Composite transparent conductive film of silver nanowire and transparent conductive oxide, and application of composite transparent conductive film

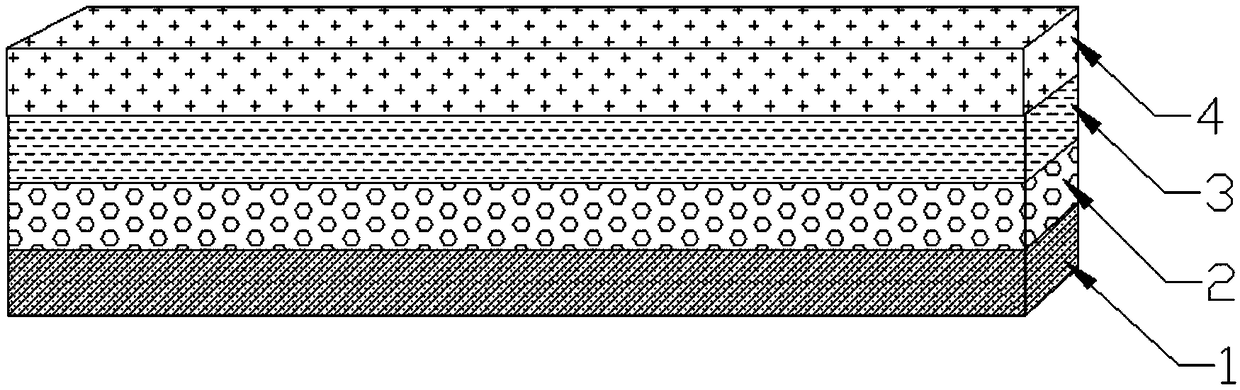

A transparent conductive film and transparent conductive technology, applied in the optical field, can solve the problems of insufficient weather resistance and friction resistance, increase downstream production costs, downstream material and process requirements, and achieve high matching, low cost, and high chemical stability. Effects of sex and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A PET with a thickness of 50 microns was selected as the base material, silver nanowire ink was coated on it, and after drying and curing, a transparent conductive film with a thickness of 40 nm was obtained. Then continue to coat resin on the conductive film to obtain a protective layer with a thickness of 50nm, and then sputter an FZO layer with a thickness of 10nm. The composite conductive film of silver nanowire and FZO was obtained.

Embodiment 2

[0032] A PET with a thickness of 50 microns was selected as the base material, silver nanowire ink was coated on it, and after drying and curing, a transparent conductive film with a thickness of 40 nm was obtained. Then continue to coat resin on the conductive film to obtain a protective layer with a thickness of 50nm, and then sputter an AZO layer with a thickness of 20nm. The composite conductive film of silver nanowire and AZO is obtained.

Embodiment 3

[0034] A PET with a thickness of 50 microns was selected as the base material, silver nanowire ink was coated on it, and after drying and curing, a transparent conductive film with a thickness of 80 nm was obtained. Then continue to coat resin on the conductive film to obtain a protective layer with a thickness of 50nm, and then sputter an ITO layer with a thickness of 10nm. A silver nanowire and ITO composite conductive film is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com