High-class LCD welding goggles

A kind of goggles, high-level technology, applied in the field of LCD goggles, can solve the problems of welding workers' operation troubles, uniformity, light diffusion response speed, viewing angle dependence can not be fully achieved, affecting welding quality and other problems, reaching a broad market Prospects and application value, the effect of improving visible light pass rate, and improving the quality of welding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

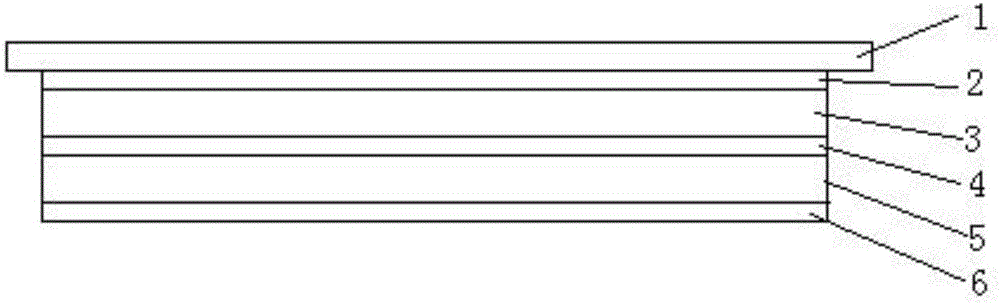

[0022] In this embodiment, a high-grade LCD welding goggle includes a thickened filter, a first C compensation polarizer, a first LCD liquid crystal cell, a second C compensation polarizer, and a second LCD liquid crystal from top to bottom. box and R compensation polarizer; the liquid crystal twist angle of the first and second LCD liquid crystal boxes is 70°, and the clamp between the absorption axis of the first and second C compensation polarizer and the internal friction axis of the first and second LCD liquid crystal boxes The angles are 1° respectively; the single transmittance of the first and second C compensation polarizers and R compensation polarizers are both 42%, and the degree of polarization is 99%; the thickened filter is an ultraviolet filter, the thickness It is 1mm, and the single transmittance is 27%.

[0023] Both the first liquid crystal cell and the second liquid crystal cell are TN type liquid crystal cells.

[0024] The thickness of the liquid crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com