Patents

Literature

248results about How to "UV protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mask liquid with multiple skin care effects and preparation method thereof

InactiveCN106074315AImprove moisturizing abilityAdjust water and oil balanceCosmetic preparationsToilet preparationsLong lastingWrinkle

The invention discloses mask liquid with multiple skin care effects and a preparation method thereof, aims at providing mask liquid which has effects of skin whitening, speckle removing, wrinkle smoothing, inflammation relieving and diminishing, long-lasting moisturizing and grease balancing, and belongs to the technical field of cosmetics. According to the technical scheme, the mask liquid is prepared from, by weight, 0.5%-3% of sericin, 3.011%-14.02% of a plant extract, 1.11%-8.35% of a moisturizer, 8%-15% of polyalcohol, 0.1%-1.5% of active peptides, 0.08%-0.15% of Carbomer, 0.08%-0.15% of triethanolamine, 0.02%-0.06% of disodium EDTA, 0.3%-0.5% of a preservative and the balance deionized water.

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

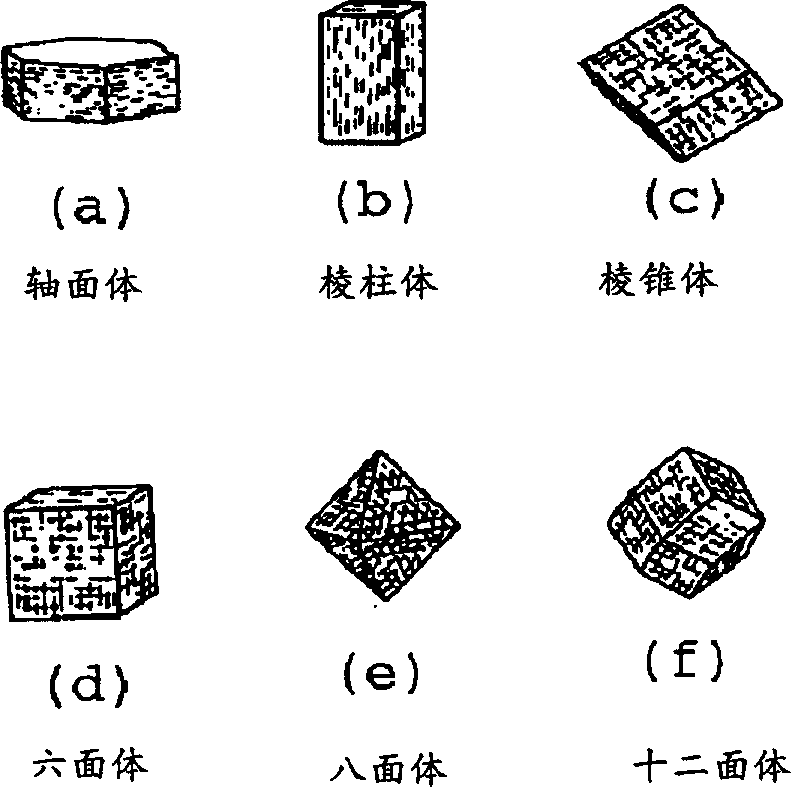

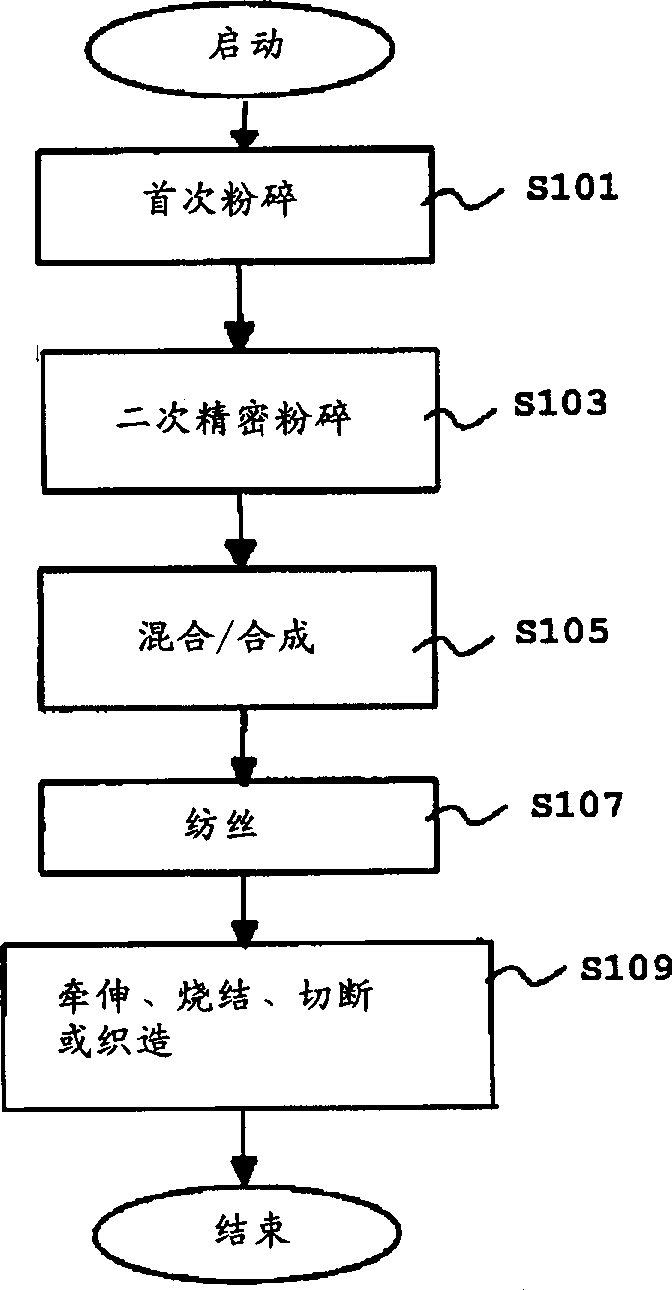

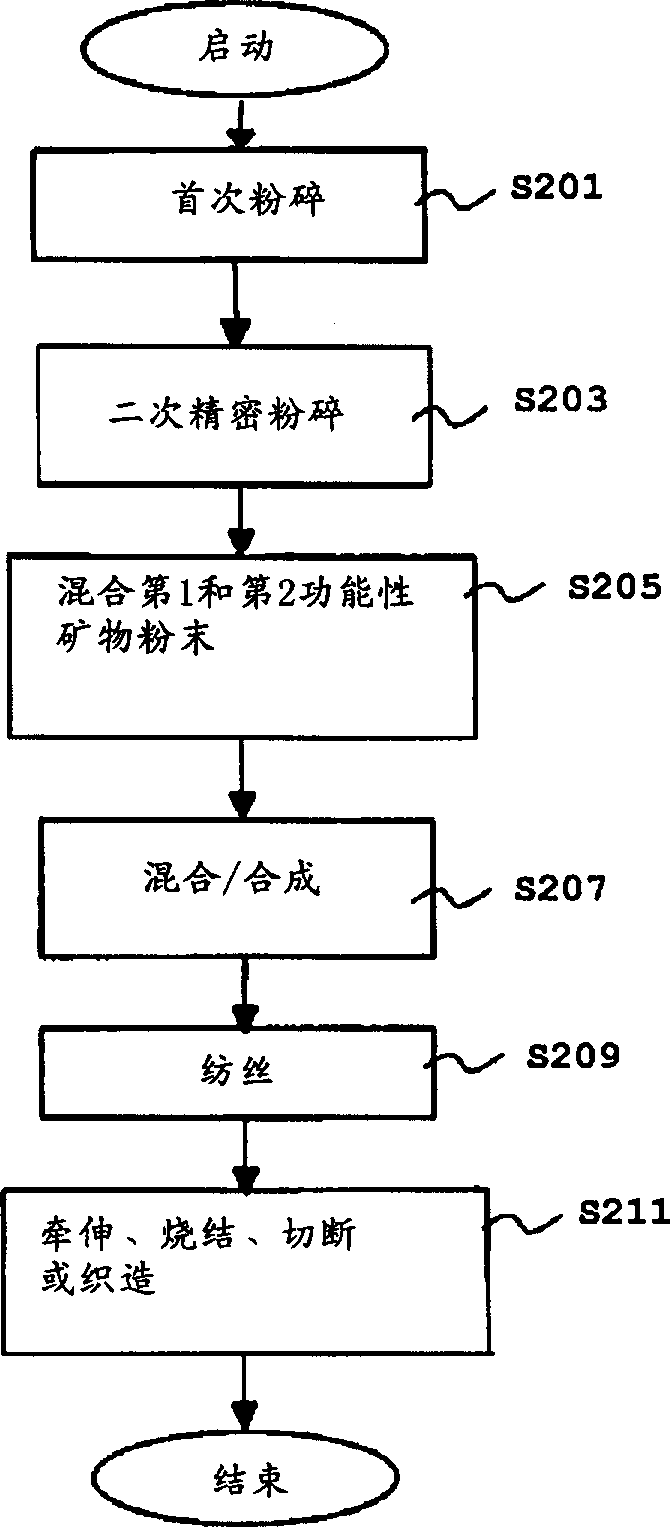

Manufacture of fibre containing functional mineral powder and fibre prepared by the same

InactiveCN1318657ABlood pressure controlRelief the painArtificial filaments from viscoseArtificial filaments from cellulose derivativesGranularityPolyresin

A method of producing fiber having functional mineral powders includes the steps of a first pulverizing functional mineral which crystal form of is pinacoid, a second closely pulverizing the first pulverized functional mineral powders to be less than 1 / 3 granularity of desired fineness, mixing and synthesizing 0.1-10 weight % of the second pulverized functional mineral powders and 90-99.9 weight % of a chemical resin, and spinning the mixture of functional mineral powders and the chemical resin.

Owner:石美秀

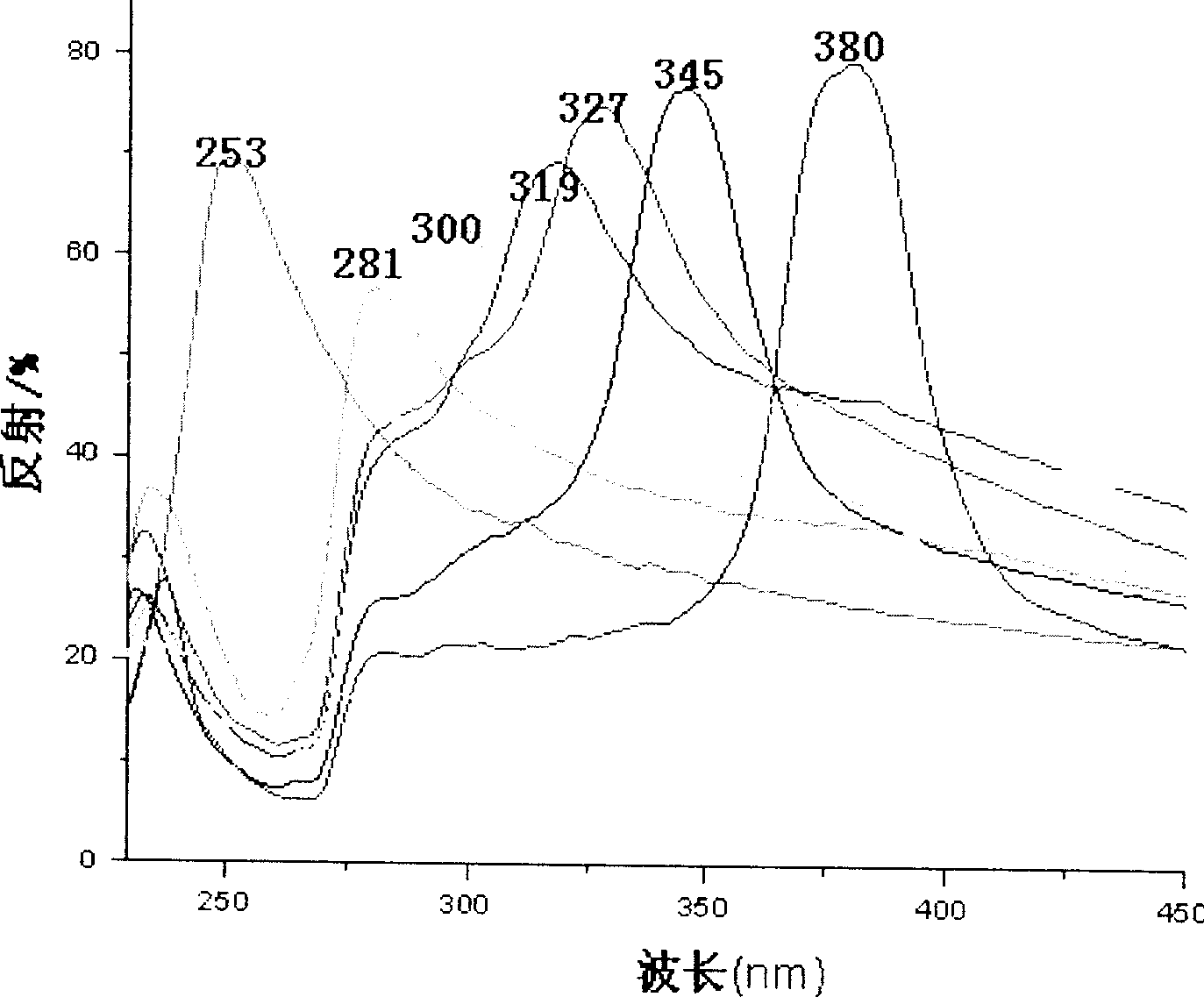

Photon crystal film of ultraviolet polymer colloid with photon band gap and its prepn and use

