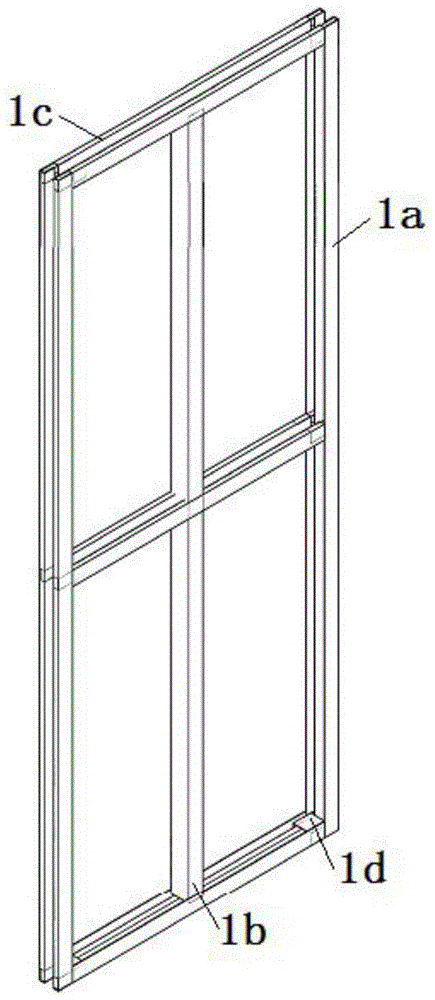

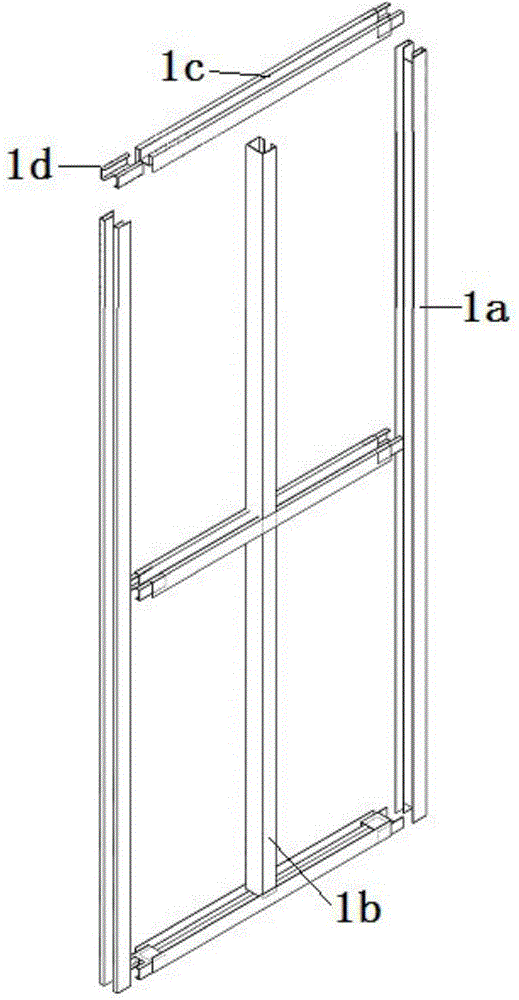

Light steel assembly type composite wall board, light steel framework, manufacturing method and installing method thereof

InactiveCN105804240AAvoid instabilityImprove stabilityWallsBuilding material handlingIsolation effectInsulation layer

The invention provides a light steel assembly type composite wall board, a light steel framework, a manufacturing method and an installing method thereof. An outer side frame of the light steel framework uses M-shaped steel; the inside uses C-shaped steel; the outer side frame is connected by C-shaped connecting elements through tapping screws; the vertical and horizontal bearing force is obviously improved; the anti-shearing and load bearing effects are good; a sandwich heat simulation layer is filled into the light steel framework; the heat simulation and light steel framework deformation limitation effects are achieved; the outer maintenance plate is attached to the outer side of the light steel framework; a heat insulation layer is arranged between the outer maintenance plate and the light steel framework; the outer maintenance plate and the light steel framework are connected through tapping screws; the horizontal anti-shearing capability, anti-cracking and anti-impacting performance of the wall body are further improved; the factory wet operation is reduced; the cold and heat bridge influence is reduced; the wall board and the main board are fixed through turnbuckles and sleeves; the connection is simple and reliable. The forming components of the composite wall board have the advantages that the types are few; the dead weight is light; steel consumption is low; heat insulation and sound isolation effects are achieved; the assembled degree is high; the fast full prefabricated assembled construction can be realized; the cost is low; the light steel assembly type composite wall board is applicable to low and multi-storey building load bearing wall systems.

Owner:江苏保力自动化科技有限公司

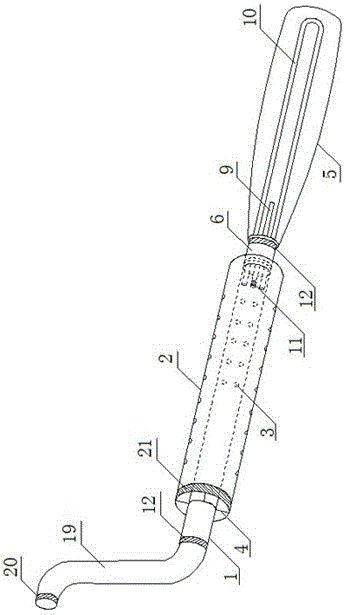

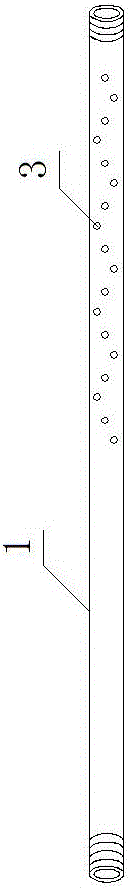

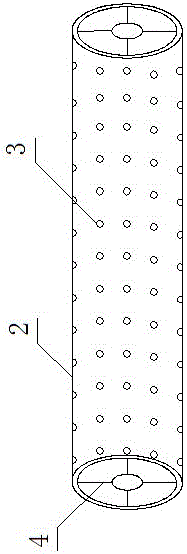

Convection-accelerating ventilating and cooling anchor pipe and construction method

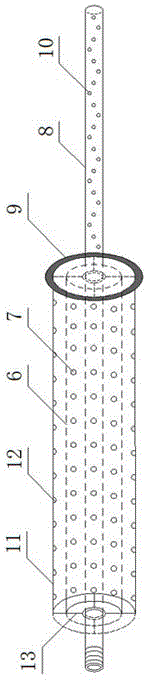

ActiveCN105672313ASpeed up dischargeEnhanced convective heat transfer rateExcavationsBulkheads/pilesFiberPermafrost

The invention discloses a convection-accelerating ventilating and cooling anchor pipe and a construction method and belongs to the field of slope supporting in cold areas. The convection-accelerating ventilating and cooling anchor pipe and the construction method are suitable for permafrost slopes. The ventilating and cooling anchor pipe comprises an anchor pipe body, a convection pipe, a fiber bag, a connector, an exhaust pipe and a freezing system. The freezing system is composed of a water pump, a water tank, a guide pipe and saline water. The anchor pipe body penetrates a positioning frame and is embedded in the convection pipe. The rear end of the anchor pipe body is connected with the connector. The fiber bag is fixed between two check rings of the connector from the outer side through a clamp. Slurry is frozen and expanded to be anchored to a stable stratum. An anchoring tool is used for anchoring the anchor pipe body to a gasket, and a convection switch penetrates the anchor pipe body and is installed at the end of the convection pipe. One end of the exhaust pipe is provided with an exhaust switch, and the other end of the exhaust pipe is connected with the anchor pipe body through a clamp. The exhaust switch controls closing and opening of the exhaust pipe, and the convection switch controls closing and opening of the convection pipe.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Novel steel structure building system

InactiveCN102979161AReduce pollutionImprove bearing capacityConstruction materialFloorsFloor slabEngineering

A novel steel structure building system comprises a steel pipe concrete column, a steel main beam, a secondary beam, a floor slab and a wall face. An assembled type steel bar truss floor support plate is used in the floor slab and comprises a steel bar truss, a profiled steel plate and an assembled connecting piece. The profiled steel plate is placed below the steel bar truss, and the assembled connecting piece is respectively connected with the steel bar truss and the profiled steel plate. A composite batten of clear channel assessment (CCA) plates and gas concrete is used, and the composite batten comprises an upper layer, a core layer and a lower layer. The upper layer and the lower layer are the CCA plates, the core layer is a gas concrete layer, the core layer covers the core layer, and the upper layer covers the core layer. The novel steel structure building system is clear in stress and simple in structural joint, convenient to industrially produce, benefit to decreasing environmental pollution and improving living environment and good in economy.

