Photon crystal film of ultraviolet polymer colloid with photon band gap and its prepn and use

A technology of colloidal photonic crystals and photonic bandgap, applied in cosmetic preparations, dressing preparations, skin care preparations, etc., can solve problems such as no special requirements, and achieve simple equipment, simple preparation process, easy size and shape The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

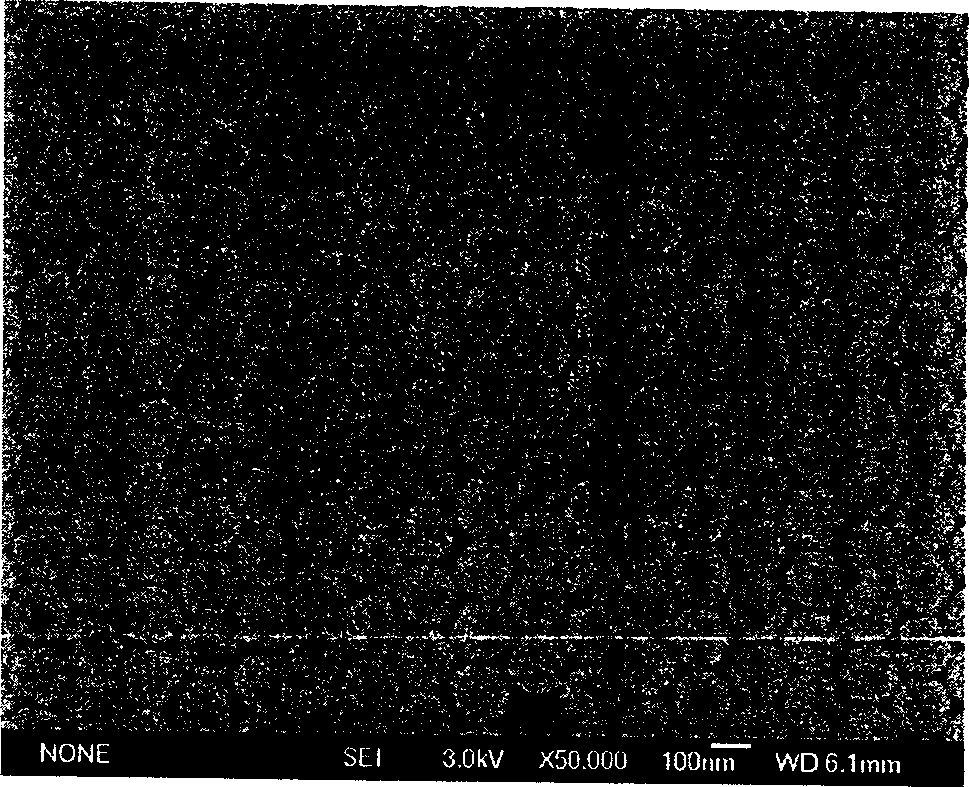

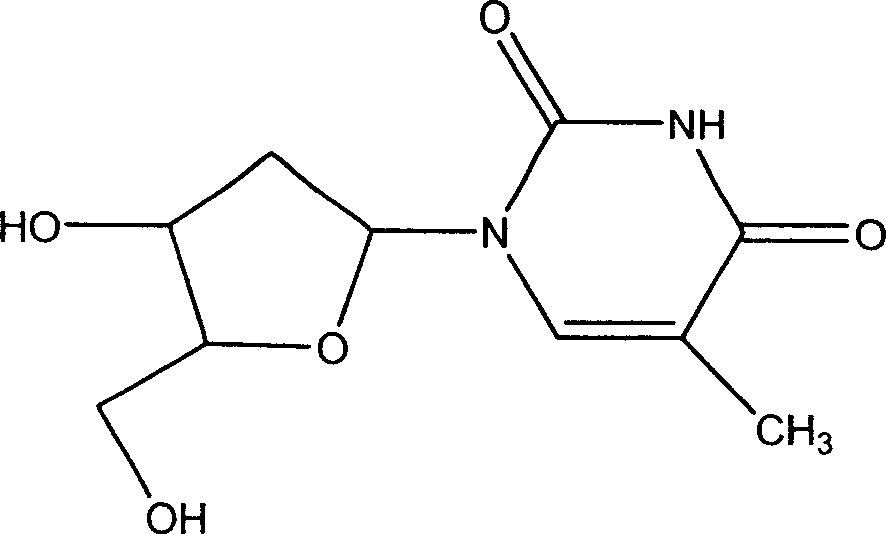

[0055] Embodiment 1: (preparation of monodisperse polymer latex particles)

[0056] Monomer mixture methyl methacrylate (0.5 gram), styrene (7 gram), methyl styrene (8 gram) and acrylic acid (0.5 gram), pH buffer ammonium bicarbonate (0.5 gram) and emulsifier ten A mixture of sodium dialkylbenzenesulfonate and sodium dodecylsulfonate (1:1 by weight) (0.038g) was dispersed in water (100mL), and the resulting mixed system was stirred and mixed at 500rpm, and heated to 65°C. Add 10 milliliters of ammonium persulfate (0.5 gram is dissolved in 20 milliliters of water) aqueous solution and start to react, add 5 milliliters of ammonium persulfate aqueous solution again after reacting 4.5 hours, all the other ammonium persulfate aqueous solutions add after continuing reaction 4.5 hours, The reaction was then continued for 3 hours to end. Finally, monodisperse polymer latex particles with a monodispersity index less than or equal to 0.005 and a particle size range of 100 nm are obtai...

Embodiment 2

[0058] Embodiment 2: (preparation of monodisperse polymer latex particles)

[0059] The monomer mixture vinyl acetate (0.5 g), butyl methacrylate (0.5 g), methyl styrene (21 g), acrylamide (0.6 g) and acrylic acid (0.4 g), pH buffer sodium hydrogen phosphate (0.6 gram) and the mixture of ammonium bicarbonate (0.6 gram) and emulsifier sodium lauryl sulfate (0.0547g) are dissolved in water (100mL), and the mixed system obtained is stirred and mixed at 800rpm, and heated to 85 ℃. Add 10 milliliters of initiator (obtained by dissolving potassium persulfate (0.6 gram) and ammonium persulfate (0.4 gram) in 20 milliliters of water) to start the reaction, add 5 milliliters of initiator aqueous solution after reacting for 2 hours, and the rest The aqueous initiator solution was added after continuing the reaction for 2 hours, and the reaction was then terminated after continuing for 1 hour. Finally, monodisperse polymer latex particles with a monodispersity index less than or equal t...

Embodiment 3

[0061] Embodiment 3: (preparation of monodisperse polymer latex particles)

[0062] The monomer mixture isobutyl methacrylate (1.2 grams), methyl styrene (18 grams) and methacrylic acid (1.2 grams), pH buffer sodium bicarbonate (1.0 grams) and emulsifier dodecyl sulfonate Sodium bicarbonate (0.0486 mg) was dissolved in water (100 mL), and the resulting mixed system was stirred and mixed at 600 rpm, and heated to 75°C. Add 10 milliliters of potassium persulfate (0.8 gram is dissolved in 20 milliliters of water) aqueous solution and start to react, react 3.5 hours and then add 5 milliliters of potassium persulfate aqueous solution, all the other potassium persulfate aqueous solutions add after continuing reaction 3 hours, The reaction was then terminated after 2 hours. Finally, monodisperse polymer latex particles with a monodispersity index less than or equal to 0.005 and a particle size range of about 100 nm are obtained.

[0063] When changing the amount of emulsifier sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com