ActiveCN1887941AThe monodispersity index is smallThe size is easy to controlCosmetic preparationsToilet preparationsPhotonic bandgapLatex particle

The present invention relates to photo crystal film, and is especially one kind of colloidal photon crystal film and its preparation and application in ultraviolet preventing material or cosmetics material. The colloidal photon crystal film is prepared through coating monodispersed polymer latex in hard core-soft shell structure on flat substrate and volatilizing the dispersing liquid; the obtained monodispersed polymer latex particle has shell of 20-50 nm thickness, particle size of 100-160 nm and multiple dispersion index not greater than 0.005; and colloidal photon crystal film has photon band gap in the ultraviolet region of 200-400 nm. The colloidal photon crystal film is used as the ultraviolet preventing material in cosmetics, paint, etc.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Acne removing and antiallergic cream and preparation method thereof

InactiveCN103565714ANo drug resistanceAnti-acidificationCosmetic preparationsToilet preparationsPolyethylene glycolGlycerol

The invention discloses an acne removing and antiallergic cream which is prepared by mixing stearyl alcohol polyether-2, stearyl alcohol polyether-20, glycerin stearate, PEG (Polyethylene Glycol)-100 stearate, stearic acid, cetearyl alcohol, aloe oil, polydimethyl siloxane, isopropyl myristate, propyl p-hydroxybenzoate, methyl p-hydroxybenzene, tocopherol, azone, bisabolol, glycerol, xanthan gum, EDTA (Ethylene Diamine Tetraacetic Acid)-2Na, propylene glycol, ethanol, menthol, salicylic acid, a golden cypress extractive, a scutellaria baicalensis extractive, an India chinaberry leaf extractive, a spiraea ulmaria extractive, a bee milk extractive, an aloe leaf extractive, tea tree oil and sodium hydroxide. The acne removing and antiallergic cream disclosed by the invention can be used for removing acnes, promoting the facial blood circulation and skin cell regeneration, improving the skin tolerance and reducing or eliminating the allergic reaction of the skin; the allergic tolerance of the skin is improved, so that the cream is safe and effective; no any spices are added, so that allergens are greatly reduced.

Owner:SHENZHEN GUAFEN BIOTECH

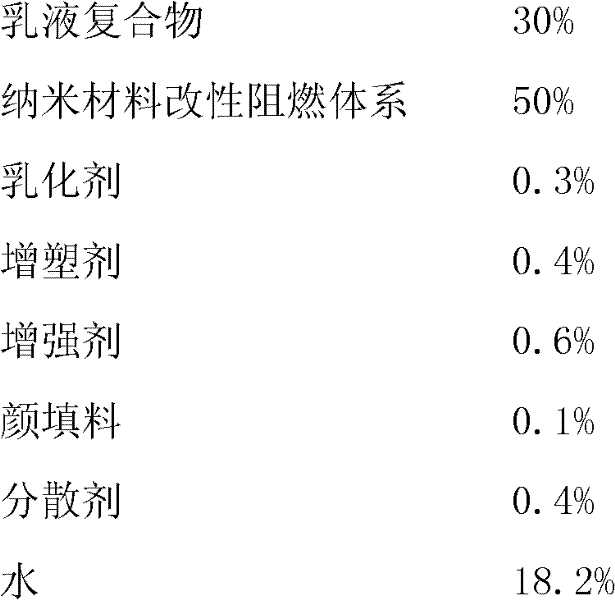

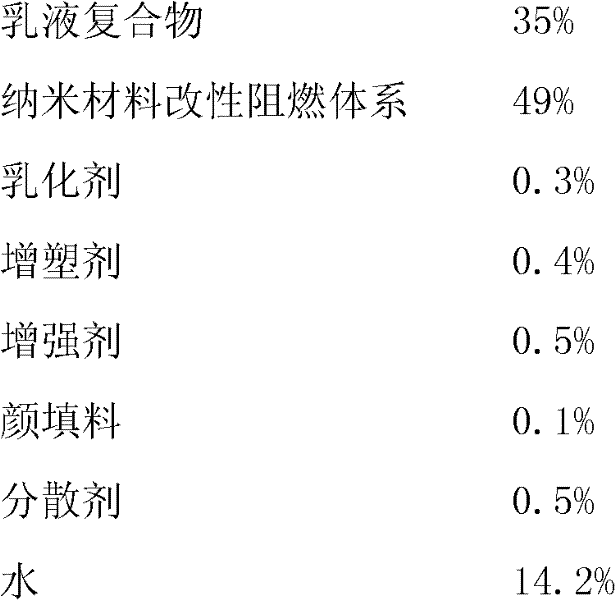

Water-borne inflation type refractory coating and preparation method thereof

The invention discloses a water-borne inflation type refractory coating and a preparation method thereof. The refractory coating is prepared from the following components: 30-40% of emulsion compound, 40-58% of modified antiflaming system of a nanometer material, 0.3-0.6% of emulsifying agent, 0.2-0.4% of plasticizer, 0.4-0.8% of reinforcing agent, 0.1-0.15% of pigment filler, 0.2-0.6% of dispersing agent and the balance of water. Compared with the prior art, the water-borne inflation type refractory coating has the advantages of excellent environmental performance, simple technology, sufficient raw material resources, proper price and the like and can be widely applied.

Owner:湖南新纪元建设发展有限公司

Colored sand and preparation method thereof

The invention discloses colored sand which comprises quartz sand, calcite, glass granules, a coloring agent, acrylic resin, a curing agent and a polishing agent. The invention also discloses a preparation method of the colored sand, which comprises the following steps of: firstly preliminarily pulverizing the quartz sand, the calcite and glass, putting the pulverized sand materials in a vibrating screen for fine separation, mixing and pouring the finely-separated sand materials and steel balls together into a ball milling machine to ball milling, cleaning the ball-milled sand materials, and drying the sand materials for standby use; putting the standby sand materials into a stirring machine to stir, adding the coloring agent, the acrylic resin, the curing agent and the polishing agent, and fully stirring the mixture to be uniform; and drying the mixture. The invention aims at providing the colored sand and the preparation method thereof. Cheap raw materials coming from a variety of sources are utilized freely according to needs, and the colorful and practical colored sand is obtained through the simple environment-friendly preparation method.

Owner:王明军

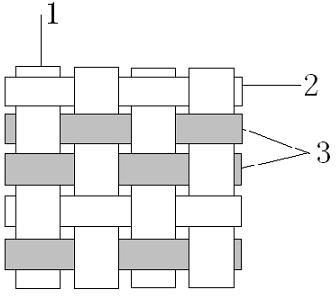

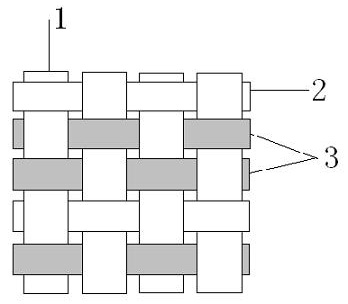

Decorative shade cloth fabric and manufacturing method thereof

The invention relates to textile, in particular to decorative shade cloth fabric, which can be widely used in household living rooms, bedrooms, high-grade hotels, restaurants and offices. The invention also relates to a manufacturing method of the decorative shade cloth fabric. The decorative shade cloth fabric comprises a surface layer, a lining layer and an intermediate layer connected between the surface layer and the lining layer, wherein the surface layer and the lining layer are interwoven as a whole through wefts and warps. The decorative shade cloth fabric is formed through batch warping, yarn pulping, shaft merging, leasing, healding, reeding, weaving, pretreatment for dyeing and finishing, dyeing, printing, embossing and treatment after dyeing and finishing. The decorative shade cloth fabric of the invention is applicable to the decorative shade cloth of curtains, feels soft and has good drape. The curtains made with the decorative shade cloth fabric have the functions of coldness insulation in winter and heat insulation in summer, and also have good privacy and soundproofing effect.

Owner:杭州宏峰纺织集团有限公司

Novel whitening skin-protecting fabric

The invention discloses a knitted fabric, namely a novel whitening skin-protecting fabric, which is formed by interweaving warps and wefts. The wefts include first wefts and second wefts, the warps are made of pearl fibers, the first wefts are made of milk protein fibers, and the second wefts are made of aloe fibers. The novel whitening skin-protecting fabric has the effects of beautifying, whitening and skin protection, and has the advantages of ultraviolet prevention, breathability, antistatic performance, greenness, safety, soft hand feel and the like.

Owner:CHANGSHU FUJIALI WEAVING

Multifunctional nano fabrics

InactiveCN1940172AAchieve water and oil repellencyLong-term water and oil repellencyFibre treatmentTemperature controlAnti virus

A multifunctional nano-fabric,composing fabric and fabric coating on the nano-coating, was introduced. Fabric described was in the form of sheet, Nano coating solution described was one of or more than two (including two species) combination nano-antibacterial agents such as anti - ultraviolet nanotechnology, and nano-scale anti-infrared agent, Nano-dredging, and nano-scale agents and nano-temperature electromagnetic shielding agent. The use of nanotechnology inventions, fabric padding, heat treatment, with anti-virus, bacteria, electromagnetic shielding, ultraviolet, kill the hepatitis C virus functions. As for further processing fabrics will have temperature control, and prevention of influenza, or even long-term water and oil repellent, refuse to fly mosquito refused function.

Owner:曾庆琳

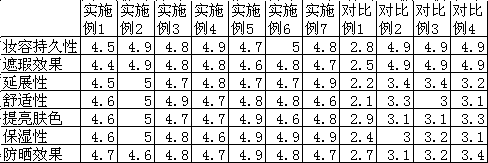

Air cushion BB cream for look beautifying and skin caring

InactiveCN108186405AImprove stabilityGood nutrition and moisturizing effectCosmetic preparationsBody powdersCross-linkSkin color

The invention discloses an air cushion BB cream for look beautifying and skin caring. The BB cream comprises diphenylsiloxyphenyl polytrimethylsiloxane, butanediol dioctanoic acid / dicaprate, polydimethylene siloxane, cyclopentasiloxane, cetyl PEG / PPG-10 / 1 polydimethylsiloxane, sorbitan stearin, acrylic acid / stearyl alcohol acrylic acid ester / polydimethylsiloxane methacrylate copolymer, polydimethylsiloxane crosspolymer, trimethylsiloxyphenyl dimethicone, HDI / trimethylol hexyl lactone cross-linked polymer, disteardimonium hectorite, titanium dioxide, tin oxide, synthetic fluorophlogopite, ironoxide, mica, polyhydric alcohols, magnesium sulfate, silica and water balance. According to the BB cream, emulsifier, emollient, stabilizer and film-forming agent are selected, the stability, efficacyand feeling of use of products are fully considered, the best formula component thereof is obtained, and the BB cream has the effects of correcting skin color, isolating ultraviolet rays and nourishing and moisturizing the skin.

Owner:FOSHAN WENSENTE INTPROP SERVICE CO LTD

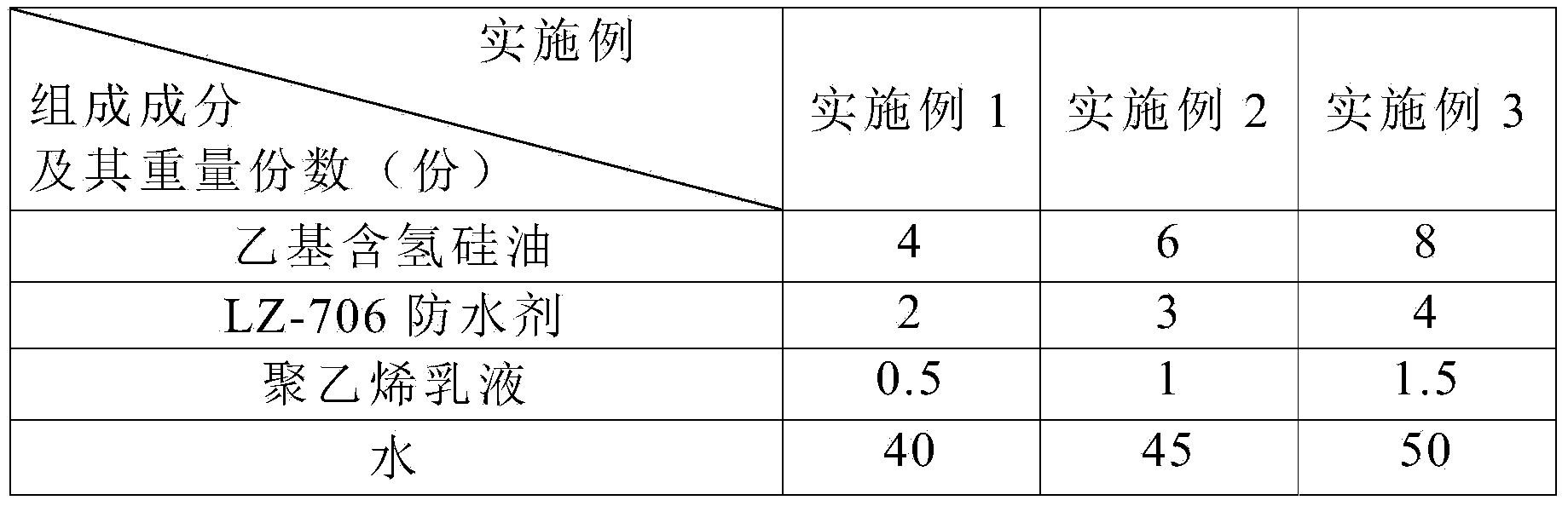

Nano inorganic powder modified organic silicon waterproof paint

The invention discloses nano inorganic powder modified organic silicon waterproof paint and belongs to the technical field of building waterproofing. The nano inorganic powder modified organic silicon waterproof paint disclosed by the invention is prepared from the following raw materials in parts by weight: 200 to 300 parts of an oligomer siloxane base material, 10 to 30 parts of an emulsifier, 20 to 60 parts of a stabilizer, 4 to 6 parts of a curing agent, 180 to 200 parts of a diluting agent, 3 to 6 parts of a thickener and 100 to 150 parts of nano inorganic powder; the nano inorganic powder is prepared from the following raw materials in parts by weight through mixing: 60 to 80 parts of nano silicon dioxide, 20 to 30 parts of nano aluminum oxide, 8 to 10 parts of nano zirconium oxide and 10 to 15 parts of nano hydroxyapatite. The nano inorganic powder modified organic silicon waterproof paint disclosed by the invention has the beneficial effects that the nano inorganic powder modified organic silicon waterproof paint has a relatively excellent weather-resisting performance and a long service life; a hydrophobic bionic structure formed by added inorganic nanoparticles does not hinder the permeation of water vapor in a substrate.