Owner:HANGXIAO STEEL STRUCTURE

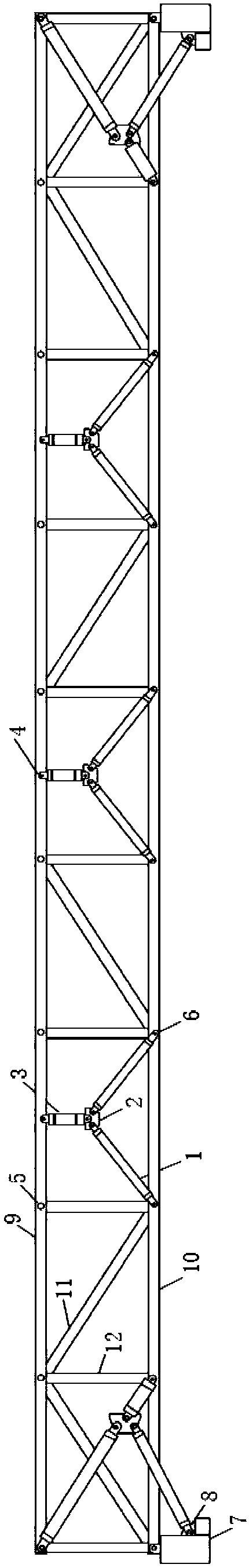

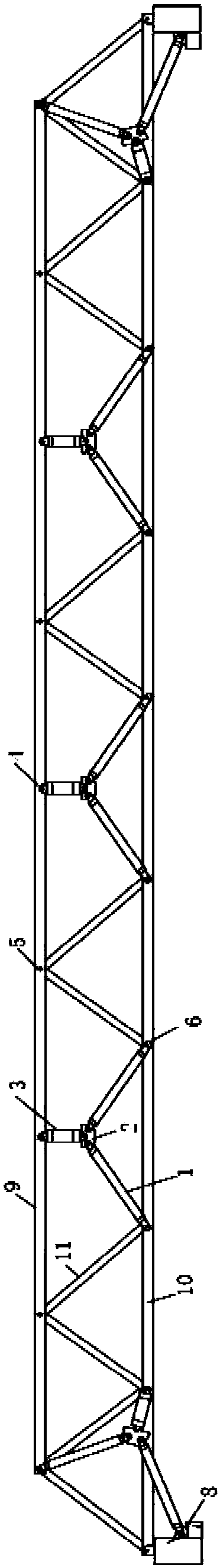

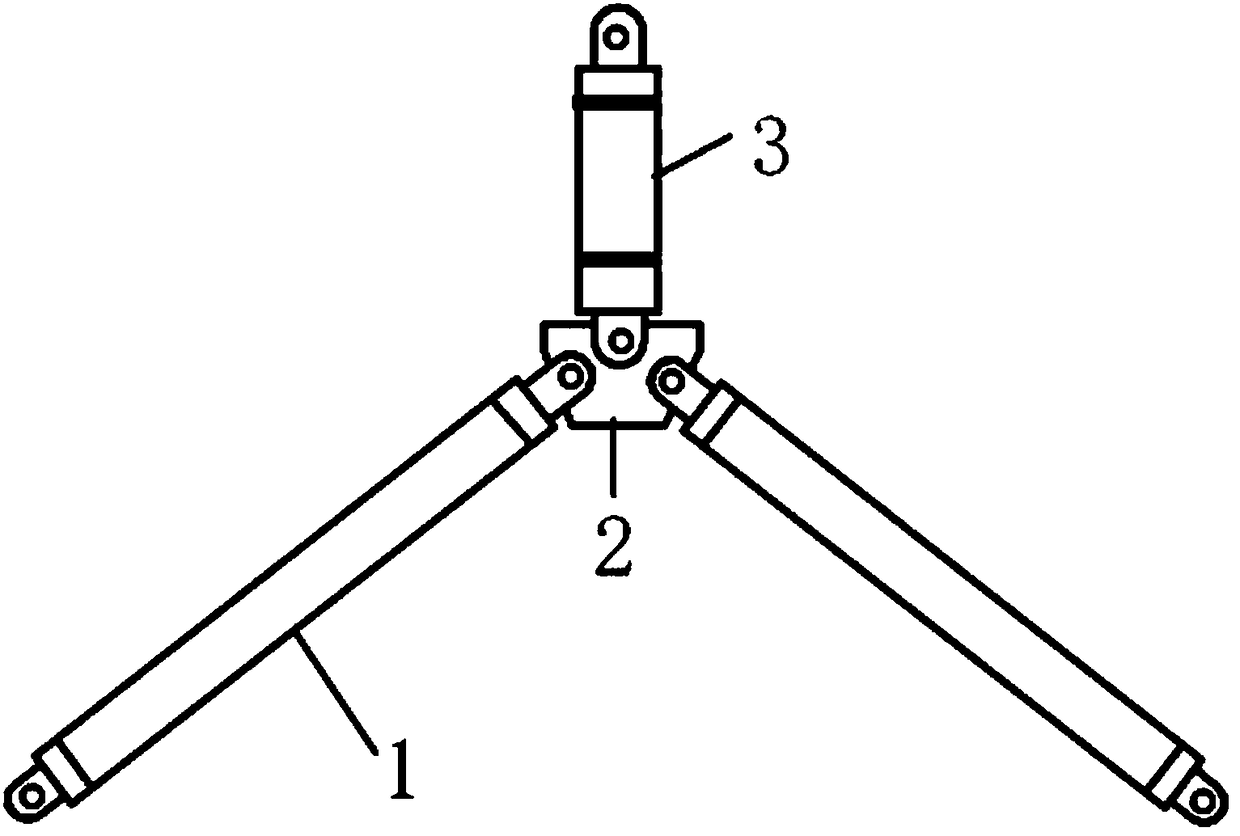

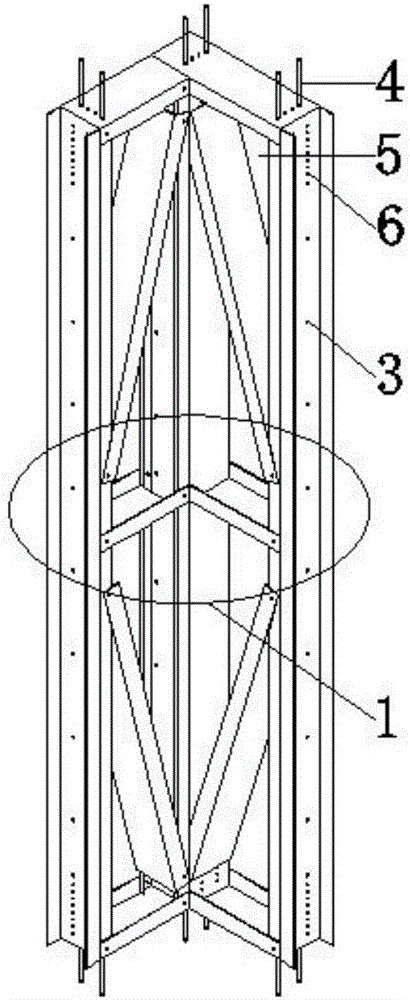

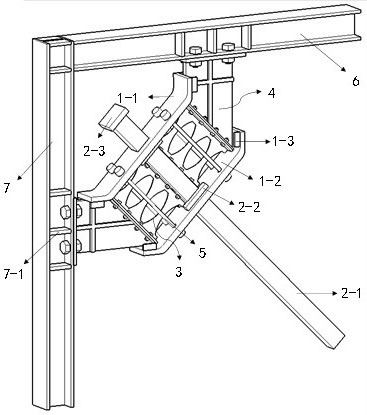

Fabricated-type truss structure comprising elbow-joint-type multi-dimensional vibration reduction rod piece

ActiveCN108612186AImprove playbackHigh degree of assemblyProtective buildings/sheltersShock proofingEarthquake resistanceMulti dimensional

The invention discloses a fabricated-type truss structure comprising an elbow-joint-type multi-dimensional vibration reduction rod piece. The fabricated-type truss structure comprising the elbow-joint-type multi-dimensional vibration reduction rod piece mainly depends on an elbow-joint-type vibration reduction part for earthquake resistance and earthquake vibration reduction. A vertical angle is formed by dampers and an upper chord member, the dampers are hinged to the upper chord member, and meanwhile, each damper is connected with two lower connecting rods through a connecting plate; the lower connecting rods are connected to joints of a lower chord member, the joints are hinged, the dampers are in bolt connection with joint plates, and main body parts of the truss structure are fixedlyconnected together through bolts; viscoelastic materials are additionally arranged at elbow-joint structure hinging points, and thus better vibration reduction and energy consumption can be achieved when the structure is displaced; and when the earthquake effect or wind load disappears, the lower connecting rods and the dampers are not displaced any more, but are reset to jointly form a truss structure system with other components for joint force bearing. According to the truss structure, the force bearing requirement of the truss structure is met, and meanwhile, the vibration resistance and reduction effects of the structure system can further be enhanced.

Owner:BEIJING UNIV OF TECH

Prefabricated lightweight steel-foam concrete composite wall and application method thereof

InactiveCN106958308AImprove insulation effectIncreased shear strengthWallsFoam concreteThermal insulation

The invention discloses a prefabricated lightweight steel-foam concrete composite wall and an application method thereof. The wall comprises a wallboard frame. The wallboard frame comprises first U-shaped lightweight steel, second U-shaped lightweight steel and third U-shaped lightweight steel which are arranged transversely in parallel. Fourth U-shaped lightweight steel and fifth U-shaped lightweight steel are arranged at the top ends and the bottom ends of the first U-shaped lightweight steel, the second U-shaped lightweight steel and the third U-shaped lightweight steel correspondingly. Pouring holes are formed in the fourth U-shaped lightweight steel. First wallboards are embedded on the two sides of the first U-shaped lightweight steel, the second U-shaped lightweight steel and the third U-shaped lightweight steel in the longitudinal direction. A cavity formed between the first wallboards and the wallboard frame is filled with foam concrete. The thermal insulation performance of the wall can be improved, and templates can also be saved by arranging fiber cement boards on the periphery of the wallboard frame, so that the prefabricated composite wall can be manufactured easily, the assembly degree is high, and the composite wall is suitable for industrialized production; and the cavity structure formed between the first wallboards and the wallboard frame is filled with the foam concrete, the shear strength and the bending strength of the whole wallboards are improved, and thermal insulation performance, sound insulation performance and fireproof performance of the wall are improved.

Owner:SHENYANG JIANZHU UNIVERSITY

Prefabricated core column type self-insulating exterior wall plate, connecting structure and construction method thereof

PendingCN107386492AClear forceImprove ductilityWallsCeramic shaping apparatusFoam concreteReinforced concrete

The invention relates to a prefabricated core column type self-insulating exterior wall plate, a connecting structure and a construction method thereof. The exterior wall plate comprises a wall body and a connecting piece which is vertically connected with the wall; the wall is formed by combining a reinforced concrete structure layer and a foam concrete insulating layer; the reinforced concrete structure layer comprises a structure layer steel framework and structure layer concrete; the foam concrete insulating layer is made of foam concrete; the structure layer steel framework comprises a core column reinforcement cage and horizontal reinforcing steel bars; each horizontal reinforcing steel bar comprises two long reinforcing steel bars; a wall top connecting piece is inserted in the top of the core column reinforcement cage in an embedded manner; and a wall bottom connecting piece which is used with the wall top connecting piece is inserted in the bottom of the core column reinforcement cage in an embedded manner. By the prefabricated core column type self-insulating exterior wall plate, the degree of industrialization and assembling is improved effectively, the bearing ability, ductility and anti-seismic property of the wall are improved comprehensively, and purposes of integration of structure insulation, reliable connection between an upper wall body and a lower wall body and convenience in mounting are achieved.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

