Beam through type corrugated steel plate energy consumption shear wall structure

A technology of corrugated steel plates and shear walls, applied to walls, building components, building structures, etc., can solve the problems of low assembly level, poor shear bearing capacity, self-heavyness, etc., so as to improve shear bearing capacity and improve Shock-absorbing ability, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

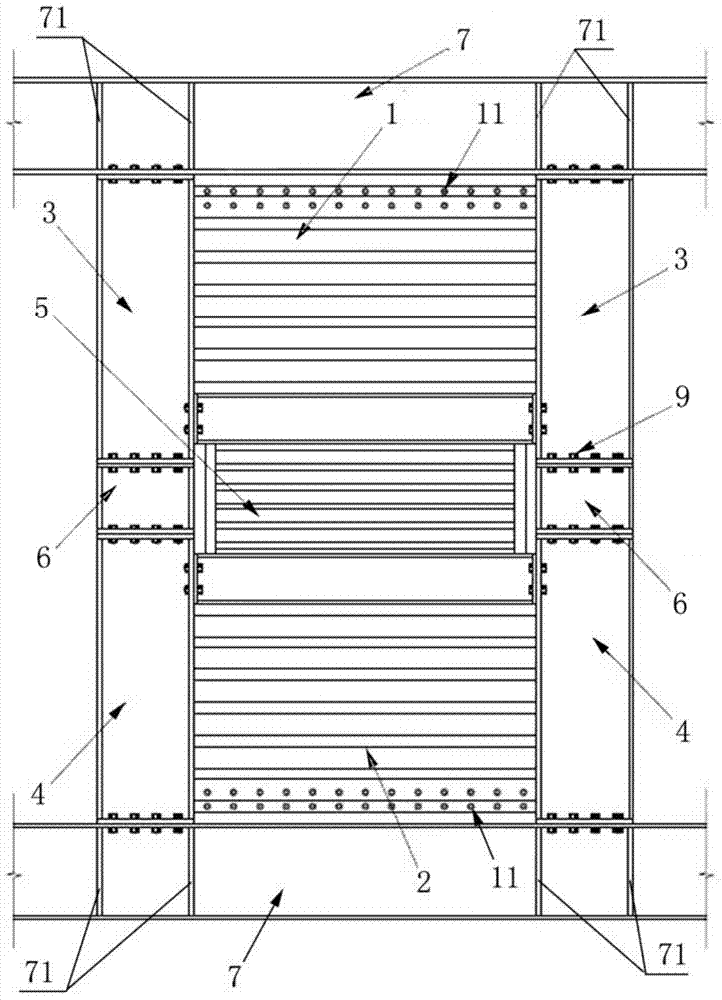

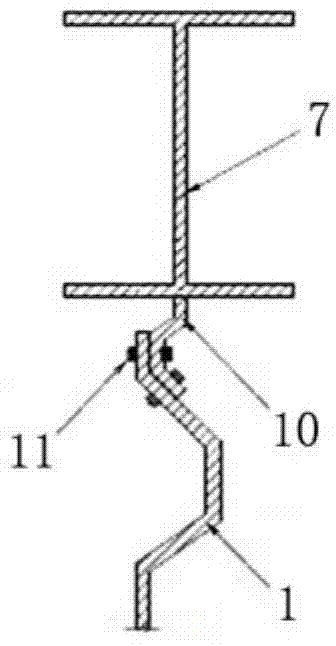

[0048] Such as figure 1 As shown, a beam-through corrugated steel plate energy-dissipating shear wall structure includes a first corrugated steel plate shear wall panel 1, a second corrugated steel plate shear wall panel 2, an upper edge steel column 3, and a lower edge steel column 4. The corrugated steel plate energy dissipation section 5 and the short steel columns 6 on the left and right sides of the corrugated steel plate energy consumption section; the corrugated steel plate energy dissipation section 5 and the short steel columns 6 on the left and right sides of the corrugated steel plate energy consumption section are located in the middle of the floor.

[0049]The upper end of the corrugated steel plate energy dissipation section 5 and the lower end of the first corrugated steel plate shear wall sheet 1 are connected together by welding or bolt connection or a combination of bolt connection and welding. The corrugated steel plate energy dissipation section 5 The lower...

Embodiment 2

[0059] The structural form of this embodiment is basically the same as that of Embodiment 1, and the difference with Embodiment 1 is:

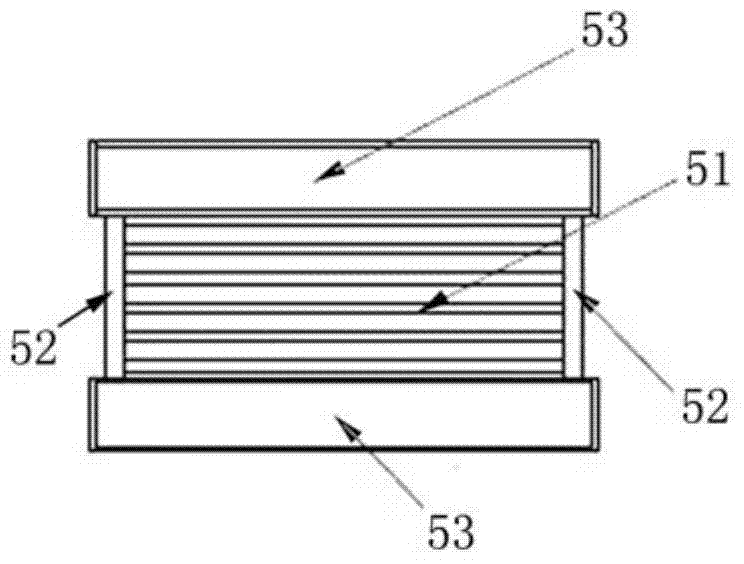

[0060] Such as Image 6 As shown, the corrugated steel plate energy dissipation section 5 includes a shear damper 54, and the left and right sides of the shear damper 54 are respectively welded with end plates or H-shaped steel columns 52, and the shear damper The device 51 and the end plate or the upper and lower ends of the H-shaped steel column 52 are respectively connected with a steel beam 53 by welding or bolt connection or a combination of bolt connection and welding. In this embodiment, the corrugated steel plate 51 of the corrugated steel plate energy dissipation section 5 in the first embodiment is replaced with a shear type damper 54, which can also achieve the purpose of energy dissipation.

[0061] To sum up, the energy-dissipating shear wall structure of the beam through corrugated steel plate of the present invention adopts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com