Owner:宁夏双玉防水防腐材料集团有限公司

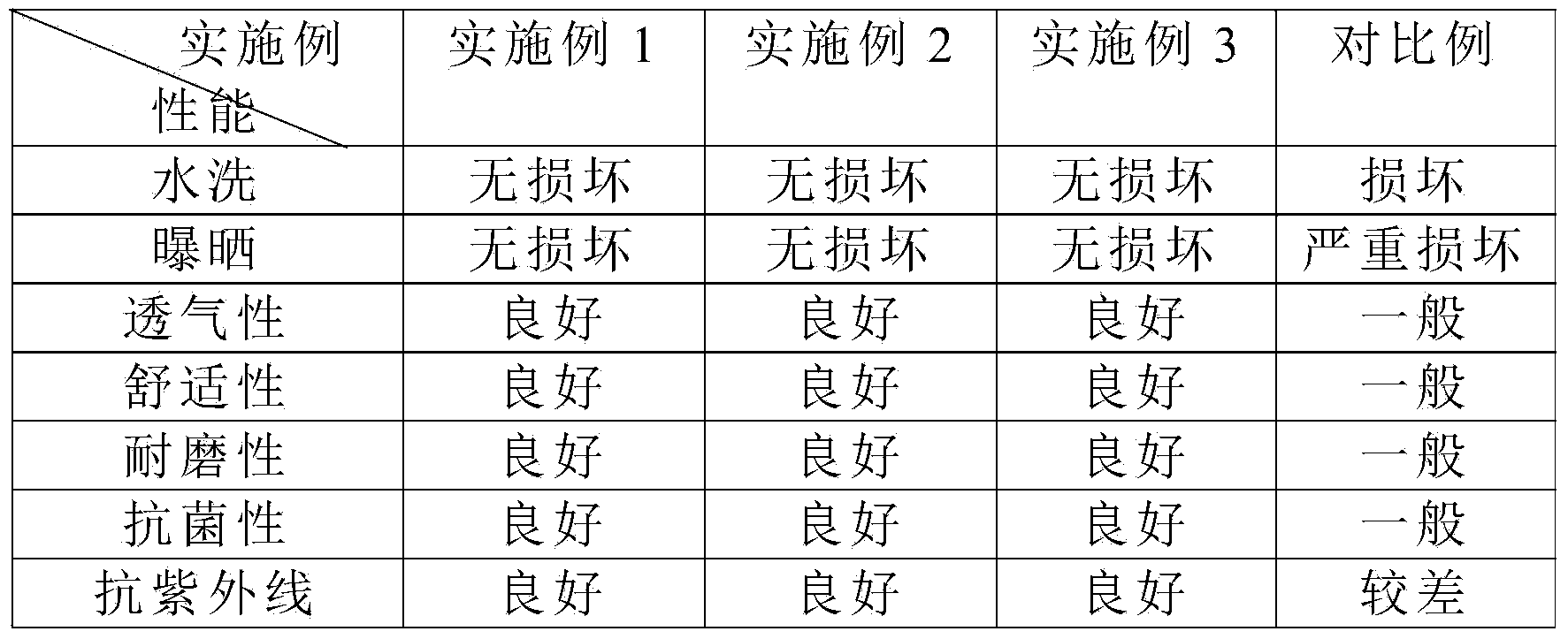

Processing technique for China-Hemp and paper straw mixed mat

ActiveCN104207561AGood hygroscopicityImprove antibacterial propertiesBed-coversWear resistantPulp and paper industry

The invention relates to a processing technique for mats and particularly relates to a processing technique for a China-Hemp and paper straw mixed mat. The processing technique comprises the following steps: cutting waterproof paper into sheets according to specifications of the mat, then wrapping straws with sheety waterproof paper so as to form ropy paper and then reeling to form wefts, and taking China-Hemp as warps for knitting, so as to obtain a mat main body; spraying water by using an atomizer of a pressing machine, heating, pressing polish and carrying out shrinking treatment on the mat main body, so as to obtain a semi-finished mat; soaking the semi-finished mat into a waterproof agent solution with a pH value of 4.5 to 6.5, and then placing the semi-finished mat into a drying oven for drying; arranging well cut lining cloth on peripheries of the dried semi-finished mat, wrapping the semi-finished mat by using the lining cloth, enabling the lining cloth to be symmetric on upper and lower surfaces of the mat, compacting, then carrying out edge covering treatment on the mat, and finally obtaining a finished mat. The mat prepared by using the processing technique provided by the invention are not only nice and cool, air-permeable, wear-resistant, sun-proof and has soft feel, but also has the advantages of bacteriostasis, uvio-resistance and the like, and is long in service life.

Owner:宁波黄古林工艺品有限公司

Nano TiO2 modified polyacrylate coating agent

InactiveCN104610832AHigh strengthLarge specific surface areaCoatingsLeather surface finishingCross-linkColor changes

The invention relates to a nano TiO2 modified polyacrylate coating agent which is prepared by performing emulsification polymerization components such as deionized water, an emulsifier, alkyl acrylate, methacrylate and alkyl methacrylate ester, an aryl unsaturated monomer, a cross-linking monomer, a coupling agent, nano titanium dioxide and the like under the action of an initiator. Due to modification of the nano titanium dioxide, the mechanical property of a coated film of the polyacrylate coating agent is improved, the color change and the aging phenomenon of the coated film are alleviated, and a self-cleaning function is achieved.

Owner:NANYANG NORMAL UNIV

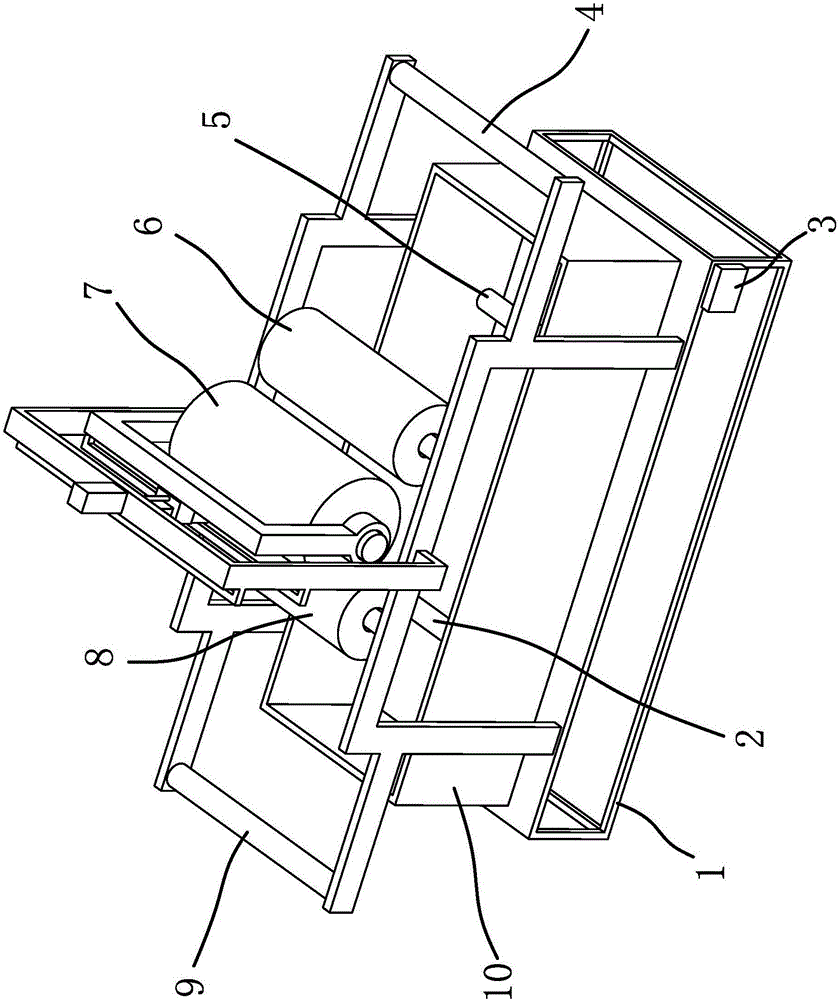

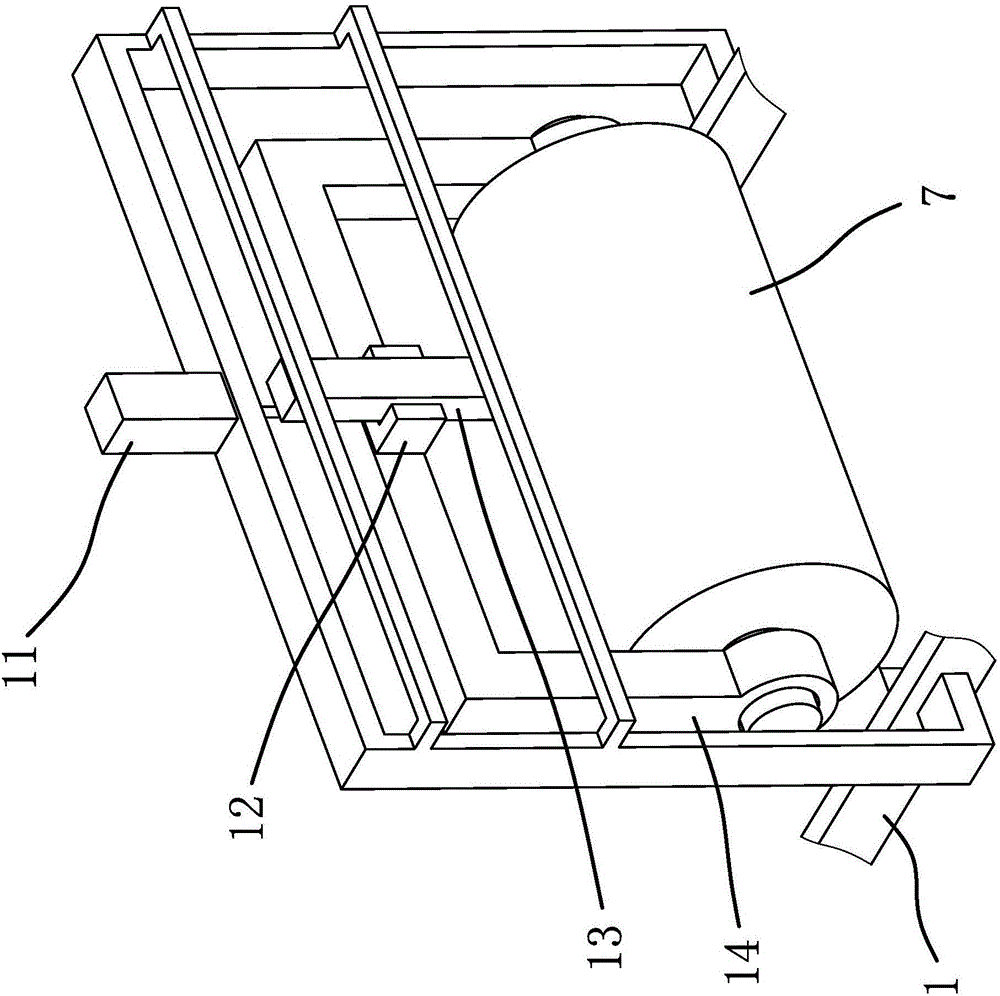

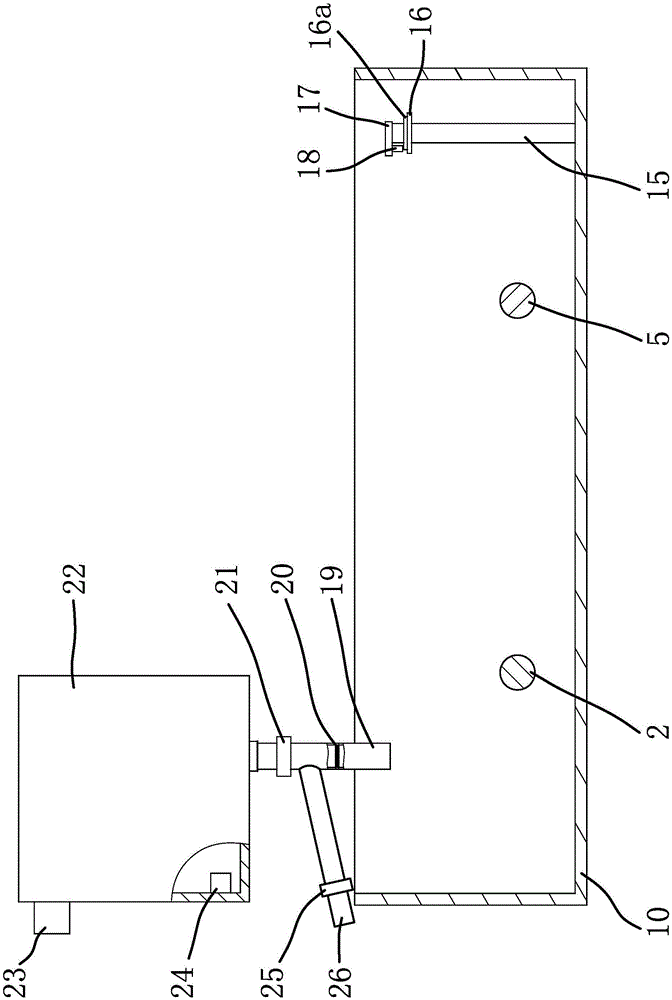

Padding machine

ActiveCN106283707AFlame retardantUV protectionFibre treatmentHeating/cooling textile fabricsUltraviolet lightsEngineering