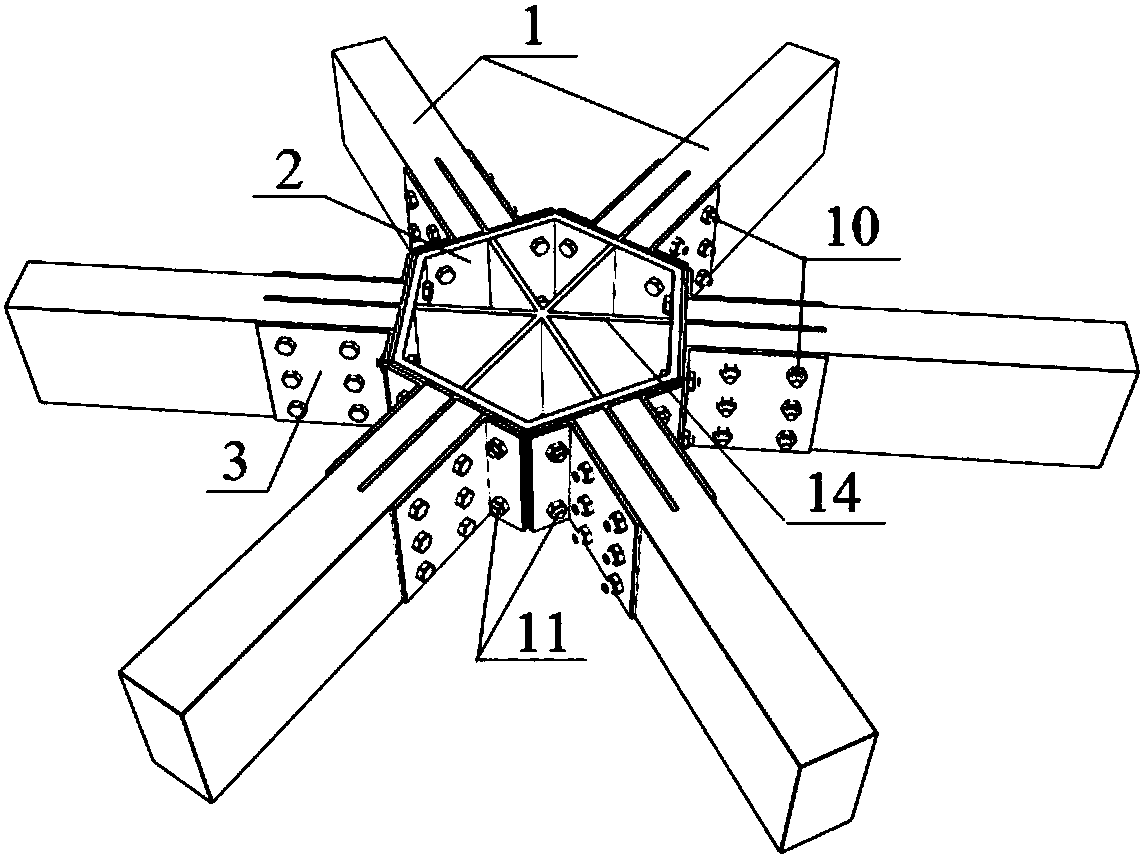

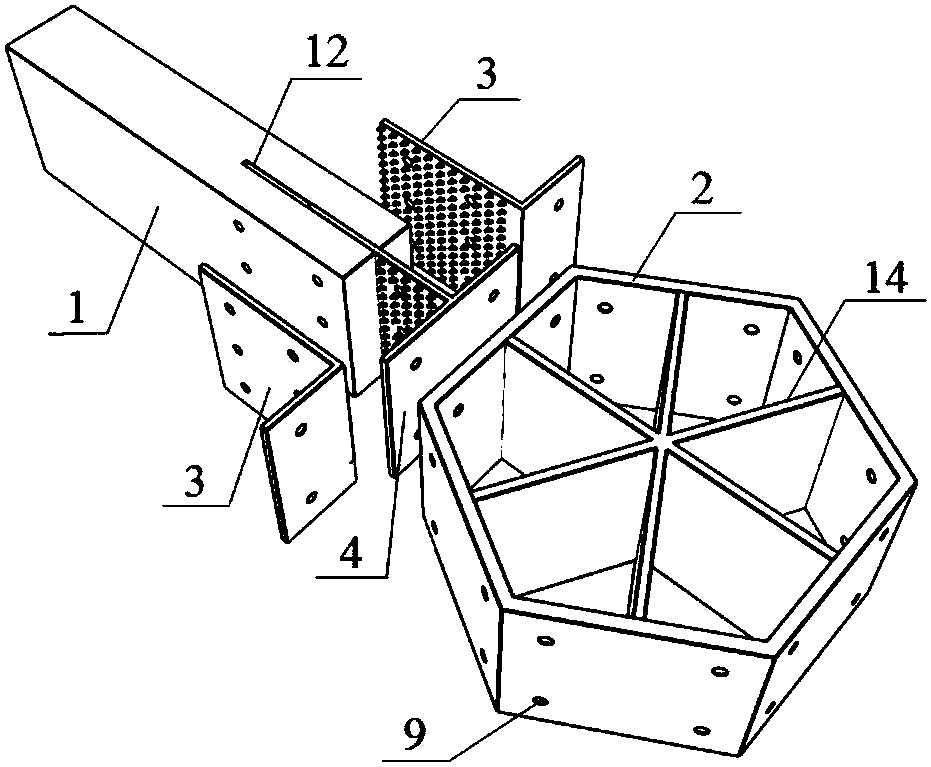

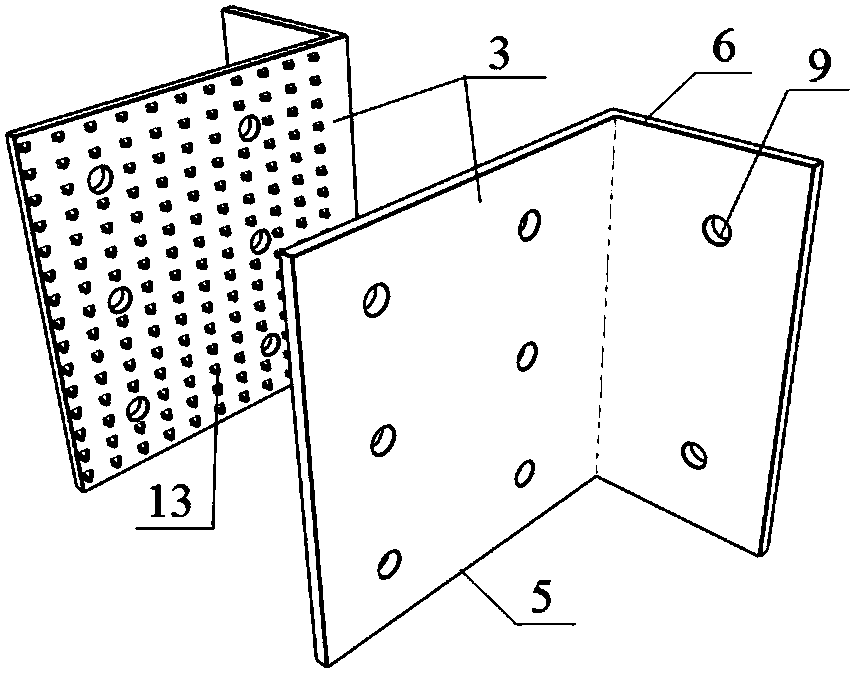

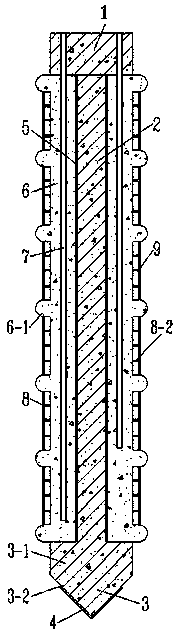

Inner ring ribbing large-span wood structure assembly type joint

InactiveCN107605043AHigh degree of assemblyImprove construction efficiencyBuilding constructionsSteel platesOcclusal forces

The invention belongs to the field of wood structure joint design, and relates to an inner ring ribbing large-span wood structure assembly type joint. Steel clamping plates are arranged on the left side and the right side of the end of each wood component, steel filling plates are inserted into plate slots at the ends of the wood components, the wood components, the steel clamping plates and the steel filling plates are connected through common bolts, and steel teeth are arranged on the faces where the steel clamping plates and the steel filling plates are in contact with the wood components;and under the effect of bolt pretightening force, the steel teeth are embedded into the wood components, the steel clamping plates and the steel filling plates are connected with a core steel cylinderthrough high-strength bolts, and steel plate ribs are arranged in the core steel cylinder. Bolt holes are formed in the corresponding positions of the wood components, the steel clamping plates, thesteel filling plates and the core steel cylinder in a factory, the parts are assembled through the bolts on a construction site, and the assembly degree of the large-span wood structure is improved; and the steel teeth on the steel clamping plates and the steel filling plates enhance mechanical occlusal force among the steel clamping plates, the steel filling plates and the wood components, slipping between the wood components and the steel plates is reduced, the initial rigidity of the joint is improved, so that the joint is close to a rigid joint, and the joint can be applied to a hectometer-grade large-span wood structure.

