Prefabricated assembly type steel plate-concrete composite shear wall structure system and construction method thereof

A combined shear wall and prefabricated assembly technology, which is applied in the direction of walls, building components, and building structures, can solve the problems of large cross-sectional dimensions of steel beams and columns in prefabricated frame structures, affecting the use of building space, and the large amount of steel used for fire protection and anticorrosion. , to avoid grouting sleeve connection, convenient and quick installation, and reduce structural cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-Figure 7 The features and principles of the present invention are described in detail, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

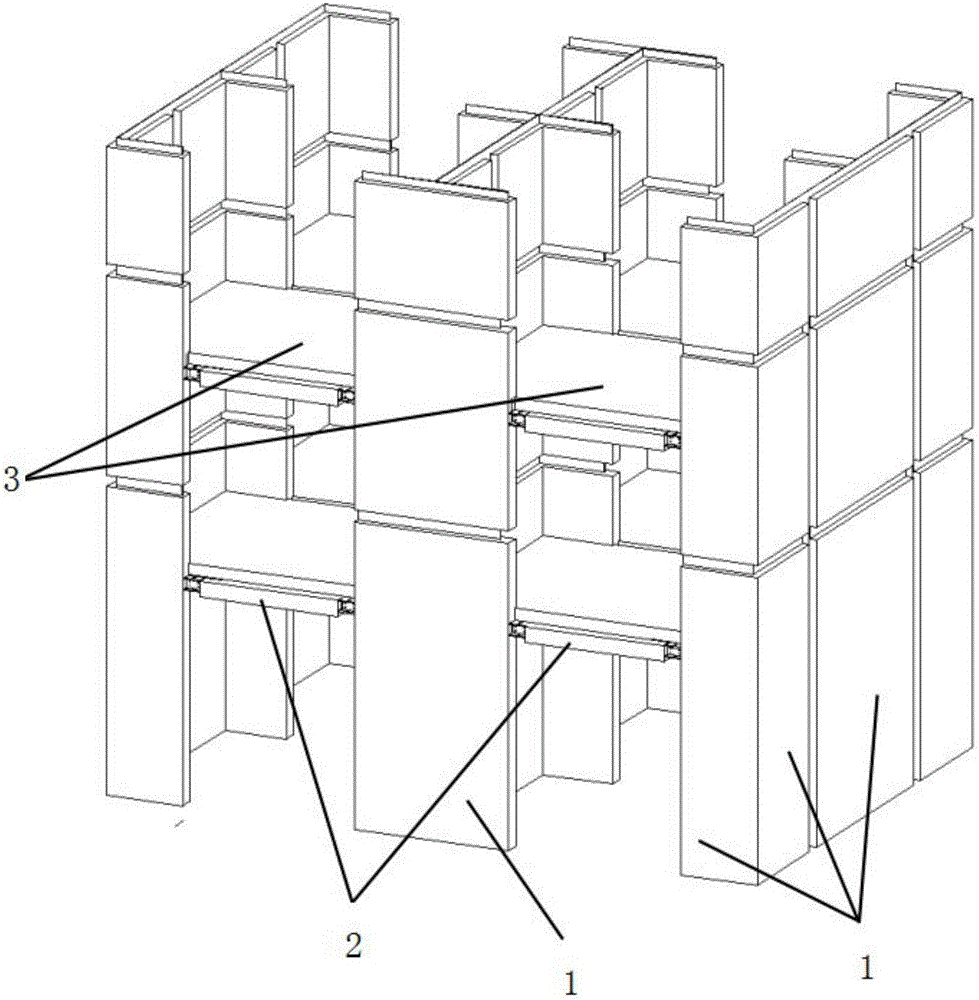

