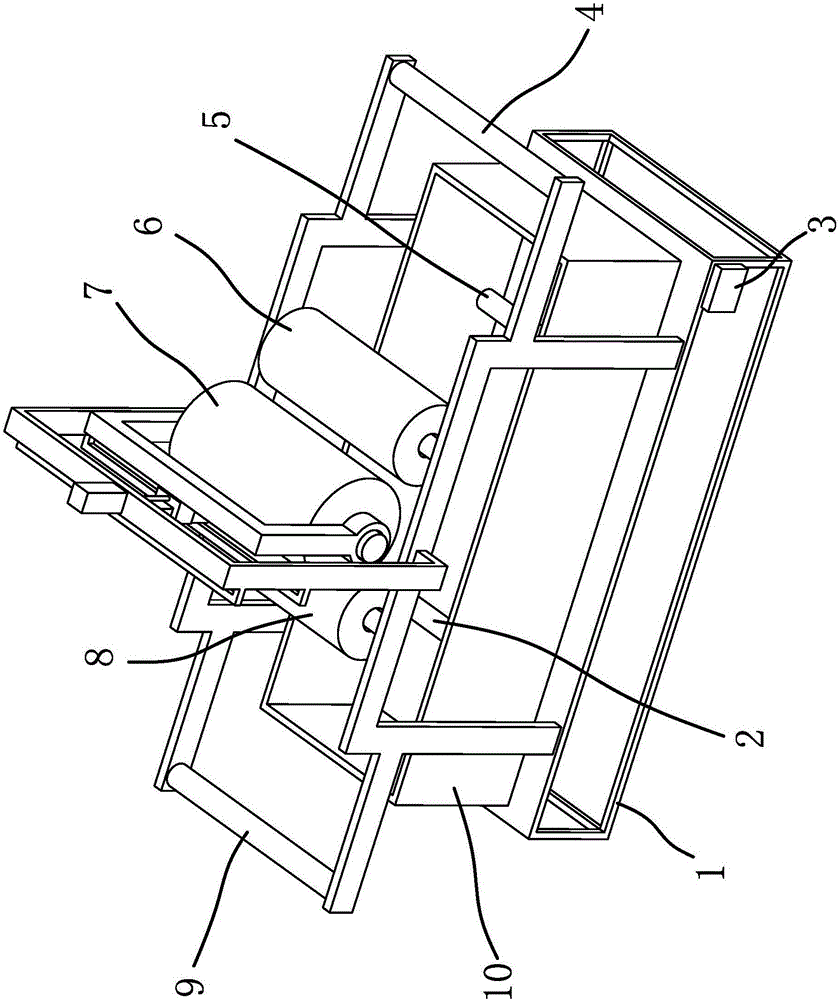

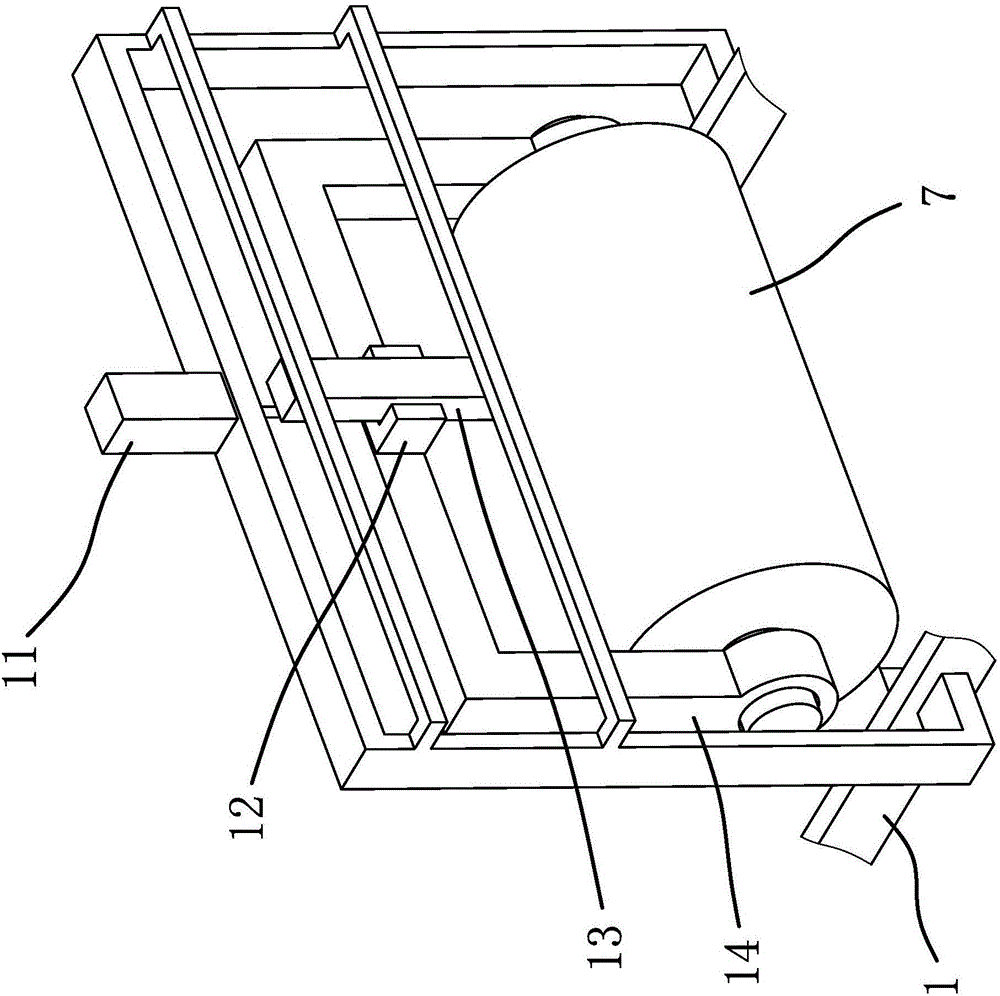

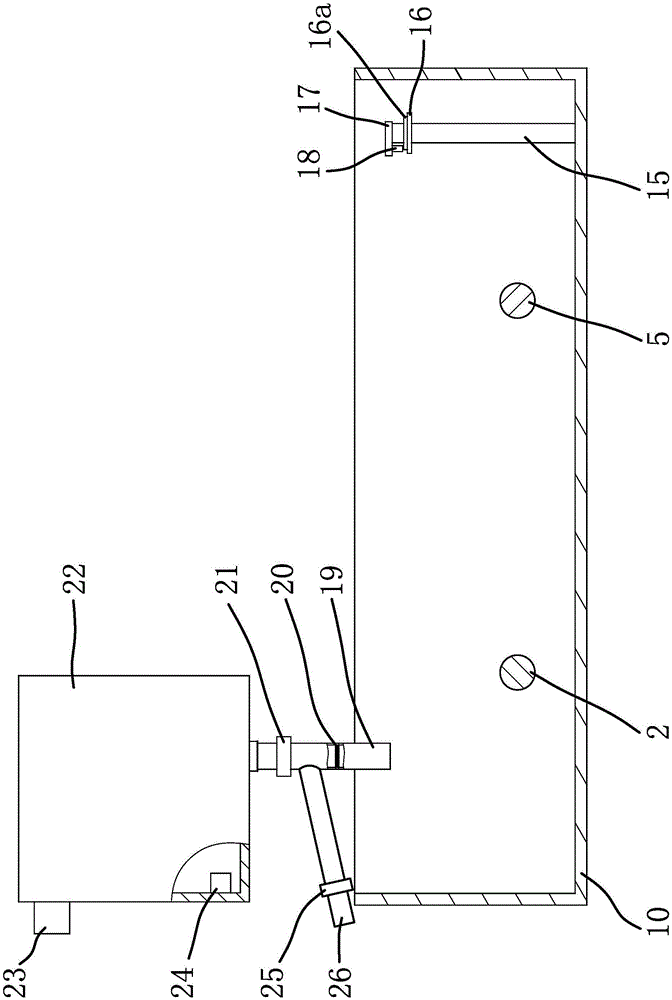

Padding machine

A padding mill and stand technology, applied in textile processing machine accessories, equipment configuration for processing textile materials, heating/cooling fabrics, etc., can solve problems such as unusability, poor functionality, no flame retardant for blended fabrics, isolation of ultraviolet light, etc. To achieve the effect of convenient rehydration, strong functionality, continuous and uninterrupted production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation method of this fiber blended high elastic fabric comprises the following steps:

[0049] A, take the required raw material by the weight part of above each component;

[0050] b. Add water-based polyurethane resin, polyvinyl chloride resin, defoamer, titanium dioxide, crosslinking agent, magnesium oxide, zinc oxide and deionized water into the reaction kettle, and the reaction time is 10min to prepare the padding solution;

[0051] c. Pour the padding solution into the padding machine, adopt the padding method for the base cloth layer, adopt the two-dipping and two-rolling process, the excess rate is 68%, and the padding solution layer is the strengthening layer;

[0052] d. Put the padded base cloth layer into an oven, the drying temperature is 80°C, and the drying time is 15 minutes;

[0053] e. Put the dried base cloth layer into a baking machine, the baking temperature is 130°C, and the baking time is 5 minutes;

[0054] f. Put the baked base cloth...

Embodiment 2

[0062] The preparation method of this fiber blended high elastic fabric comprises the following steps:

[0063] A, take the required raw material by the weight part of above each component;