Owner:QINGDAO TENGYUAN DESIGN ACCOUNTANTS CO LTD

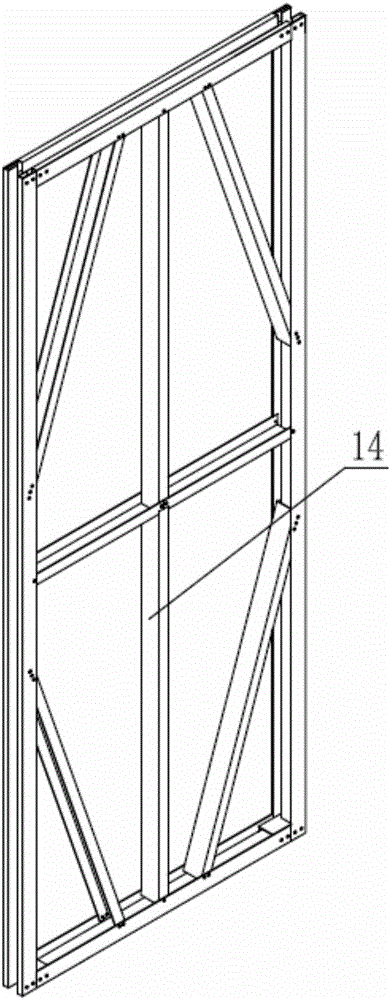

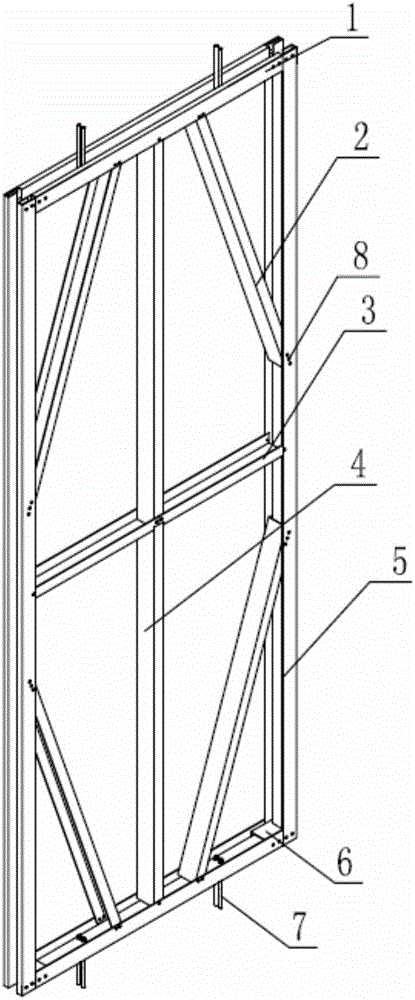

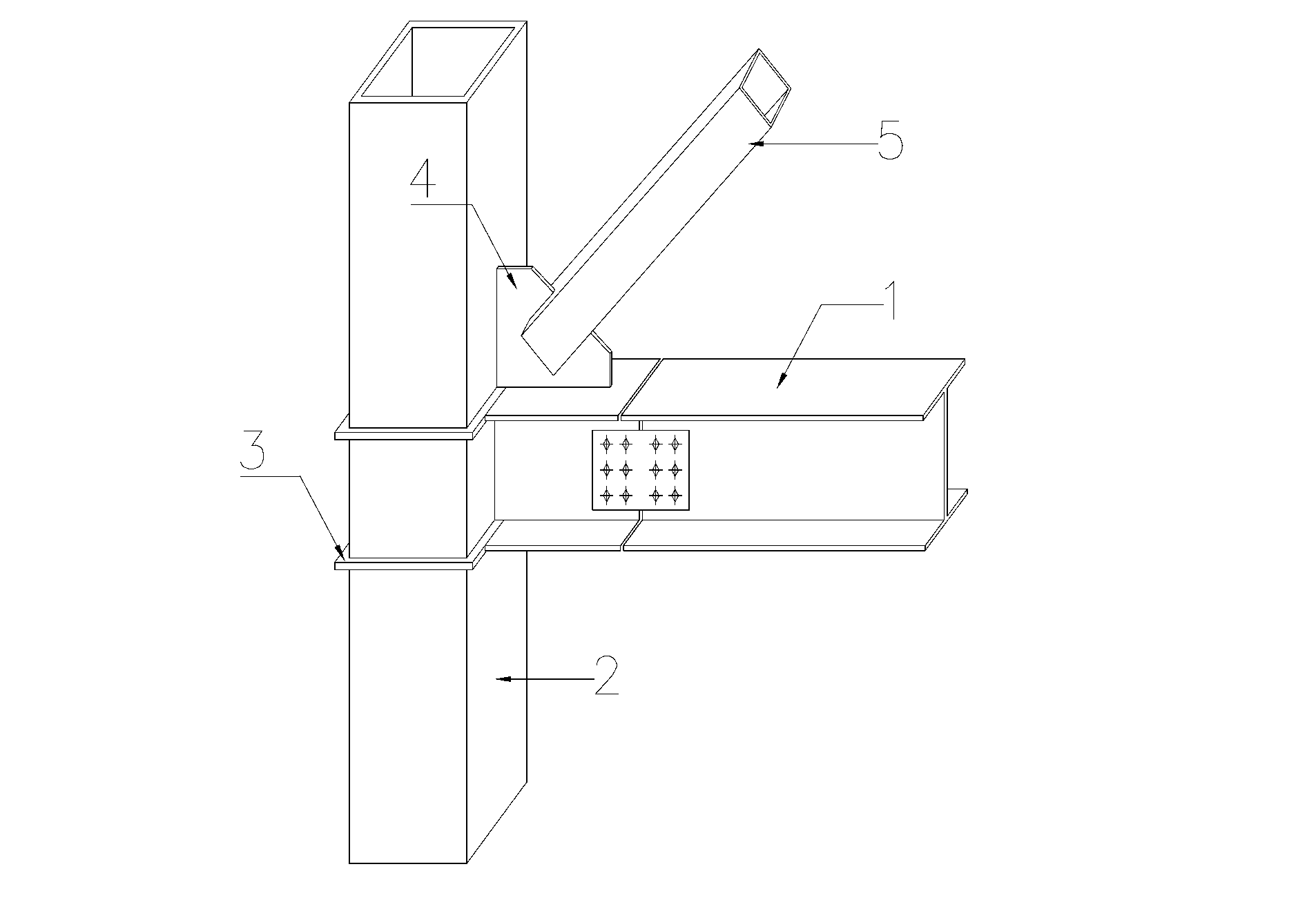

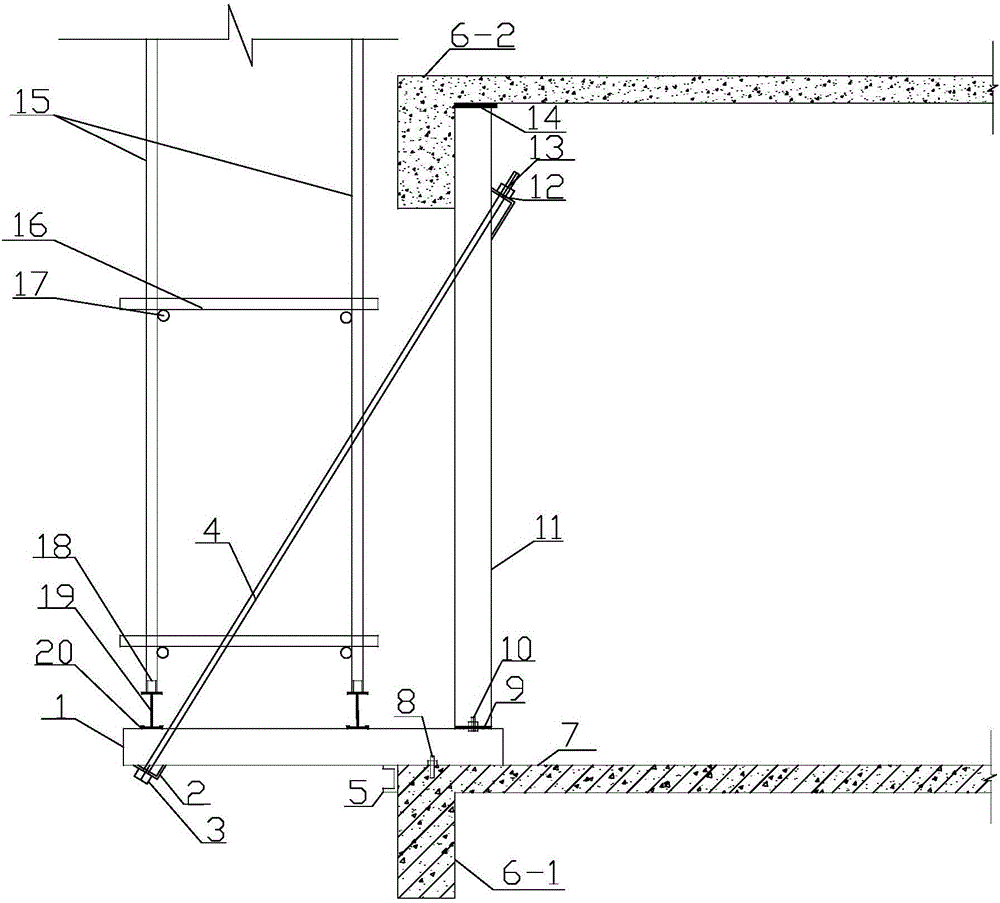

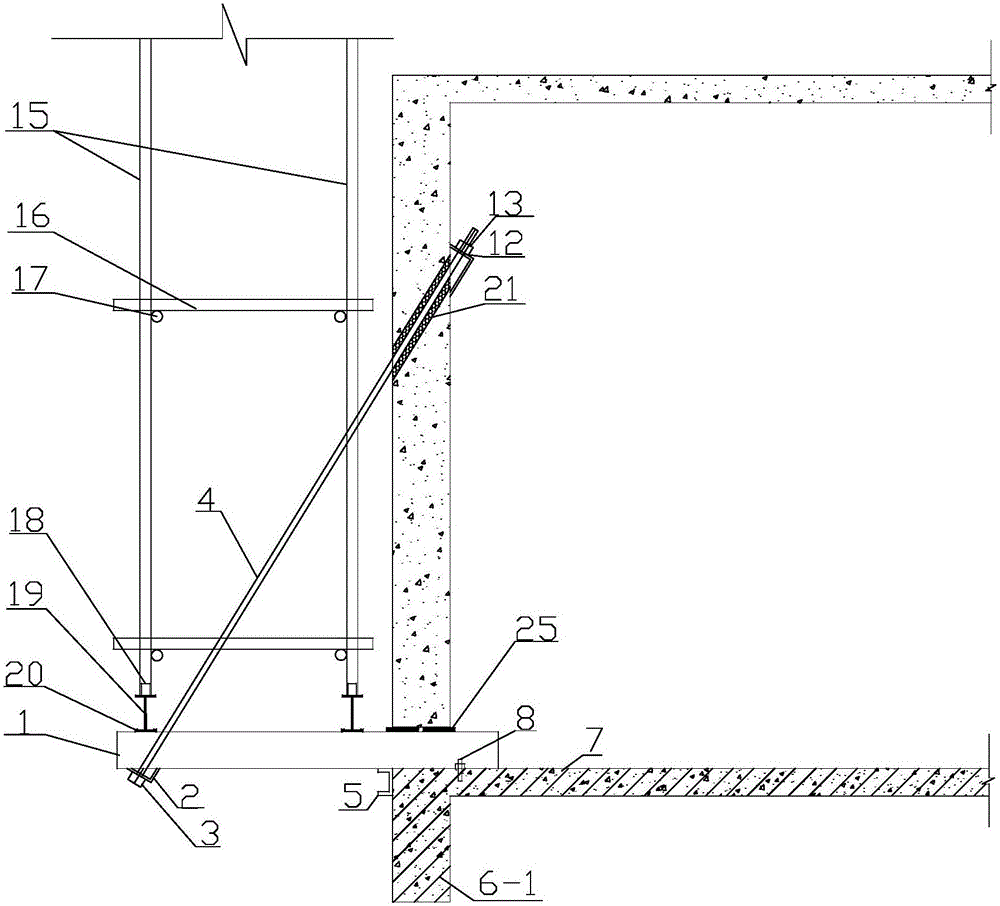

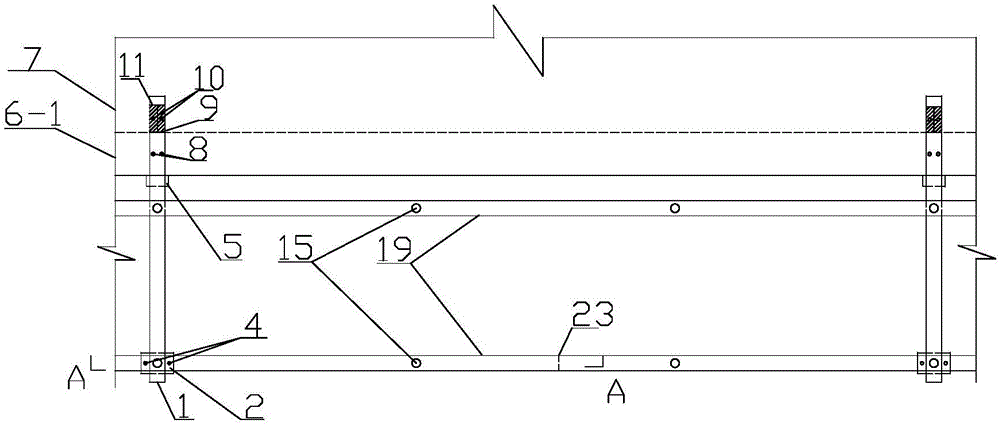

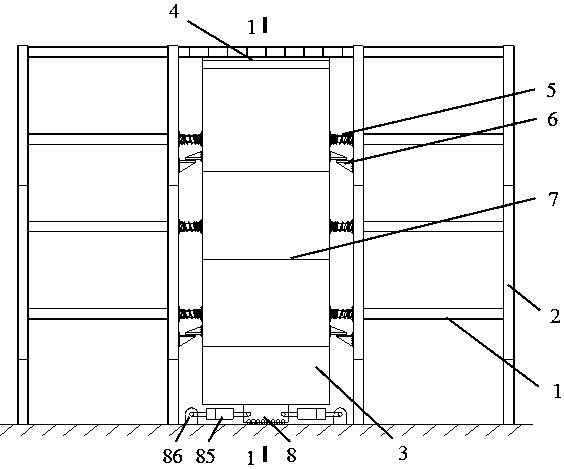

Design and construction technology of self-stabilized section steel suspended scaffold

ActiveCN106592948ASolve key technical problems such as crackingImprove bearing capacityBuilding support scaffoldsFalseworkSocial benefits

The invention belongs to the field of structural design and construction, and particularly relates to a design and construction technology of a self-stabilized section steel suspended scaffold. The design and construction technology mainly adopts the following steps that 1, the state bearing capacity of a main beam cantilever is calculated; 2, the bearing capacity of suspended system force bearing rod pieces is calculated; 3, a main beam is made; 4, a vertical beam is made; 5, secondary beams are made; 6, a rebar pulling rod is made; 7, the main beam is mounted; 8, the vertical beam is mounted; 9, the secondary beams are mounted; 10, the rebar pulling rod is mounted; and 11, the suspended system scaffold is built. Compared with a section steel cantilever scaffold, the design and construction technology of the self-stabilized section steel suspended scaffold is not provided with pre-buried lifting rings of steel wire ropes and anchoring rings of section steel supporting seats, and meanwhile, the nationwide key technical problems, caused by overturning force of a cantilever steel beam supporting seat, that a cast-in-place plate cracks and the front end of the cast-in-place plate is in torsional deformation are solved. Construction operation is easy; the construction period of the scaffold is shortened by a large margin; costs of section steel, pre-buried pieces and manpower are reduced in large quantities; significant economical and social benefits are achieved; and the requirements of efficiency, energy-saving and environment friendly construction are met.

Owner:SHANDONG WANXIN CONSTR

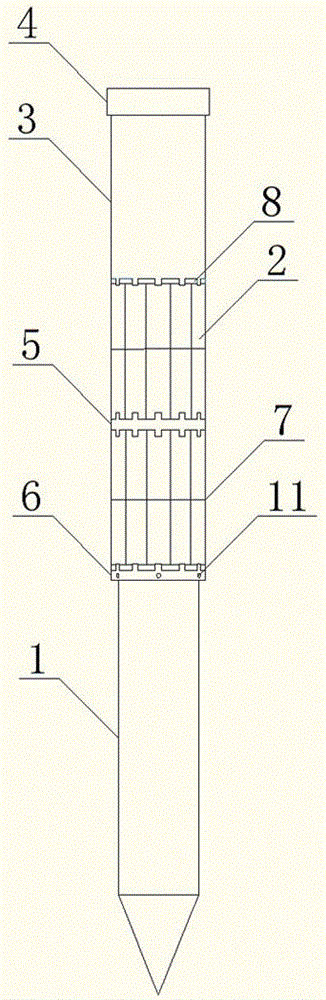

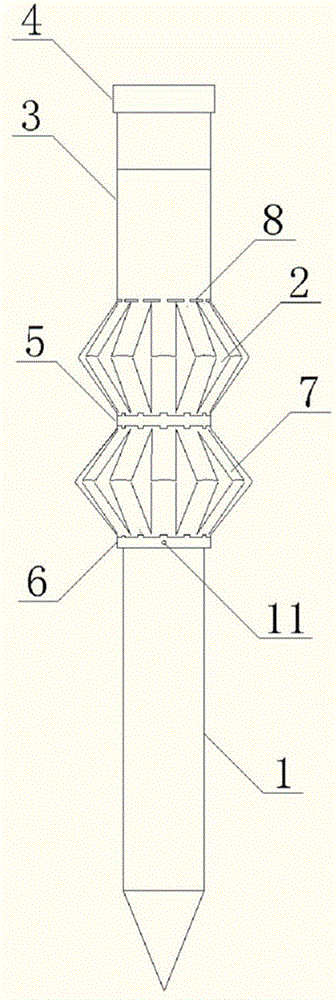

Extension body compaction pile capable of eliminating pile foundation negative friction and construction method

ActiveCN106592585AEliminate negative frictionEliminate the effects of negative frictionBulkheads/pilesReinforced concreteSoft clay

The invention discloses an extension body compaction pile capable of eliminating pile foundation negative friction and a construction method, and belongs to the field of geotechnical engineering foundation treatment. The extension body compaction pile structurally comprises a pile body, an extension device, a sleeve and a bearing platform. The pile body is a concrete steel tube pile; the extension device is formed by connecting a two-way clamping hoop, a unidirectional clamping hoop, crank connecting rods, and rotating shaft pins. The crank connecting rods are connected on rotating shaft supporting seats located on the two sides of the two-way clamping hoop through the rotating shaft pins, the crank connecting rods on one side of the two-way clamping hoop are connected with the unidirectional clamping hoop, and the extension device is formed. The sleeve is a cylindrical steel drum and is connected with the crank connecting rods located on the free side of the extension device. The connected device is inserted in the pile body, the top of the sleeve is flush with the top of the pile, and the unidirectional clamping hoop is fixed with positioning bolts. The pile body is driven to a designed position through a piling machine. The reinforcement concrete bearing platform is cast on the top of the pile. Assembly of the parts of the extension body compaction pile is simple, practicability is strong, construction is convenient, safety and environmental protection are achieved, and the extension body compaction pile is particularly suitable for the foundation treatment in collapsible loess areas and soft clay areas.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

