Retard-bonded prestressed prefabricated integral frame joint system

A kind of slow bonding prestressed, integral technology, applied in the direction of building, building structure, etc., can solve the problems of poor seismic performance of the structure, unreachable, inconvenient construction and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

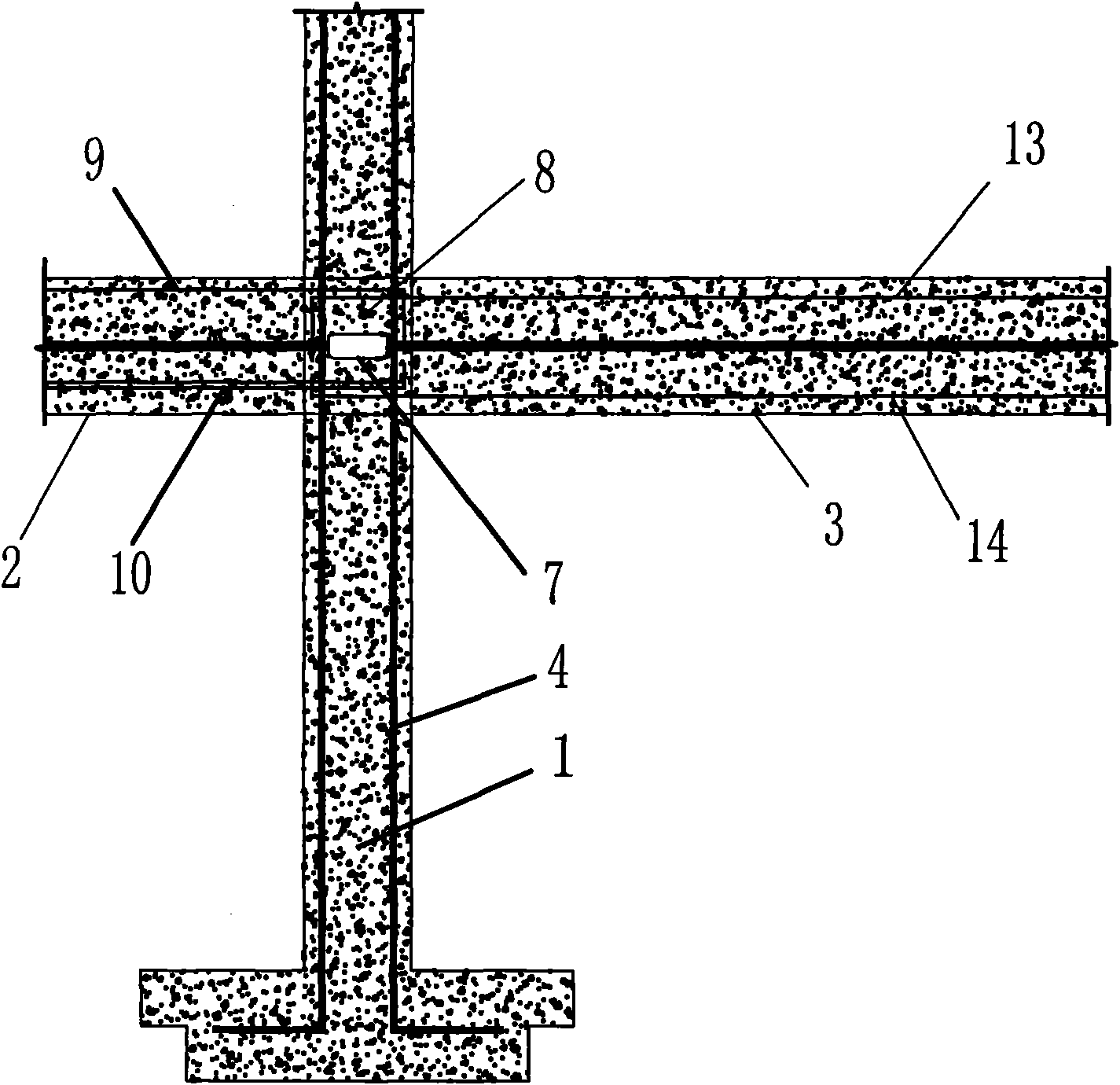

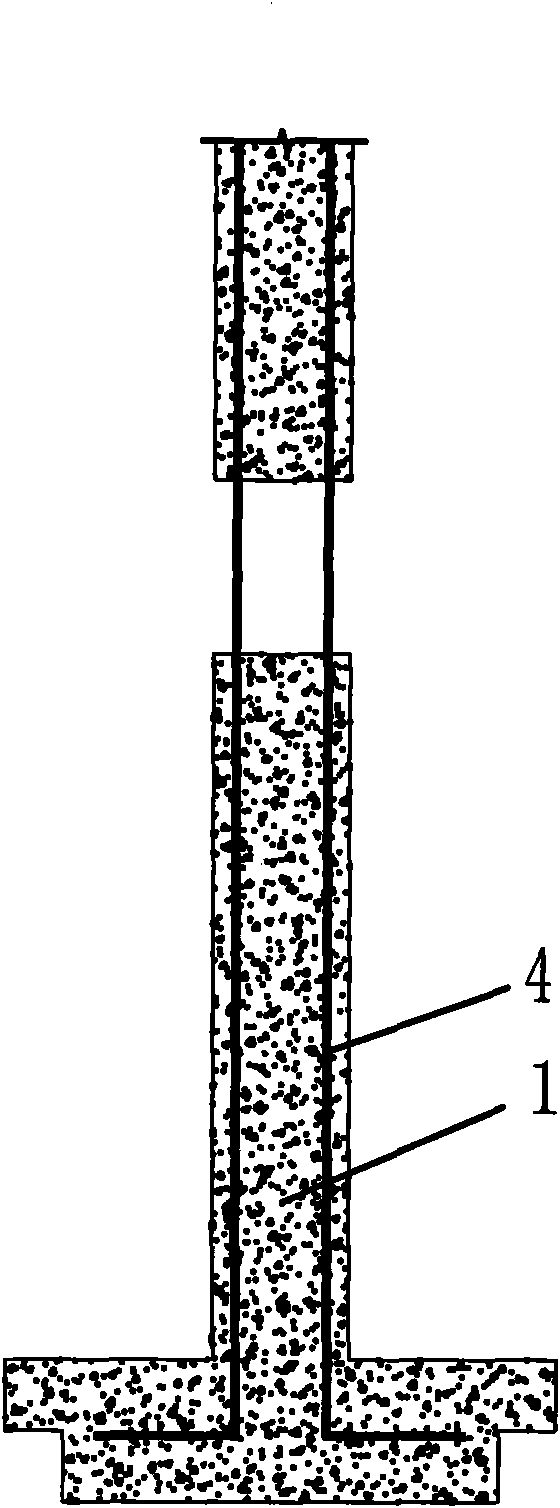

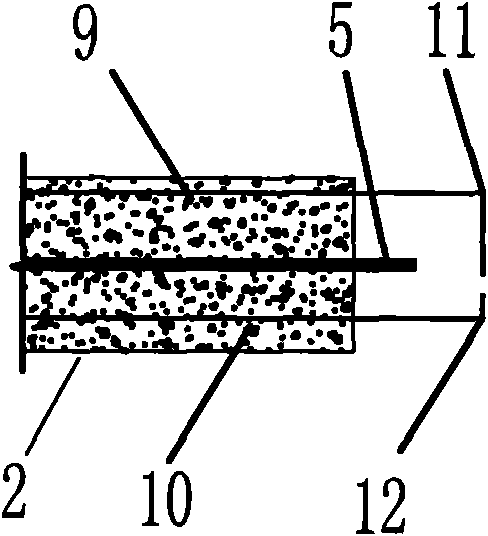

[0014] For the convenience of further understanding the purpose means of the present invention, hereby attach preferred embodiment figure to describe in detail as follows:

[0015] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the slow bonded prestressed assembled integral frame joint system of the present invention includes: a precast concrete column 1, a left precast concrete beam 2 and a right precast concrete beam 3; wherein, the precast concrete column 1 is preset with a main reinforcement 4, The precast concrete column 1 is only composed of the main reinforcement 4 at the node position. The left precast concrete beam 2 and the right precast concrete beam 3 are respectively equipped with slow bonded prestressed tendons, and the slow bonded prestressed tendons in the left precast concrete beam 2 are The right end extends from the right end of the left precast concrete beam to form a connecting part 5, and its left end is connected with the tension end ancho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com