Prefabricated lightweight steel-foam concrete composite wall and application method thereof

A foamed concrete, prefabricated technology, used in walls, building components, buildings, etc., can solve the problems of poor wall insulation, sound insulation, fire protection, poor structural integrity, etc. Bending strength, easy to hoist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with embodiment.

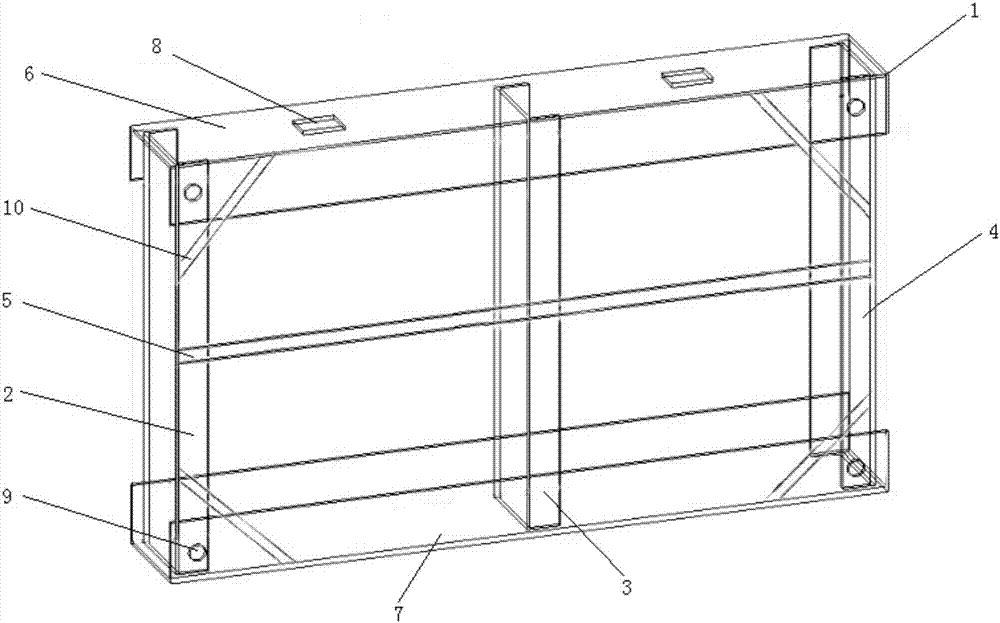

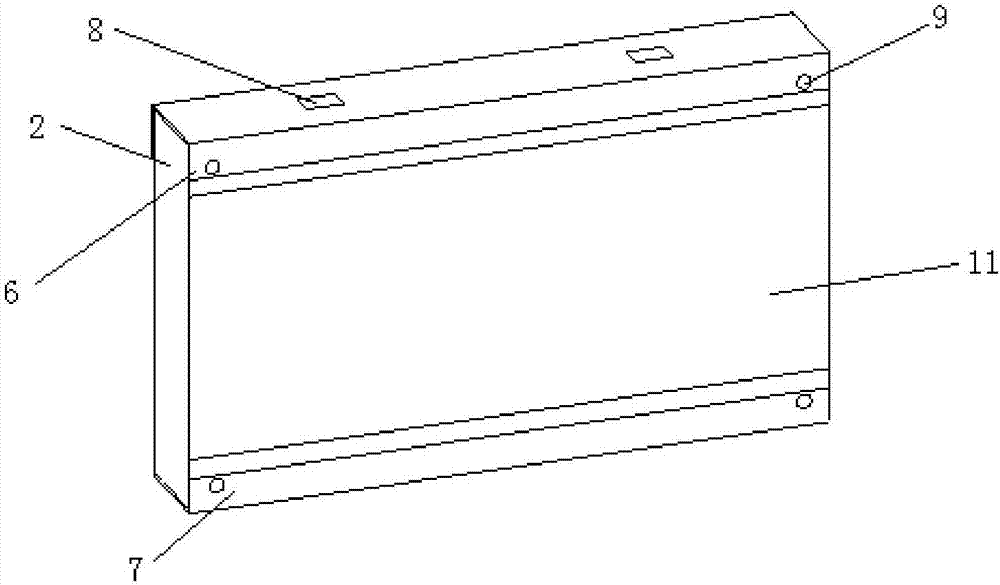

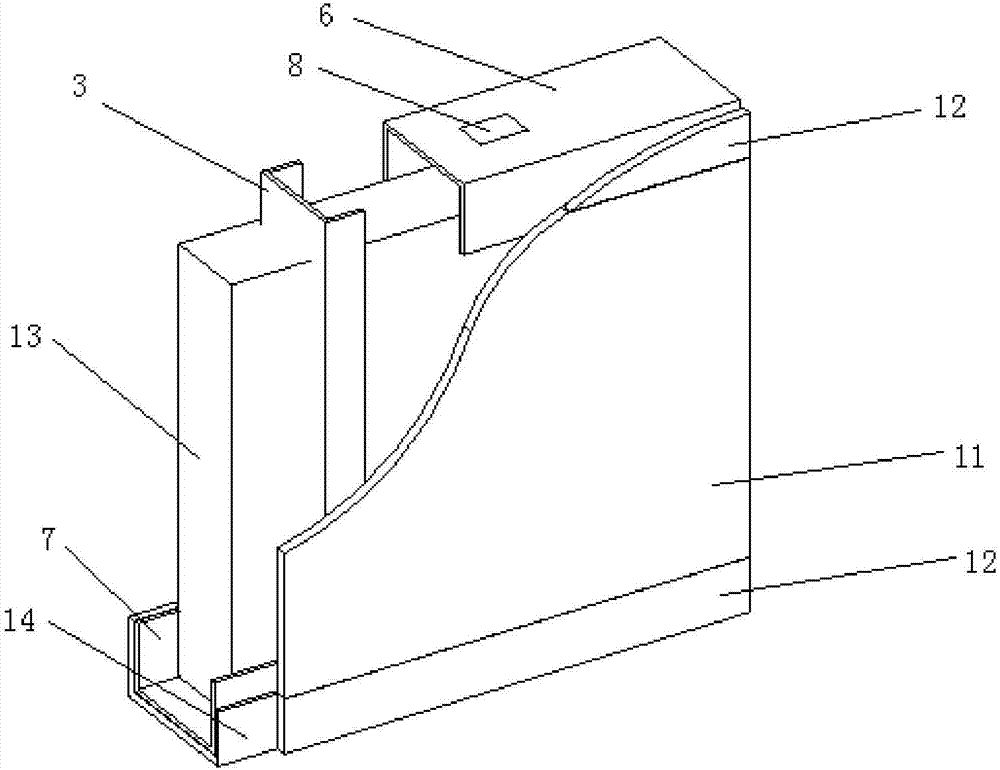

[0041] according to Figure 1 ~ Figure 3 As shown, an assembled light steel-foam concrete composite wall provided by the present invention includes a wall panel frame 1, and the wall panel frame 1 includes a first U-shaped light steel 2 and a second U-shaped Light steel 3 and the third U-shaped light steel 4, in the middle section of the first, second and third U-shaped light steel, there are braces 5 along the transverse direction, and in the first, second and third U-shaped The top and bottom ends of the light steel are respectively provided with a fourth U-shaped light steel 6 and a fifth U-shaped light steel 7. The fourth U-shaped light steel 6 is provided with two pouring holes 8 of 40mm×40mm. The overlapping parts of the first and third U-shaped light steels and the fourth and fifth U-shaped light steels are provided with hoisting holes 9, and the wall can be hoisted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com