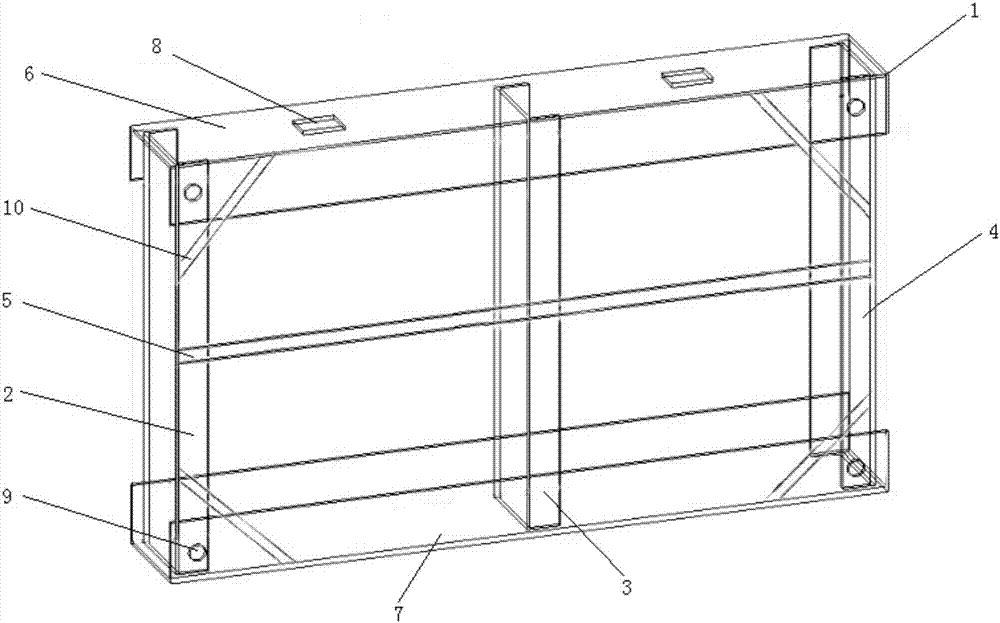

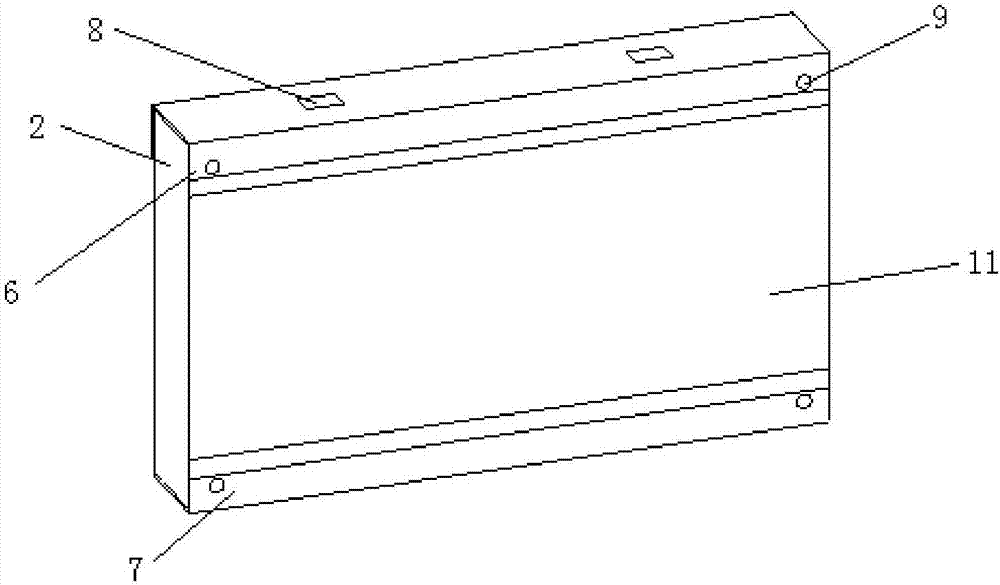

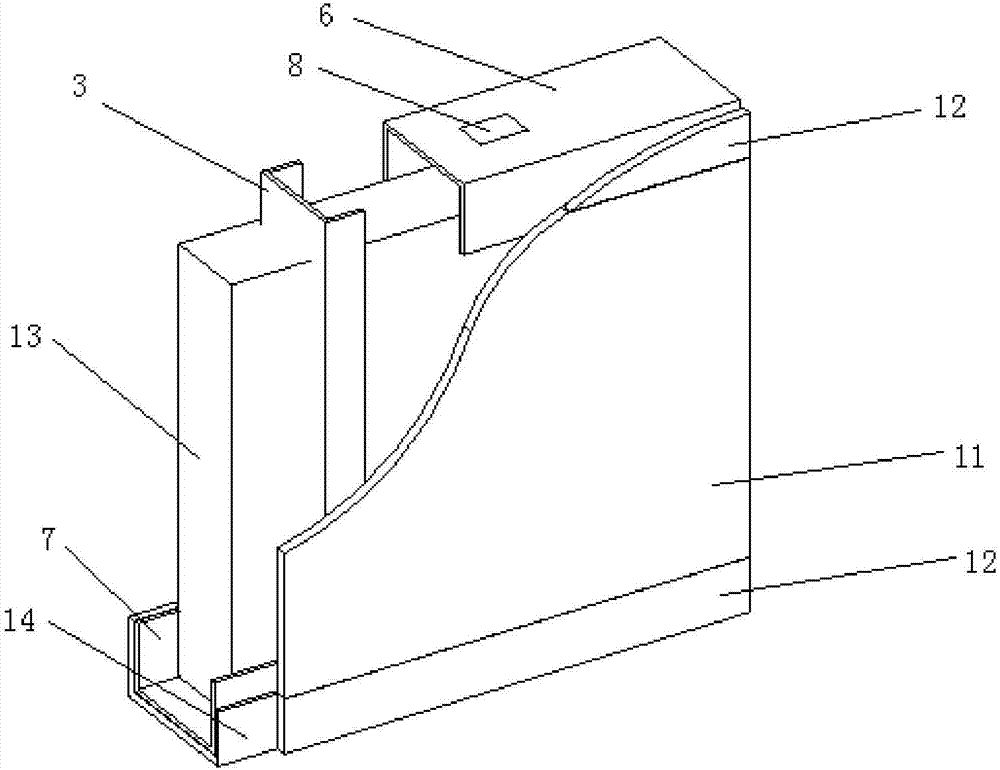

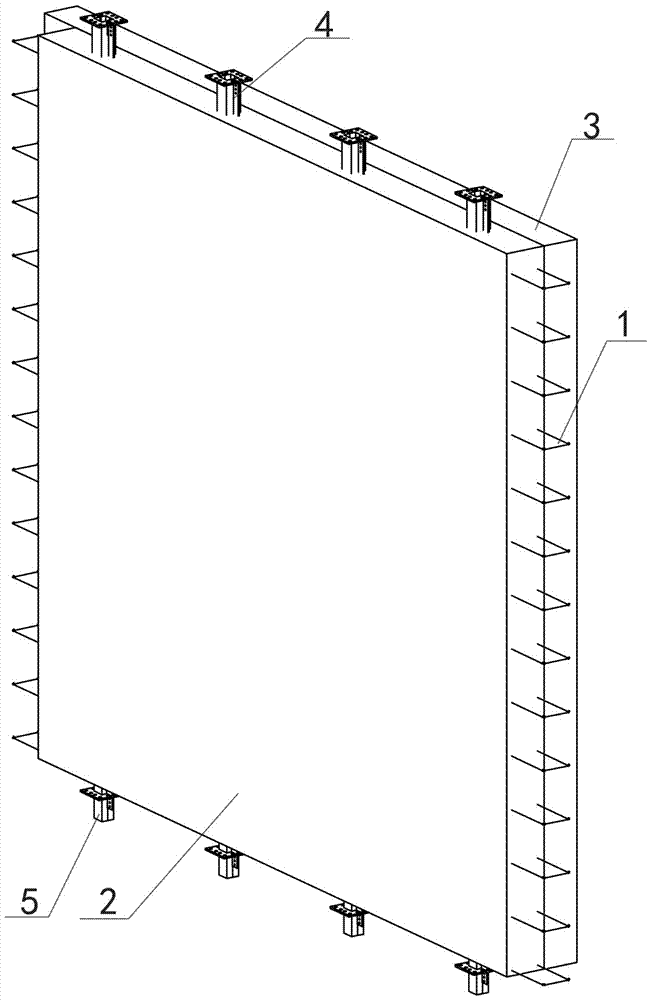

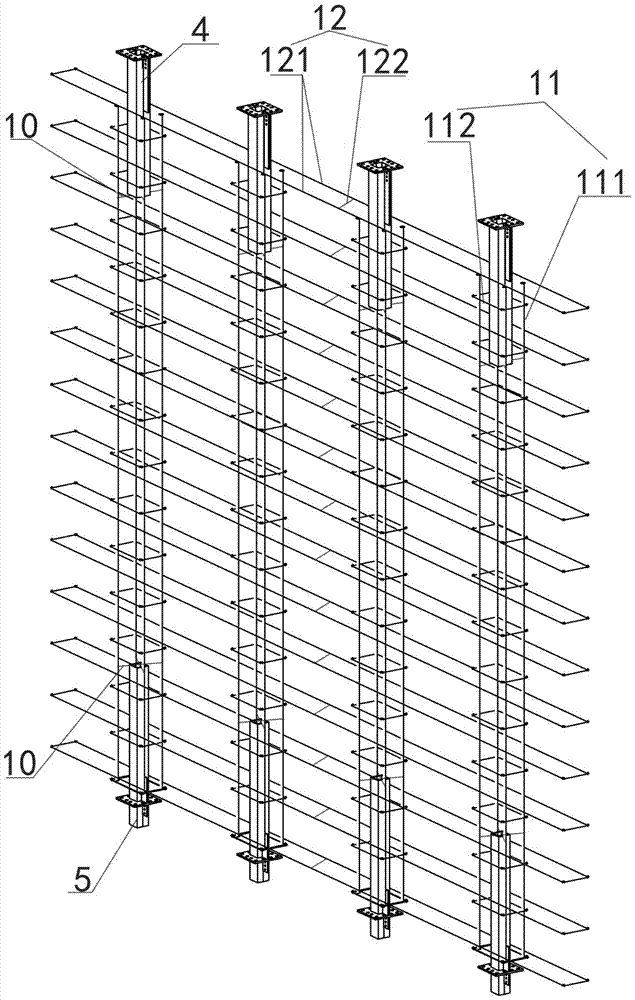

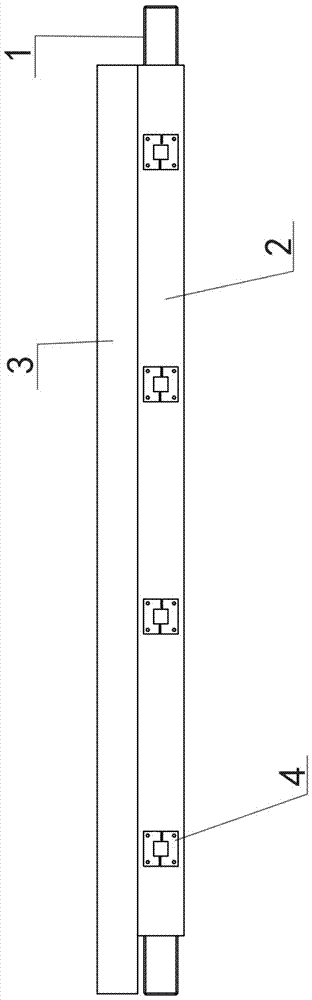

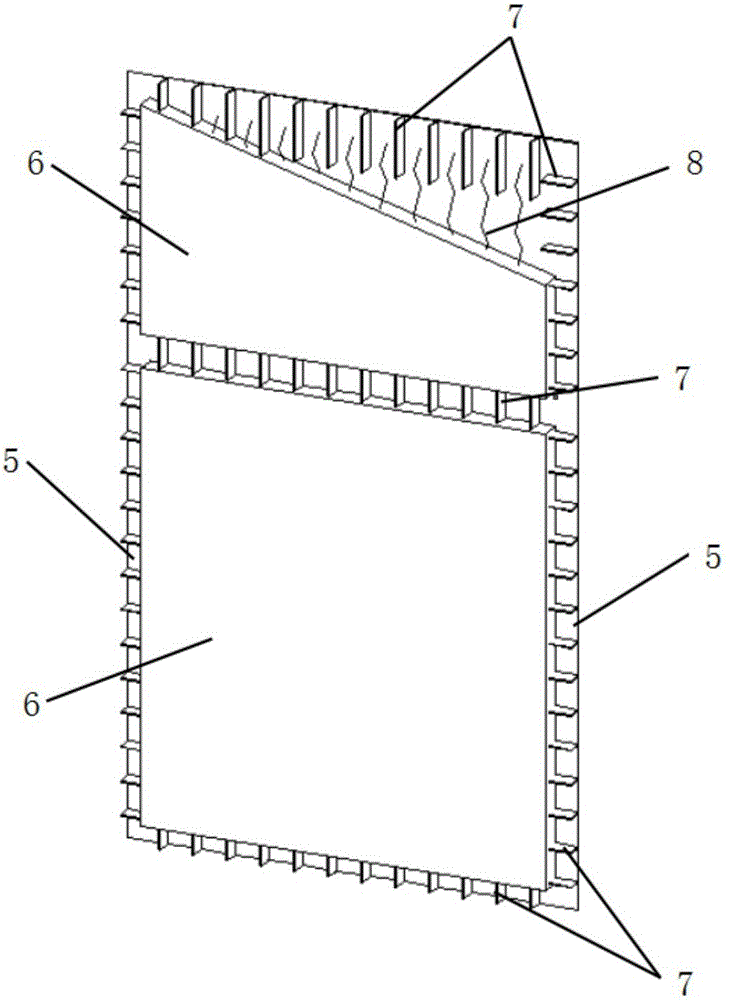

Prefabricated assembly type steel plate-concrete composite shear wall structure system and construction method thereof