The invention provides a padding machine which solves the technical problems that existing blended fabric has no flame retarding or ultraviolet light isolating function, cannot be used in complex environments and is poor in functionality and the like. The padding machine comprises a rack, a first roller, a second roller, a third roller and a padding liquid box. The first roller, the second roller and the third roller are arranged on the rack in parallel in an axial fixation and circumferential rotation mode, the first roller and the second roller are located at the same height, the third roller is located above the first roller and the second roller and is arranged on the rack through a first moving mechanism capable of driving the third roller to move vertically, the padding liquid box is fixed to the rack, an opening is formed in the upper end of the padding liquid box, the padding liquid box is located below the first roller, a first rotating shaft and a second rotating shaft are arranged in the padding liquid box, the first rotating shaft is located below the first roller, the second rotating shaft is located below the second roller, and a liquid supplementing mechanism capable of automatically supplementing liquid to the padding liquid box is further arranged on the rack. The padding machine has the advantage of being high in production efficiency.

Owner:ZHEJIANG HUAYUAN TEXTILE

Sunscreen cream with double-isolation and post-basking repairing functions

ActiveCN106176259AStop tanningProtection from sunburnCosmetic preparationsToilet preparationsSunscreen agentsUltraviolet b

The invention provides sunscreen cream with double-isolation and post-basking repairing functions. The sunscreen cream comprises the following effective components in parts by weight, 45-55 parts of water, 10-14 parts of physical sunscreen agents, 8.1-11.9 parts of emollient, 3-5 parts of emulsifiers, 11.7-15.6 parts of chemical sunscreen agents, 1.5-6.1 parts of skin conditioners, 0.4-0.6 part of preservatives, 0.4-0.6 part of thickening agents, 2-3 parts of PH (potential of hydrogen) conditioning agents, 0-0.2 part of flavoring agents and 0.2-0.3 part of complexing agents. According to the sunscreen cream, the physical sunscreen agents and the chemical sunscreen agents are scientifically matched, UVA (ultraviolet A) and UVB (ultraviolet B) are effectively stopped, the sunscreen cream can prevent skins from being tanned and effectively protect the skins from sunburn, the skin conditioners are added into the sunscreen cream, and the post-basking repairing function is achieved.

Owner:TIANJIN DARENTANG JINGWANHONG PHARMA

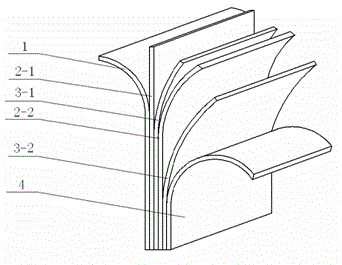

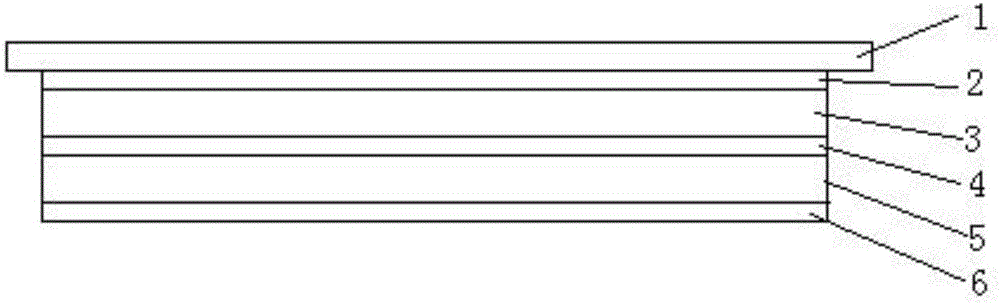

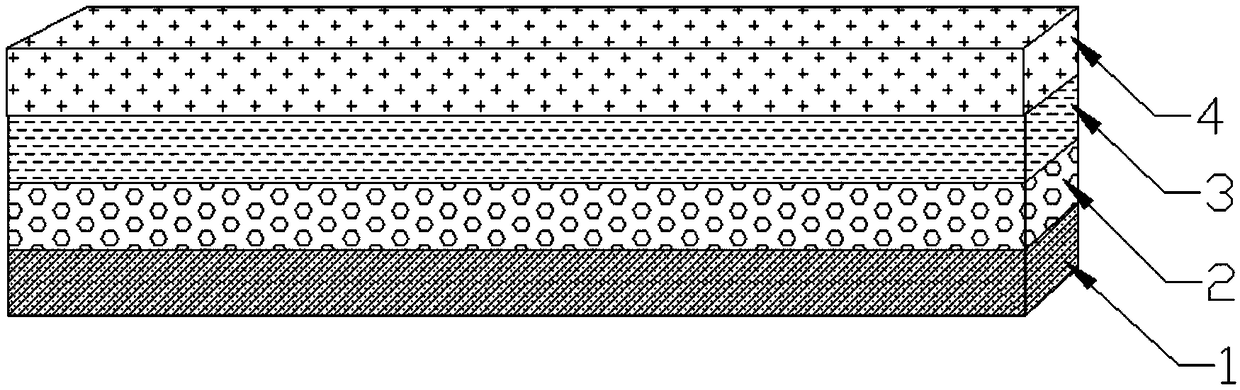

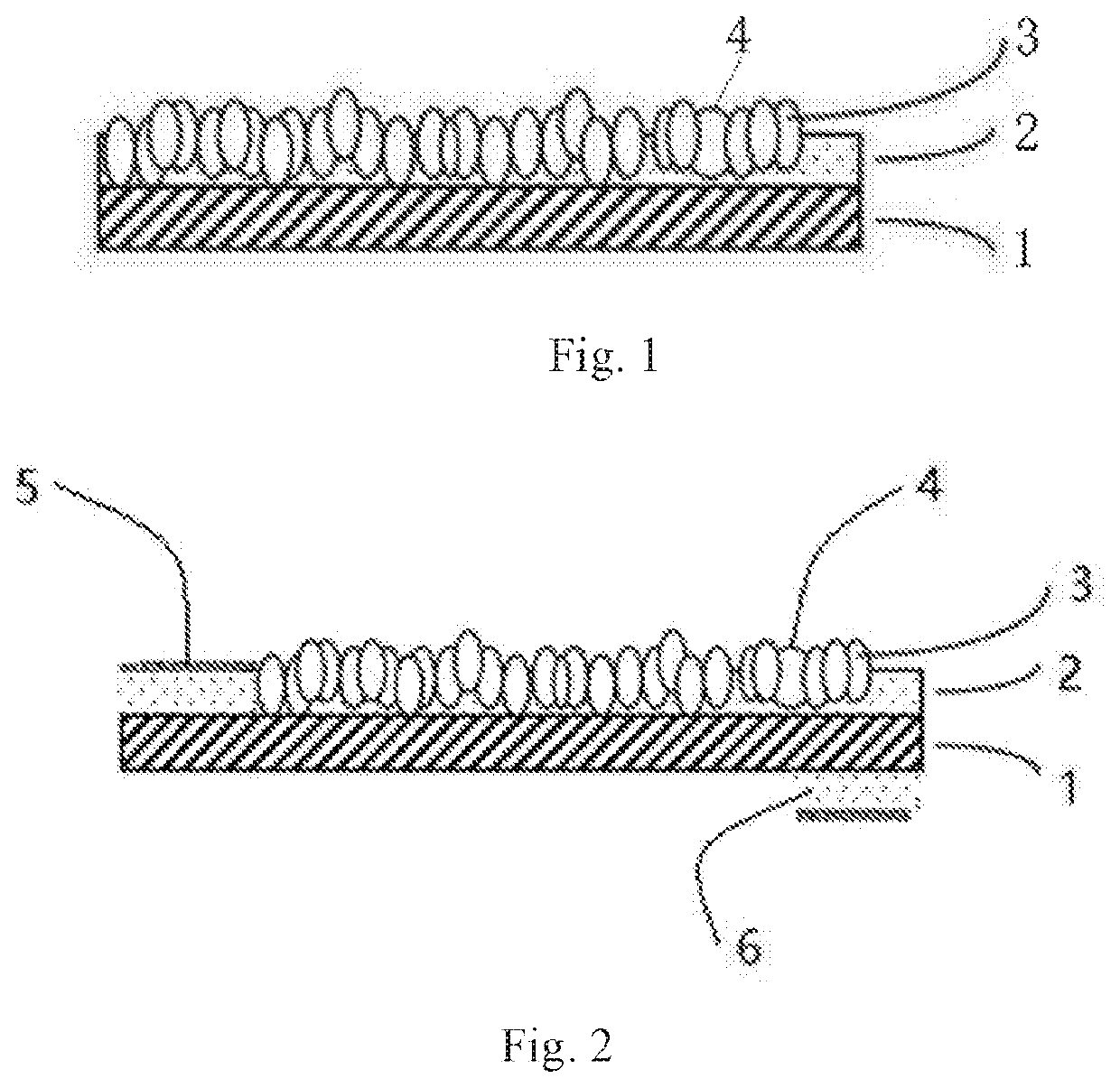

Ultraviolet-blocking window film

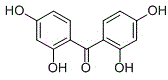

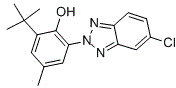

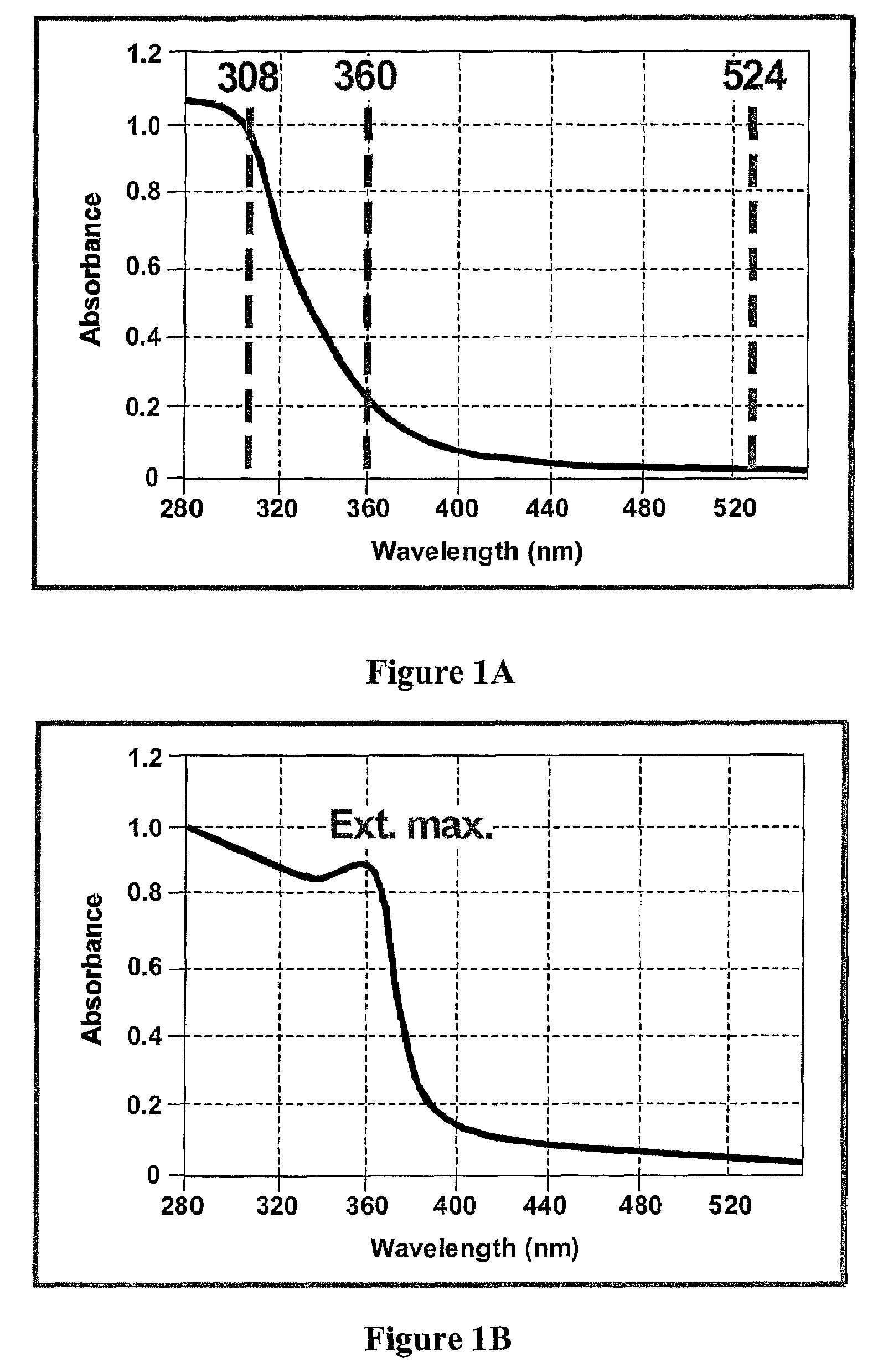

ActiveCN104149433AExtend the life cycleLong-lasting UV blocking propertiesSynthetic resin layered productsFlat articlesSolventPressure sensitive

