A kind of transparent milk packaging film and preparation method thereof

A technology for packaging film and milk, applied in packaging, wrapping paper, packaged food, etc., can solve problems such as dissolution of small molecules, and achieve the effect of reducing oxidized food, good compatibility, good crystallinity and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of transparent milk packaging film comprises the following steps:

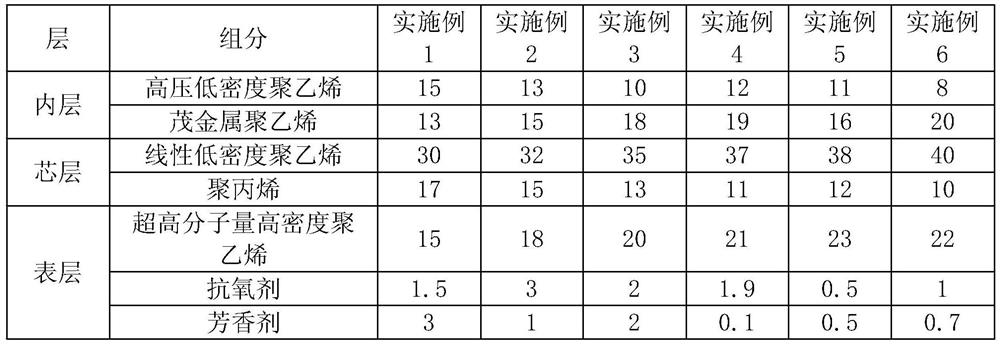

[0029] Step 1: Weigh each raw material according to Table 1, mix each raw material according to the respective formulas of the inner layer, core layer and surface layer, and obtain the inner layer mixture, the core layer mixture and the surface layer mixture respectively;

[0030] Step 2: Add the inner layer compound, the core layer compound and the surface layer compound into the three hoppers of the extruder respectively, and perform three-layer co-extrusion blown film processing, wherein the temperature of the extruder is 150°C to obtain a film. The thickness is 0.05mm, of which the inner layer is 0.01mm, the core layer is 0.03mm, and the surface layer is 0.01mm;

[0031] Step 3: cooling and winding the film to obtain a transparent milk packaging film.

[0032] The transparent milk packaging film can enable consumers to directly see whether the milk has turned yellow or whether there...

Embodiment 2

[0036] To prepare a transparent milk packaging film, the dosage of each raw material is shown in Table 1, and the method is the same as in Example 1, except that the temperature of the extruder in step 2 is 155°C.

[0037] The transparent milk packaging film can enable consumers to directly see whether the milk has turned yellow or whether there is agglomeration, so that consumers can buy with confidence. At the same time, the product has a blocking effect on ultraviolet rays with a wavelength below 400nm, and the oxygen transmission rate is: (23°C, 50%RH) 3.60cm 3 / m 2 ·24h·0.1Mpa, with anti-oxidation and fresh-keeping effect.

Embodiment 3

[0039] To prepare a transparent milk packaging film, the dosage of each raw material is shown in Table 1, and the method is the same as in Example 1, except that the temperature of the extruder in step 2 is 160°C.

[0040] The transparent milk packaging film can enable consumers to directly see whether the milk has turned yellow or whether there is agglomeration, so that consumers can buy with confidence. At the same time, the product has a blocking effect on ultraviolet rays with a wavelength below 400nm, and the oxygen transmission rate is: (23°C, 50%RH) 3.53cm 3 / m 2 ·24h·0.1Mpa, with anti-oxidation and fresh-keeping effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com