Provided are a prefabricated assembly type steel plate-concrete composite shear wall structure system and a construction method thereof. The prefabricated assembly type steel plate-concrete composite shear wall structure system comprises prefabricated steel plate-concrete composite shear walls, prefabricated steel rib-concrete composite beams, composite floor slabs and composite floor slab installation supports; the vertically-arranged prefabricated steel plate-concrete composite shear walls are connected with the prefabricated steel rib-concrete composite beams and the composite floor slabs through the composite floor slab installation supports; and the prefabricated steel plate-concrete composite shear walls are connected through bolted steel plates. Longitudinal stress rebars in components are omitted, so that grouting sleeve connection of the longitudinal rebars in an assembly type concrete structure is avoided, the construction process is simplified, and the structure construction cost is reduced. The outer sides of the steel plates or the steel ribs in the composite structure are all protected by concrete, so that the rust prevention and fire prevention cost caused by exposure of steel in structural steel buildings is avoided, and durability of the structure is improved. The prefabricated assembly type steel plate-concrete composite shear wall structure system is suitable for assembly type high-rise residences, component connection nodes are constructed simply, stress is reasonable, installation is convenient and rapid, the assembly degree is high, and construction is rapid.

Owner:SHANDONG ZHONGTONG STEEL STRUCTURE ENG

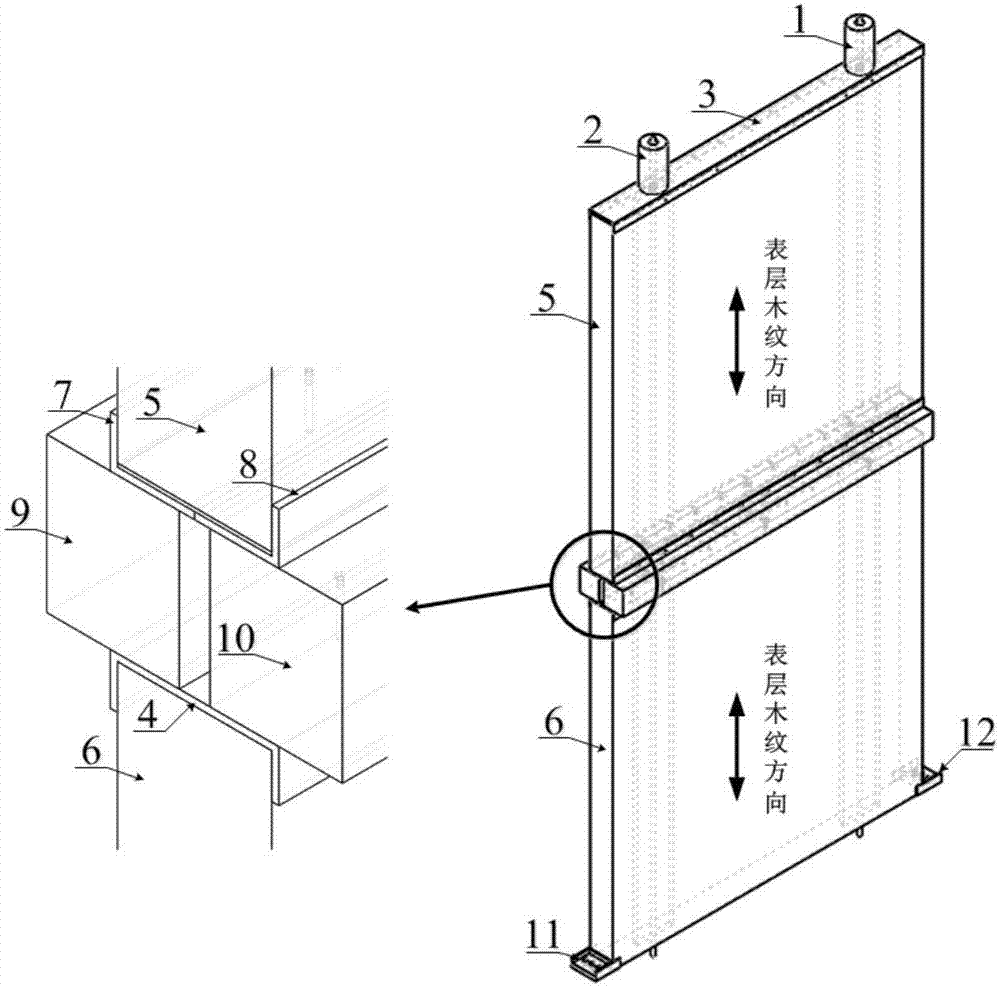

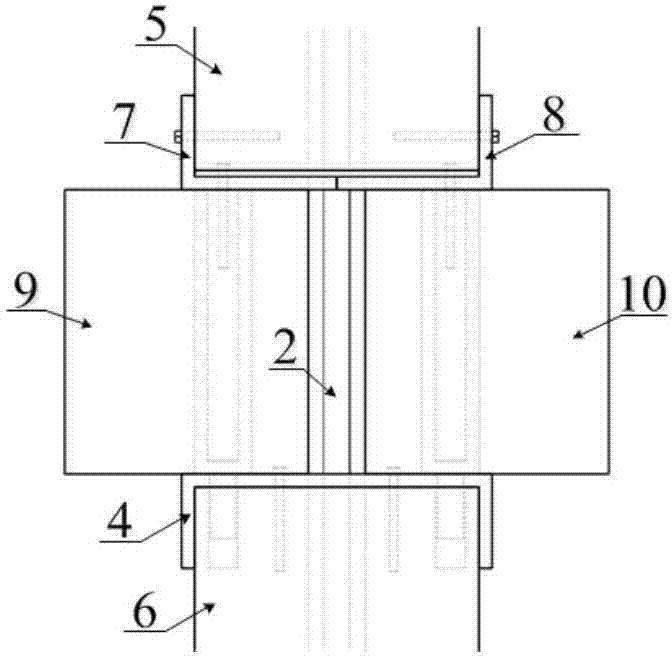

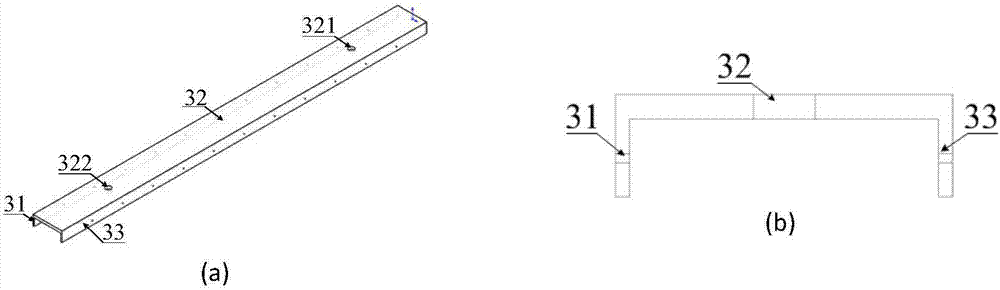

Assembling prestress orthogonal laminated wood shear wall

ActiveCN107574953AIn line with the structural design conceptImprove lateral force resistanceWallsProtective buildings/sheltersPre stressSelf recovery

The invention discloses an assembling prestress orthogonal laminated wood shear wall. The assembling prestress orthogonal laminated wood shear wall comprises bond-free prestress bars, bearing beams, CLT wall plates, slab supporting frames and limiting steel components. The two limiting steel components are connected with a base. The CLT wall plates on the lower layer tightly abut against the basethrough the bond-free prestress bars. The bearing beams on the lower layer are connected with the CLT wall plates on the lower layer. The slab supporting frames on the lower layer are connected with the CLT wall plates on the lower layer and then put on the top of the bearing beams on the lower layer. The CLT wall plates on the upper layer are connected with the two slab supporting frames on the lower layer. The bearing beams on the upper layer are connected with the CLT wall plates on the upper layer. The two bond-free prestress bars penetrate through the CLT wall plates on the upper layer and the lower layer. The CLT shear wall has high initial rigidity, high ultimate bearing capacity and a certain self-recovery characteristic under lateral loads after the bond-free prestress bars are applied, and the common damage mode of weak joints and strong components of a common CLT shear wall is avoided. The assembling prestress orthogonal laminated wood shear wall is high in assembling degree, and prestress loss caused when CLT slabs have big creep deformation under the band stress action can be reduced obviously due to the arrangement of the slab supporting frames on the lower layer.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

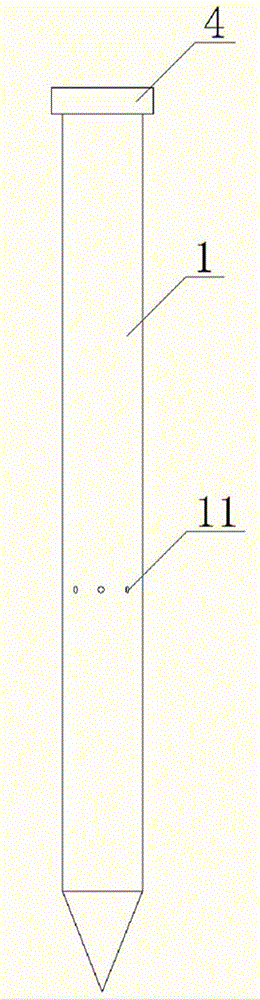

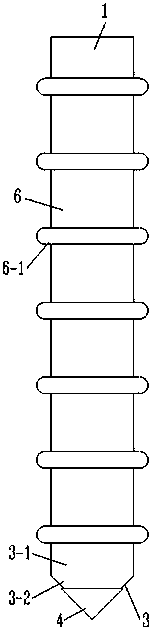

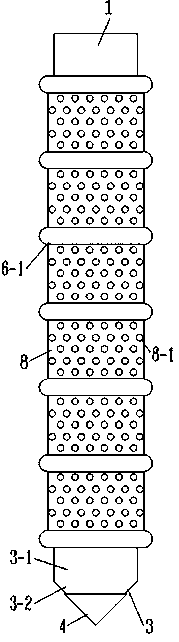

Prefabricated drainage bamboo pile and preparation method thereof

InactiveCN109083131AAvoid the problem of easy blockage of drainage and single drainage pipeAvoid destructionProtective foundationShaping reinforcementsPile capReinforced concrete

The invention relates to a prefabricated drainage bamboo pile and a preparation method thereof, and belongs to the technical field of construction. The prefabricated drainage bamboo pile includes interconnected pile caps, prefabricated reinforced concrete pile cores, pile tips, pile tip metal protection heads, waterproofing layers, prefabricated permeable concrete pipes, drainage pipes, prefabricated metal filters, and geotextile filter layers; the prefabricated reinforced concrete pile cores are cylindrical and connected with the pile tips as a unitary member, each pile tip is composed of a pile tip cylindrical section and a pile tip conical section, the surface of the pile tip conical section is provided with a pile tip metal protection head, the prefabricated permeable concrete pipes are hollow cylindrical shapes, the surface of the prefabricated permeable concrete pipes are provided with annular bamboo segments at equal intervals along the vertical direction of the pile body, and aprefabricated metal filter is arranged between the two annular bamboo segments; a metal filter is semicircular and annular, a filter hole is formed in the surface of the metal filter, and a geotextile filter layer is arranged on the outer surface of the metal filter. The prefabricated drainage bamboo pile has the advantages of high assembly degree, convenient assembly, a bearing function of the pile body is combined with a drainage function, the damage of the pile tip is avoided, the drainage of the pile body is easy to block, and the drainage pipe is single.