The invention relates to an ultraviolet-blocking window film. The ultraviolet-blocking window film consists of a scratch-resistant layer (1), a first polyester film or polyethylene film base material (2-1), a first ultraviolet-blocking pressure-sensitive adhesive layer (3-1), a second polyester film or polyethylene film base material (2-2), a second ultraviolet-blocking pressure-sensitive adhesive layer (3-2) and a release film (4) which are compounded into a whole, wherein the scratch-resistant layer (1) is obtained through ultraviolet curing after coating of a mixed material consisting of a scratch-resistant agent, ethyl acetate and methylbenzene; both the first ultraviolet-blocking pressure-sensitive adhesive layer (3-1) and the second ultraviolet-blocking pressure-sensitive adhesive layer (3-2) are obtained through thermosetting operation after coating of a mixed material consisting of a benzophenone ultraviolet absorbent, a benzotriazole ultraviolet absorbent, acrylic adhesive, a curing agent and a solvent. The ultraviolet-blocking window film can block ultraviolet lastingly.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

Zinc oxide powder blends, their production and use

This disclosure provides sunscreen products that contain metal oxide powders having discrete size distributions. Metal oxide powders include, for example, zinc oxide and titanium dioxide. Sunscreen products made in accordance with the principles of this disclosure contain metal oxide powders having primary particle sizes of about 10-30 ran and about 50-200 nm.

Owner:KOBO PRODUCTS INC

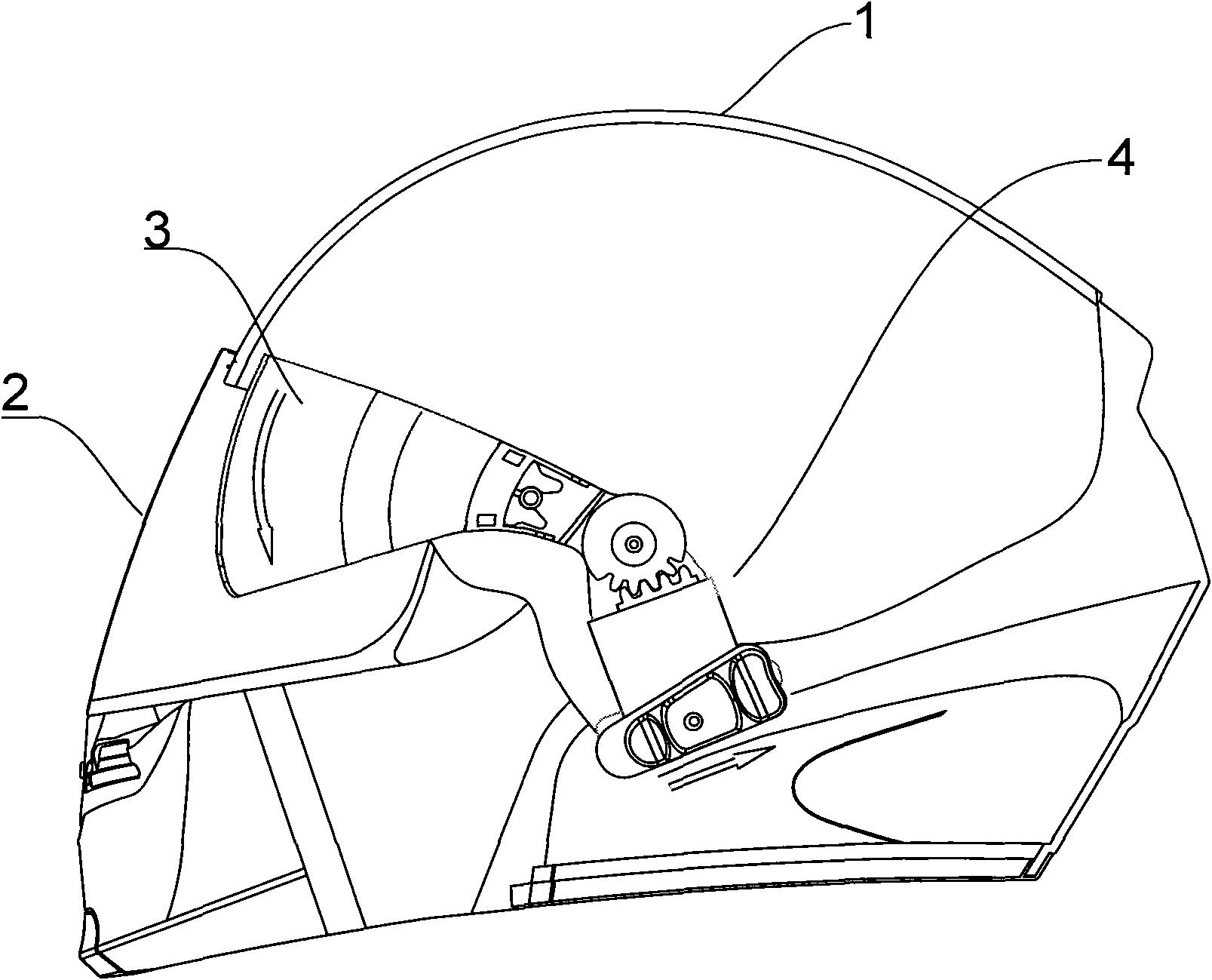

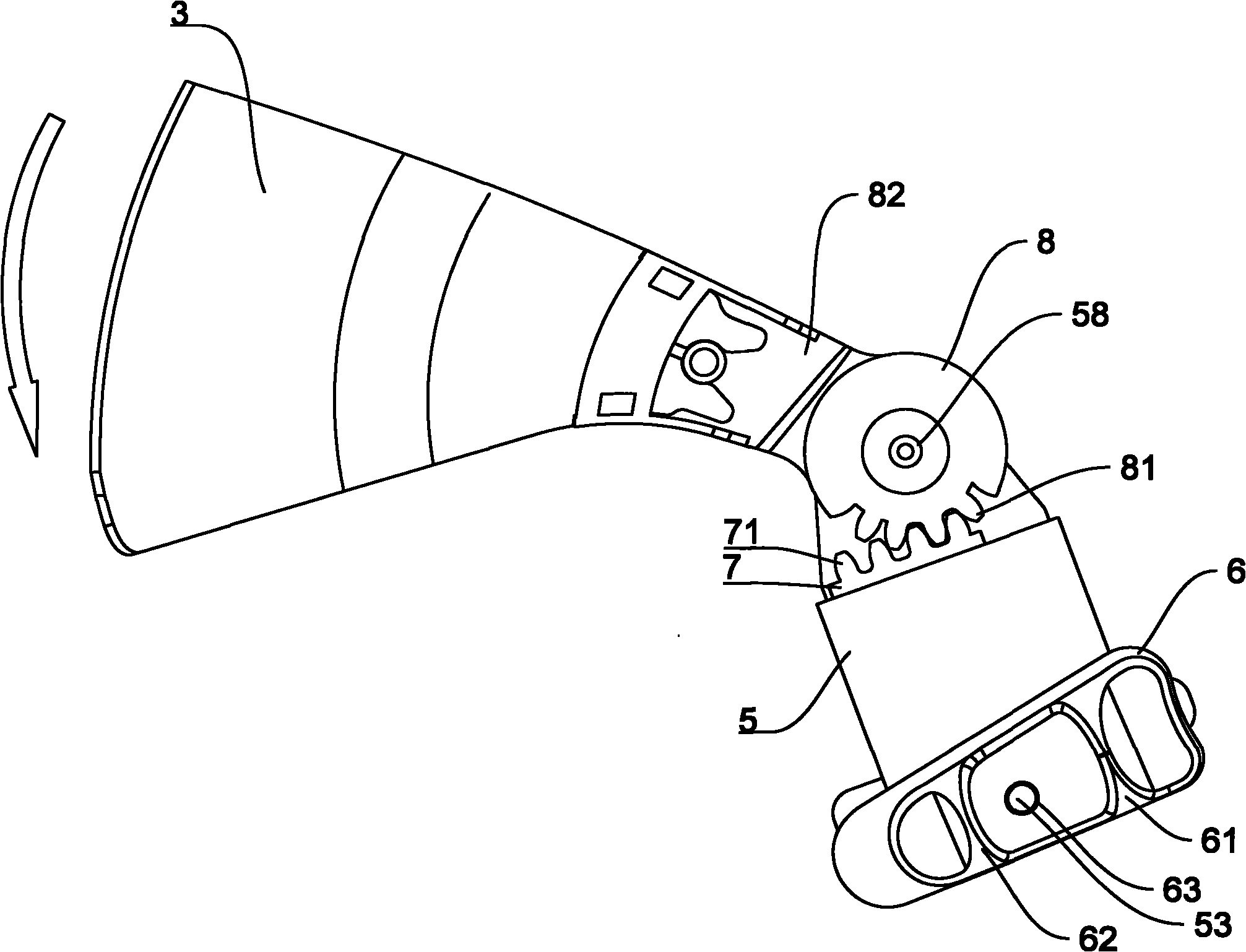

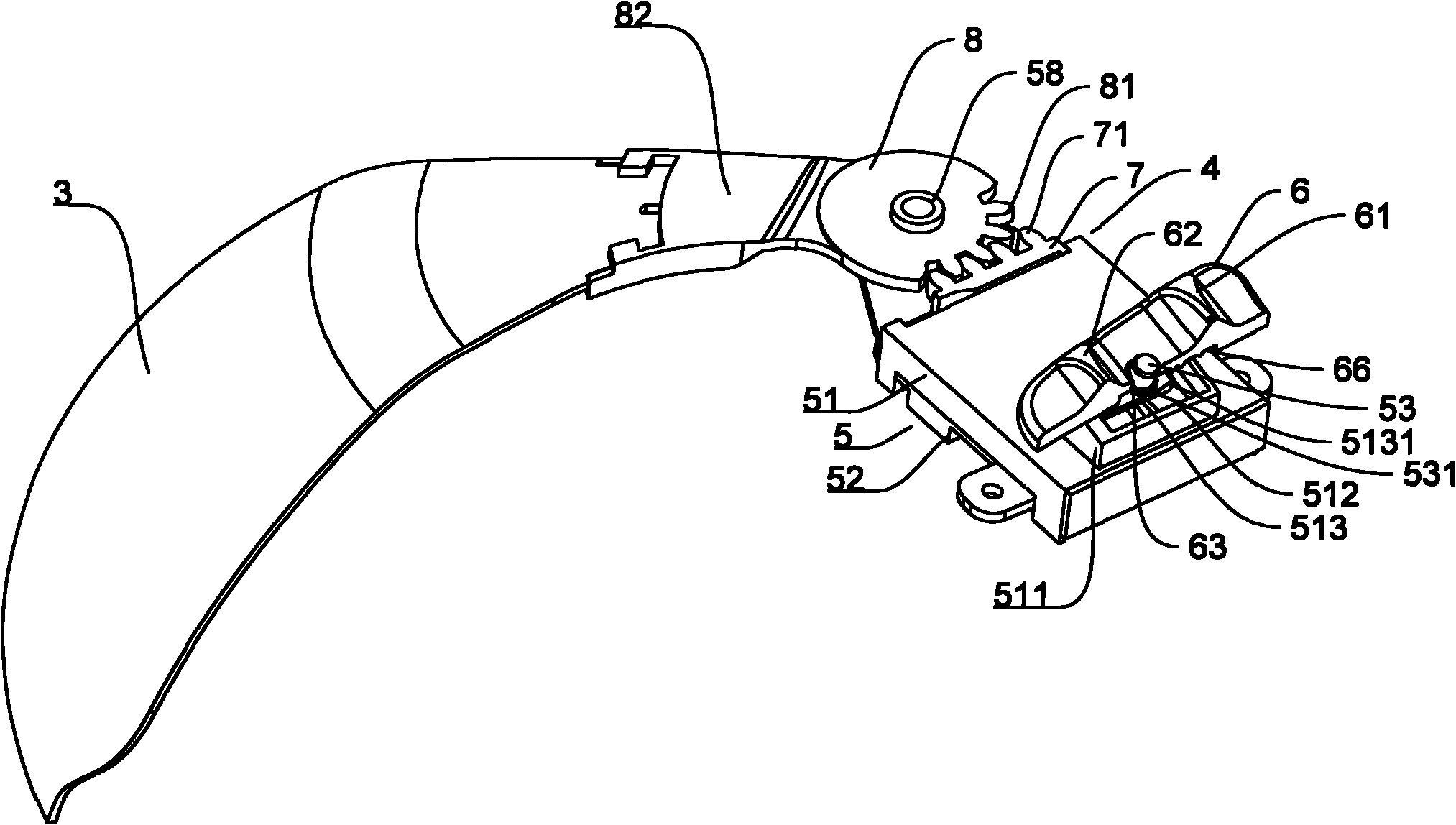

Helmet lens position adjustment device and helmet

ActiveCN101940378AEasy to useAvoid direct sunlight in the eyesMountingsHelmetsSight lineCovering eye

