Large-span, secondary-beam-free and high-assembly industrialized steel structure system

A large-span, steel structure technology, applied in building components, building structures, floors, etc., can solve problems such as no engineering application cases, and achieve the effects of no construction waste, high degree of assembly, and less wet work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

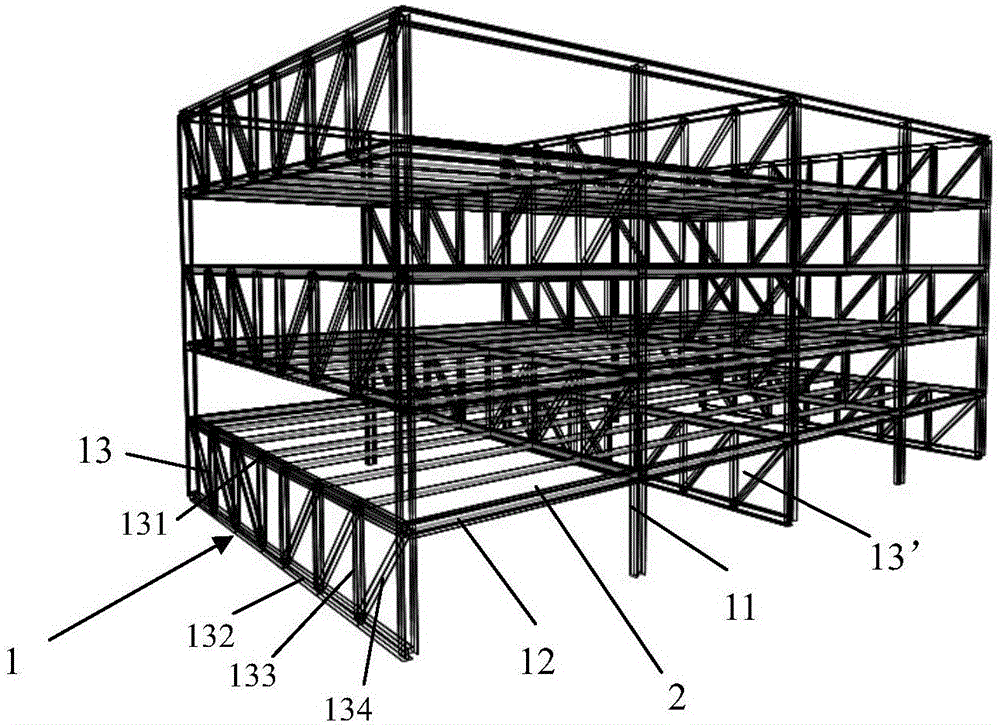

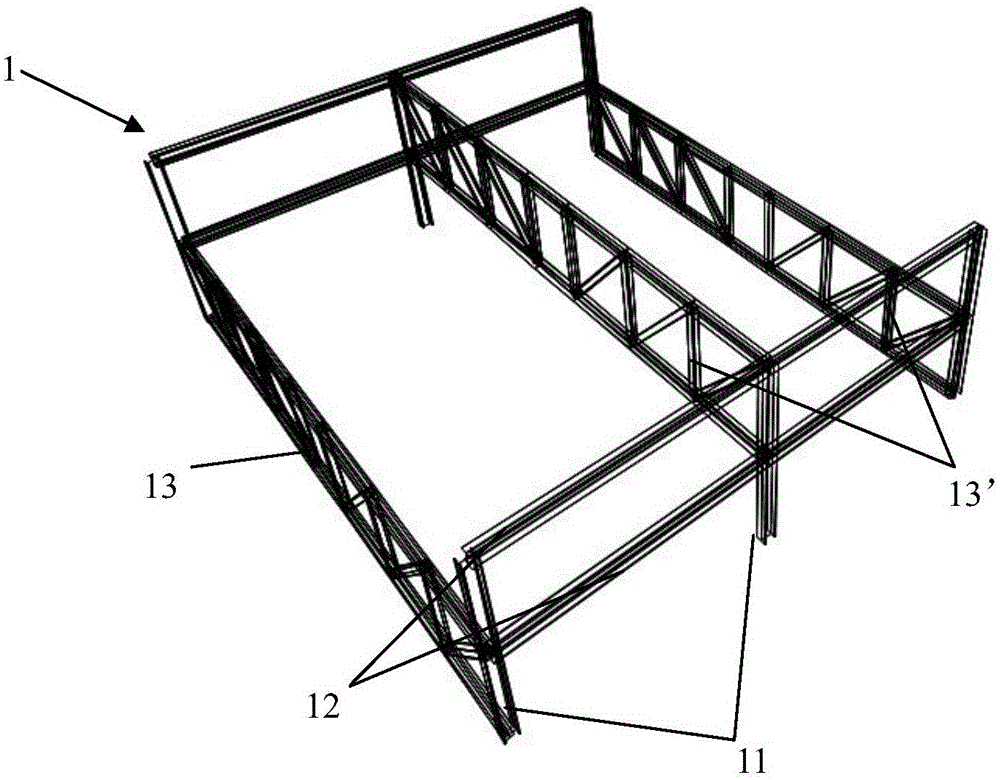

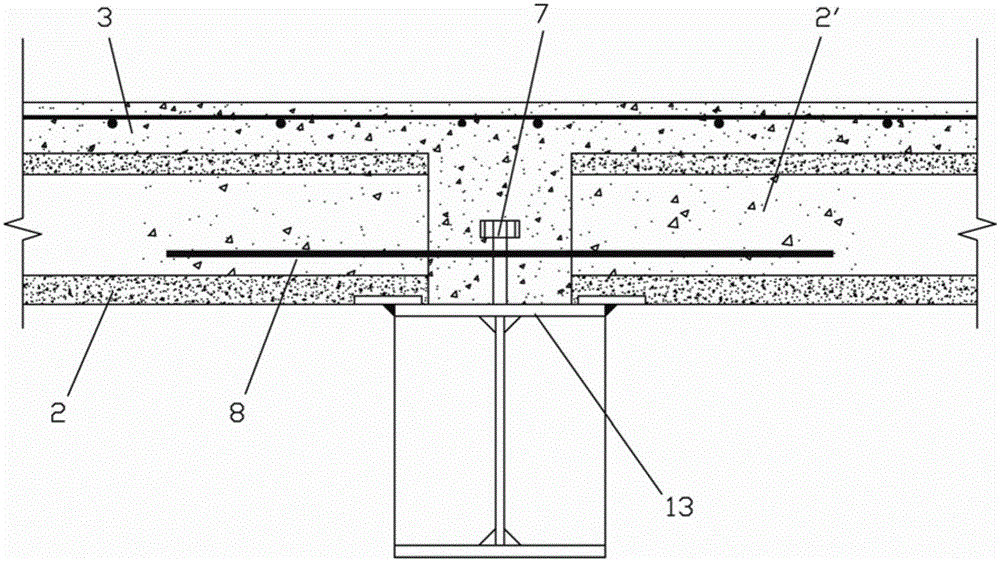

[0025] refer to Figure 1 to Figure 5 , a large-span, non-secondary beam, and highly assembled industrialized steel structure system of the present invention, which includes a steel structure staggered truss 1, which is at least a double-span, multi-layer structure, including several frame columns 11, frame Beams 12 and planar trusses 13, 13'; the frame columns 11 and frame beams 12 are longitudinally arranged along the periphery of the structure to form a frame structure; the planar trusses 13 are arranged alternately in the upper and lower layers along the height direction of the frame columns 11, and adjacent The plane trusses on the frame columns are also arranged alternately on the upper and lower floors; the two ends of the plane trusses 13 are respectively supported on the frame columns 11 on both sides; , lower chord 132, straight web 133 and oblique web 134; several prefabricated large-span prestressed hollow slabs 2 are arranged on the steel structure staggered truss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com