Owner:SHENYANG JIANZHU UNIVERSITY

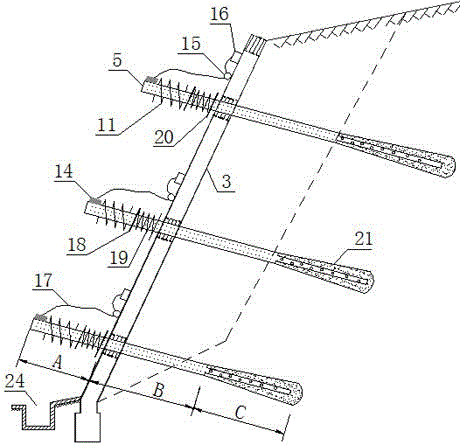

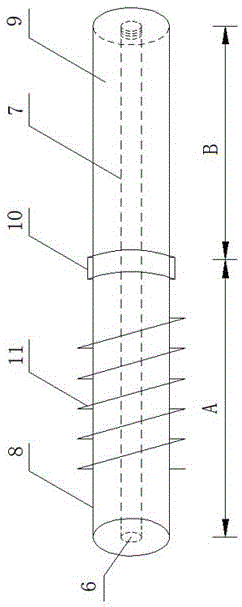

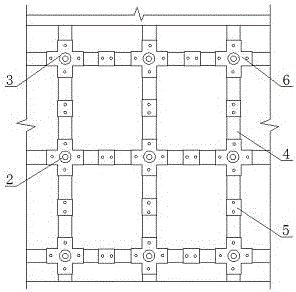

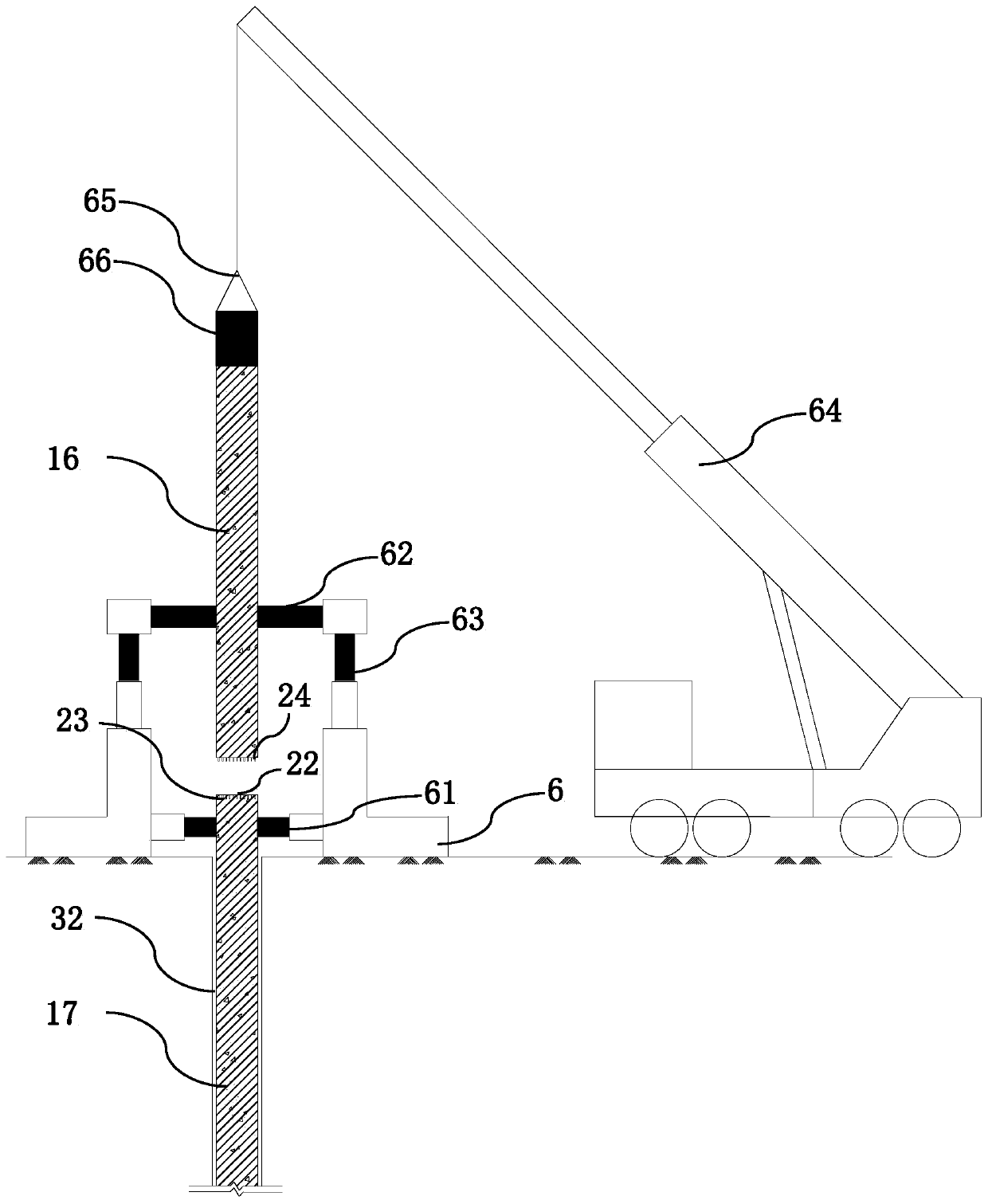

Recoverable assembling framework and sawtooth anchor rod structure and construction method

ActiveCN106284368AAchieve recyclingSimple structureExcavationsBulkheads/pilesPush and pullEngineering

The invention discloses a recoverable assembling framework and sawtooth anchor rod structure and a construction method, and belongs to the technical field of geotechnical anchoring. The recoverable assembling framework and sawtooth anchor rod structure comprises a framework, anchor rods and anchor devices. The framework is formed by square tubes, sleeves and crosses through connection, wherein the square tubes extend into the sleeves and are connected with the sleeves through bolts so as to form cross beams and stand columns; the cross beams and the stand columns are inserted into the crosses; and the peripheries of the crosses are fixed by bolts. Each anchor rod consists of a steel tube, an expansion link, steel discs and a rotation shaft; a sliding chute, a first positioning hole and a second positioning hole are formed on the steel tube; the expansion link penetrates into the steel tube; the rotation shaft penetrates through the sliding chute to connect the expansion link with the steel tube; the rotation shaft is inserted into the first positioning hole; two ends of the rotation shaft are sleeved by the steel discs and fixed by nuts; and the adjacent steel discs are connected by bolts. The anchor rods penetrate through center holes of the crosses to reach into a slope, push-and-pull instruments sleeve the ends of the anchor rods to push the expansion links; the steel discs extend into a soil mass in a zigzag manner; pins are inserted into the second positioning holes to connect the steel tubes with the expansion links; and the anchor rods are anchored on the framework through the anchor devices and backing plates. The recoverable assembling framework and sawtooth anchor rod structure is recoverable in structure and high in construction speed, and has the effect of reducing the cost.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

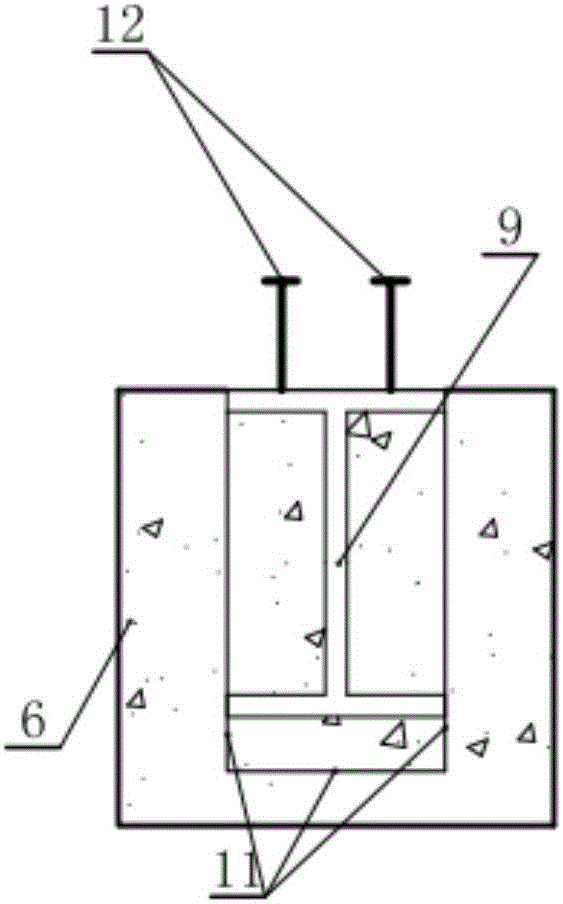

Fabricated embedded foundation pit retaining pile and pile wall integrated structure and construction method thereof

InactiveCN110130363AHigh degree of assemblyGuaranteed integrityExcavationsBulkheads/pilesPre stressEngineering

The invention discloses a fabricated embedded foundation pit retaining pile and pile wall integrated structure and a construction method thereof. Sheet piles are composed of prefabricated reinforced concrete sheet piles and steel H-piles. The prefabricated sheet piles are prestressed high-strength reinforced concrete members, and cross sections are divided into a hollow T shape, a rectangle and anH shape. Each prefabricated sheet pile has the maximum length of 15 meters and the width of not more than 2.5 meters. Equal-strength mechanical connection joints of each steel bar are adopted in thesheet piles in the axial direction-extension; the prefabricated sheet piles are used as external walls of underground structures to bear stratum pressure and are combined with lining walls to form theexternal walls of the underground structures. The sheet piles are implanted into the stratum at certain intervals and fabricated into discrete type row pile enclosure structures. A sheet pile body with U-shaped grooves in both sides is inserted between every two sheet piles and fabricated into continuous wall type enclosure structures which are engaged with each other. The foundation pit enclosure structure fabricated in this way has the social values of green, environmental protection, safety and reliability, the construction cost can be reduced, and the construction period is shortened meanwhile, and great economic value is achieved.

Owner:王琪

Externally-mounted prefabricated sandwich type thermal-insulation concrete wallboard and assembling system and construction method thereof

ActiveCN106760158AImprove structural strengthIncrease stiffnessPassive housesBuilding componentsFloor slabThermal insulation

The invention provides an externally-mounted prefabricated sandwich type thermal-insulation concrete wallboard and an assembling system and construction method thereof. The technical problem that a connecting structure between vane boards on the two sides of an existing thermal-insulation wallboard is insufficient in strength is solved by enabling steel bar truss web bars in a continuously-bent status to be connected to longitudinal reinforcing bars on an inner vane board and an outer vane board of the thermal-insulation wallboard. In addition, the externally-mounted wallboard is in assembling connection with a steel beam and a floorslab through a pre-buried bolt technical means or a split bolt technical means. Meanwhile, the self-characteristics of a steel structure are considered, and the assembly structure strength between the wallboard and the steel beam as well as between the wallboard and the floorslab is guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

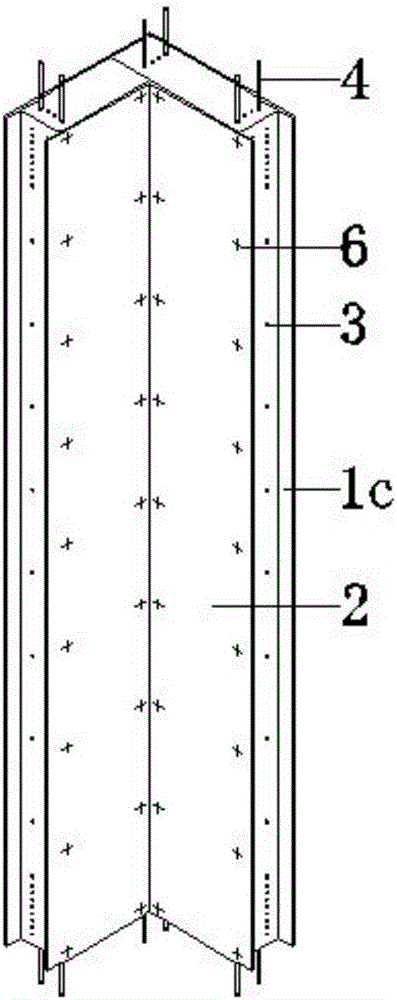

Modular assembly type L-shaped cold-formed thin-walled steel combined wall and connecting mode thereof

The invention discloses a modular assembly type L-shaped cold-formed thin-walled steel combined wall and a connecting mode of the modular assembly type L-shaped cold-formed thin-walled steel combined wall. The modular assembly type L-shaped cold-formed thin-walled steel combined wall is characterized in that the middle part of an L-shaped cold-formed thin-walled steel framework is filled with a heat preservation layer; a wall panel and the L-shaped cold-formed thin-walled steel framework are connected through self-tapping screws; the modular assembly type L-shaped cold-formed thin-walled steel combined wall is formed by the L-shaped cold-formed thin-walled steel framework, the heat preservation layer and the wall panel. Horizontal-direction connection between an L-shaped cold-formed thin-walled steel combined wall module and a common wall module is realized through a horizontal connecting mode between wall modules; vertical-direction connection between two adjacent L-shaped cold-formed thin-walled steel combined wall modules which are adjacent in the vertical direction is realized through a vertical connecting mode between the wall modules. The modular assembly type L-shaped cold-formed thin-walled steel combined wall disclosed by the invention integrates structural bearing and heat preservation, and has the advantages of high integration and assembly degrees, applicability in industrial production and the like, and the problems of weak connection between a longitudinal wall and a horizontal wall, high difficulty and difficulty in handling installation seams, and the like can be solved. The connecting mode of the modular assembly type L-shaped cold-formed thin-walled steel combined wall is simple in structure and is quick and efficient, and a large amount of labor cost can be reduced.