Owner:上海和汇安全用品有限公司

Anti-ultraviolet composite fireproof glass

The invention discloses a fireproof composite structure glass that can effectively block ultraviolet rays. The glass includes two glass substrates, between which a fireproof layer is stuffed. The fireproof layer comprises, by weight: 50% of methyl methacrylate, 15% of dibutyl ester, 20% of sodium sulfite, 1.3% of zinc oxide (ZNO), 3% of magnesium hydroxide, 0.2% of benzyl butyl phthalate, 10% of acrylamide, 0.1% of ethanol, and 0.4% of 2-hydroxy-4-methoxybenzophenone. By adopting the fireproof layer with the formula, ultraviolet rays can be effectively blocked, good fire resistance can be achieved, and the fireproof layer is unlikely to undergo foaming under a long-term use state, therefore, the light transmission performance is good.

Owner:杭州福隆鼎门窗幕墙有限公司

High-class LCD welding goggles

InactiveCN106361495AVisible light transmission rate is improvedProtect eye healthEye-masksNon-linear opticsWelding gogglesPrimary standard

The invention relates to a pair of high-class LCD welding goggles. The pair of high-class LCD welding goggles sequentially comprises a thickened light filter, a first C compensating polaroid, a first LCD liquid crystal box, a second C compensating polaroid, a second LCD liquid crystal box and an R compensating polaroid from top to bottom. The uniformity, light dispersivity, response speed and viewing angle dependence meet the primary standard of European union (CE) certification. When the pair of high-class LCD welding goggles is used, strong arc light can be blocked in time during welding, the state of clear viewing field can be also rapidly recovered after welding is stopped, and smooth performing of welding work is effectively guaranteed.

Owner:亚世光电(鞍山)有限公司

Total-synthesis solid wax capable of forming platinum coating film and preparation method of total-synthetic solid wax

The invention relates to solid wax and a preparation method, in particular to total-synthesis solid wax capable of forming a platinum coating film and a preparation method of the total-synthesis solid wax. The total-synthesis solid wax has lasting protection performance, can form a thin and stable platinum coating film layer on car paint, so that car wax of the car paint is protected enduringly. Besides, the total-synthesis solid wax has the functions of prevention of paint ageing, water repellent, self-cleaning, ultraviolet resistance, bacterial resistance, mold proofing, static prevention and the like and can comprehensively protect the car paint; steps of the preparation method are simple and easy to operate, and the production cost is low.

Owner:GUANGZHOU HELIOSON CAR CARE

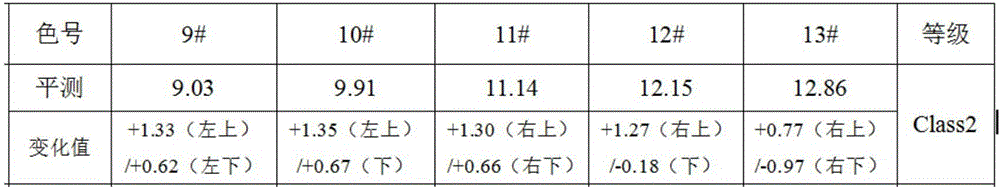

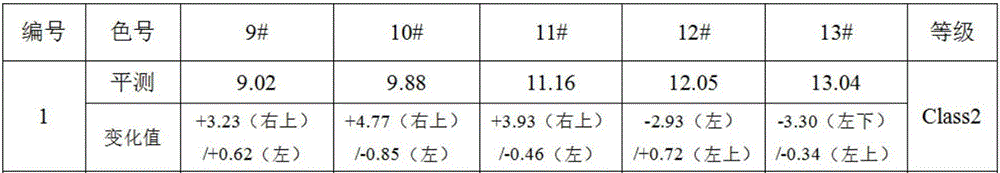

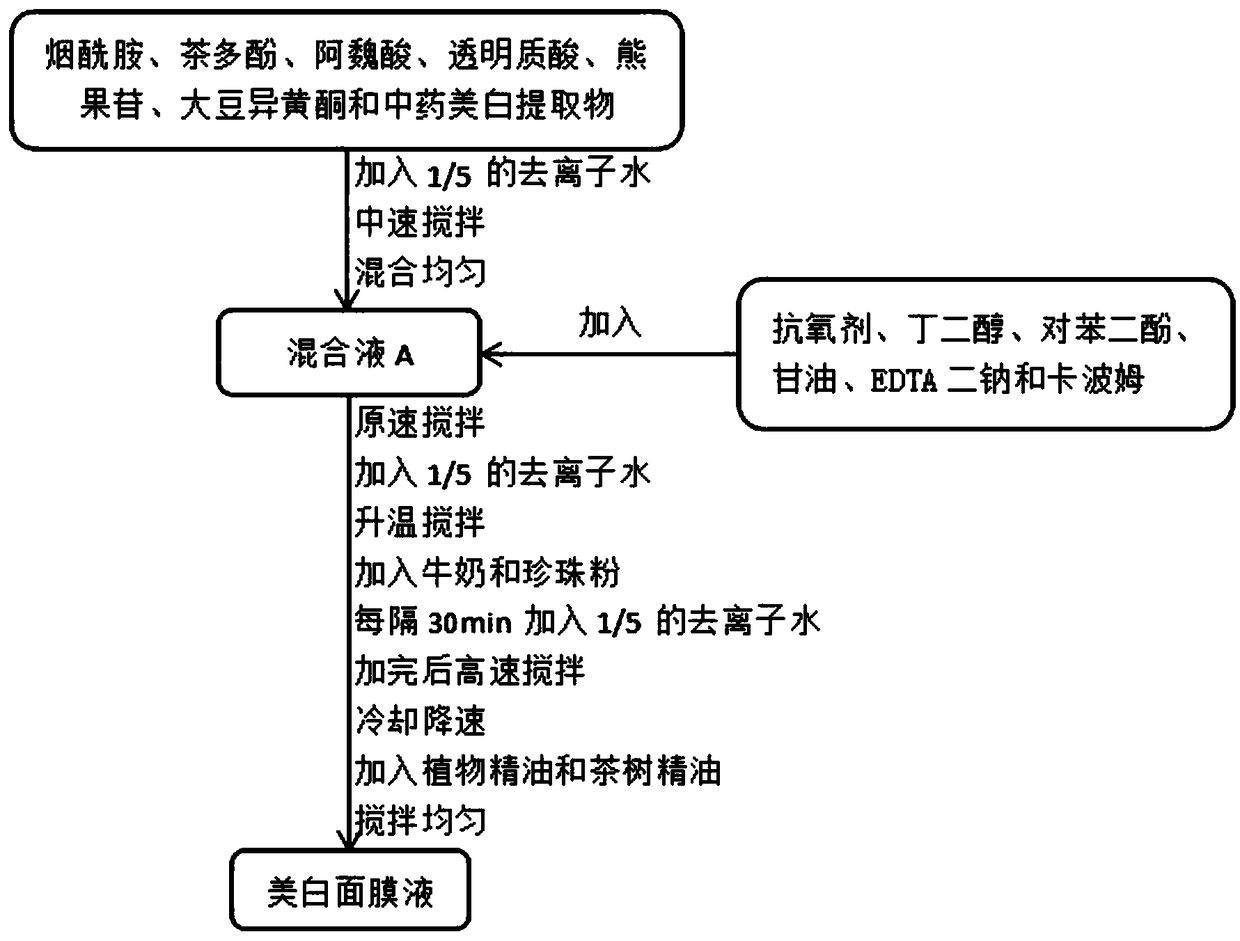

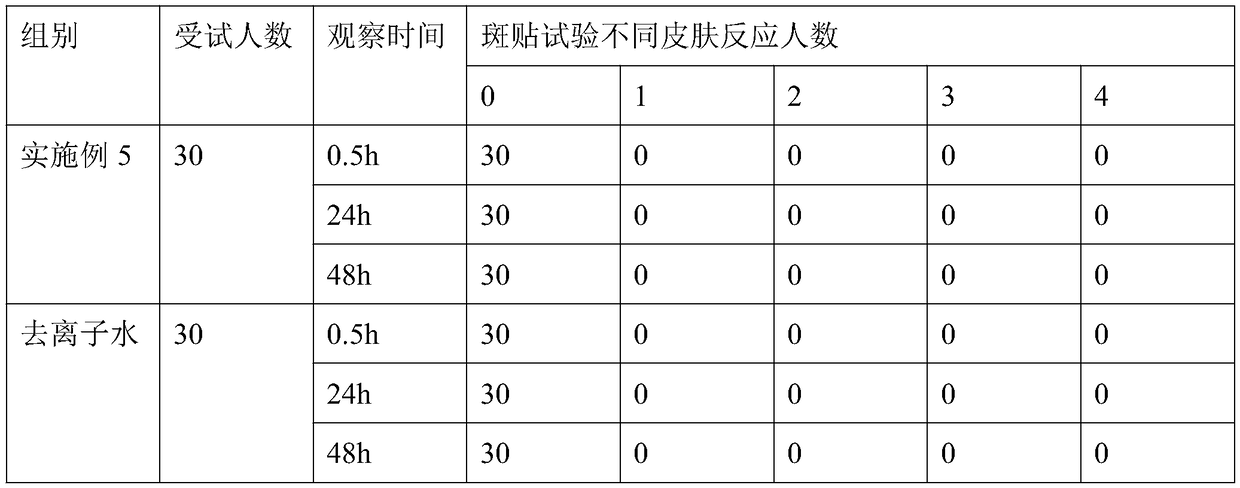

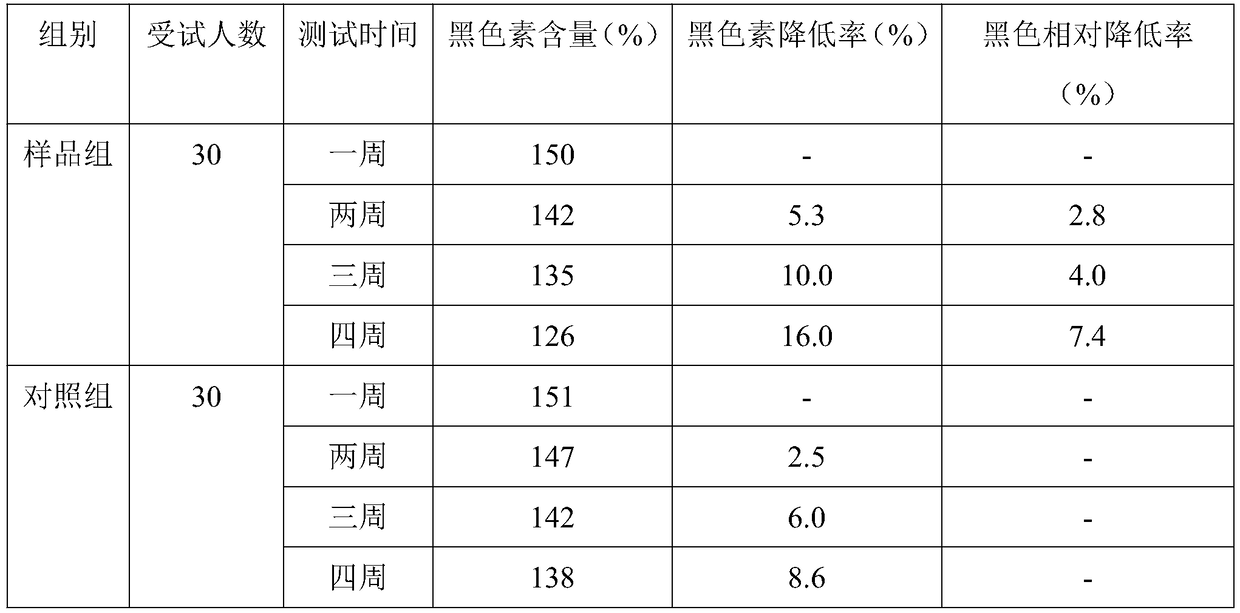

Whitening mask liquid and preparation method thereof

InactiveCN109330966ASuppress generationGenerate slow or reduceCosmetic preparationsToilet preparationsAdditive ingredientTyrosinase

The invention provides whitening mask liquid. The whitening mask liquid is prepared fromy the following raw materials: 10-20 parts of nicotinamide, 5-10 parts of tea polyphenol, 30-40 parts of ferulicacid, 20-40 parts of hyaluronic acid, 5 to 10 parts of arbutin, 5 to 15 parts of soy isoflavones, 20 to 30 parts of milk, 10 to 20 parts of pearl powder, 5 to 10 parts of butanediol, 5 to 10 parts ofhydroquinone, 1 to 10 parts of glycerin, 5 to 15 parts of tea tree oil, 30 to 50 parts of a whitening extract of traditional Chinese medicine, 1 to 3 parts of EDTA disodium, 1 to 3 parts of carbomer,1 to 5 parts of an antioxidant, 5 to 10 parts of plant essential oil and 80 to 120 parts of deionized water. according to the whitening mask liquid, various whitening ingredients are utilized to start from the source so as to inhibit tyrosinase production, slow down or reduce the formation of melanin, match natural whitening ingredients, resist free radicals, decrease the generation of melanin, and isolate ultraviolet rays at the same time; and for formed melanocytes, the renewing speed of skin cells is improved to promote the falling of cells with melanin.

