Knowledge base-based three-dimensional X-ray computed tomography (CT) detection system and method

A technology of tomography and detection system, which is applied in the direction of material analysis using radiation, etc., can solve the problems of difficulty in quality inspection from SiP chip die to package printed circuit board, troubles in analysis and quality inspection, and inability to determine the level and position, etc., to achieve Good defect analysis and quality control, easy detection and analysis, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

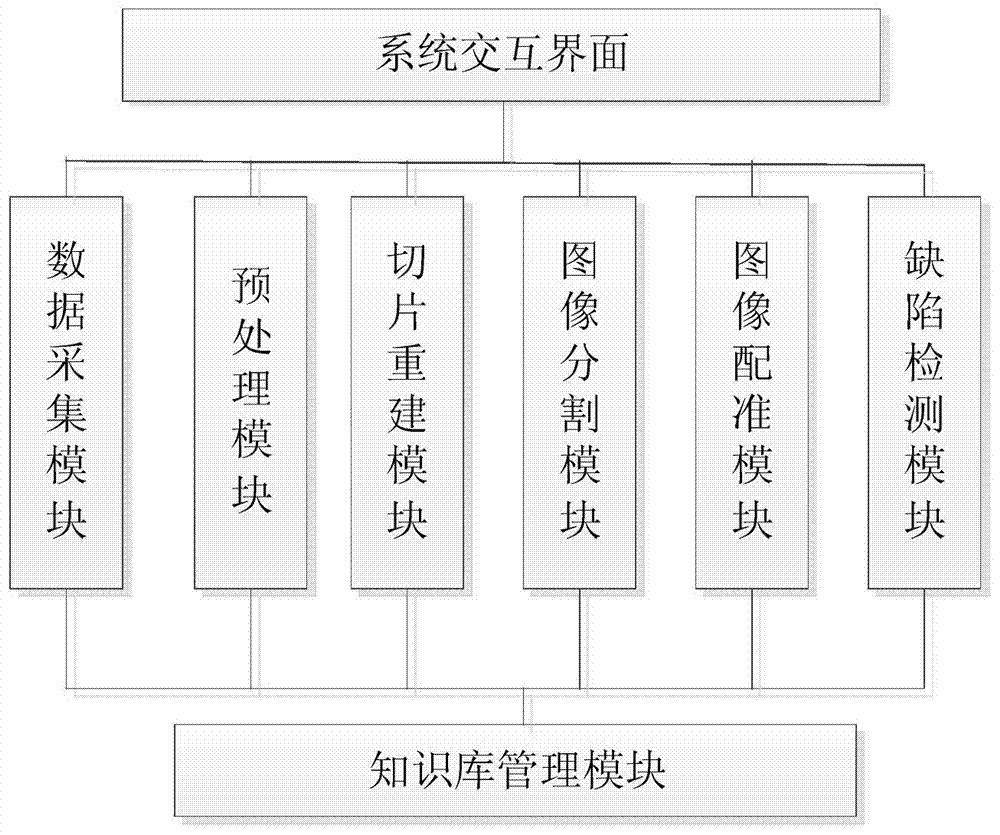

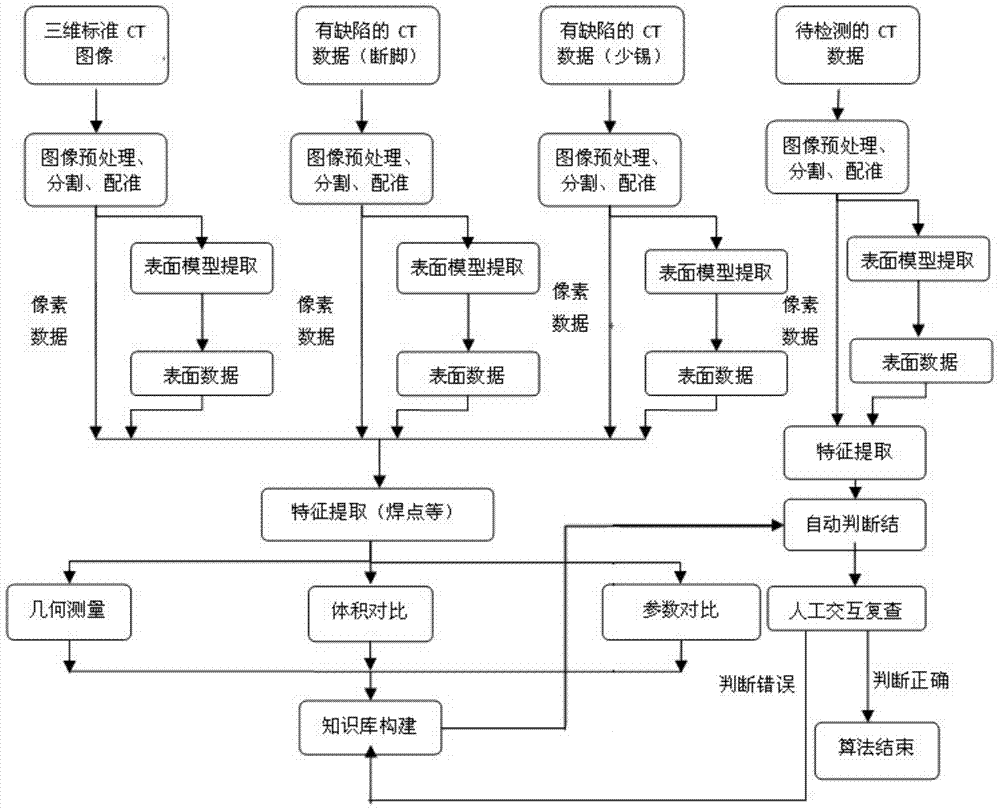

[0060] Such as figure 1 , a 3D X-ray tomographic detection system based on knowledge base, including data acquisition module, preprocessing module, slice reconstruction module, image segmentation module, image registration module, defect detection module and knowledge base management module, through the system man-machine Interactive interface, users can perform corresponding operations, among which

[0061] Data acquisition module, the chip used to collect standard CT projection data is placed on the loading platform, the X-ray tomography machine is turned on, the angle of the loading platform is converted, multiple sets of CT projection data are obtained, and CT projection data of defective chips are collected and CT projection data of the chip to be tested, where the defects of the chip include lack of soldering, wrong soldering, less tin, more tin, broken wires, sticky feet, and broken feet;

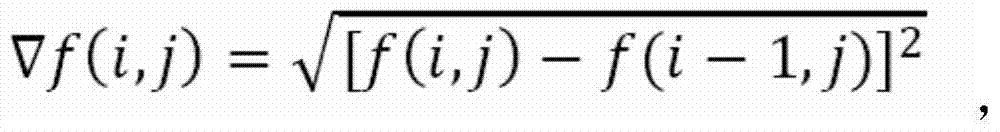

[0062] The preprocessing module performs noise reduction processing on the CT p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com