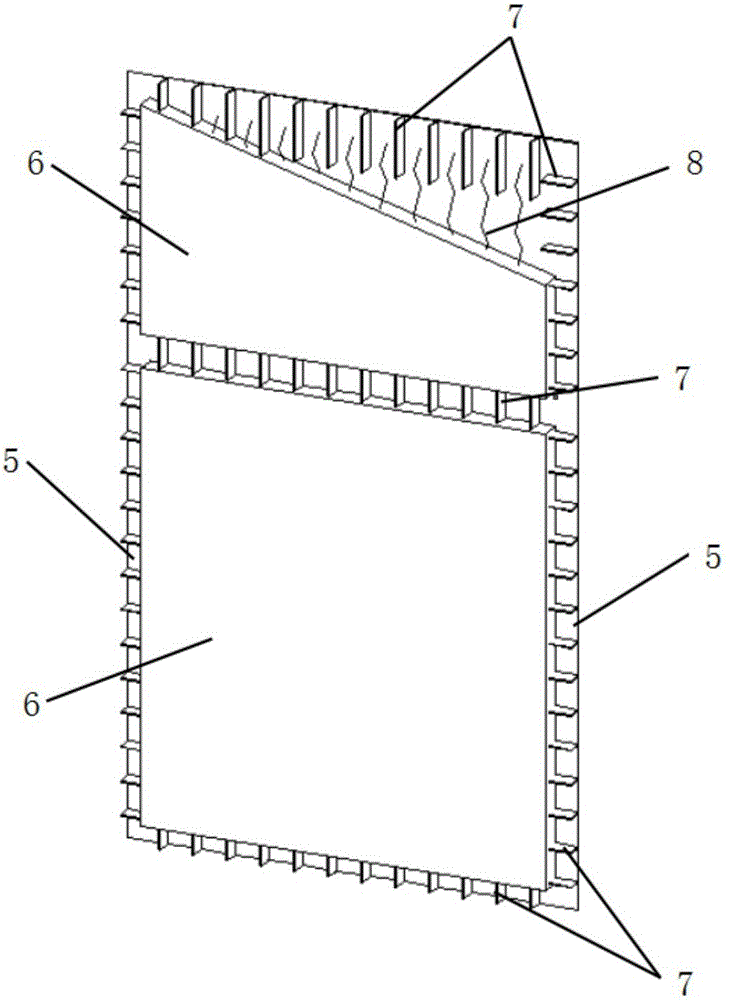

[0039] Such as Figure 1-Figure 7 As shown, the invention includes: prefabricated steel plate-concrete composite shear wall 1, prefabricated steel frame-concrete composite beam 2, laminated floor 3, laminated floor installation bracket 4, vertically arranged prefabricated steel plate-concrete composite shear wall The prefabricated steel frame-concrete composite beam and the composite floor are connected by the installation bracket of the composite floor, and the prefabricated steel plate-concrete composite shear walls are connected by bolted steel plates.

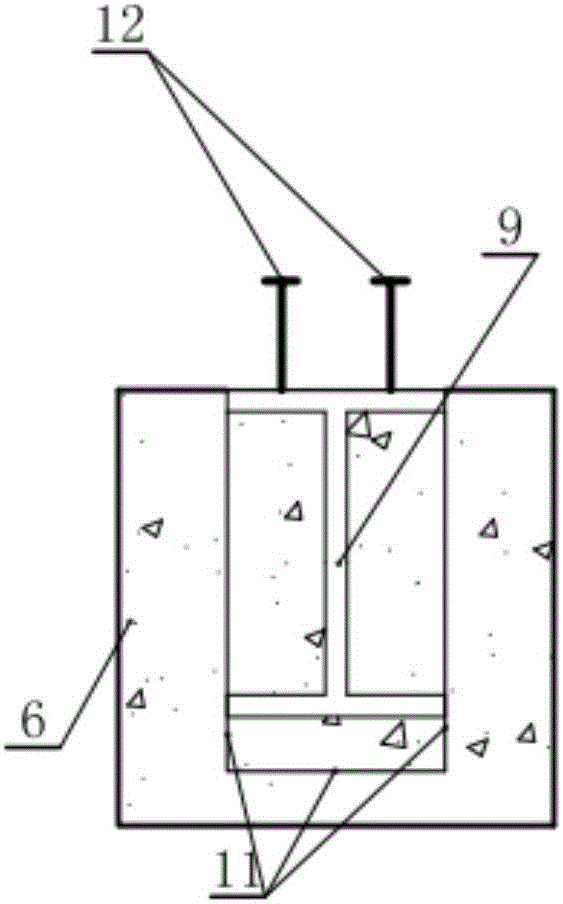

[0040] The prefabricated steel plate-concrete composite shear wall is prefabricated by the steel plate 5 in the middle and the concrete layers 6 on both sides. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com