Owner:宁波蒙曼生物科技有限公司

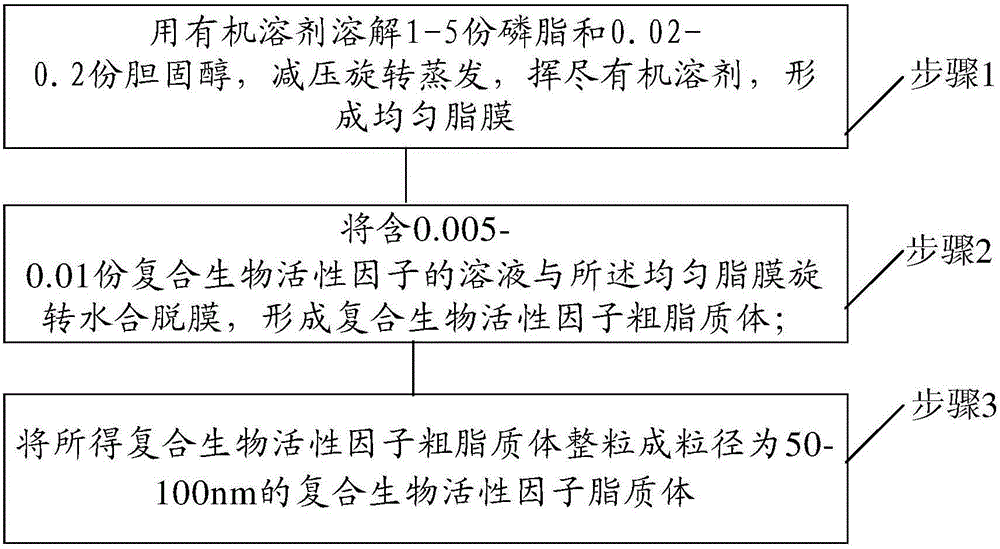

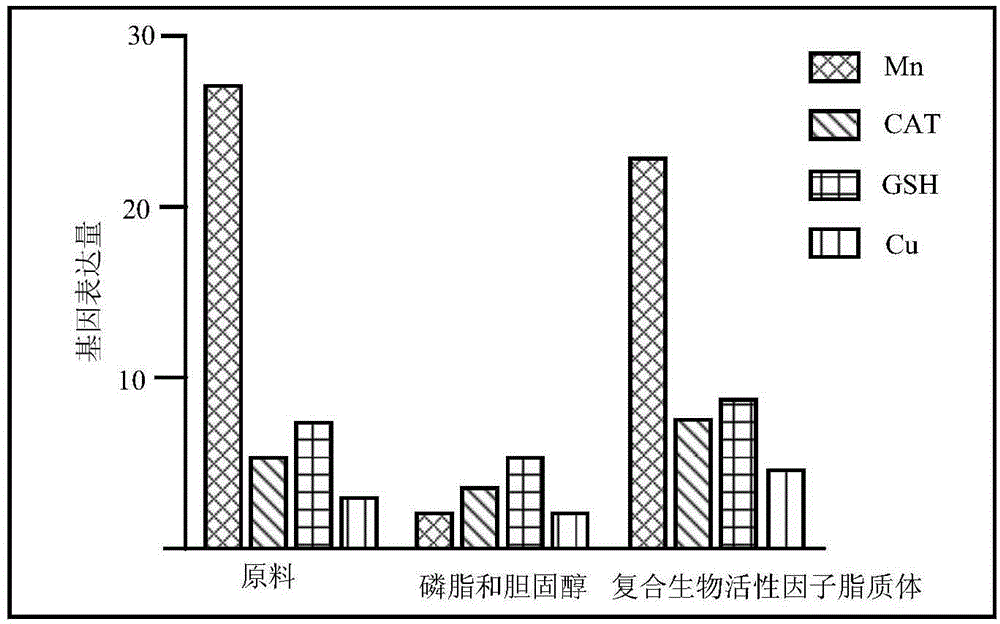

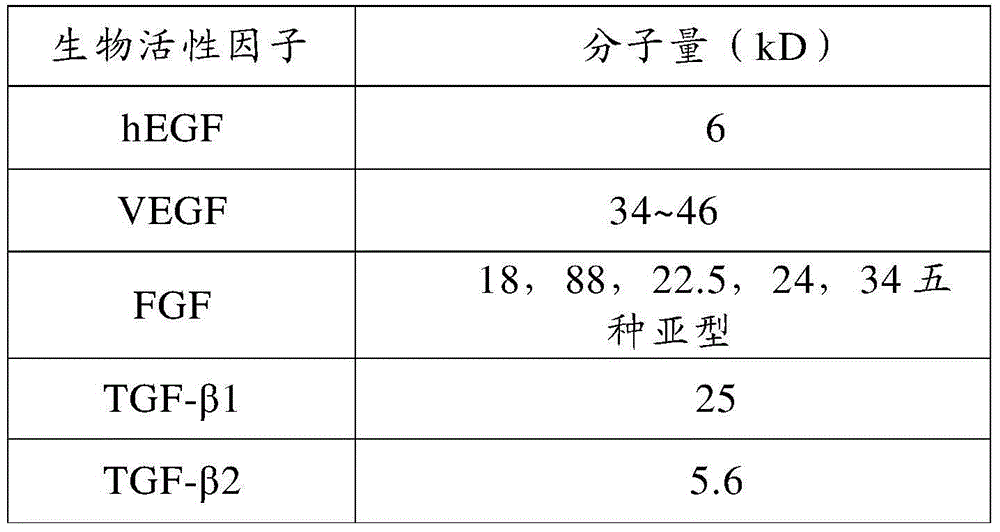

Composite bioactive factor liposome and preparation method thereof

ActiveCN105543161AUV protectionImprove nutrient metabolismAnimal cellsCosmetic preparationsMedicinePhospholipid

The invention relates to the field of biology, and especially relates to a composite bioactive factor liposome and a preparation method thereof. The preparation method can improve the bioactivity and the stability of the composite bioactive factor liposome, and the composite bioactive factor liposome can be refrigerated for a long time. The composite bioactive factor liposome provided in the embodiment of the invention comprises 1-5 parts of phospholipid, 0.02-0.2 parts of cholesterol, 0.005-0.01 parts of a composite bioactive factor, and the balance of purified water, wherein the phospholipid and the cholesterol form a liposome, and parts of the composite bioactive factor is encapsulated in the liposome to form the composite bioactive factor liposome.

