Preparation method for functionalized monodisperse polystyrene hybrid colloid emulsion

A polystyrene and colloidal emulsion technology, applied in the field of emulsion preparation, can solve the problems of complexity, time-consuming, poor product monodispersity, etc., and achieves the effects of convenient operation, cheap and easy-to-obtain raw materials, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

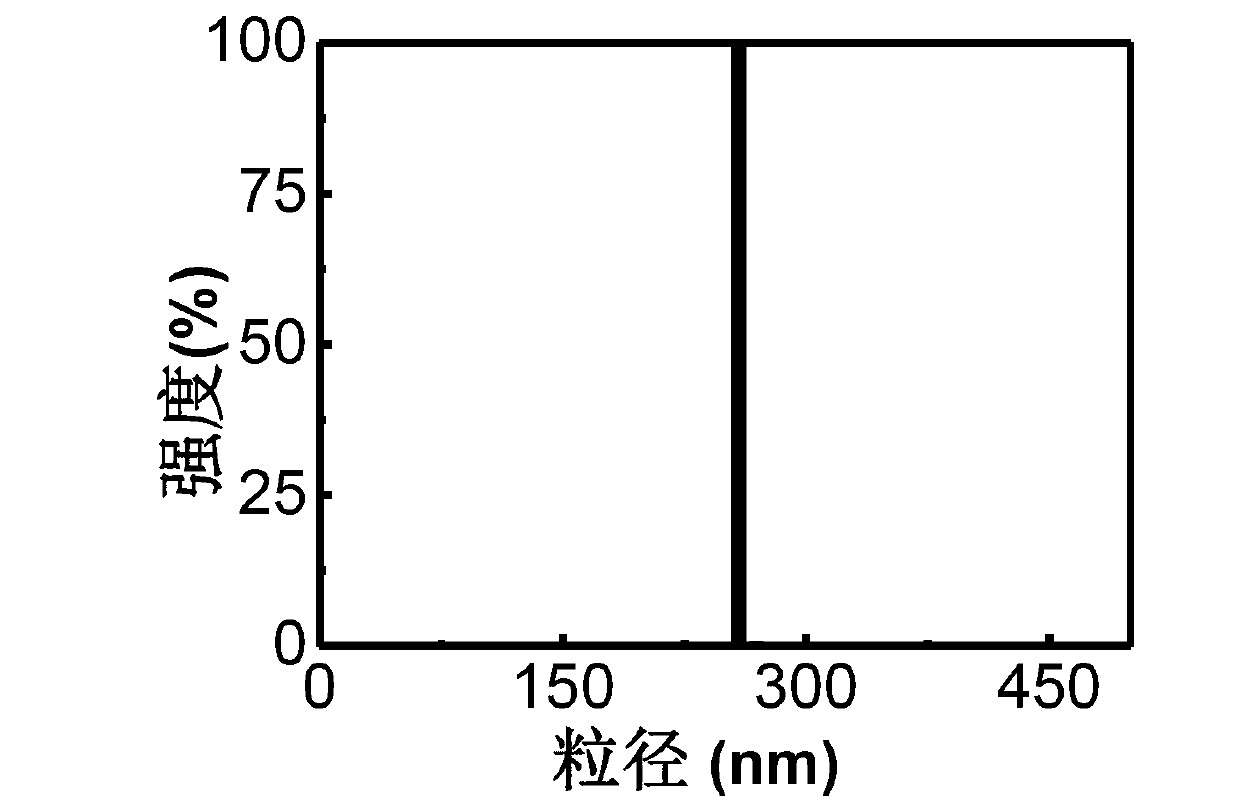

Embodiment 1

[0029] Weigh 0.5g of stabilizer polyvinylpyrrolidone and 1.5g of pH regulator sodium bicarbonate with a balance, add 150mL of water to a 250mL four-necked bottle, then add 5g of styrene monomer and 1g of functional monomer hydroxyethyl acrylate, quickly The temperature was raised to 98°C, the initiator dissolved in 15mL of water was added dropwise and per 1g of potassium persulfate was added to initiate polymerization, and the stirring speed and temperature of 150rmp were kept constant, and the reaction system was carried out under stable conditions for 2h. Then, a mixed aqueous solution of 0.5 g of hydroxyethyl acrylate, 0.5 g of vinylimidazole, and 0.1 g of potassium persulfate was added, and the reaction was continued for 3 hours. Cool to room temperature, remove a small amount of gel by filtering with a 200-mesh gauze, and then obtain poly[styrene-co-hydroxyethyl acrylate] poly[hydroxyethyl acrylate-co-vinyl imidazole] hybrid colloidal particles. The emulsion has a monodi...

Embodiment 2

[0031] Take 0.5g of stabilizer polyvinylpyrrolidone and 1.5g of pH regulator sodium bicarbonate, add 150mL of water to a 250mL four-necked bottle, then add 5.5g of styrene monomer and 1g of functional monomer acrylic acid, and rapidly heat up to 99°C , drop the initiator dissolved in 18mL of water per 1g of potassium persulfate to initiate polymerization, keep a constant stirring speed and temperature of 150rmp, and keep the reaction system under stable conditions for 2h. Then, a mixed aqueous solution of 0.5 g of acrylic acid, 0.5 g of vinylimidazole, and 0.1 g of potassium persulfate was added, and the reaction was continued for 3 hours. Cool to room temperature, filter with a 200-mesh gauze to remove a small amount of gel, and then obtain poly[styrene-co-acrylic acid]poly[acrylic acid-co-vinylimidazole] hybrid colloidal particles with a monodisperse core-shell structure . The emulsion has a monodispersity index of less than 5% and has a particle size of 259 nm.

Embodiment 3

[0033] Take 0.5g of stabilizer polyvinylpyrrolidone and 1.5g of pH regulator sodium bicarbonate and add 150mL of water to a 250mL four-necked bottle, then add 6g of styrene monomer and 1g of functional monomer acrylic acid, and rapidly heat up to 100°C. The initiator dissolved in 20mL of water was added dropwise with 1g of potassium persulfate to initiate polymerization, and the stirring speed and temperature were kept constant at 150rmp, and the reaction system was carried out under stable conditions for 2h. Then, a mixed aqueous solution of 0.5 g of acrylic acid, 0.5 g of hydroxyethyl acrylate, and 0.1 g of potassium persulfate was added, and the reaction was continued for 3 hours. Cool to room temperature, filter with a 200-mesh gauze to remove a small amount of gel, and then obtain poly[styrene-co-hydroxyethyl acrylate] poly[hydroxyethyl acrylate-co-acrylic acid] with a monodisperse core-shell structure Hybrid colloidal particles. The emulsion has a monodispersity index o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com