[0064] b. Add water-based polyurethane resin, polyvinyl chloride resin, defoamer, titanium dioxide, crosslinking agent, magnesium oxide, zinc oxide and deionized water into the reaction kettle, and the reaction time is 18min to prepare the padding liquid;

[0065] c. Pour the padding solution into the padding machine, adopt the padding method for the base cloth layer, adopt the two-dipping and two-rolling process, and the excess rate is 70%, and the padding solution layer is the strengthening layer;

[0066] d. Put the padded base cloth layer into an oven, the drying temperature is 88°C, and the drying time is 20 minutes;

[0067] e. Put the dried base cloth layer into a baking machine, the baking temperature is 140°C, and the baking time is 8 minutes;

[0068] f. Put the baked base clo...

Embodiment 3

[0076] The preparation method of this fiber blended high elastic fabric comprises the following steps:

[0077] A, take the required raw material by the weight part of above each component;

[0078] b. Add water-based polyurethane resin, polyvinyl chloride resin, defoamer, titanium dioxide, crosslinking agent, magnesium oxide, zinc oxide and deionized water into the reaction kettle, and the reaction time is 25min to prepare the padding solution;

[0079] c. Pour the padding solution into the padding machine, adopt the padding method for the base cloth layer, adopt the two-dipping and two-rolling process, and the excess rate is 72%, and the padding solution layer is the strengthening layer;

[0080] d. Put the padded base cloth layer into an oven, the drying temperature is 95°C, and the drying time is 15-24 minutes;

[0081] e. Put the dried base cloth layer into a baking machine, the baking temperature is 150°C, and the baking time is 5-12 minutes;

[0082] f. Put the baked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com