Owner:陕西瑞妍化妆品有限公司

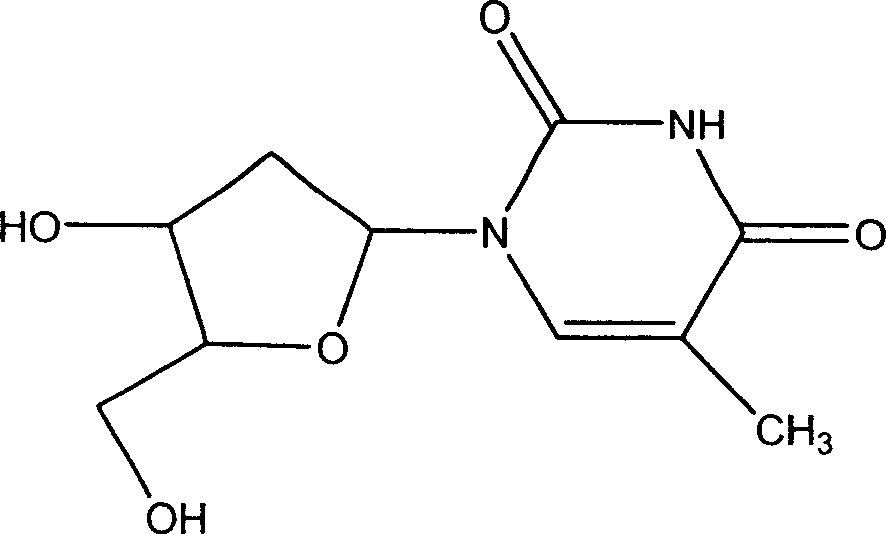

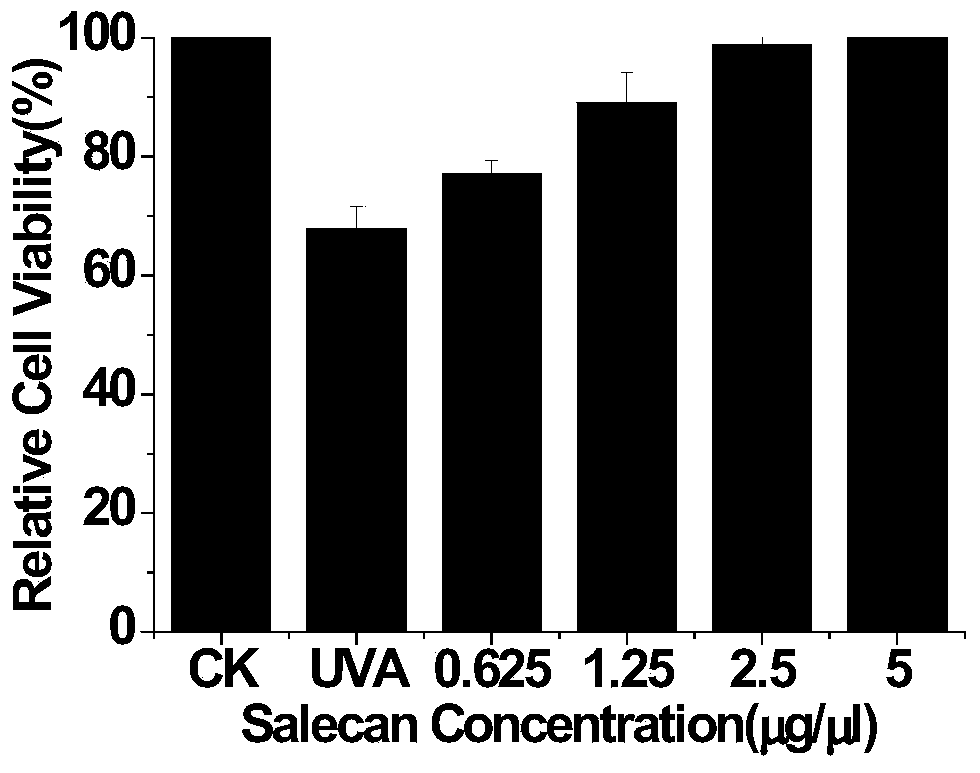

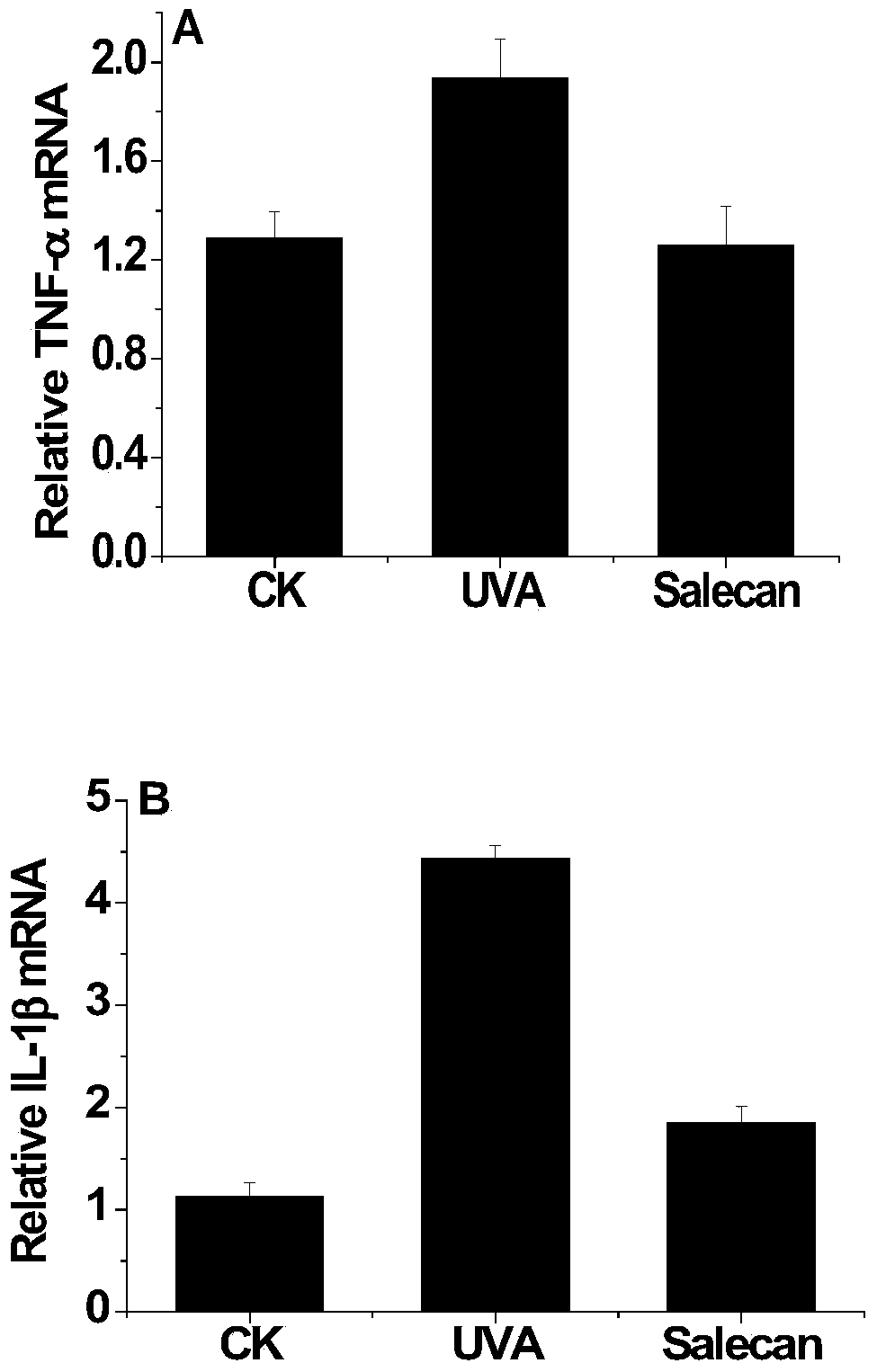

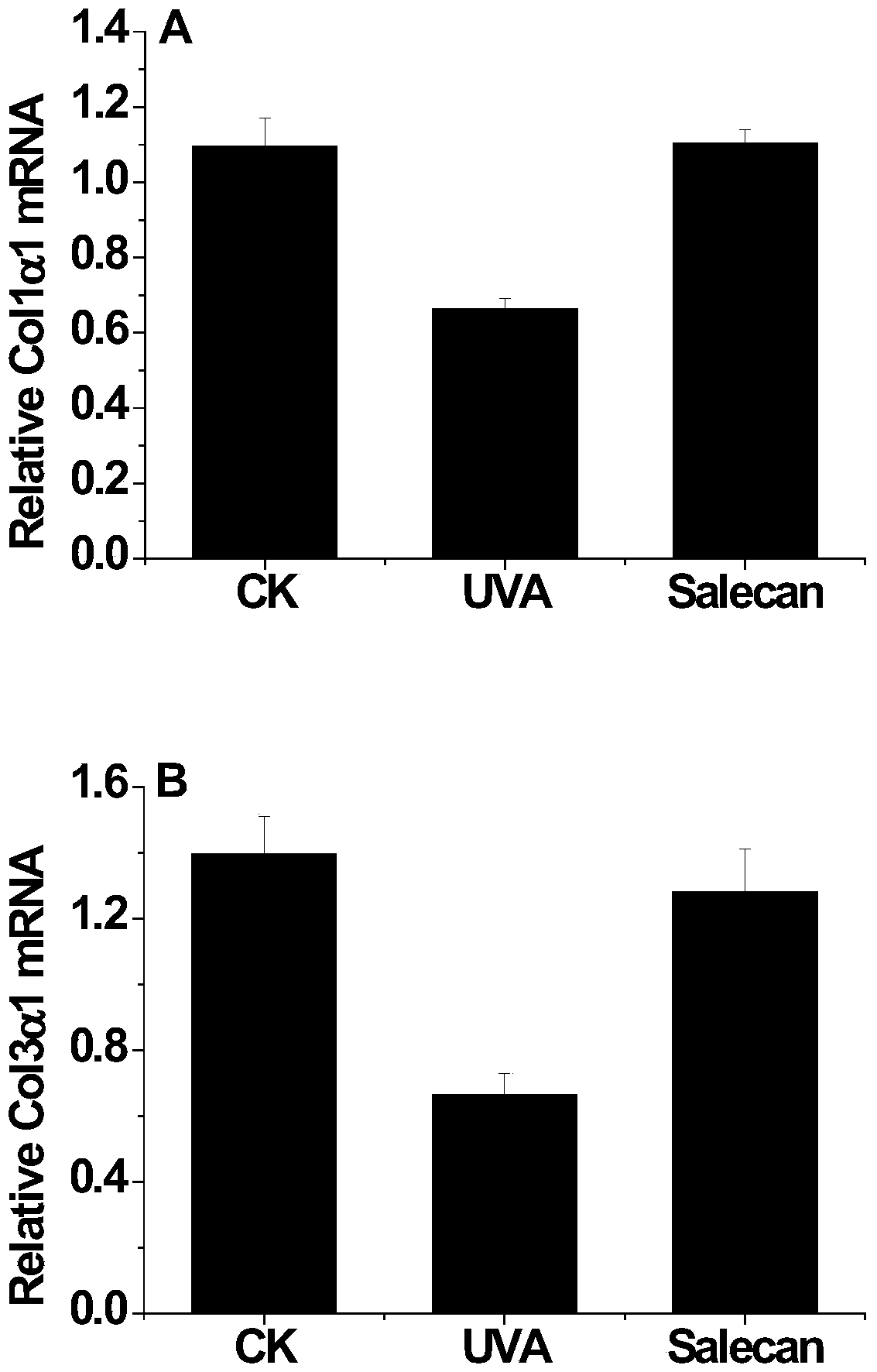

Application of soracan gum in inhibiting skin injury of ultraviolet ray

InactiveCN103735566ASimple extraction methodGood UV resistanceOrganic active ingredientsCosmetic preparationsUltravioletUltraviolet A Radiation

The invention discloses application of soracan gum in inhibiting skin injury of ultraviolet ray, and relates to application of soracan gum with different mass concentrations in protecting skin from injury due to ultraviolet ray UVA. A cell model adopted in the invention is an ultraviolet ray UVA induced cell injury model, wherein the dosage of soracan gum is 0.625-5 mu g / mu l; a mouse model adopted in the invention is an ultraviolet ray UVA induced mouse skin injury model, and the dosage of the soracan gum is 200mu l of 1 percent solution, the soracan gum can be used for improving the cell survival rate of cells in ultraviolet radiation, reducing inflammation factors in mouse skin and improving gene expression of synthetic collagen, so that skin injury caused by ultraviolet ray UVA can be inhibited. Cell and animal experiments prove that soracan gum has a remarkable effect of inhibiting skin injury of ultraviolet ray, so that soracan gum can be used in processes of preventing and repairing skin injury due to ultraviolet ray UVA, and can be used for preparing anti-ultraviolet radiation injury medicines and anti-ultraviolet radiation cosmetics.

Owner:NANJING UNIV OF SCI & TECH

Polycarbonate plastic sheet

InactiveCN103554890AHigh impact strengthUV protectionOptical elementsCross-linkPolycarbonate plastic

The invention discloses a polycarbonate plastic sheet. The polycarbonate plastic sheet comprises polycarbonate plastics and additives, wherein the additives comprise a shock resistant modifier, an ultraviolet absorber, a slip agent, an antifogging agent, a nucleating agent and a cross-linking agent, wherein the shock resistant modifier is ethylene-vinyl acetate copolymer, the ultraviolet absorber is benzophenone, the slip agent is organic siloxane emulsion, the antifogging agent is sorbitan monopalmitate, the nucleating agent is butadiene rubber, and the cross-linking agent is poly alkyl acrylate. The polycarbonate plastic sheet has high shock resistance, is not easy to scratch, can well absorb ultraviolet rays of sunlight, and has a long service life. And the lens has a smooth surface and fog is not easy to form on the surface of the lens.

Owner:苏州市双赢包装材料有限公司

Composite transparent conductive film of silver nanowire and transparent conductive oxide, and application of composite transparent conductive film

PendingCN109390080AGood chemical stabilityGood weather resistanceConductive layers on insulating-supportsCable/conductor manufactureConductive coatingTransmittance

The invention discloses a composite transparent conductive film of a silver nanowire and transparent conductive oxide, and an application of the composite transparent conductive film, and belongs to the technical field of optics. The conductive film sequentially comprises a substrate, a silver nanowire transparent conductive coating layer which is attached to the substrate, a protective layer, anda transparent conductive oxide layer. The thickness of the silver nanowire transparent conductive coating layer is 10 to 500 nm, the thickness of the protective layer is 5 to 5000 nm, and the thickness of the transparent conductive oxide layer is 2 to 500 nm. The conductive film can realize the advantages of high light transmittance, low square resistance, high chemical stability, high wear resistance and high matching performances.

Owner:浙江星隆新材料科技有限公司

Sun-blocking composition and daily chemical product with sun-blocking effect

ActiveCN105496872ASmall side effectsGood clinical efficacyCosmetic preparationsAntipyreticSunscreen agentsAdditive ingredient

The invention relates to sun-blocking composition and a daily chemical product with a sun-blocking effect. The sun-blocking composition comprises raw materials in percentage by mass as follows: 0.01%-3% of a purple coneflower extract, 0.01%-3% of an emblic extract, 0.01%-3% of a meadowrue root and rhizome extract, 0.01%-10% of crambe abyssinica seed oil, 0-20% of a physical sunscreen and the balance of an auxiliary. The sun-blocking composition contains various plant ingredients and has multiple effects including ultraviolet light absorption, inflammation resistance, after-sunburn repair and the like; the sun-blocking composition contains naturally sourced ingredients, is safe and mild and has broader market prospect.

Owner:肇庆迪彩日化科技有限公司 +1

Pre-laid polymer waterproof rolling material

InactiveUS20210147729A1Improve bindingImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

A pre-laid polymer waterproof rolling material, which comprises a sheet-like polymer carrier, a hot-melt pressure-sensitive adhesive layer on the sheet-like polymer carrier, and a plurality of anti-sticking particles on the hot-melt pressure-sensitive adhesive layer, wherein the particle size of the anti-sticking particles is smaller than the thickness of the hot-melt pressure-sensitive adhesive layer; the surface of the anti-sticking particles is coated with an organic layer; and the anti-sticking particles are connected with the hot-melt pressure-sensitive adhesive layer by means of the organic layer; the organic layer comprises the following components: a solvent, a polyurethane resin, a pigment, a filler, a cross-linking agent, an antioxidant, an anti-ultraviolet agent and a thickener. The anti-sticking particles will not shed during transportation and will not be trapped into the hot-melt pressure-sensitive adhesive layer, such that the hot-melt pressure-sensitive adhesive layer is exposed to the outside.

Owner:JIANGSU CANLON BUILDING MATERIALS

Infant care essential oil and preparation method thereof

InactiveCN107174539AUnique skin feelUnique smoothnessCosmetic preparationsAntipyreticSide effectIrritation

The invention discloses infant care essential oil and a preparation method thereof. The infant care essential oil comprises, by weight, 80-120 parts of camellia oil, 5-15 parts of olive oil, 0.5-2.5 parts of sunflower seed oil, 1-3 parts of frankincense essential oil, 0.5-1.5 parts of crambe seed oil, 0.5-2.0 parts of sacha inchi oil, 1-3 parts of passion fruit oil and 1-3 parts of fish squalane. The infant care essential oil is prepared from various pure natural essential oils and free from irritation and has no any side effects on delicate infant skins, the essential oil has the functions of diminishing inflammation, resisting bacteria, relieving itching, cleaning skin, stopping bleeding and the like, skin nutrition can be provided, damaged skins are repaired, skin immunity is improved, the care essential oil can be used for nursing of infant hips and can prevent or treat diaper rash and eczema.

Owner:广西茶仔龙科技股份有限公司

Two-component heat-insulated waterproof paint

The invention discloses two-component heat-insulated waterproof paint which comprises a slurry A component and a powder B component; the A component comprises the following ingredients by weight: 1-20% of soft water, 0.1-0.25% of organic amine, 80-95% of pure acrylic emulsion, and 2-14% of ethylene-polyvinyl acetate emulsion; the B component comprises the following ingredients by weight: 2-25% of heavy calcium, 2-14% of talcum powder, 1-14% of titanium dioxide, 1-7% of calcined kaolin, 4-17% of borsal hollow microspheres with an average particle size of about 10-80 microns, and 50-90% of cement; the mass ratio of the A component to the B component is 1:0.7-1.4. The invention is applicable to roofs, exterior walls, and the like, has good heat insulation and waterproof effect, good endurance, easy coating, no toxicity, no smell, no harm to human body, and no environment pollution.

Owner:NINGBO HUAGAOKE WATERPROOF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com