Fabricated-type truss structure comprising elbow-joint-type multi-dimensional vibration reduction rod piece

A technology of truss structure and damping rods, which is applied in the direction of building components, building types, building structures, etc., can solve problems such as damage, inconvenient installation, and inability to absorb multi-dimensional vibrations, and achieve a high degree of assembly and easy installation and replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

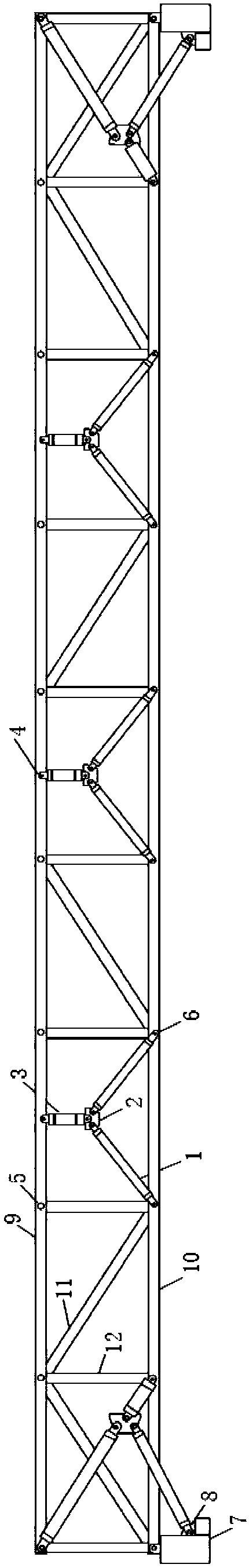

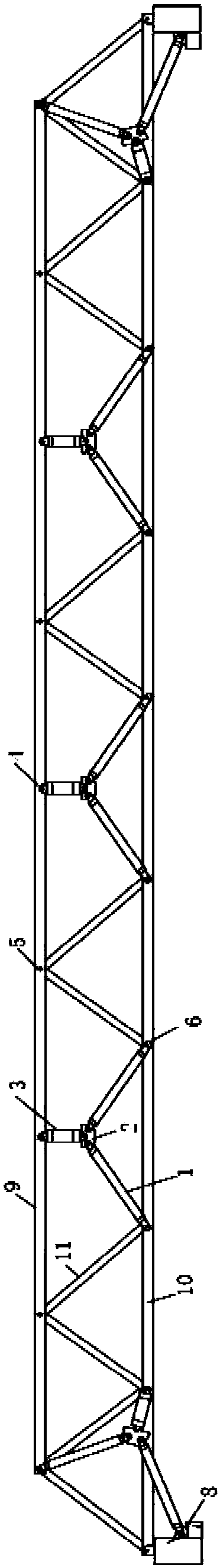

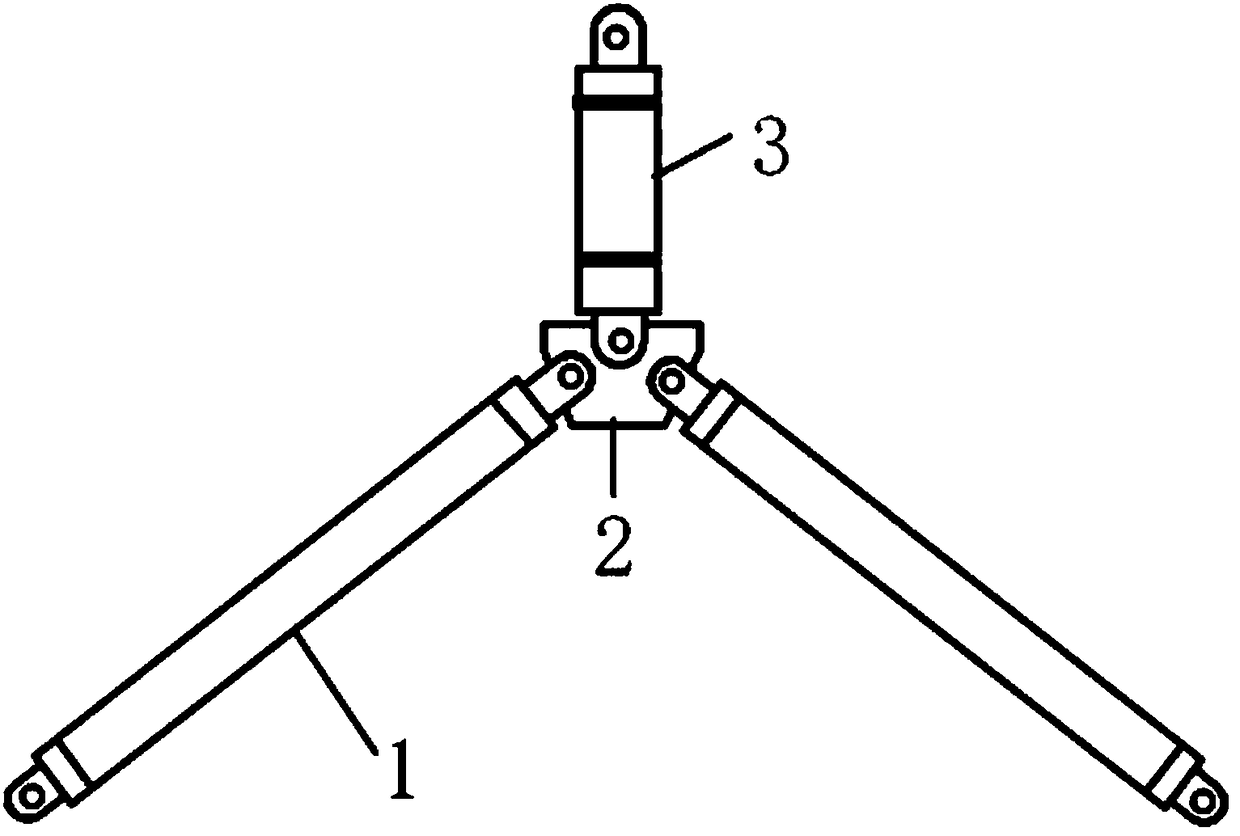

[0029] like figure 1 As shown, the prefabricated toggle energy-dissipating truss includes: lower link 1, connecting plate 2, damper 3, pin 4, bolt 5, viscoelastic material 6, support 7, ear plate 8, upper chord 9 , Bottom chord 10, oblique web bar 11, vertical web bar 12.

[0030] Taking a planar truss as an example, the truss has 9 spans, the length of each upper chord is 1.5 meters, the length of the lower chord is 1.5 meters, and the length of the vertical web is 1 meter. 5. With 7 spans, the horizontal toggle energy-dissipating structure is set on both sides of the span. The setting method is the same as that of the vertical toggle structure, except that the connection points are different. The third span is selected, and each part of the toggle energy-dissipating truss structure The dimensions and settings are as follows:

[0031] 1) T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com