Owner:BEIJING UNIV OF TECH

Supporting building with tension and compression reversing characteristic and assembling method thereof

ActiveCN111809734AIncrease contact areaAvoid stress concentration damageProtective buildings/sheltersBuilding material handlingSteel columnsWall plate

Owner:HUNAN UNIV

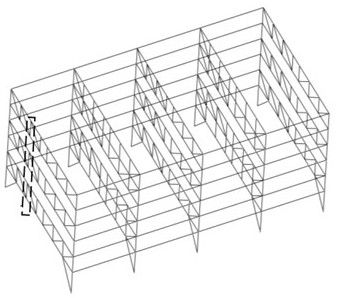

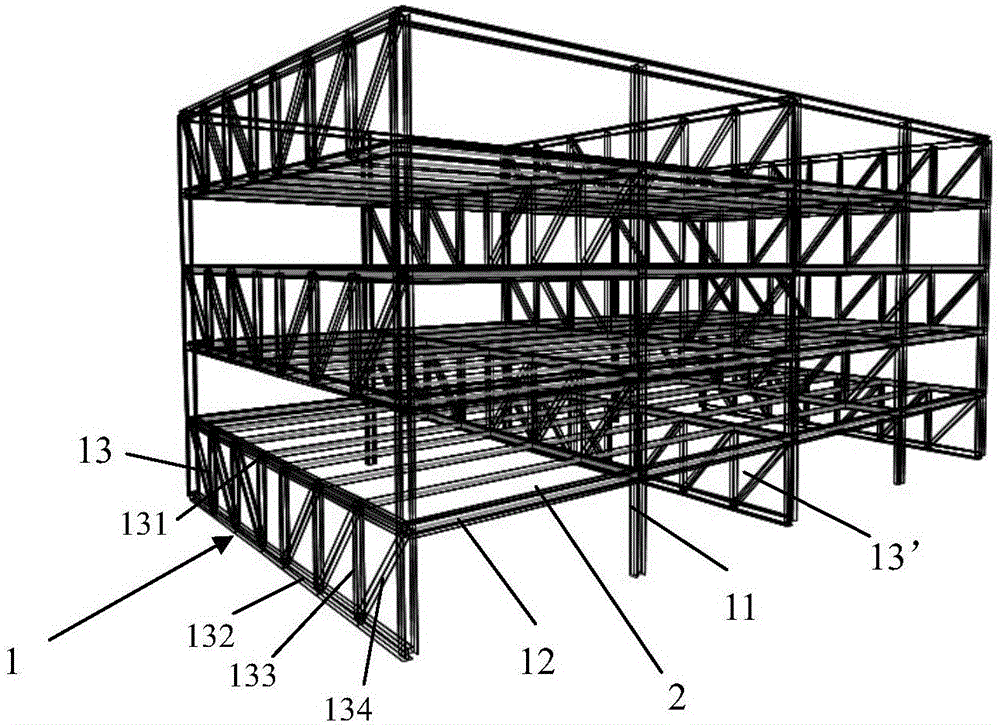

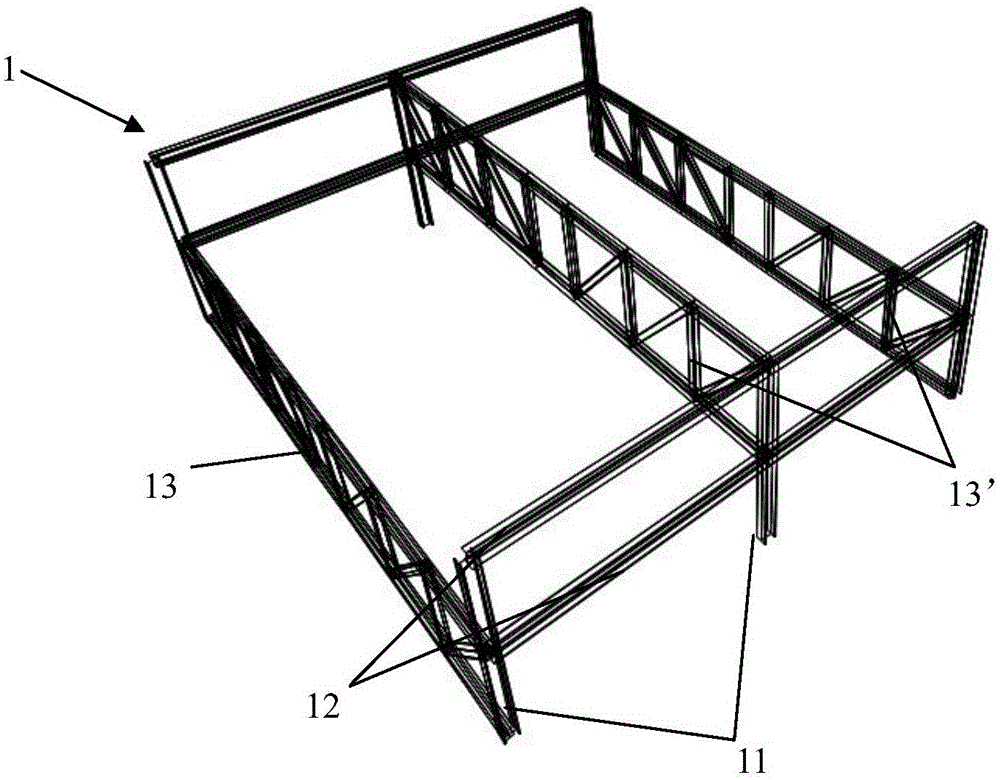

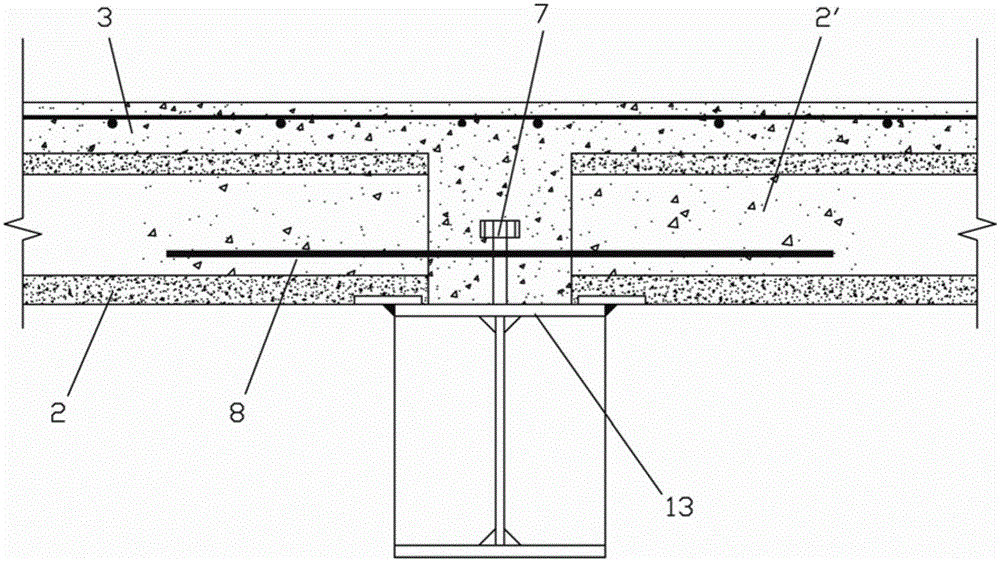

Large-span, secondary-beam-free and high-assembly industrialized steel structure system

A large-span, secondary-beam-free and high-assembly industrialized steel structure system comprises a staggered steel structure truss, a plurality of prefabricated large-span prestressed hollow slabs and concrete composite layer, wherein the staggered steel structure truss adopts a multilayer structure with at least double spans, and comprises framework columns, framework beams and plane trusses; the framework columns and the framework beams are vertically arranged at the periphery of the staggered steel structure truss to form a framework structure; the plane trusses are arranged in an upper-and-lower staggered manner in the height direction of the framework columns, and the plane trusses on the adjacent framework columns are arranged in an upper-and-lower staggered manner; the two ends of each plane truss are supported on the framework columns on the two sides; each plane truss is formed by connecting upper chords, lower chords, straight web members and diagonal web members; the prefabricated large-span prestressed hollow slabs are arranged on the staggered steel structure truss; one ends of the prestressed hollow slabs are supported on the upper chords of the plane trusses, and the other ends of the prestressed hollow slabs are supported on the lower chords of the adjacent plane trusses; the concrete composite layers are paved on the prefabricated large-span prestressed hollow slabs. The large-span, secondary-beam-free and high-assembly industrialized steel structure system is economical in steel consumption, standard in element production, convenient and fast to construct, and convenient for industrialized production.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Assembly-type anti-vibration water-saving anti-mosquito plant wall

ActiveCN108401729AHigh degree of assemblyFlexible assemblyGeneral water supply conservationSelf-acting watering devicesWater savingWater source

The invention provides an assembly-type anti-vibration water-saving anti-mosquito plant wall. The main concept is that a plurality of plant wall units capable of being freely assembled and disassembled on a wall surface are arranged, and the plant wall units are flexibly arranged according to the requirements and the area of the wall. Meanwhile, root irrigation and drip irrigation are combined, and the pipeline systems of the root irrigation and the drip irrigation communicate with a building down pipe, so that the roof rainwater is collected for supplying water to plants. Based on the concept, the invention provides the plant wall which can be assembled in three types, respectively a crib type, a rope type and a cantilever slab type. According to the plant wall, roof rain is used as a maintenance water source, the plant wall has a sponge building effect and anti-vibration water-saving anti-mosquito functions, the assembling is simple and flexible, the maintenance is easy, and the manufacturing cost and maintenance cost are low.

Owner:SICHUAN UNIV +1

Damping ground connection type fabricated reinforced concrete tuning quality damping wall

PendingCN109898691AGood vibration reduction effectUniform distribution of displacement angle between layersWallsBuilding repairsConnection typeReinforced concrete

The invention provides a damping ground connection type fabricated reinforced concrete tuning quality damping wall. The damping ground connection type fabricated reinforced concrete tuning quality damping wall comprises a plurality of structural beams, a plurality of structural columns, a prefabricated concrete wall, an upper connecting joint, a horizontal spring, distributed sliding support, a wall splice joint and a bottom connecting joint, the structural beams and the structural columns form a main structure, the main structure is connected with the prefabricated concrete wall separately through the upper connecting joint, the horizontal spring and the distributed sliding support, and the prefabricated concrete wall is connected with the ground through the bottom connecting joint. Whenwind damage and an earthquake comes, frequency modulation resonance occurs to the main structure and the damping ground connection type fabricated reinforced concrete tuning quality damping wall, energy of the main structure is dissipated, so that the main structure is protected, the damping effect is good, inter-story displacement distribution is more uniform, the structural damage mode is improved, the corrosion resistance and the fire-resistant performance are good, the construction is simple, and the assembly degree is high.

Owner:SUZHOU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com